Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236 results about "Tetrahydrofurfuryl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrahydrofurfuryl alcohol is a food additive permitted for direct addition to food for human consumption as a synthetic flavoring substance and adjuvant in accordance with the following conditions: a) they are used in the minimum quantity required to produce their intended effect, and otherwise in accordance with all the principles of good ...

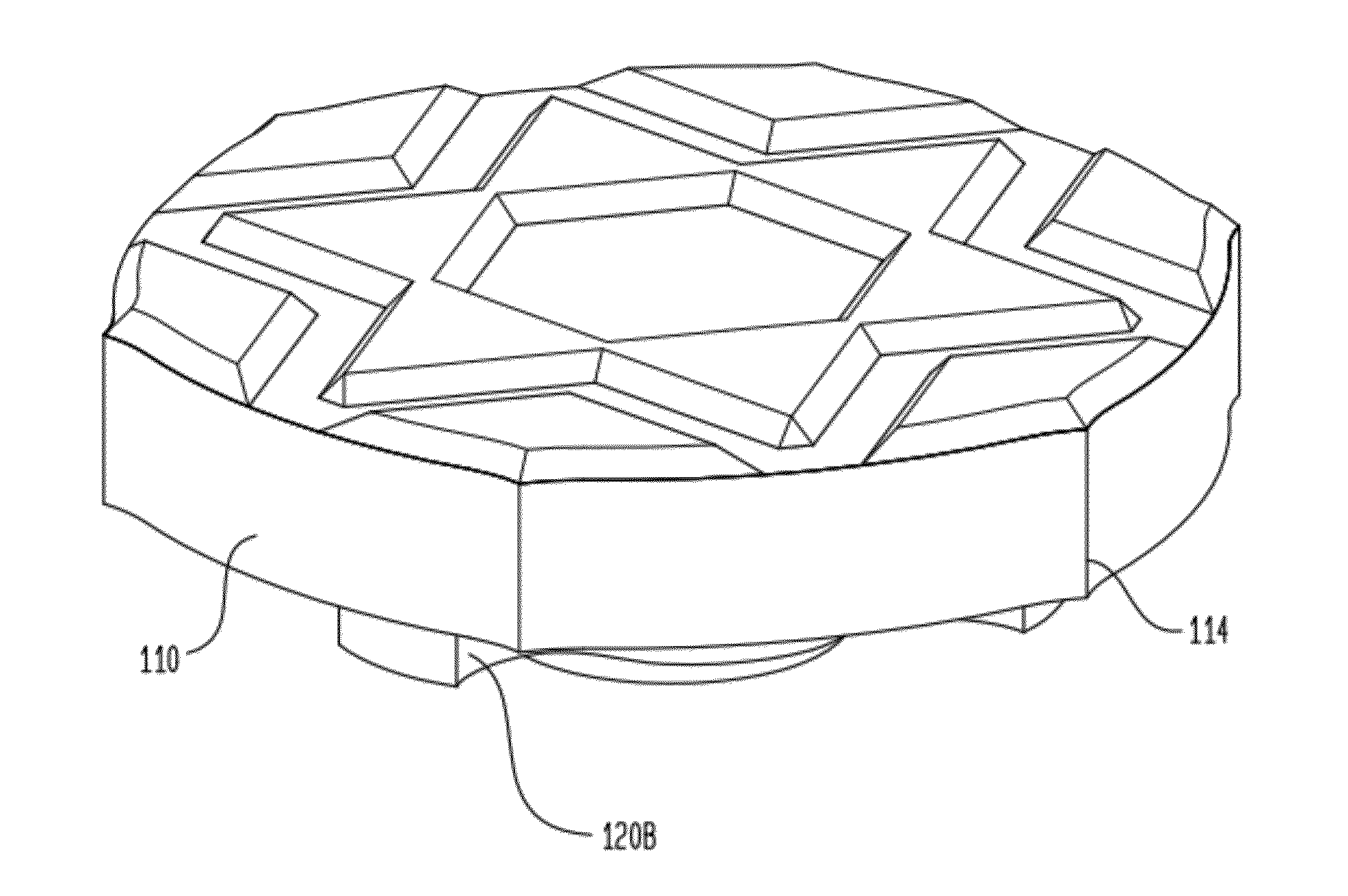

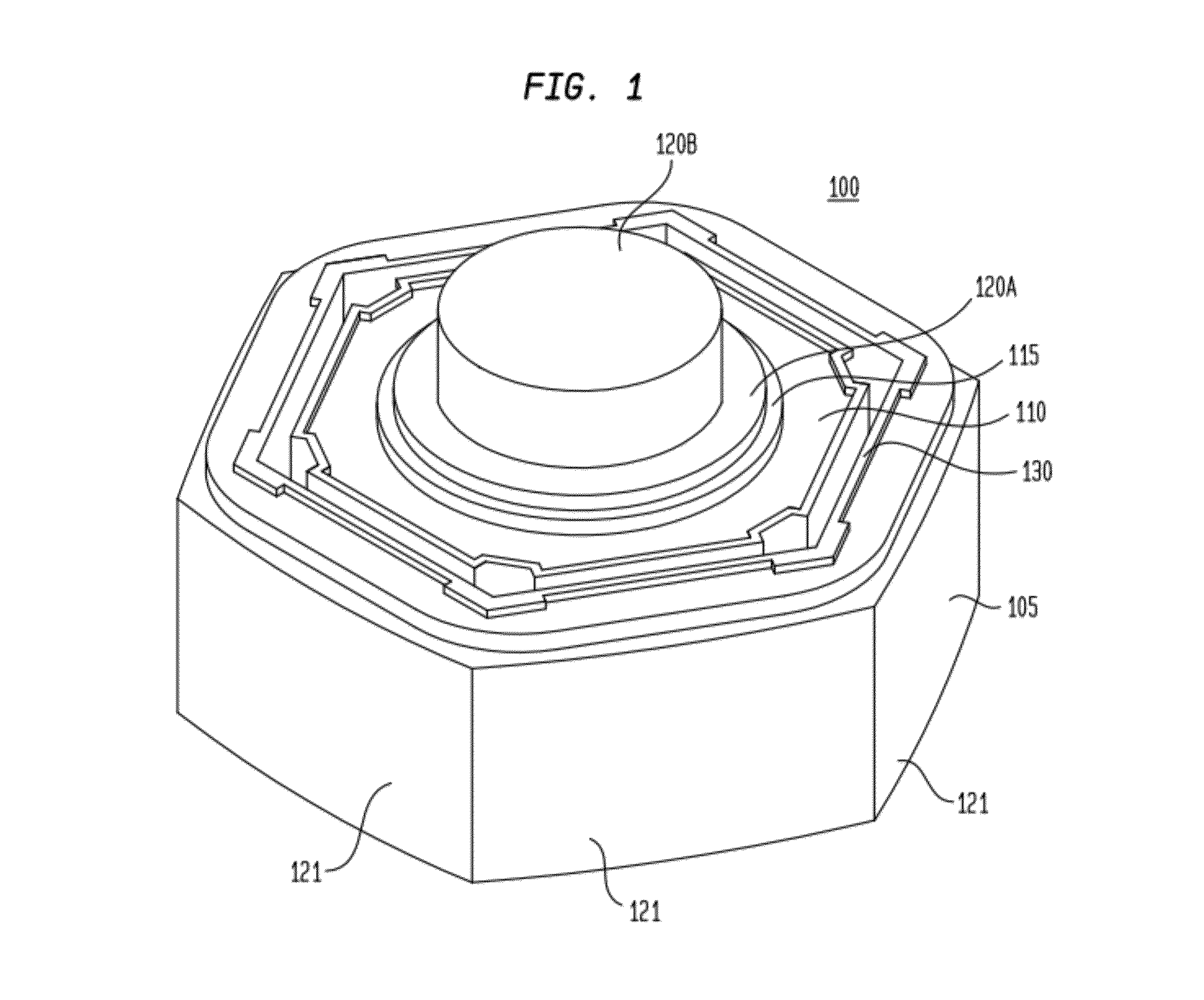

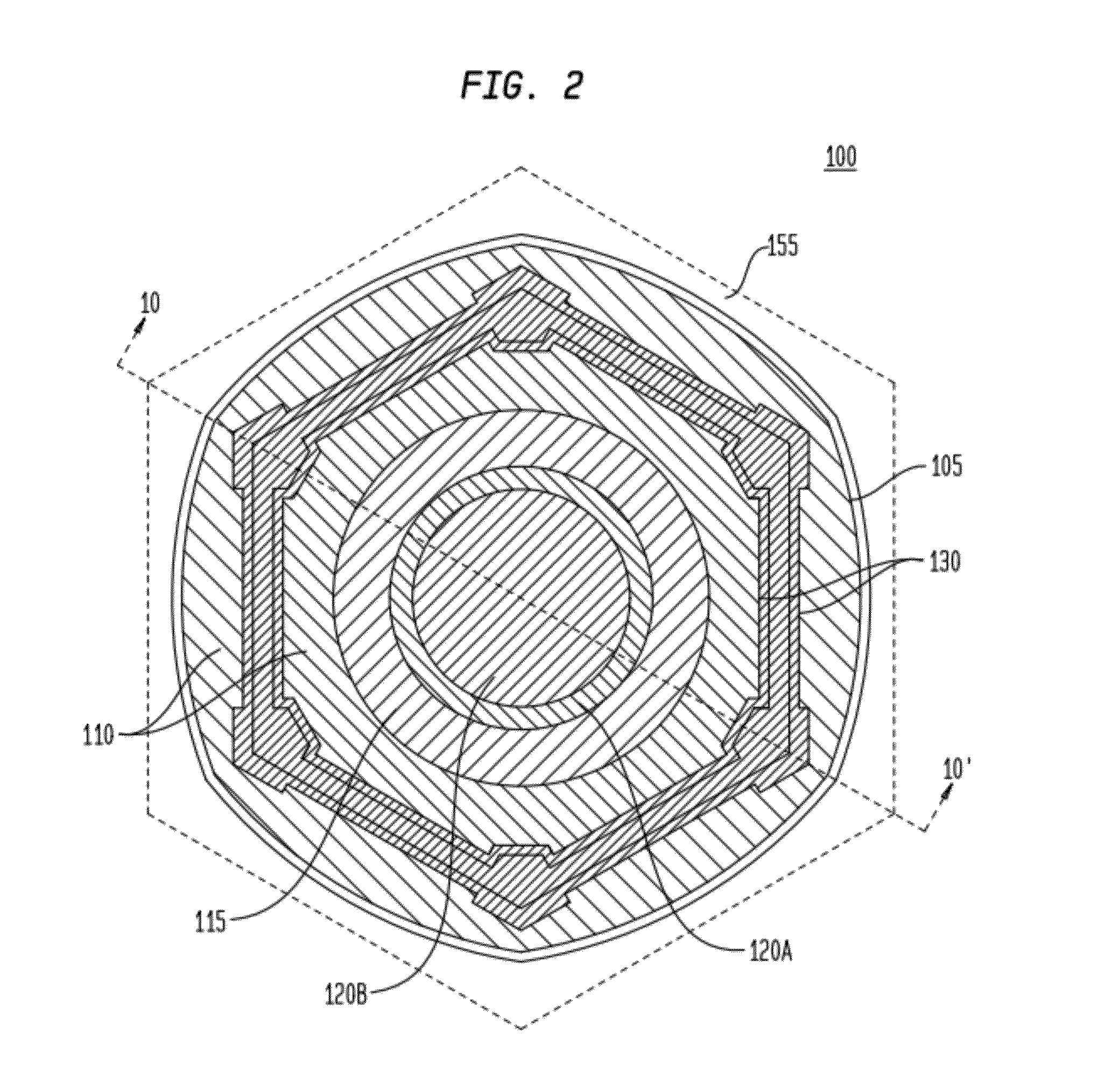

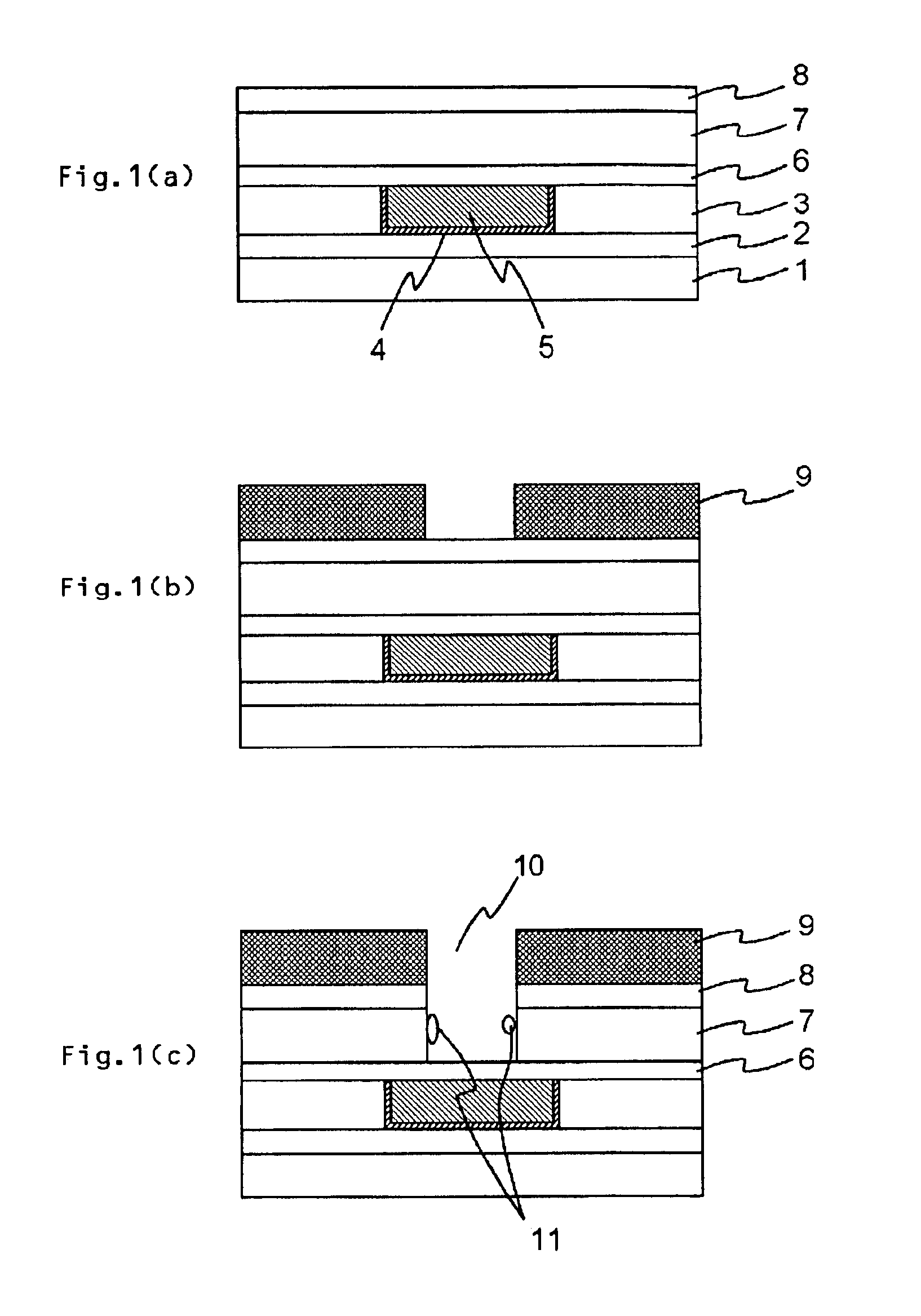

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

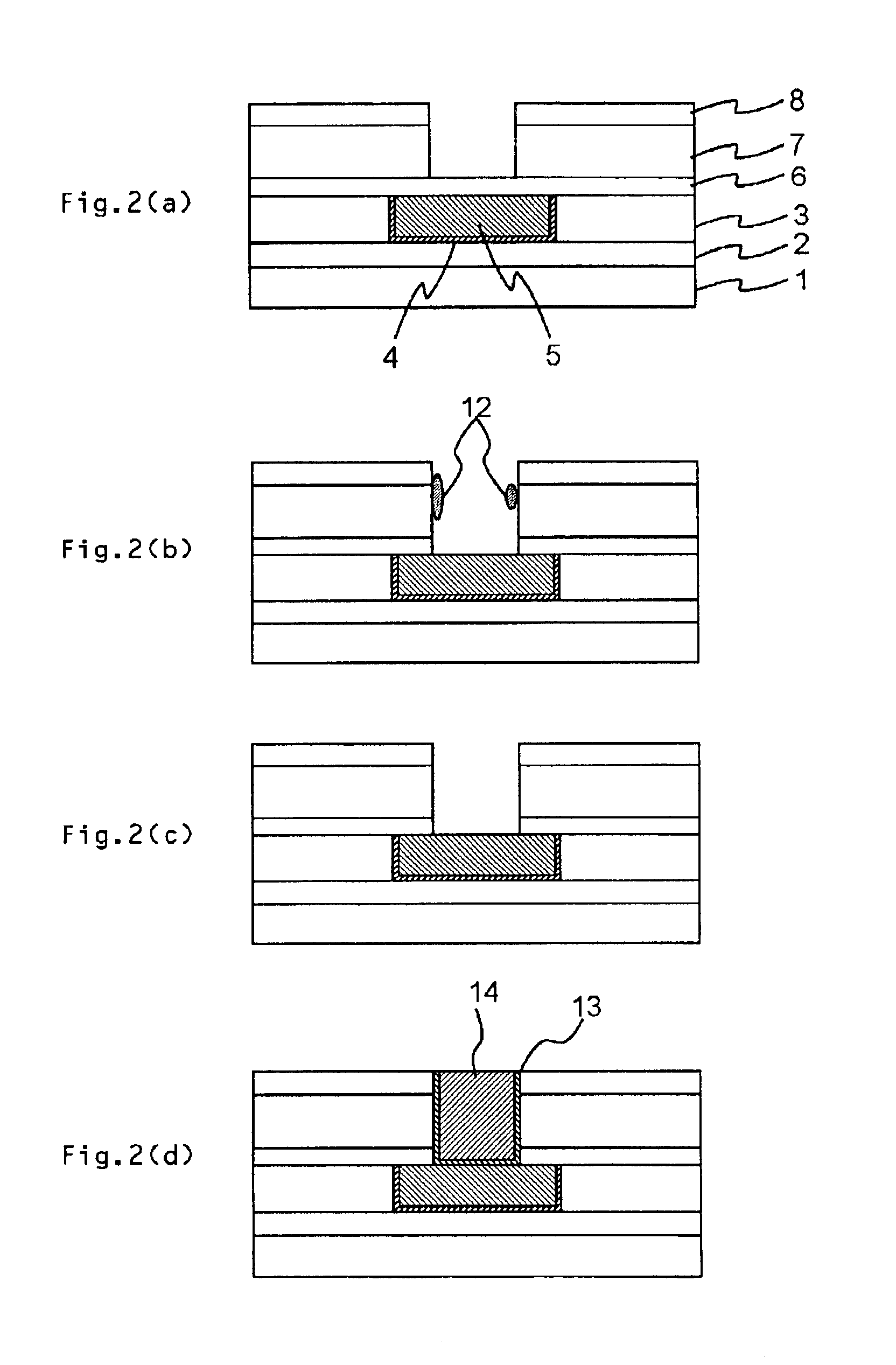

Stripping composition

InactiveUS6869921B2Excels in ability to removeExcellent stripping compositionSurface-active detergent compositionsDetergent mixture composition preparationAlcoholPreservative

A stripping composition comprising at least one of alcohols having an ether-bond in the molecule thereof as component (a), and an anticorrosive as component (b). Furfuryl alcohol or tetrahydrofurfuryl alcohol is preferable as component (a).

Owner:KANTO CHEM CO INC +1

Printable composition of a liquid or gel suspension of diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

Method for preparing tetrahydrofurfuryl alcohol from furfural by aqueous phase hydrogenation

InactiveCN104672185AAvoid separabilityAvoid purification processOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogen atmosphereFurfural

The invention discloses a method for preparing tetrahydrofurfuryl alcohol from furfural by aqueous phase hydrogenation. According to the method, furfural is directly converted into tetrahydrofurfuryl alcohol by using water as a solvent in a 0.5-10MPa hydrogen atmosphere at 80-180 DEG C in the presence of a nickel-based catalyst and an alkali additive, wherein the yield of the tetrahydrofurfuryl alcohol can reach 94%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

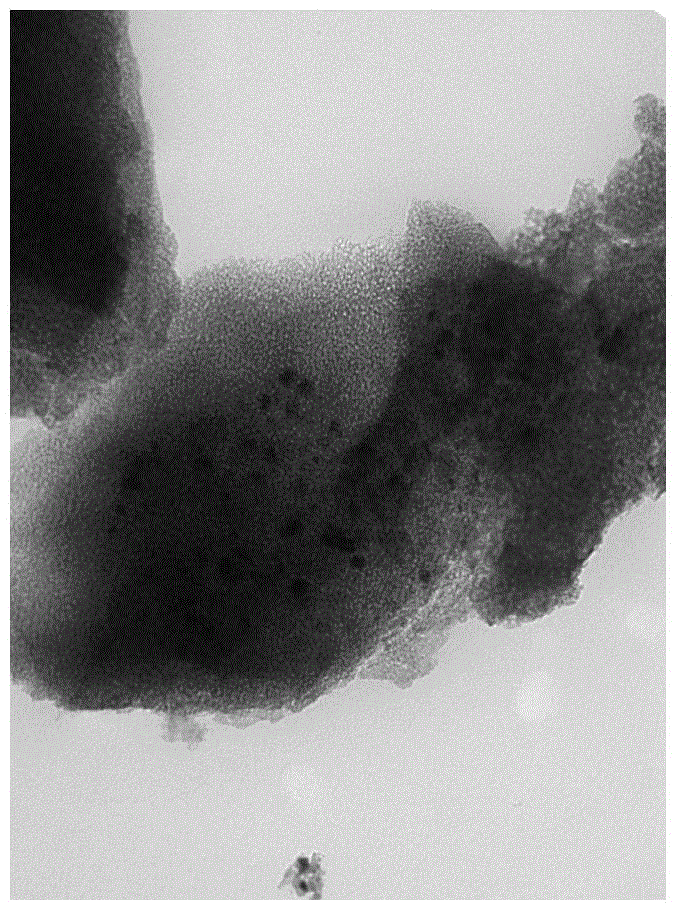

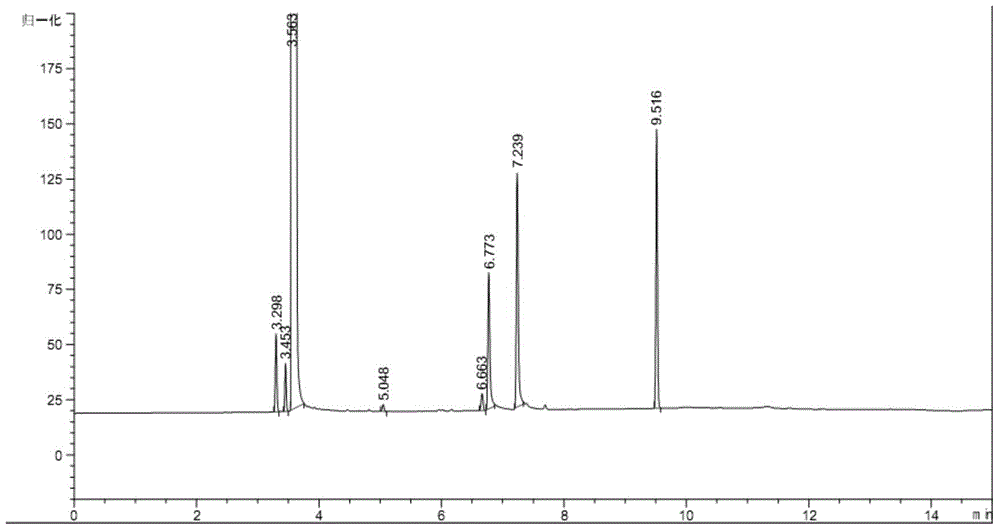

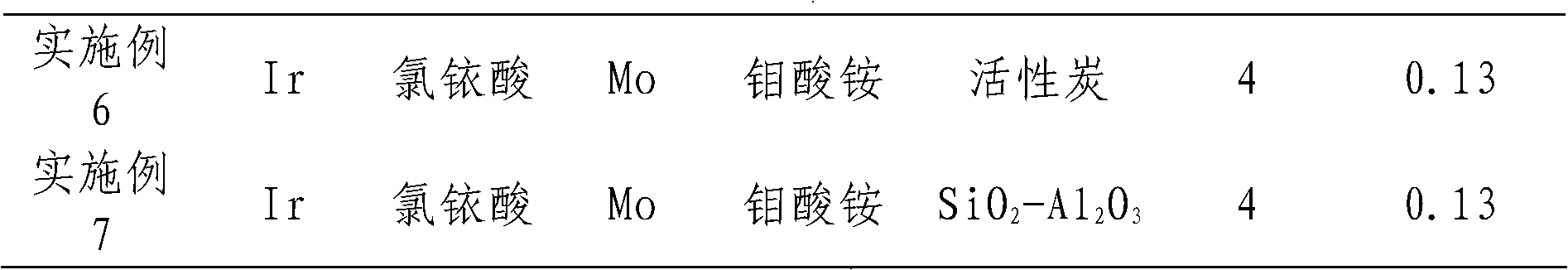

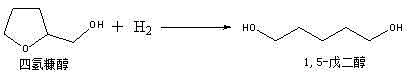

Method for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol

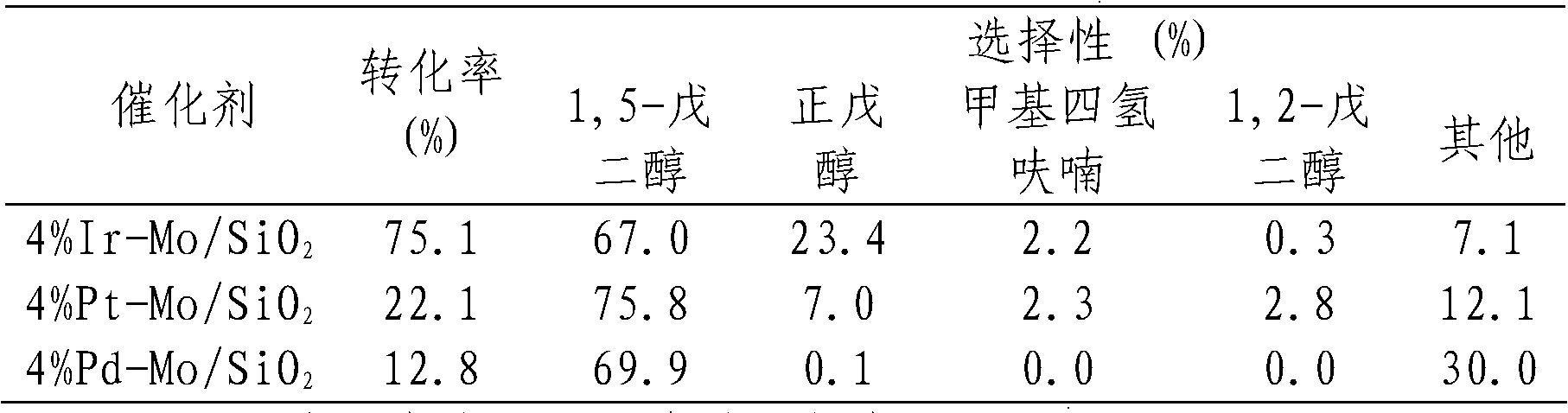

InactiveCN102911011APreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHydrogen

The invention relates to a novel A-B / X or A / X supported catalyst for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol obtained from forestry and agricultural residues. The component A refers to one or more of precious metals Ir, Pt and Pd, the auxiliary B refers to one or more of Mo, Re and W, and the carrier X refers to any one of SiO2, activated carbon and SiO2-Al2O3. The capacity of the precious metal A in the catalyst is 0.5-10%, the molar ratio of the auxiliary B to the precious metal A is 0.0-1.0, the reaction pressure is 2-20MPa, and the reaction temperature is 80-150 DEG C. The catalyst has the advantages of mild reaction conditions, high reactivity and high selectivity, and a novel effective way for preparation of 1,5-pentadiol from biomass of forestry and agricultural residues is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 1,5-pentanediol via selective hydrogenolysis of tetrahydrofurfuryl alcohol

The invention relates to a method for preparing a novel A-B / X or A / X carried catalyst of 1,5-pentanediol by performing a selective hydrogenolysis reaction on tetrahydrofurfuryl alcohol obtained from forestry and agricultural residues taken as raw materials. According to the novel A-B / X or A / X carried catalyst, wherein the component A is any one or more than one of Rh, Ir, Pt, Pd and Ru; the assistant B is any one or more than one of V, Nb and Ta; the carrier X is any one of SiO2, activated carbon, SiO2-Al2O3, titanium oxide and zirconium oxide; the carrying quantity of a precious metal A in the catalyst is between 0.5% and 10%; the molar ratio of the assistant B to the precious metal A is 0.01-1.0; the reaction pressure is between 1MPa and 20MPa; and the reaction temperature is between 50 DEG C and 150 DEG C. The novel A-B / X or A / X carried catalyst has the characteristics of moderate reaction condition, high reaction activity and good selectivity, thereby providing a novel effective way for preparing the 1,5-pentanediol by utilizing biomasses of the forestry and agricultural residues.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

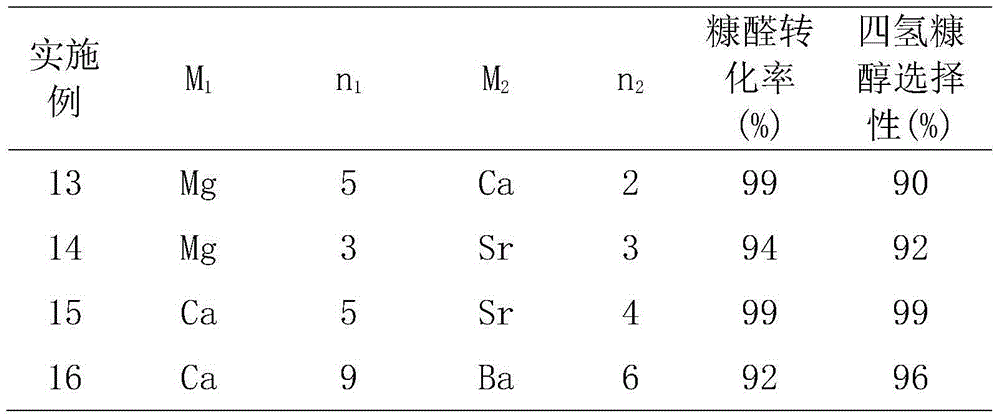

Preparation method for tetrahydrofurfuryl alcohol

ActiveCN105693659ALow costLower reaction costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalHydrogen atmosphere

The invention discloses a method for preparing tetrahydrofurfuryl alcohol through water-phase hydrogenation of furfural. According to the method, in a water-phase reaction medium, furfuryl alcohol undergoes one-step hydrogenation at 80 to 180 DEG C in a hydrogen atmosphere with a pressure of 0.5 to 10 Mpa under the action of alkaline earth metal-modified alumina-loaded nickel-based catalyst, thereby producing tetrahydrofurfuryl alcohol. The catalyst used in the water-phase hydrogenation is a metal-loaded catalyst; a carrier is an alumina carrier modified by one or more alkaline earth metals; the alkaline earth metal is one or more selected from a group consisting of Mg, Ca, Sr and Ba; and water is used as a solvent, which accords with the principles of green chemistry and enables cost to be reduced. The catalyst provided by the invention can realize high-yield preparation of tetrahydrofurfuryl alcohol in a water phase, reduces reaction cost and separating difficulty and enables the yield of tetrahydrofurfuryl alcohol to reach more than 99%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for recovering distillation waste liquid generated by producing 1,4-butanediol

InactiveCN103274898AHigh recovery rateImprove overall recoveryOrganic compound preparationHydroxy compound preparationDistillationButanediol

The invention relates to a process for recovering distillation waste liquid generated by producing 1,4-butanediol and belongs to the technical field of recycling of organic waste liquid in the industrial production. According to the invention, the distillation waste liquid generated in the process of producing 1,4-butanediol by a Reppe method is used as a raw material; drained wastewater is used as an extracting agent; sodium sulfate is used as a salting-out agent; sulfuric acid is used as a catalyst for depolymerizing reaction; and by a circulating process of salting-out-extraction, reduced pressure batch distillation separation and depolymerizing reaction, various products in the distillation waste liquid, such as 1,4-butanediol, butanol and 3-tetrahydrofurfuryl alcohol are recovered. The process disclosed by the invention has the characteristics that various products can be recovered, the recovery rate of the products is high and the recovery economic benefits are good; the process sufficiently utilizes waste liquid resources and is beneficial to environment protection; the process is simple, reaction conditions are mild, equipment is conventional and recovery cost is low; and the process has a wide application range and is convenient to popularize and apply. The process can be widely applied to recycling of the organic waste liquid in the industrial production and is particularly suitable for recycling the waste liquid generated in the process of producing 1,4-butanediol by the Reppe method.

Owner:CHONGQING UNIV

Scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering

InactiveCN103785973AEnhanced spread rate effectHigh spreading rateWelding/cutting media/materialsSoldering mediaDiethylene glycol diethyl etherSalicylic acid

The invention discloses scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering. The scaling powder comprises 12 percent to 16 percent of activating agents, 8-10 percent of colophony, 2-3 percent of surface active agents, 0.05-0.1 percent of antioxidants, 5-8 percent of organic amine and the balance organic solvents. The activating agents comprise compound components of 40-57 parts of anhydrous citric acid, 7-14 parts of salicylic acid, 0.6-3.6 parts of lactic acid and 36-43 parts of DL-malic acid, the surface active agents comprise compound component Tween 60 and a Span, the organic amine is one or more of monoethanolamine, diethanol amine and triethanolamine, the antioxidants are tertiary butylhydroquinone, and the organic solvents are mixed solvents of ethylene glycol, diethylene glycol diethyl ether, nitroethane, tetrahydrofurfuryl alcohol and propylene glycol by mass. According to the method, the scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering has the advantages of improving the coverage rate of the welding materials and reducing the cost.

Owner:SUZHOU LOTTE CHEM TECH

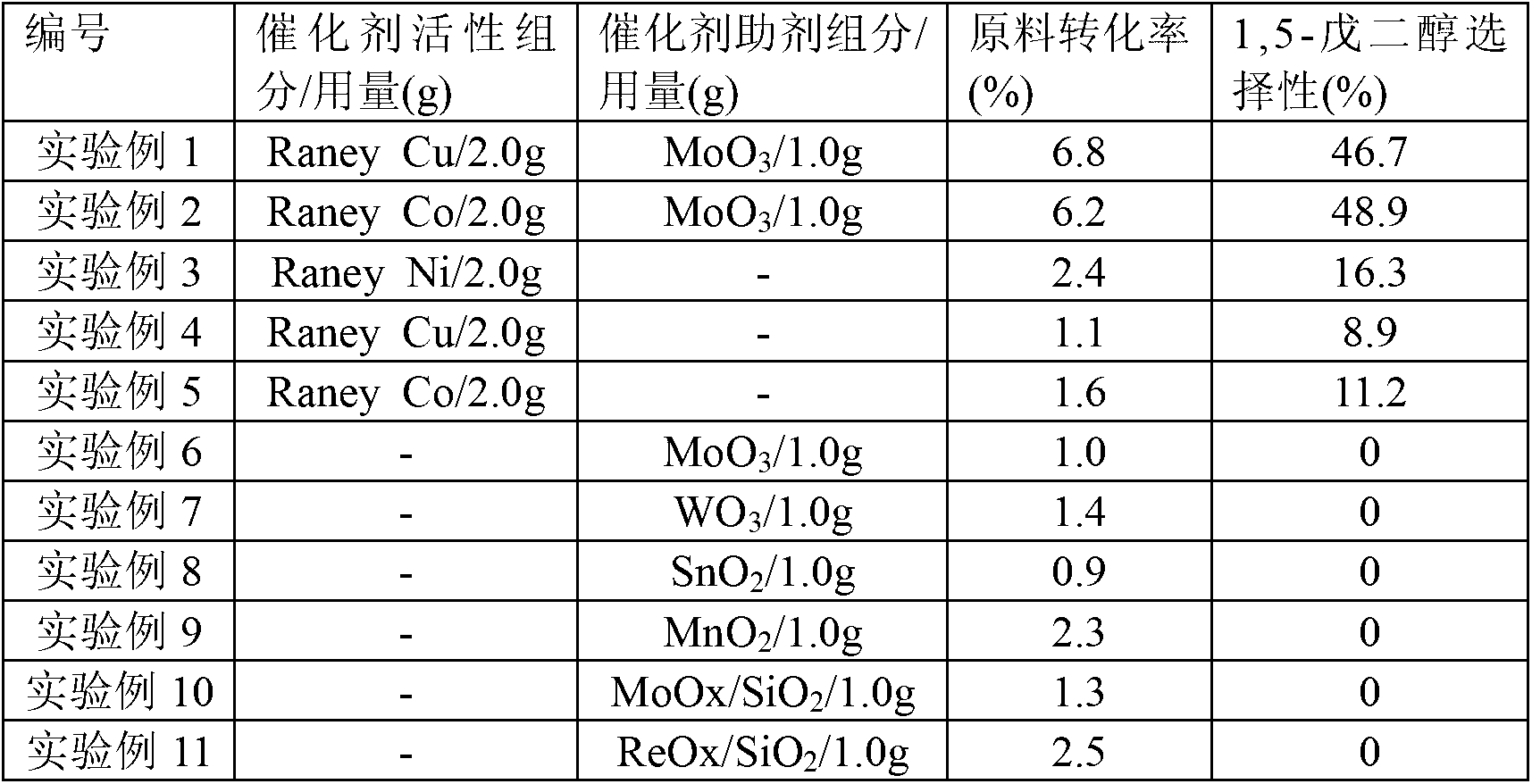

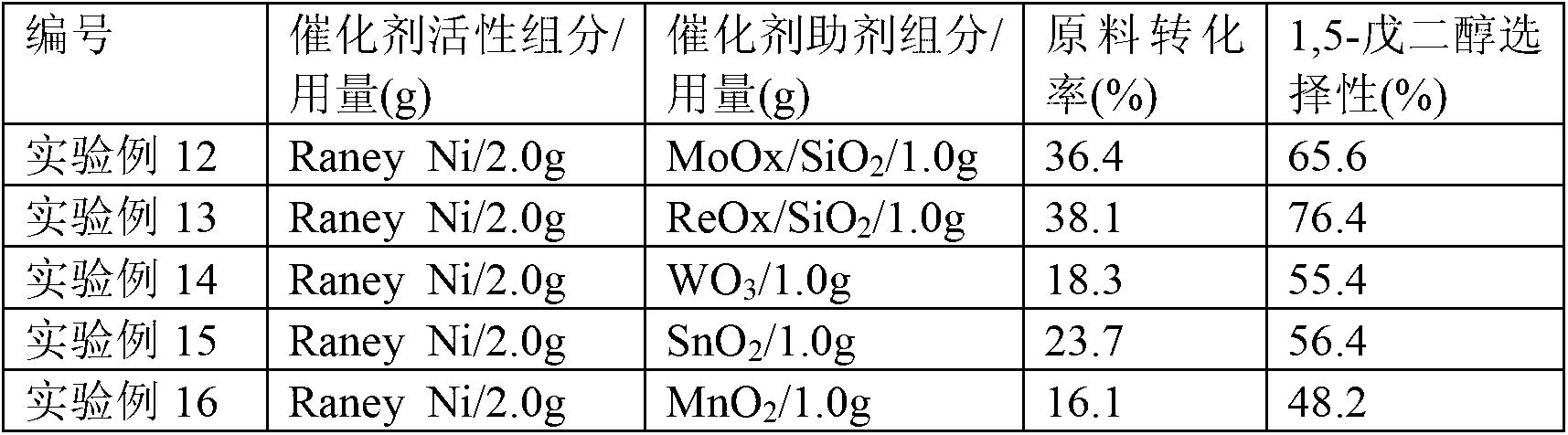

Catalyst and application of catalyst in technology for preparing 1,5-pentanediol through hydrogenolysis of tetrahydrofurfuryl alcohol

InactiveCN103071512AThe synthesis process is simpleSave raw materialsPreparation by oxygen reductionRaney catalystsActive componentNon noble metal

The invention relates to a catalyst and an application of the catalyst in a technology for preparing 1,5-pentanediol through hydrogenolysis of tetrahydrofurfuryl alcohol. The catalyst comprises an active component and an assistant, wherein the active component is one out of raney Ni, raney Co, raney Cu, and the assistant is one out of MoO3, MoOx / SiO2, ReOx / SiO2, WO3, SnO2 and MnO2. A synthesis technology of the catalyst is simple, a noble metal Rh or Ir catalyst is replaced by a non-noble metal raney catalyst, the cost of the catalyst is greatly lowered, the catalysis effect is excellent, the reaction of preparing 1,5-pentanediol with the catalyst adopts one-step hydrogenation, the flow is simple, and the reaction route is a sustainable development route.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Anti-rust oil having high resistance to damp-heat

InactiveCN103980994AExcellent heat and humidity resistanceImprove water resistanceAdditivesHigh resistancePotassium

The invention discloses anti-rust oil having high resistance to damp-heat. The anti-rust oil having high resistance to damp-heat comprises, by weight, 62-70 parts of light diesel fuel 0#, 2-3 parts of polyoxyethylene abietate, 1-2 parts of ammonium molybdate, 4-6 parts of acetylated lanolin, 1-2 parts of dodecanamine, 0.3-1 part of alkenyl succinic acid, 0.2-1 part of potassium dodecylbenzosulfonate, 0.2-0.3 parts of tetrahydrofurfuryl alcohol, 3-5 parts of phthalic acid ester, 2-3 parts of potassium oleate, 1-2 parts of methylbenzotriazole and 10-14 parts of a film-forming assistant. The anti-rust oil has good resistance to damp-heat, water and salt mist, has lasting workpiece protection effects and has good weatherability. The used film-forming assistant can effectively improve anti-rust oil stability.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Method for continuously preparing 1, 5-pentanediol from tetrahydrofurfuryl alcohol

InactiveCN102942448ABroad concentrationWide concentration rangeMetal/metal-oxides/metal-hydroxide catalystsPreparation by oxygen reductionFixed bedComposite oxide

The invention discloses a method for continuously preparing 1, 5-pentanediol from tetrahydrofurfuryl alcohol. According to the method, platinum loaded tungsten-zirconium composite oxide is taken as a catalyst, and a 10-90% solution tetrahydrofurfuryl alcohol aqueous 10-90% solution and hydrogen are simultaneously and continuously introduced into a fixed bed reactor for reaction so as to generate1, 5-pentanediol under the reaction conditions that the temperature is 100-150 DEG C, the pressure is 1-5 MPa, the mass flow rate of the tetrahydrofurfuryl alcohol is 0.05-1 A / H (A is the mass of the catalyst in the reactor), and the mol ratio of hydrogen to tetrahydrofurfuryl alcohol is 10-100. The mol ratio of various metal elements in the catalyst is Pt: W: Zr=(0.05-0.5): 1: (5-30). The method is moderate in reaction condition, high in catalytic activity, good in product selectivity, simple in process and continuous in production; and the raw materials are from biomass, thereby meeting the green chemical development direction.

Owner:NANJING UNIV OF TECH

Solid-supported Cu-Ni bimetallic catalyst and method for preparing tetrahydrofurfuryl alcohol by full hydrogenation of furfural catalyzed by catalyst

ActiveCN109529946AImprove stabilityHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsContinuous useMicrosphere

The invention discloses a solid-supported Cu-Ni bimetallic catalyst and a method for preparing tetrahydrofurfuryl alcohol by full hydrogenation of furfural catalyzed by the catalyst. Coarse pore microsphere silica gel is used as a carrier, and the surface of the carrier is modified with an organosilicone coupling agent with a terminal group having -NH2; reflux is performed on the microsphere silica gel modified by organosilicone together with an active metal Cu source and an active metal Ni source; and the solid-supported Cu-Ni bimetallic catalyst is prepared by complexing coordination of themetals Cu and Ni with the terminal group NH2. When the catalyst is used for catalyzing the furfural to prepare the tetrahydrofurfuryl alcohol by full hydrogenation, the stability of a Cu-Ni double-active metal site in a catalytic reaction as well as the low-temperature hydrogenation activity and selectivity of the Cu-Ni double-active metal site are remarkably improved. The catalyst disclosed by the invention can be continuously used, has universality, and has the advantages of being good in active metal dispersion degree, high in low-temperature hydrogenation activity, easy to recover, good instability, simple in preparation process and high in product yield.

Owner:SHANXI UNIV

Application of apatite substance in catalytic hydrogenation and tetrahydrofurfuryl alcohol preparation method

ActiveCN106967018AMild reaction conditionsHigh catalytic efficiencyOrganic chemistryPhysical/chemical process catalystsHydrogen atmosphereIon exchange

The invention discloses application of an apatite substance in catalytic hydrogenation and a tetrahydrofurfuryl alcohol preparation method. The method can be used for an alcohol or alkane solvent system, furfural is completely hydrogenated in the hydrogen atmosphere of 0.1-6 MPa at the temperature of 0-200 DEG C under the effects of Pd-HAP prepared from hydroxyapatite and palladium metal by adopting an ion exchange method and other catalysts to generate the tetrahydrofurfuryl alcohol, and the method is provided for efficient utilization of biomass raw materials. The used catalysts can be used for high-conversion-rate and high-yield preparation of tetrahydrofurfuryl alcohol in the alcohol or alkane solvent system, and the conversion rate of the furfural and the yield of the furfural can be up to 100%. The tetrahydrofurfuryl alcohol preparation method is simple, reaction devices are simple, the operation is simple and convenient, a product and the catalysts are easy to separate, the catalysts are cheap and easy to obtain, and the catalysts have good hydrothermal stability and recycling performance, are suitable for industrial production and have a very broad application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Process for preparing tetrahydrofurfuryl alcohol by catalytic hydrogenation of furfuralcohol

InactiveCN1789257AImprove conversion rateGood choiceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemical platingAlloy

The invention relates to a process of preparing tetrahydrofurfuryl alcohol with furfuryl alcohol catalytic hydrogenation, under condition of furfuryl alcohol catalytic hydrogenation and existence of loading NiB and NiCoB amorphous alloy catalyst prepared with metallic revulsion chemical plating method, making furfuryl alcohol contact with alcohol in autoclave for reaction. The catalyst is the amorphous alloy with inorganic oxidate loading effective amount of active component NiB or NiCoB, the mass of the said effective active component NiB or NiCoB is 20% of the catalyst mass. The invention is characterized by the good catalytic activity of the furfuryl alcohol hydrogenation, high conversion rate of furfuryl alcohol, good selectivity of tetrahydrofurfuryl alcohol, temperate reacting condition, simple process, easy for industrial production and no pollution to environment.

Owner:天津孚信达光电科技有限公司

Tantalum-based catalyst and applications of tantalum-based catalyst in 1,5-pentanediol preparation reaction through catalytic conversion of tetrahydrofurfuryl alcohol

InactiveCN108187674AWide variety of sourcesLow costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsIridiumHydrogen pressure

The invention provides a tantalum-based catalyst and applications of the tantalum-based catalyst in a 1,5-pentanediol preparation reaction through catalytic conversion of tetrahydrofurfuryl alcohol. According to the catalyst, one or a plurality of a small amount of metals selected from platinum, palladium, iridium rhodium and the like are used as the active metal component and are supported on oneor a plurality of carriers selected from different forms of tantalum oxides, or two metals such as platinum and tantalum are supported on one or a plurality of carriers selected from SBA-15, MCM-41,silicon dioxide and active carbon; and the catalyst can achieve the catalytic conversion of tetrahydrofurfuryl alcohol at a temperature of 100-300 DEG C under a hydrothermal condition of the initial hydrogen pressure of 1-10 MPa. According to the present invention, the catalyst has characteristics of stable property, easy separation from the reaction system, convenient recovery and convenient regeneration, and can be conveniently used in industrial production application in the future.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lacquer thinner

A lacquer or other coating thinner having a low volatile organic compound (VOC) rating which permits its use for cleaning and thinning in government regulated areas. The thinner has an acetone, methyl acetate or tertiary butyl acetate or mixture as a base. It has various non-hazardous ingredients which include a soy oil material, a dibasic ester and a glycol and carbonate ingredient such as tetrahydrofurfuryl alcohol.

Owner:BORTZ DISTRIBUTING CO

Lignocellulose biomass component separation method

ActiveCN109134708AExcellent ability to dissolve ligninReduce energy consumptionPaper material treatmentLignocellulosic biomassDissolution

The invention discloses a lignocellulose biomass component separation method. According to the method, through mixing of a tetrahydrofurfuryl alcohol solution and lignocellulose biomass, degradation stripping of hemicellulose in a raw material and dissolution of lignin are completed in a hydrothermal environment, separation of cellulose, the hemicellulose and the lignin in lignocellulose biomass is achieved at a low temperature, and energy consumption can be effectively reduced. The pressure in a reaction process is low, and the requirements for a device can be effectively reduced. The technical process is simple, the tetrahydrofurfuryl alcohol solution can be recycled, and the cost can be effectively reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

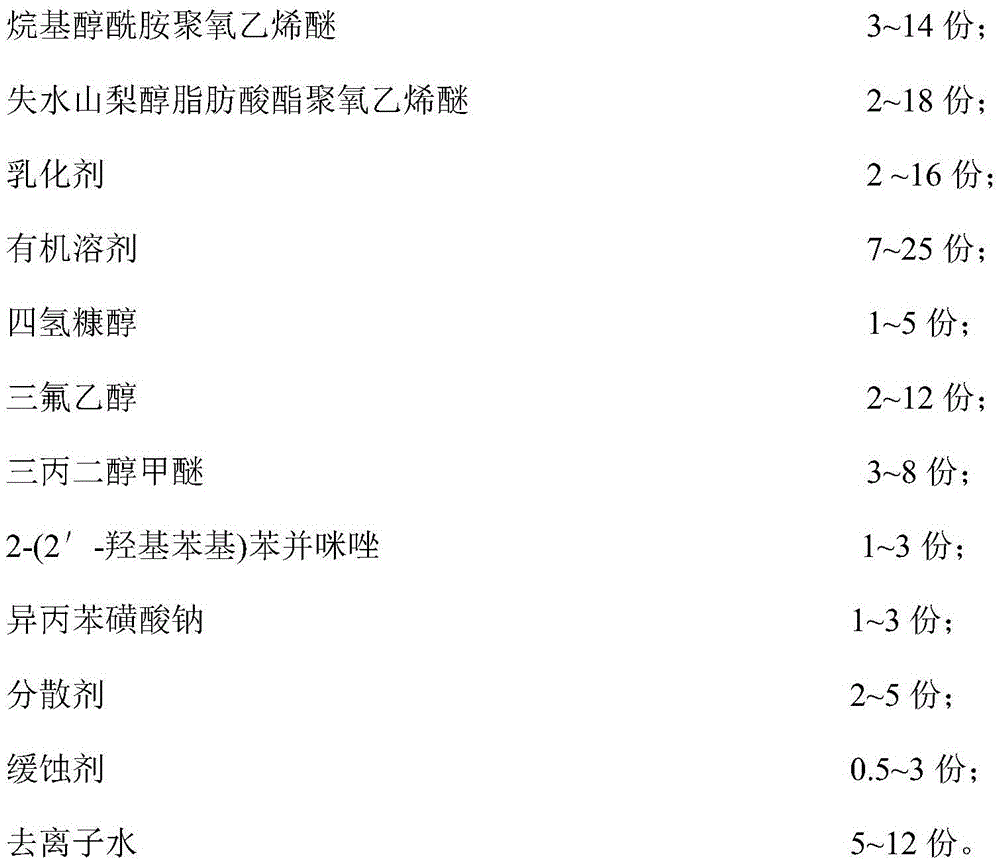

Water-based LED (light emitting diode) chip cleaning agent

InactiveCN105542990ANo generationReduce harmOrganic detergent compounding agentsSurface-active detergent compositionsWater basedCleansing Agents

The invention discloses a water-based LED (light emitting diode) chip cleaning agent, prepared from the following components of alkylolamide polyoxyethylene ether, polyoxyethylene sorbitan fatty acid ester, an emulsifier, an organic solvent, tetrahydrofurfuryl alcohol, trifluoroethanol, tripropylene glycol monomethyl ether, 2-(2'-hydroxylphenyl)benzoimidazole, sodium cumenesulfonate, a dispersant, a corrosion inhibitor and deionized water. The cleaning agent provided by the invention has the advantages that the effects of high cleaning efficiency, strong detergency, good safety performance, freeness from environmental pollution, energy saving and low washing cost are achieved; an LED is not damaged in a washing process; a protective film can be formed on the surface of a chip through the cleaning agent, so that air is isolated, and the chip is prevented from being corroded by moisture and other molecules in the air, therefore the effect of oxidation resistance is achieved, and a next production process is conveniently performed.

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

Method for preparing tetrahydrofurfuryl alcohol, and supported nickel catalyst

InactiveCN110240578AHigh yieldReduce energy consumptionOrganic chemistryCatalyst activation/preparationNickel catalystHydrogenation reaction

The invention discloses a method for preparing tetrahydrofurfuryl alcohol. According to the method, a supported nickel catalyst is adopted to perform hydrogenation on furfural, so that the tetrahydrofurfuryl alcohol can be obtained; the raw material conversion rate is greater than 99%, and the product selectivity is greater than 99%. The invention also discloses a preparation method of the supported nickel catalyst, and application of the supported nickel catalyst in a hydrogenation reaction of the furfural. The technical route provided by the invention has the beneficial characteristics of being simple and convenient to operate, mild in reaction conditions, high in target product yield and low in energy consumption.

Owner:EAST CHINA NORMAL UNIV

Ultraviolet (UV) curing acrylic ester adhesive

A UV curing acrylic ester adhesive is composed of, by mass, 40-50 parts of methyl methacrylate (MMA), 50-60 parts of butyl acrylate, 5-10 parts of vinyl acetate, 3-5 parts of acrylic acid, 5-20 parts of dioctyl-phthalate (DOP), 0.2-1 part of benzoyl peroxide, 60-70 parts of toluene, 5-10 parts of tetrahydrofurfuryl alcohol, 5-10 parts of quartz powder and 0.5-2 parts of ammonium persulfate. According to the UV curing acrylic ester adhesive, in a double glass detection under 40 DEG C, the glass cannot be penetrated by a 227g steel ball which falls from a height of 12m, spalling fragments at the back are lighter than 20g, the glass cannot be aged after three hours of water boiling at 100 DEG C, and the shear strength maintains at 6-7MPa.

Owner:SUZHOU FEN LAKE ELEVATOR

Cleaning composition in a concentrated form comprising tetrahydrofurfuryl alcohol

InactiveUS7008917B2Easy to prepareSimple compositionOrganic detergent compounding agentsSurface-active detergent compositionsOrganic solventDistilled water

A cleaning composition, in a concentrated form comprising a water-soluble organic solvent, an ionic surfactant, a nonionic surfactant, a chelating agent, and distilled water.

Owner:KNOCKOUT GRP

Cleaning composition in a concentrated form comprising tetrahydrofurfuryl alcohol

InactiveUS20050277572A1Easy to optimizeSimple compositionOrganic detergent compounding agentsSurface-active detergent compositionsOrganic solventDistilled water

A cleaning composition, in a concentrated form comprising a water-soluble organic solvent, an ionic surfactant, a nonionic surfactant, a chelating agent, and distilled water.

Owner:KNOCKOUT GRP

Flux paste special for unleaded tin-bismuth solder and preparation method thereof

InactiveCN106001998AHigh activityImprove wettabilityWelding/cutting media/materialsSoldering mediaPolyamideSuccinic acid

The invention discloses flux paste special for unleaded tin-bismuth solder. The flux paste special for the unleaded tin-bismuth solder comprises, by weight, 10-20 parts of hydrogenated rosin, 5-10 parts of disproportionated rosin, 10-15 parts of dimer rosin, 5-10 parts of tetrahydrofurfuryl alcohol, 5-10 parts of pentaerythritol, 5-8 parts of butyl cellosolve, 5-8 parts of octyl ether, 5-8 parts of dibasic acid esters, 2-5 parts of phthalic acid dibutyl esters, 2-3 parts of oleyl alcohol polyoxyethylene ether, 3-6 parts of polyamide modified hydrogenated castor oil, 2-4 parts of succinic acid, 1-2 parts of pyridine hydrochloride, 1-2 parts of bromic acid tributylamine, 4-8 parts of DIACID 1550 and 1-3 parts of N,N,N,N'',N''-pentamethyldiethylenetriamine. The flux paste special for the unleaded tin-bismuth solder is good in wettability, the welding defect is lower than that of existing flux paste for the unleaded tin-bismuth solder, organic acid and polyamine decompose and volatilize in the welding process, the amount of residues generated after welding is small, and protective films can be formed on the surfaces of welding points through the used rosin.

Owner:丘以明

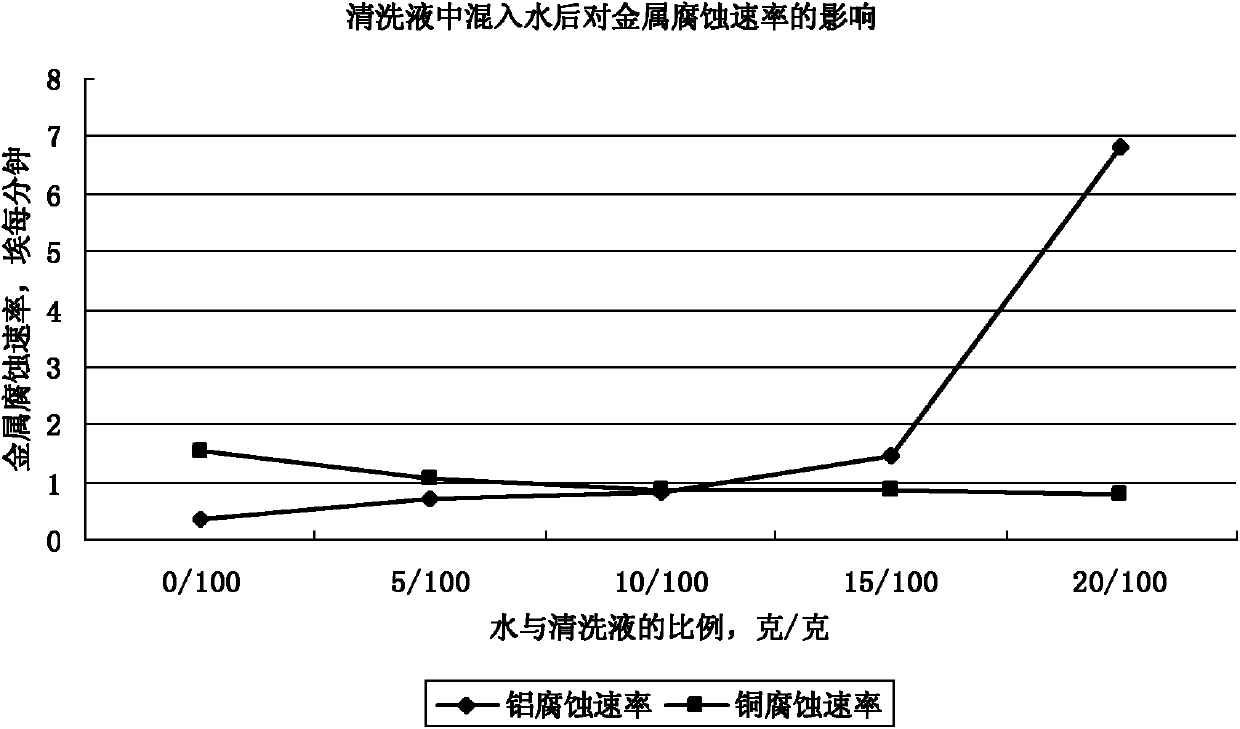

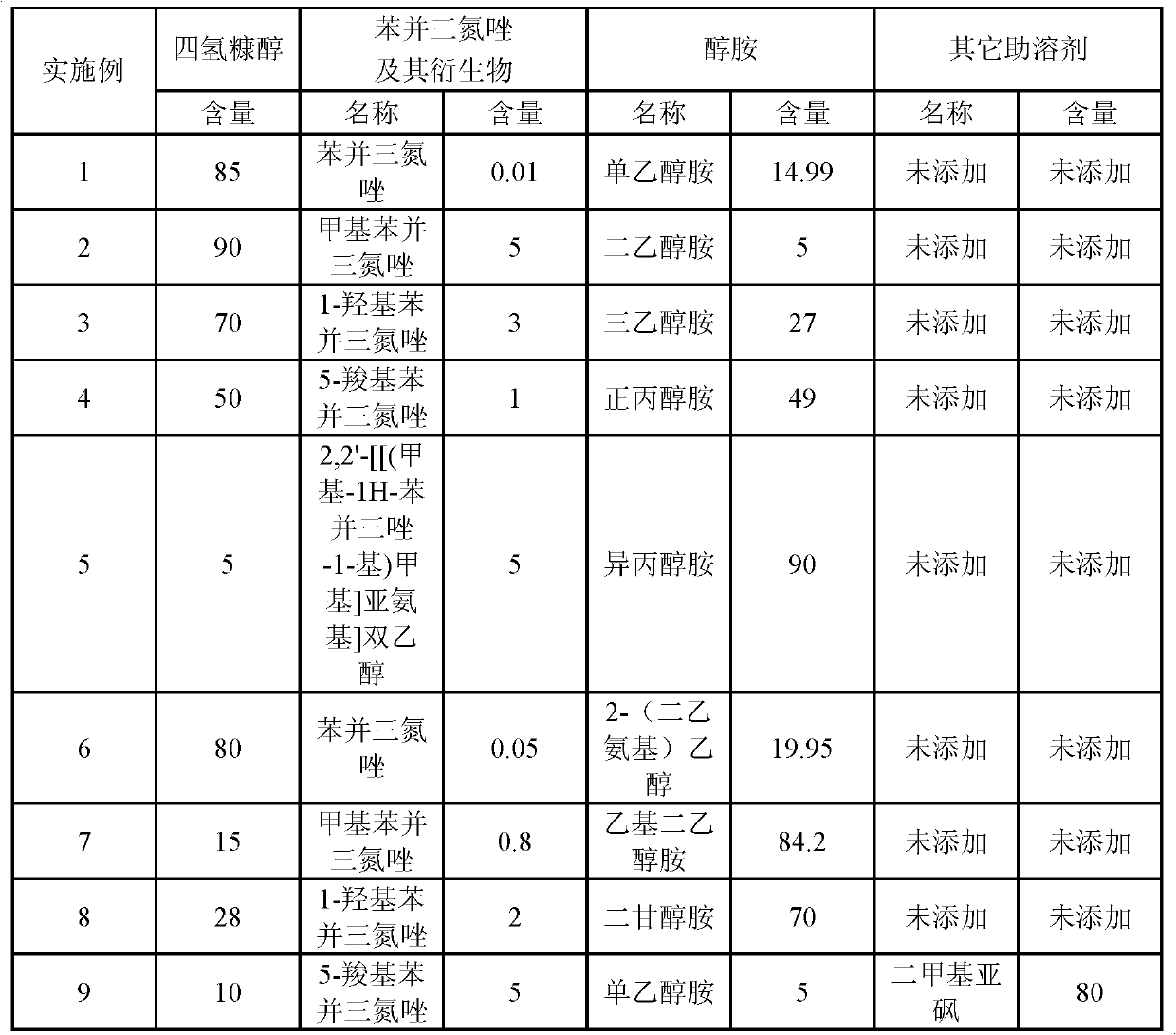

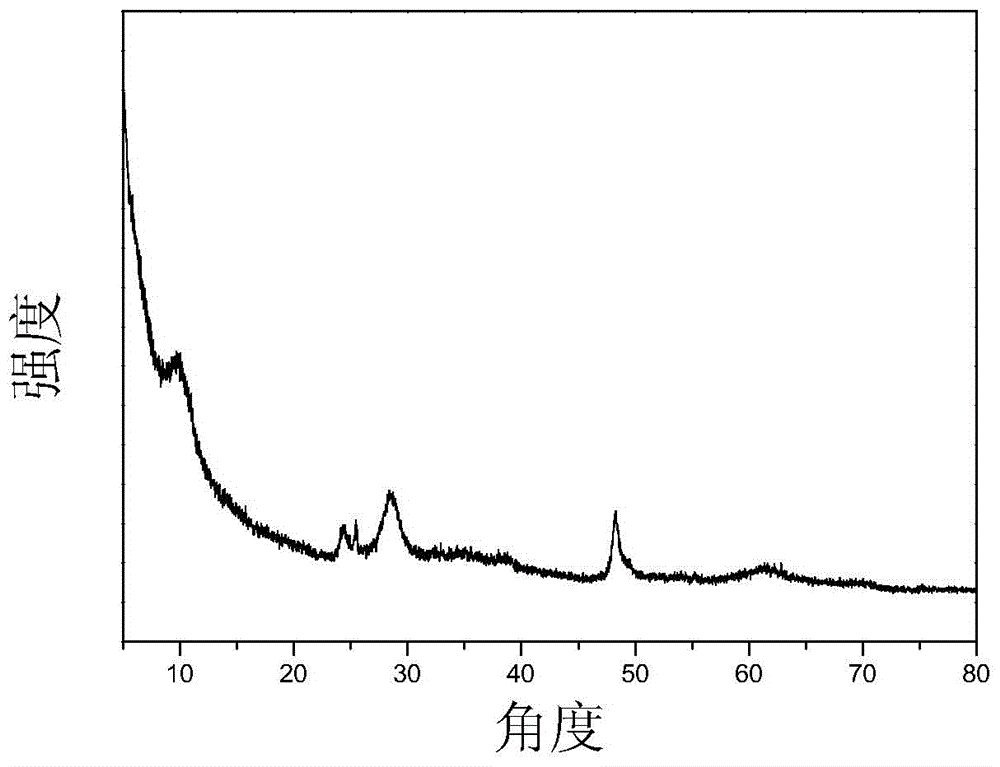

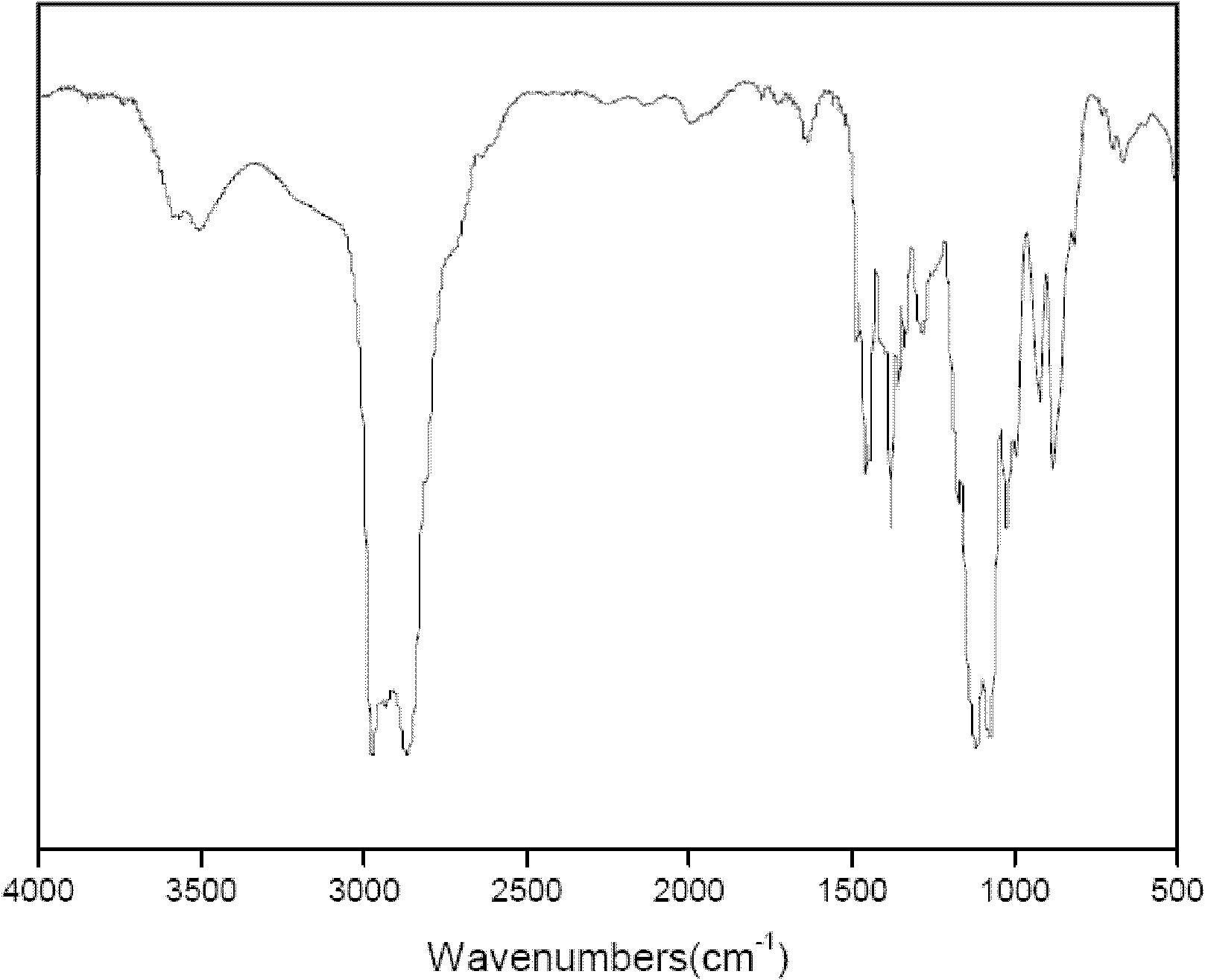

Photoresist cleanout fluid

InactiveCN103293882AGood removal effectStrong corrosion inhibition abilityPhotosensitive material processingAlcoholBenzotriazole

The invention discloses photoresist cleanout fluid. The cleanout fluid comprises alcohol amine, tetrahydrofurfuryl alcohol and benzotriazole and / or derivatives thereof. The photoresist cleanout fluid can be used for removing photoresist in light-emitting diodes (LED) and semiconductors and basically does not attack base materials, such as metallic aluminium and copper, and moreover, the cleanout fluid system has high water resistance, and the operating window is widened.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

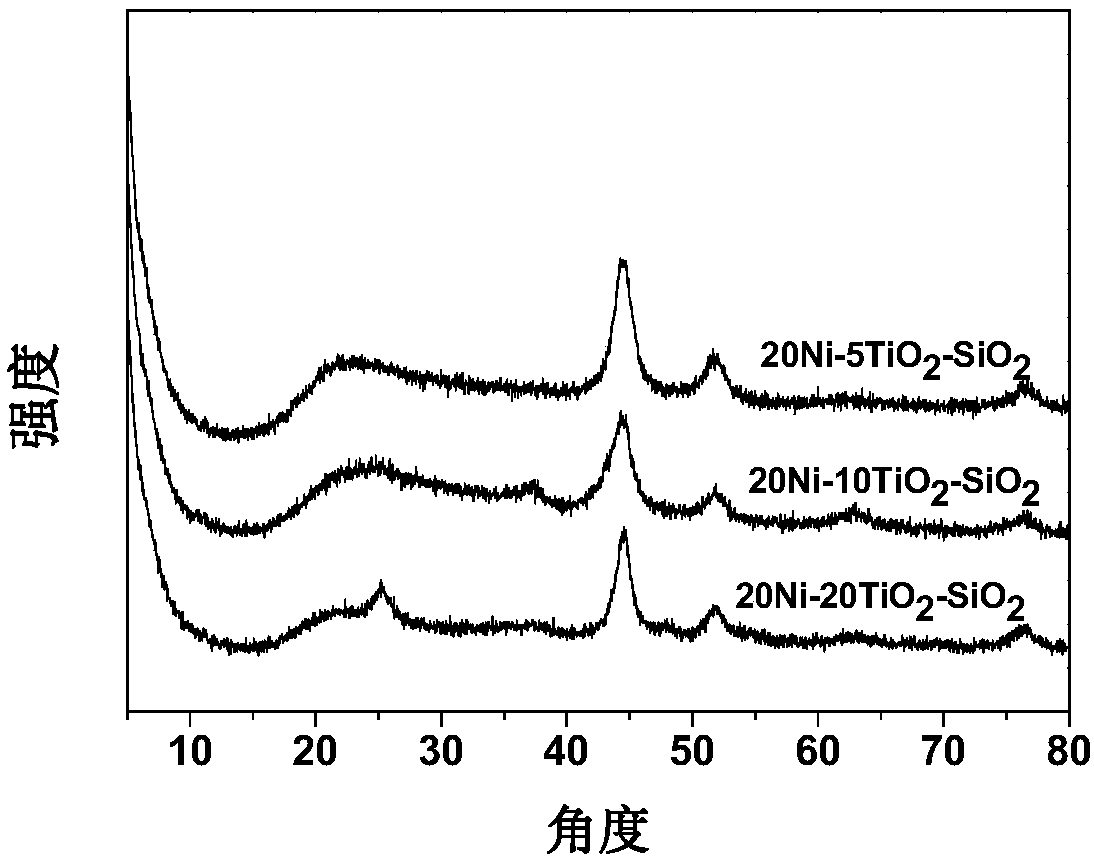

Method for preparing tetrahydrofurfuryl alcohol by liquid phase hydrogenation and catalyst used by method

InactiveCN104610199AHigh selectivityMild reaction conditionsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystTitanium oxide

The invention discloses a method for preparing tetrahydrofurfuryl alcohol by liquid phase hydrogenation. According to the method disclosed by the invention, the tetrahydrofurfuryl alcohol is prepared through the following steps: applying a loaded palladium catalyst for performing high-selective hydrogenation on furfuryl alcohol under the conditions of a low temperature and low pressure, and performing a reaction. The carrier of the loaded palladium catalyst is a titania material, and palladium nanometer metal ions are loaded on the carrier. The invention further discloses a preparation method of the loaded palladium catalyst. The method disclosed by the invention has the characteristics of mild reaction condition, high catalytic activity, high selectivity of the tetrahydrofurfuryl alcohol and the like.

Owner:EAST CHINA NORMAL UNIV

Preparation method of gamma-butyrolactone

The invention provides a novel method for preparing gamma-butyrolactone. With the method, molecular oxygen (air or oxygen) is adopted as an oxygen source; a high-efficiency catalyzing method is adopted, and tetrahydrofurfuryl alcohol is directly subjected to liquid-phase selective oxidation, such that gamma-butyrolactone is obtained. The method adopts a reaction raw material of tetrahydrofurfuryl alcohol which can be obtained from biomass raw materials such as corn cob, husk, and downstream product furaldehyde. The material source is rich, and price is low. The method is a gamma-butyrolactone preparation novel technological path which is independent of fossil resources. During the reaction process, no solvent is needed. The reaction condition is mild. The method has important application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Synthesis method of ethyl tetrahydrofurfuryl ether

InactiveCN101805315AHigh yield synthesisReduce process stepsOrganic chemistryHalohydrocarbonSynthesis methods

The invention relates to a synthesis method of ethyl tetrahydrofurfuryl ether, wherein tetrahydrofurfuryl alcohol, halohydrocarbon and alkali are placed in a reactor and react when being stirred. The reaction temperature is 5 to 95 degrees centigrade. The reaction time is 0.5 to 9 hours. The mole ratio of the tetrahydrofurfuryl alcohol, the halohydrocarbon and the alkali is 1 to 1-4 to 1-4. The invention adopts the tetrahydrofurfuryl alcohol, the halohydrocarbon and the alkali to react together and can synthesize the ethyl tetrahydrofurfuryl ether with high yield. The technological method provided by the invention leaves out the technology step of preparing sodium alkoxide, eliminates the dangerous factor of production technology, reduces the pollution discharge in the production process and effectively reduces the manufacture cost.

Owner:XINJIANG KEYUAN CHEM

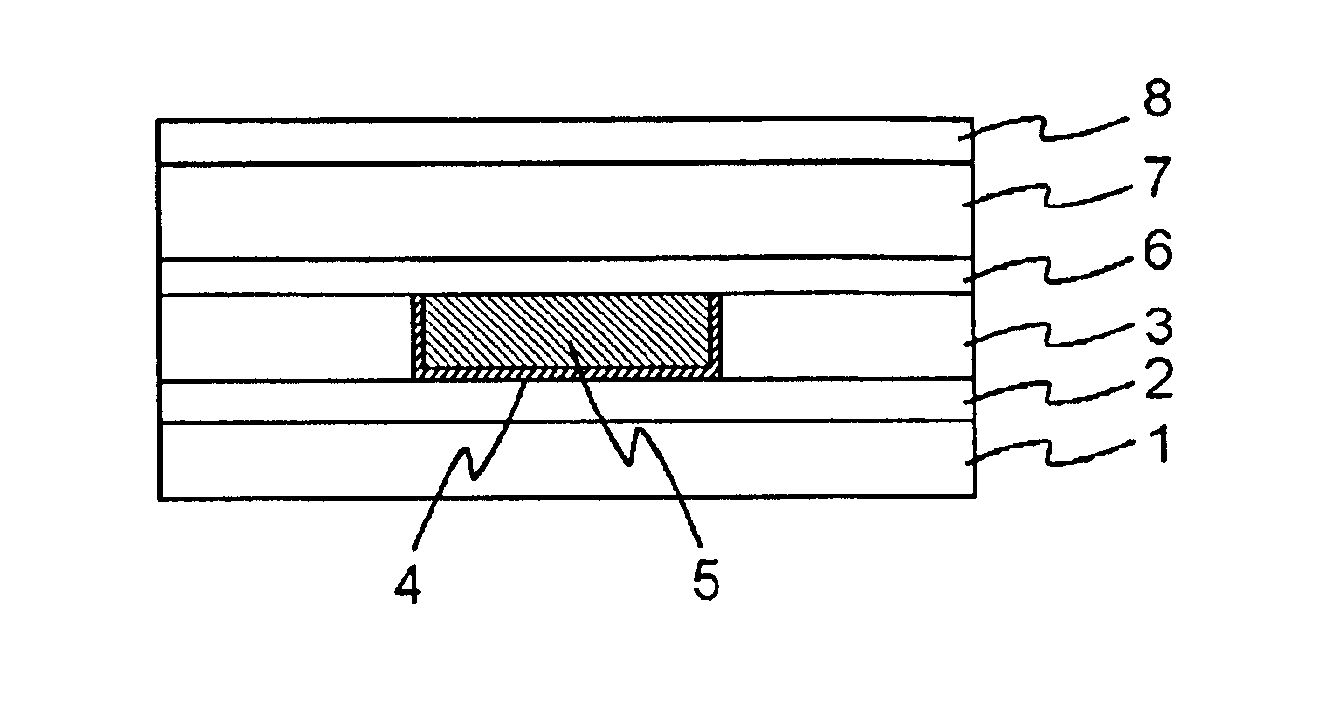

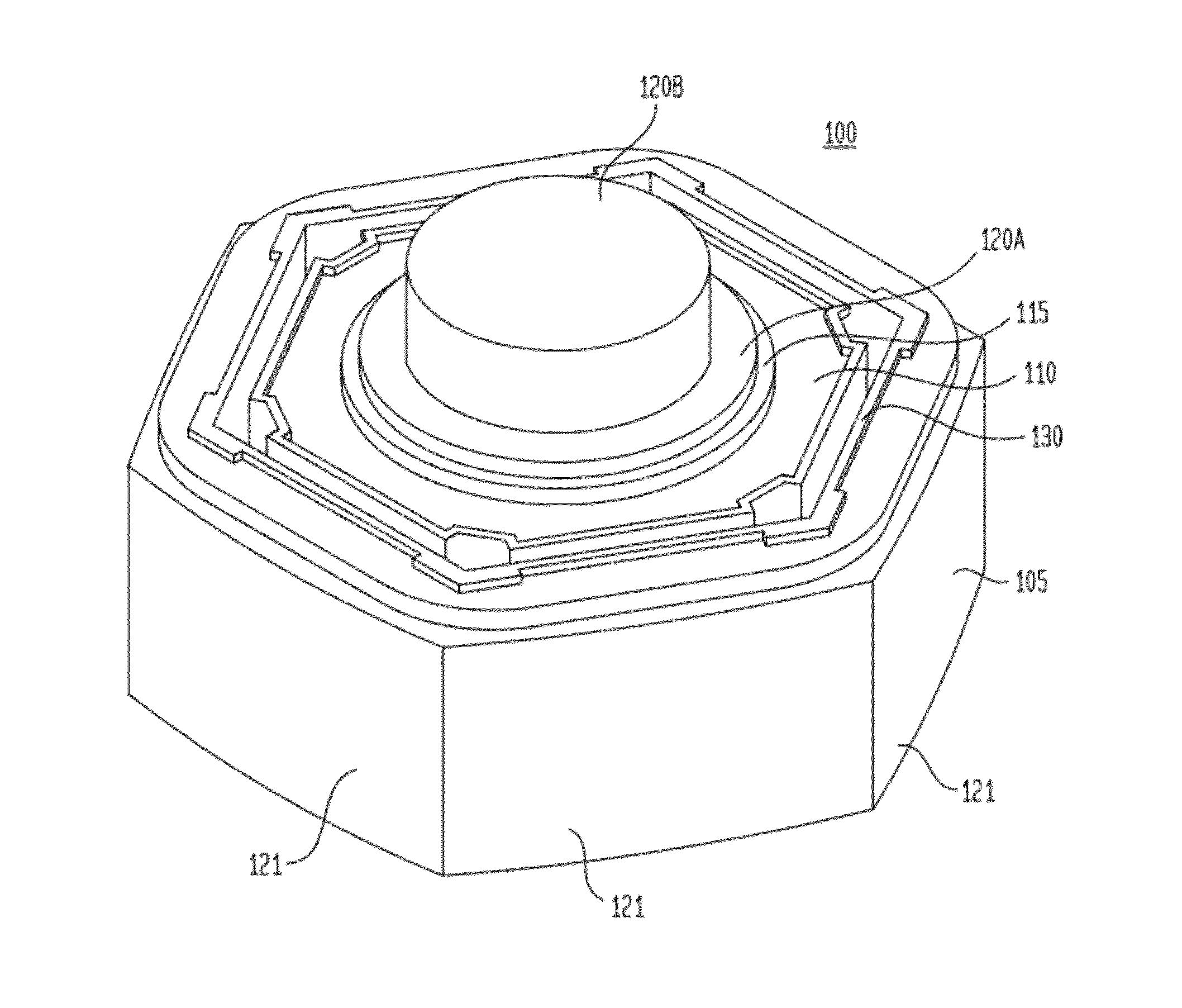

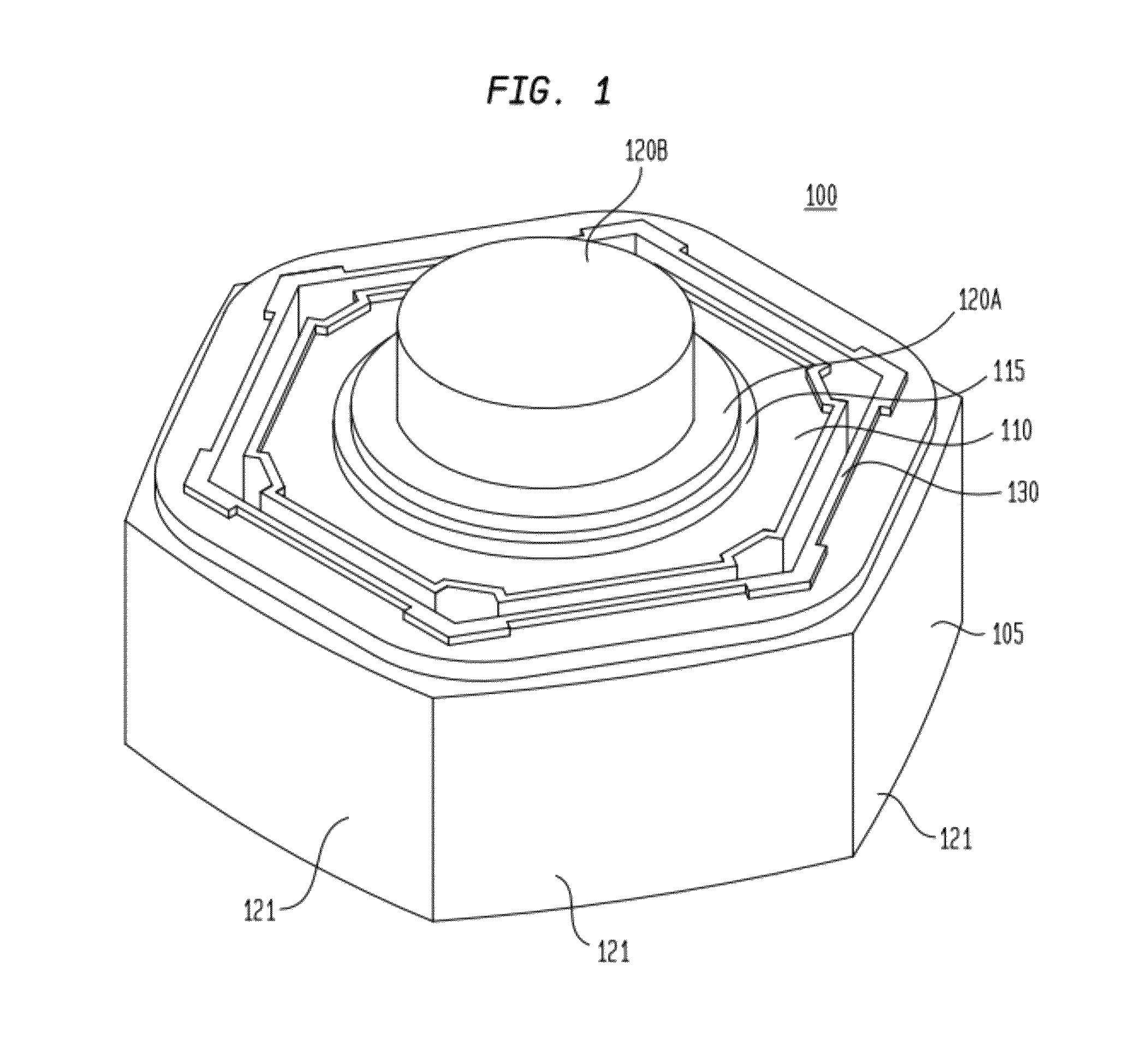

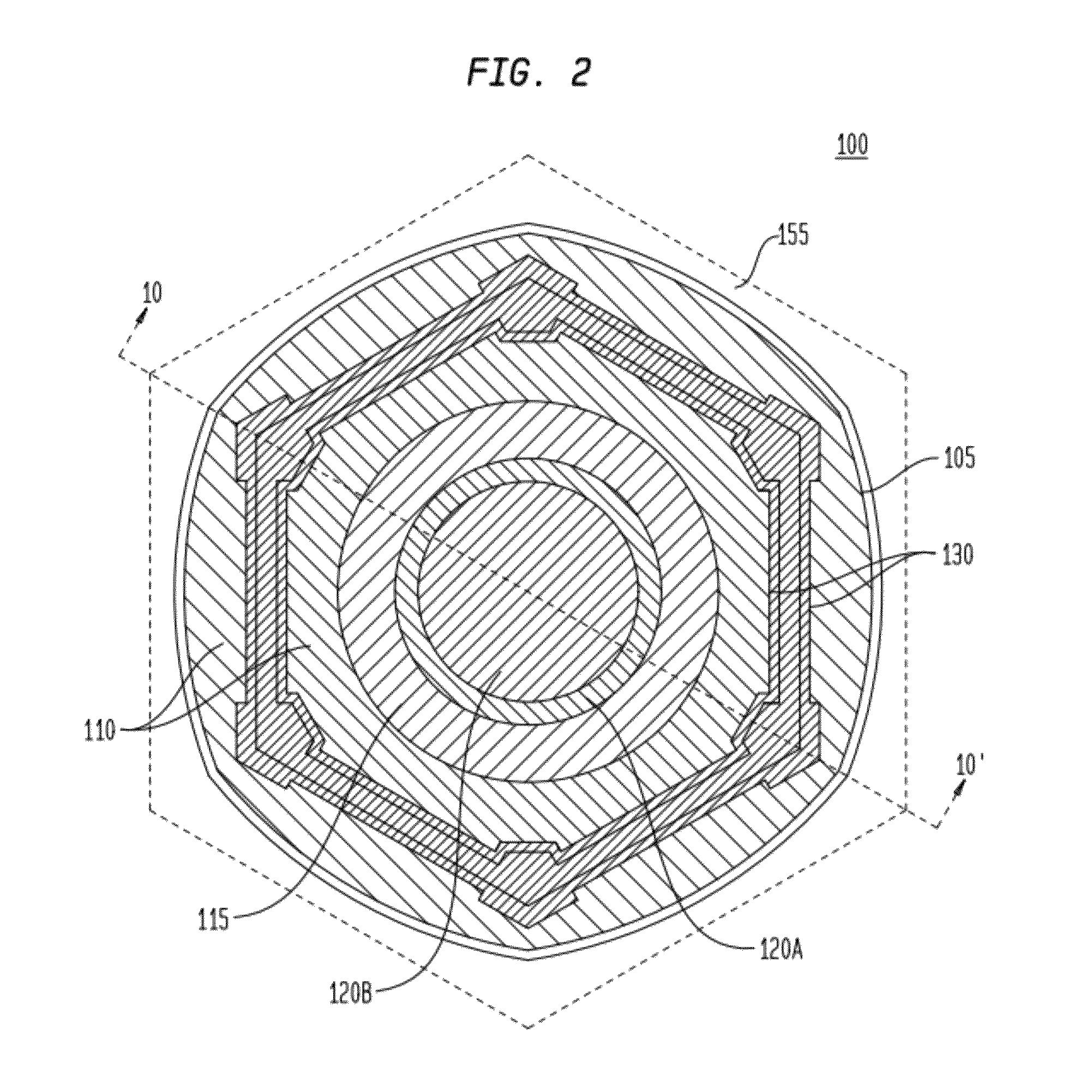

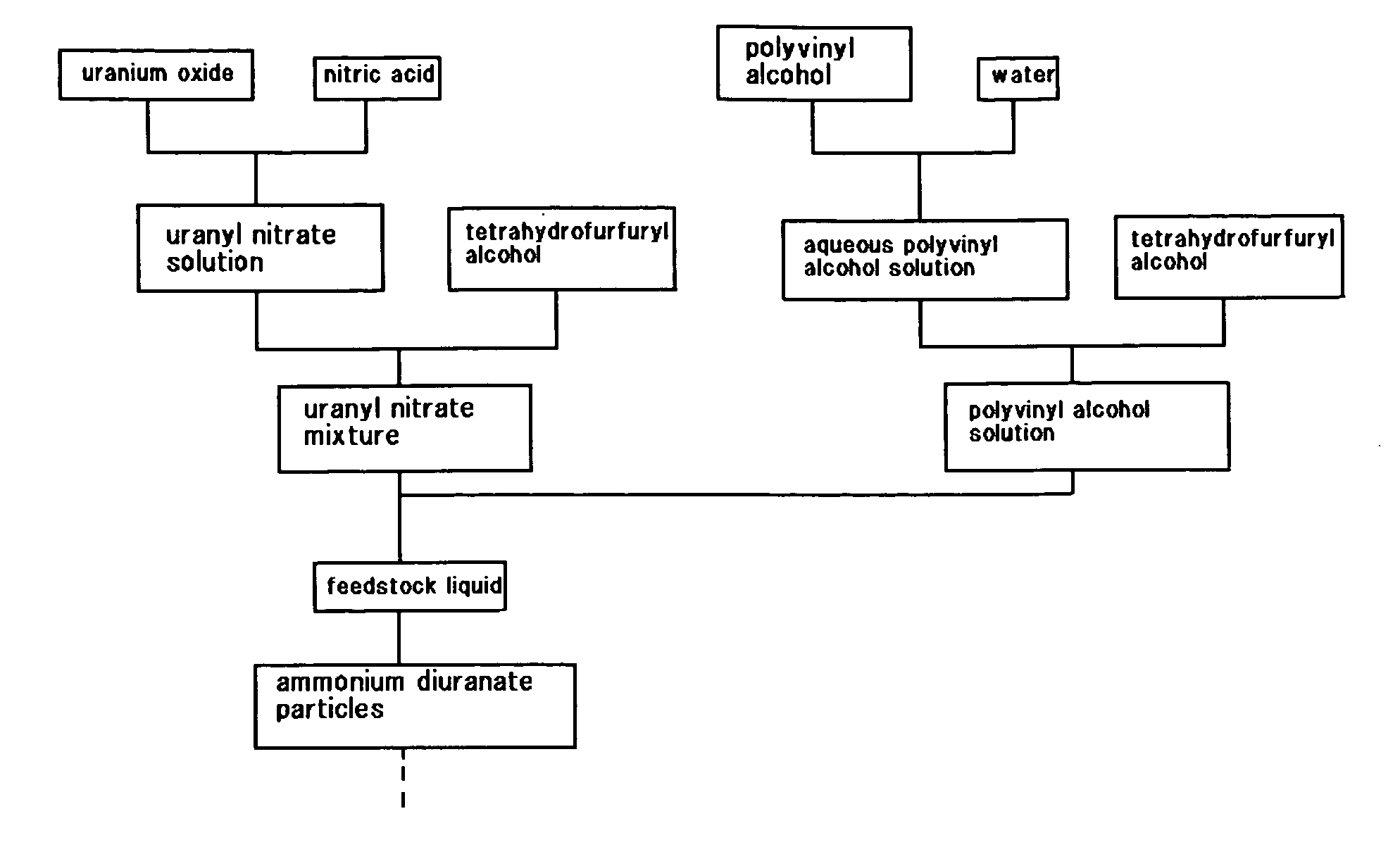

Method of preparing feedstock liquid, method of preparing uranyl nitrate solution, and method of preparing polyvinyl alcohol solution

InactiveUS20070178036A1Good spherical shapeSimple internal structureNuclear energy generationReactors manufacturePolyvinyl alcoholAmmonium diuranate

The object of the present invention is to provide a feedstock liquid, from which fuel kernels with good quality can be produced, and a method of preparing the feedstock liquid. The present invention provides a feedstock liquid with a viscosity from 4.0×10−2 to 6.5×10−2 Pa·s at 15° C., for the production of ammonium diuranate particles. The present invention also provides a method of preparing a feedstock liquid used for the production of ammonium diuranate particles, which includes mixing a uranyl nitrate solution and tetrahydrofurfuryl alcohol to produce a uranyl nitrate mixture, dissolving polyvinyl alcohol in water to produce an aqueous polyvinyl alcohol solution, mixing the aqueous polyvinyl alcohol solution with tetrahydrofurfuryl alcohol to produce a polyvinyl alcohol solution, and mixing the uranyl nitrate mixture with the polyvinyl alcohol solution.

Owner:NUCLEAR FUEL INDS

Liquid for activating plant and method for producing the same

InactiveCN101438708APromote growthPromote photosynthetic reactionBiocidePlant growth regulatorsPropanoic acidCarbonization

The invention relates to a plant activate fluid which comprises organic acids, alcohol, phosphoryl compounds, phenols, a small amount of inorganic matter and water. According to weight percentage, the organic components comprise 48 percent to 55 percent of acetic acid, 0.9 percent to 4.0 percent of formic acid, 0.8 percent to 3.1 percent of propionic acid, 0.04 percent to 0.08 percent of valeric acid, 0.46 percent to 0.8 percent of butylric acid, 0.04 percent to 0.2 percent of crotonic acid, 0.9 percent to 2.1 percent of methanol and 1.8 percent to 2.4 percent of acetaldehyde; and the organic components further comprise 0.3 percent to 1.6 percent of pyridine, 1.6 percent to 3.2 percent of furan, 0.83 percent to 1.87 percent of phenol, 0. 4 percent to 1.6 percent of 2-furfural alcohol, 1.2 percent to 2.9 percent of 2(3H)2 hydrogen furanone, 1.6 percent to 2.8 percent of 2(5H)2 hydrogen furanone, 0.09 percent to 0.32 percent of tetrahydrofuran, 0.1 percent to 1.5 percent of 2-tetrahydrofurfuryl alcohol, 0.89 percent to 2.1 percent of furfurol, 0.3 percent to 1.7 percent of methyl acetate and 0.2 percent to 1.5 percent of hydroxy methyl acetate. The invention takes branch and leaf wastes of ligneous plants as the raw material for carbonization, the smoke is collected during the carbonization process, and the plant activate fluid is obtained through water-cooling, temperature reduction and condensation.

Owner:陈首畅 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com