Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1327results about How to "Lower reaction cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

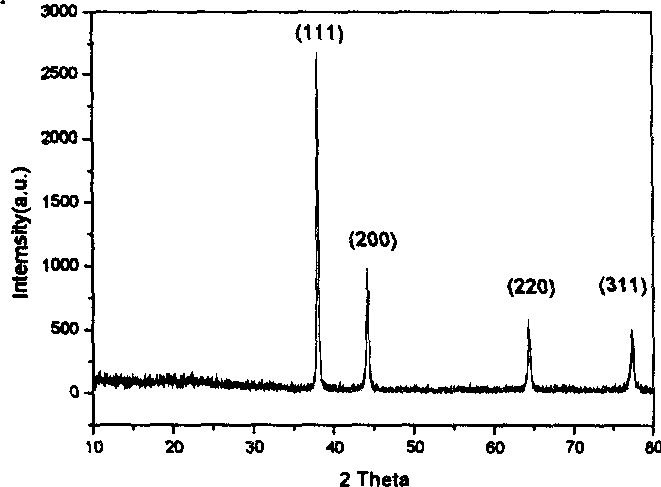

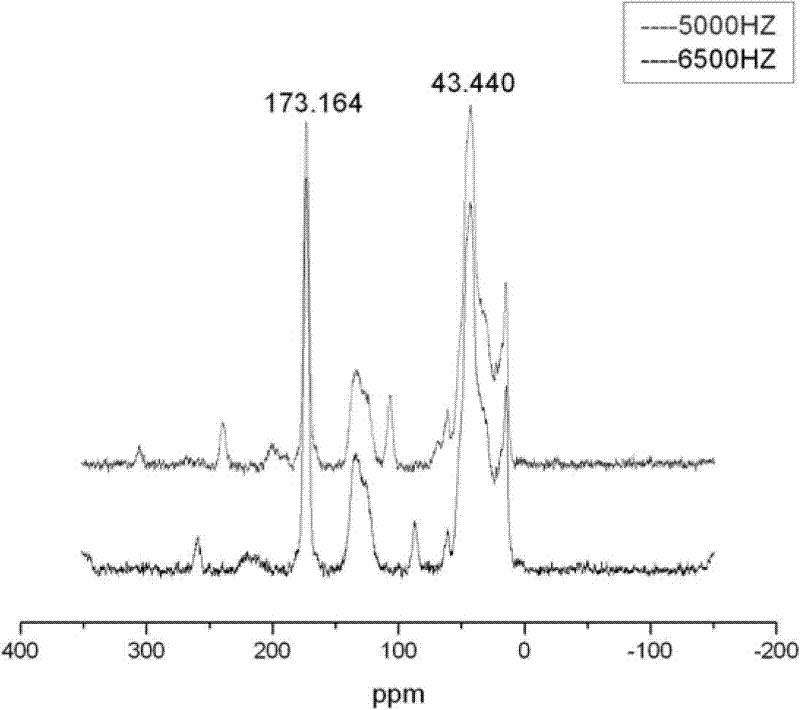

Silver nanometer wire synthesizing process

InactiveCN1740405ARaw materials are easy to getSimple processFrom melt solutionsHigh concentrationPolymer solution

The present invention belongs to the field of nanometer material preparing technology, and provides a two-step silver nanometer wire synthesizing process with high form selectivity and high efficiency. Under the protection of inert gas, very dilute ethylene glycol solution of silver nitrate is first added into ethylene glycol to prepare silver crystal seed; ethylene glycol solution of silver nitrate in relatively high concentration and ethylene glycol polymer solution in the corresponding concentration and volume are then added into the reaction system with crystal seed; and through crystal growth, silver nanometer wire is obtained. By means of regulating reaction condition, the size and form of the silver nanometer wire may be controlled. The present invention has low reaction cost and high silver nanometer wire yield, and the obtained silver nanometer wire has high purity, good structure and high mechanical performance.

Owner:ZHEJIANG UNIV

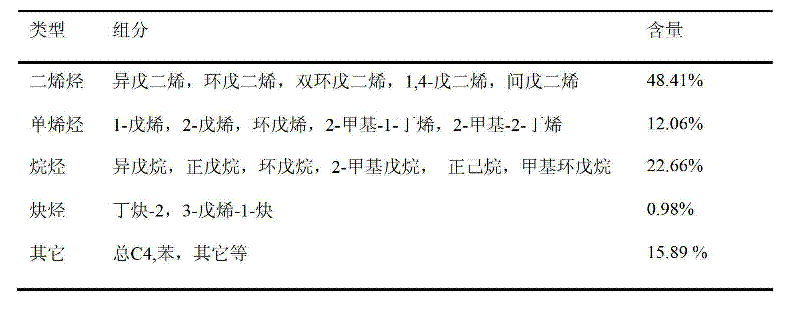

Copolymer containing functional group and prepared by C5 mixture and maleic anhydride, and preparation of copolymer

The invention provides a copolymer containing a functional group and prepared by a C5 mixture and maleic anhydride and a preparation of the copolymer, belonging to the field of applications of C5 resource. The preparation method comprises the following steps of: adding monomer maleic anhydride and initiator azobisisobutyronitrile (AIBN) into ester medium under the protection of nitrogen, dissolving completely, adding C5 mixture into the system, and dissolving, wherein the mol ratio of the maleic anhydride and the C5 is 1:1, reacting for 0.05-7 hours at 50-90 DEG C so as to obtain a milky and stable solid-liquid disperse system of the copolymer of C5 and maleic anhydride, centrifugally separating and drying at vacuum condition so as to obtain the white solid powder of copolymer of C5 and maleic anhydride. According to the invention, the C5 mixture is directly used as the raw material to prepare the highly crosslinked copolymer containing the functional group in one-step reaction, in this way, the C5 resource is used reasonably and effectively.

Owner:BEIJING UNIV OF CHEM TECH

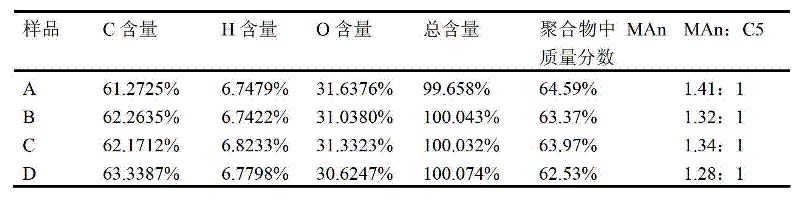

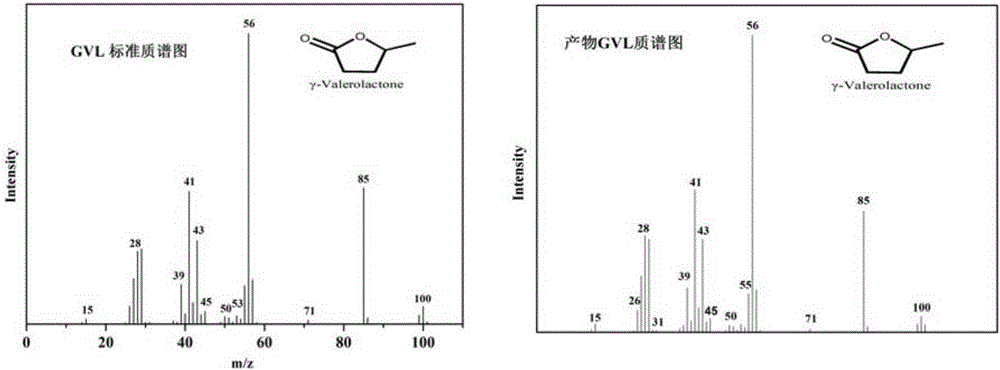

Method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation

ActiveCN105289592AHigh activityGood reaction selectivityOrganic chemistryMolecular sieve catalystsOrganic acidPtru catalyst

The invention discloses a method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation. Through high efficiency catalysis of levulinic acid hydrogenation based on a loaded ruthenium catalyst under mild conditions, gamma-valerolactone is prepared. The method has a levulinic acid conversion rate of 100% and gamma-valerolactone selectivity of 99.9%. The loaded ruthenium catalyst has a low active metal load capacity (less than 1.5w.t.%) and high activity (TOF, 7676h<1>), has good water and acid resistance and is suitable for an intermittent reactor and a continuous fixed bed reactor. The method solves the problem that the existing gamma-valerolactone preparation method needs a high temperature and high pressure and utilizes organic acids and bases and an organic solvent, improves preparation method economy and safety, utilizes a small amount of a catalyst, realizes catalyst recycle, has a high product yield and product separation easiness, and has a latent industrial application value.

Owner:SYNFUELS CHINA TECH CO LTD

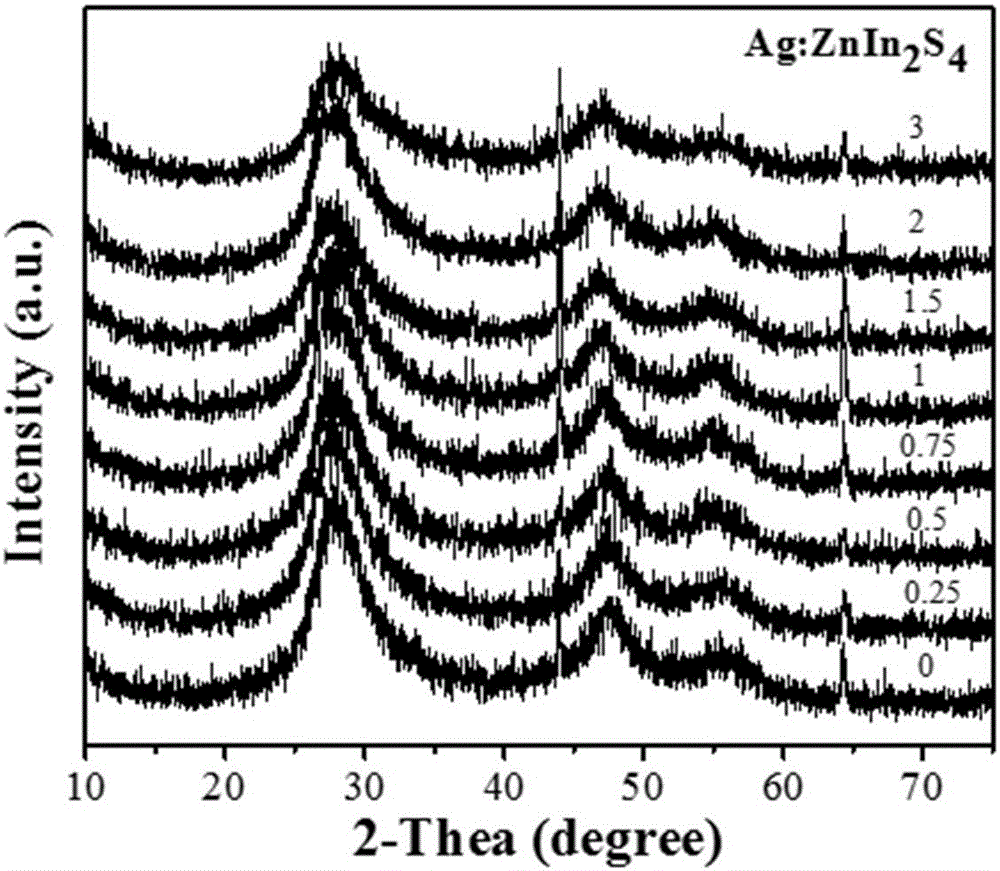

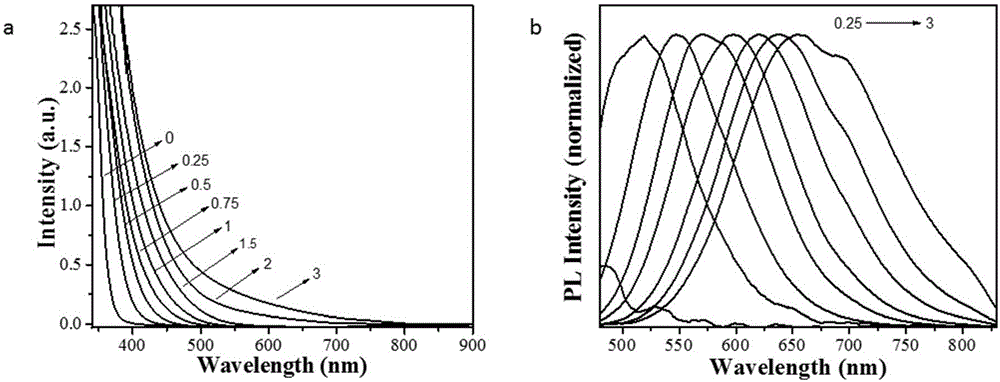

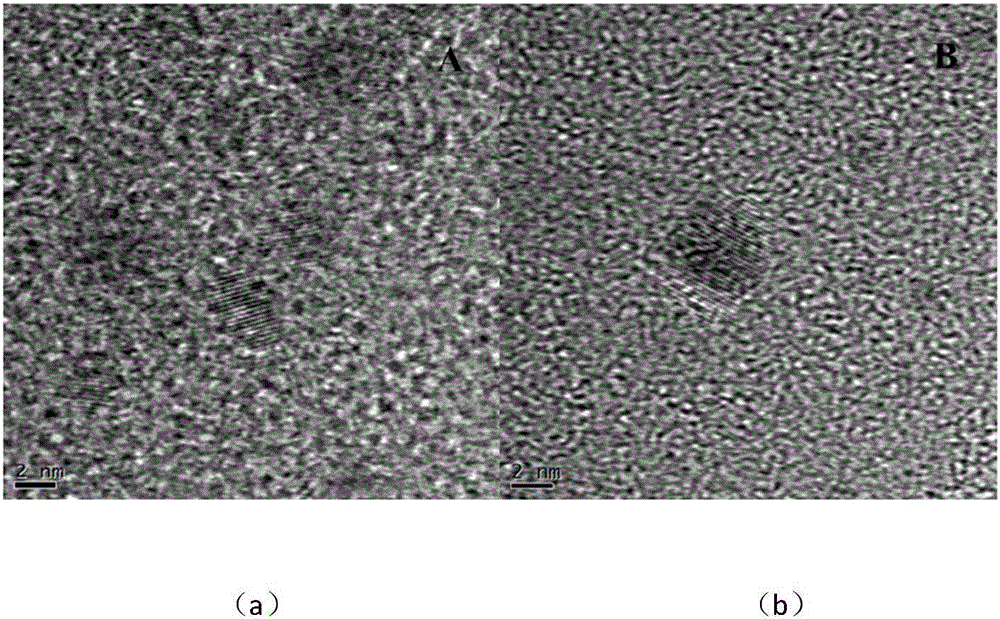

Method for preparing Ag:ZnIn2S4 luminescent quantum dots and photocatalyst

InactiveCN105950140AFully crystallizedGood dispersionMaterial nanotechnologyPhysical/chemical process catalystsFluorescenceZinc Acetate Dihydrate

The invention relates to the field of synthesis of nano-materials and particularly relates to a method for synthesizing a series of Ag:ZnIn2S4 luminescent quantum dots by using a simple and rapid hydrothermal method in one step. Fluorescence is adjustable in the range of 460nm to 830nm, the fluorescent life is relatively long, and the luminescent quantum dots can be applied to water-decomposed hydrogen production under visible light. The method comprises the steps of firstly, mixing and dissolving silver nitrate, indium nitrate, zinc acetate dihydrate and L-cysteine in an aqueous solution, adjusting the pH value of the solution to 8.5 by using NaOH, adding thioacetamide into the solution, carrying out ultrasonic stirring, then, carrying out a hydrothermal reaction for 4 hours at the temperature of 110 DEG C, and carrying out centrifugal drying after the reaction ends, thereby obtaining Ag@ZnIn2S4 nanocrystals of different ratios. Proven by a photocatalytic hydrogen production experiment under the visible light, the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

Preparation method of biodegradable nasal hemostatic sponge

ActiveCN104031287AShort synthesis reaction timeReduce dosageAbsorbent padsBandagesPolymer sciencePtru catalyst

Owner:SAIKE SAISI BIOTECH CO LTD

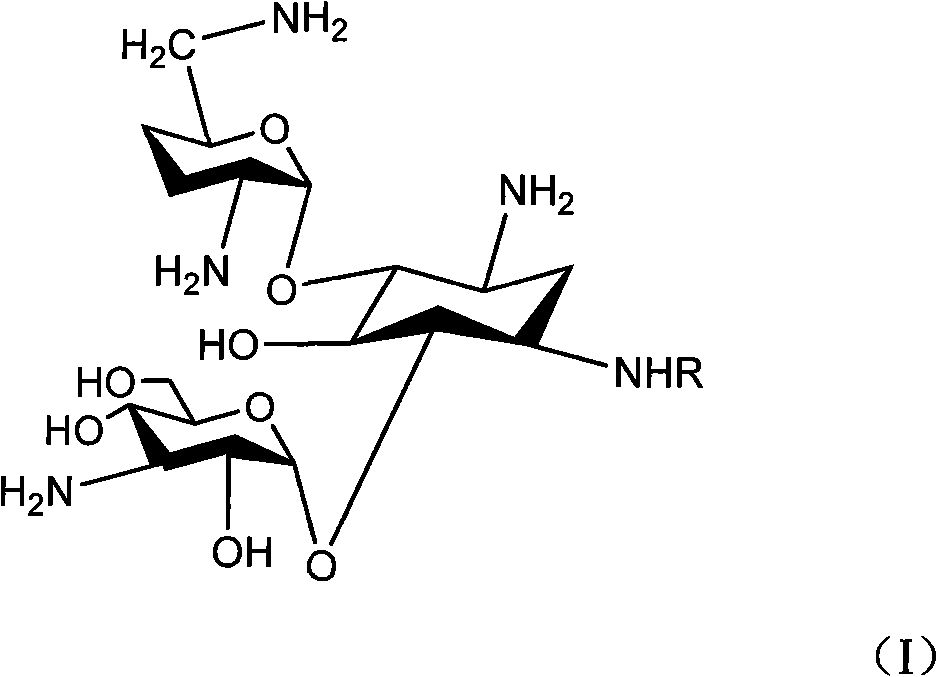

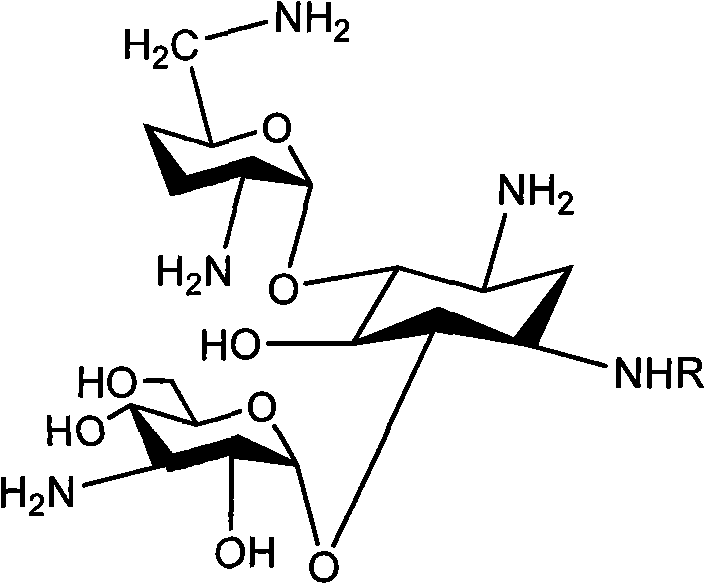

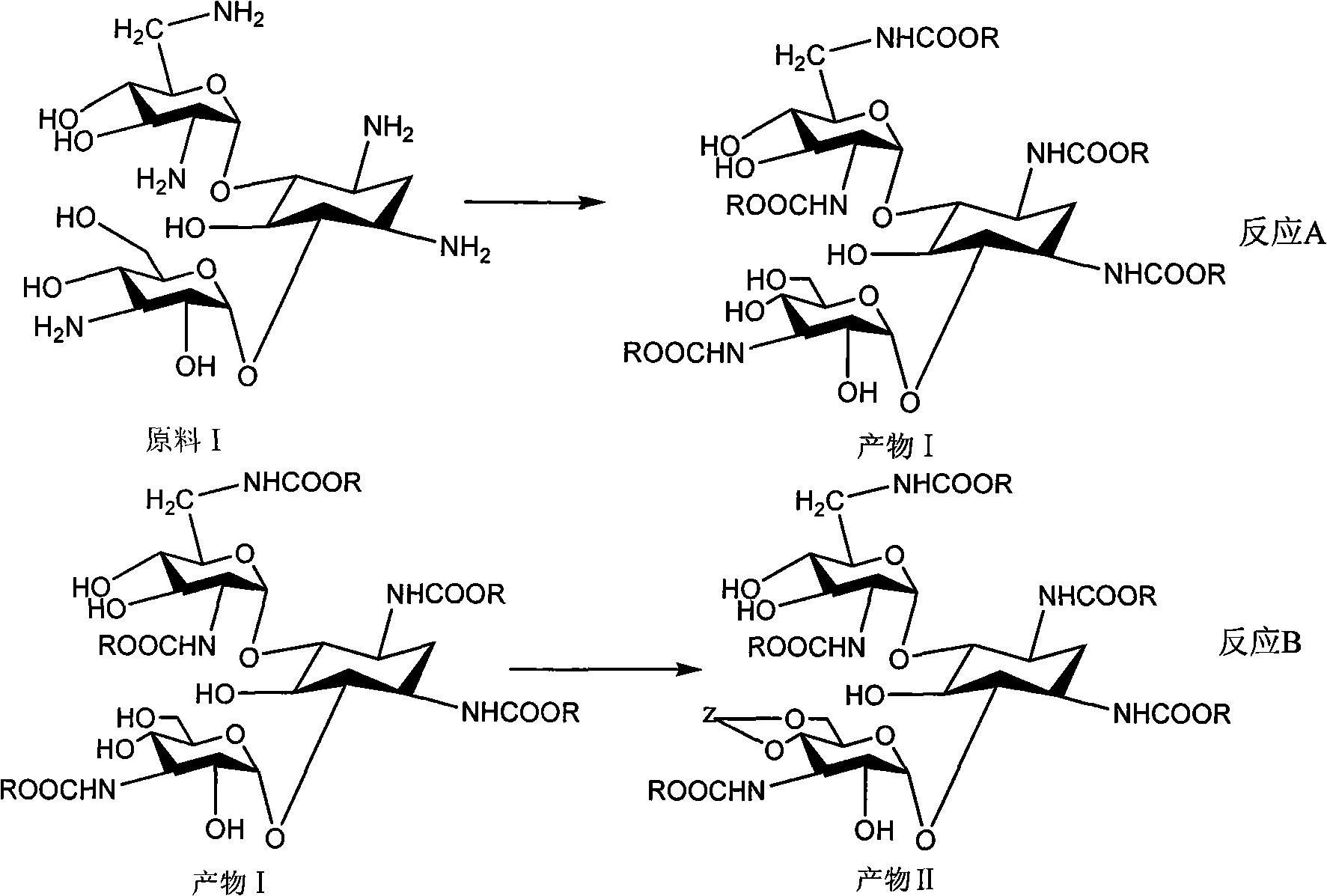

Method for synthesizing Arbekacin and intermediate dibekacin thereof

InactiveCN101575354AHigh yieldReduce generationSugar derivativesSugar derivatives preparationFluoroacetic acidSynthesis methods

The invention relates to an organic synthesis method, in particular to a method for synthesizing an Arbekacin and an intermediate dibekacin thereof. The method comprises the following steps of: takinga kanamycin B as initial raw material, carrying out the following processes of aldol condensation, sulfonylation, sodium iodide replacement and elimination to form double bond, de-protection under acidic condition, amino-electron reduction and final hydrogenation, thus obtaining the dibekacin; taking 3',4'-dideoxy -3',4'-didehydro-kanamycin B as raw material, using a di-tert-butyl dicarbonate toselectively protect the amidogen of 3, 2', 6', 3'' sites; subsequently using the synthesized active ester to protect the 1-site amidogen; subsequently using tri-fluoroacetic acid to remove BOC; and carrying out hydrazinolysis and catalysis and hydrogenation of platinum oxide, thus obtaining the Arbekacin. The synthesis method has the advantages of simple operation, high outcome yield, reducing thecost of raw material, optimizing the reaction route, lowering the requirements to the reaction conditions and being beneficial to industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

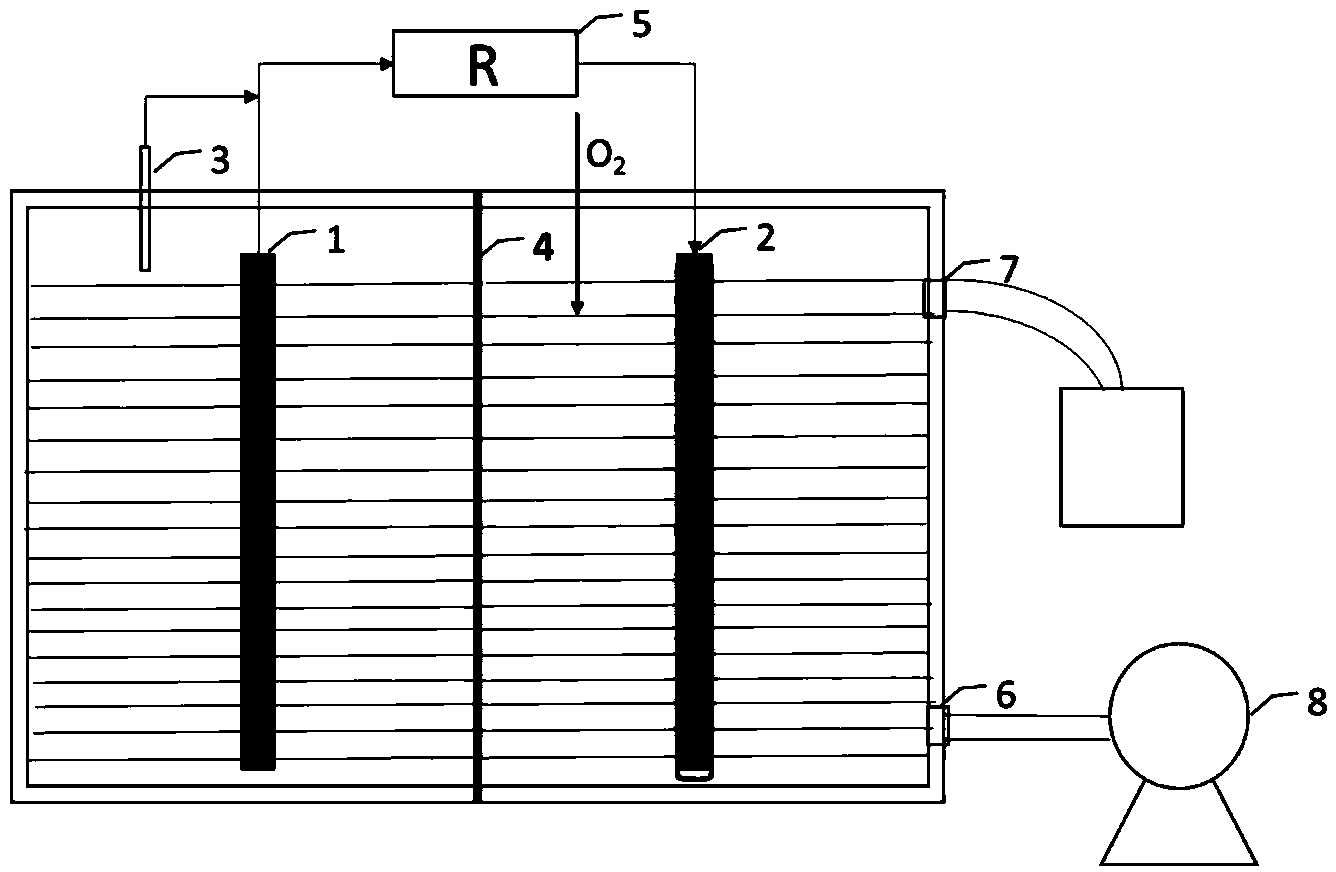

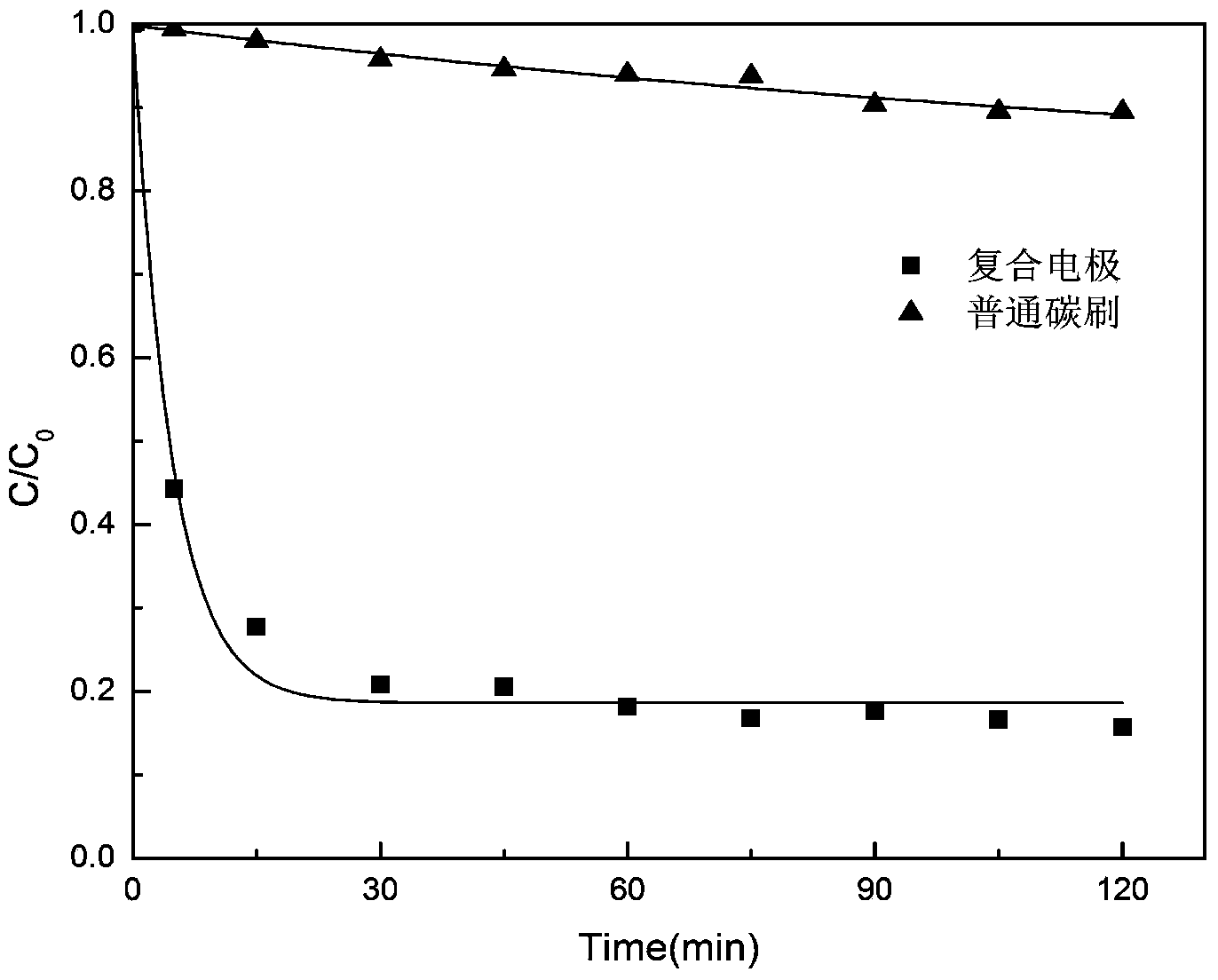

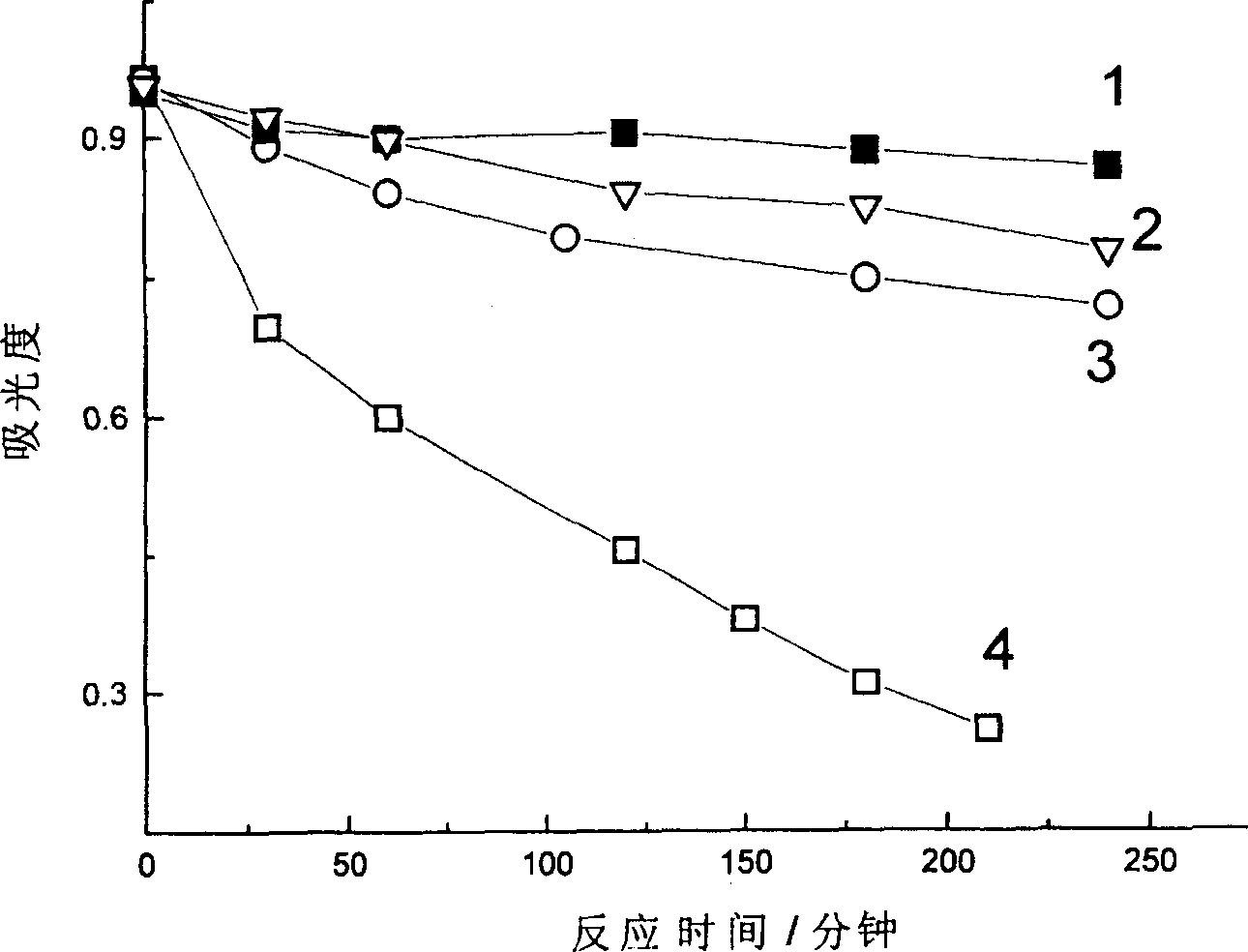

Combination electrode preparation method and application of combination electrode preparation method in bioelectricity Fenton system

InactiveCN104310573ARealize processingEasy to handleWaste water treatment from textile industryBiological water/sewage treatmentElectronBioelectrochemistry

The invention discloses a combination electrode preparation method and the application of the combination electrode preparation method in a bioelectricity Fenton system, and belongs to the field of environmental engineering and waste water treatment. According to a combination electrode prepared through the combination electrode preparation method, a bioelectrochemistry system serves as a reactor to treat azo dye waste water, anode electro-microorganisms oxidize organic matter so that electrons and protons can be generated, the electrons and the protons are transferred to a cathode chamber through an external circuit and an ion exchange membrane, H2O2 is generated on a cathode in an in-situ mode with O2 as the electron acceptor, a cathode iron source is slowly released, Fenton reaction is performed between iron and H2O2 generated in the in-situ mode, and thus non-biodegradable pollutants are treated.

Owner:JIANGNAN UNIV

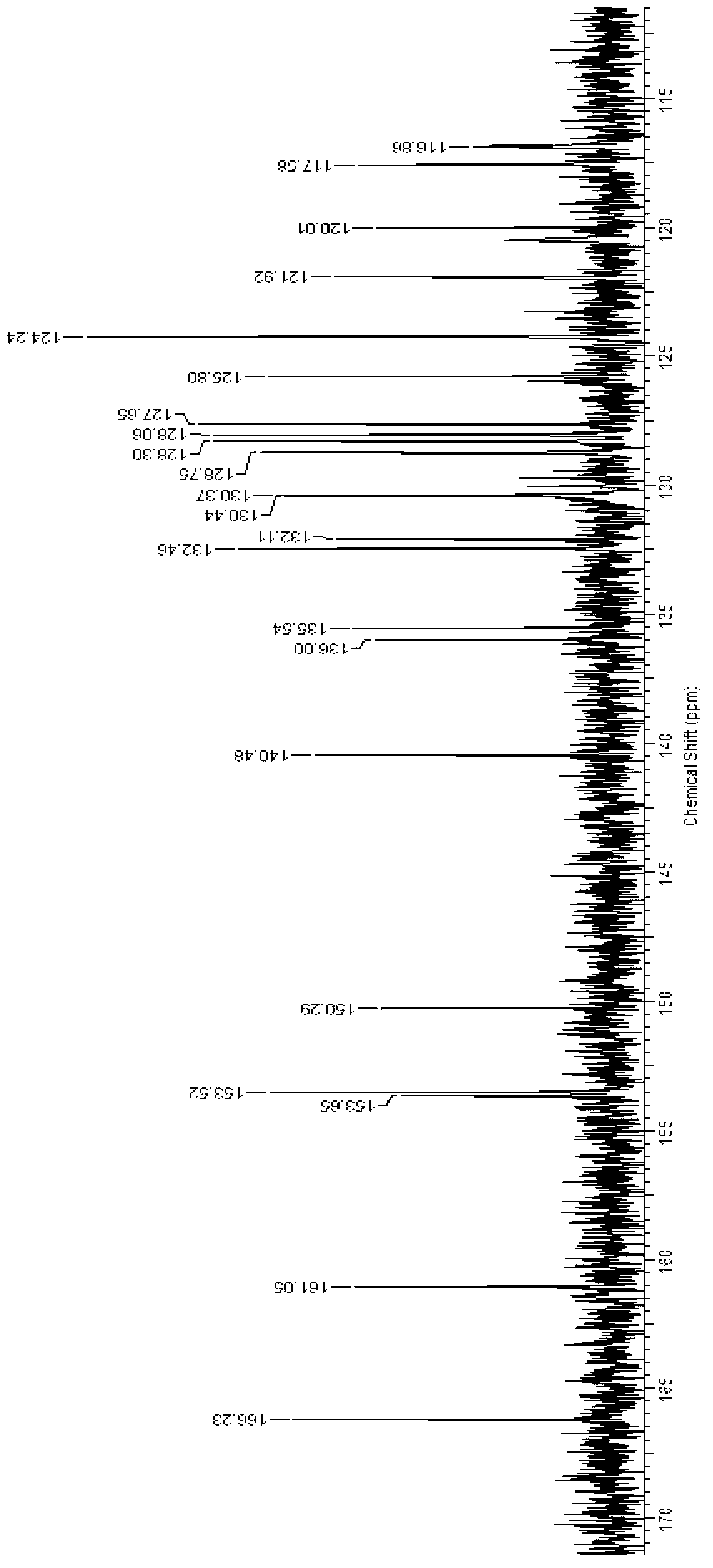

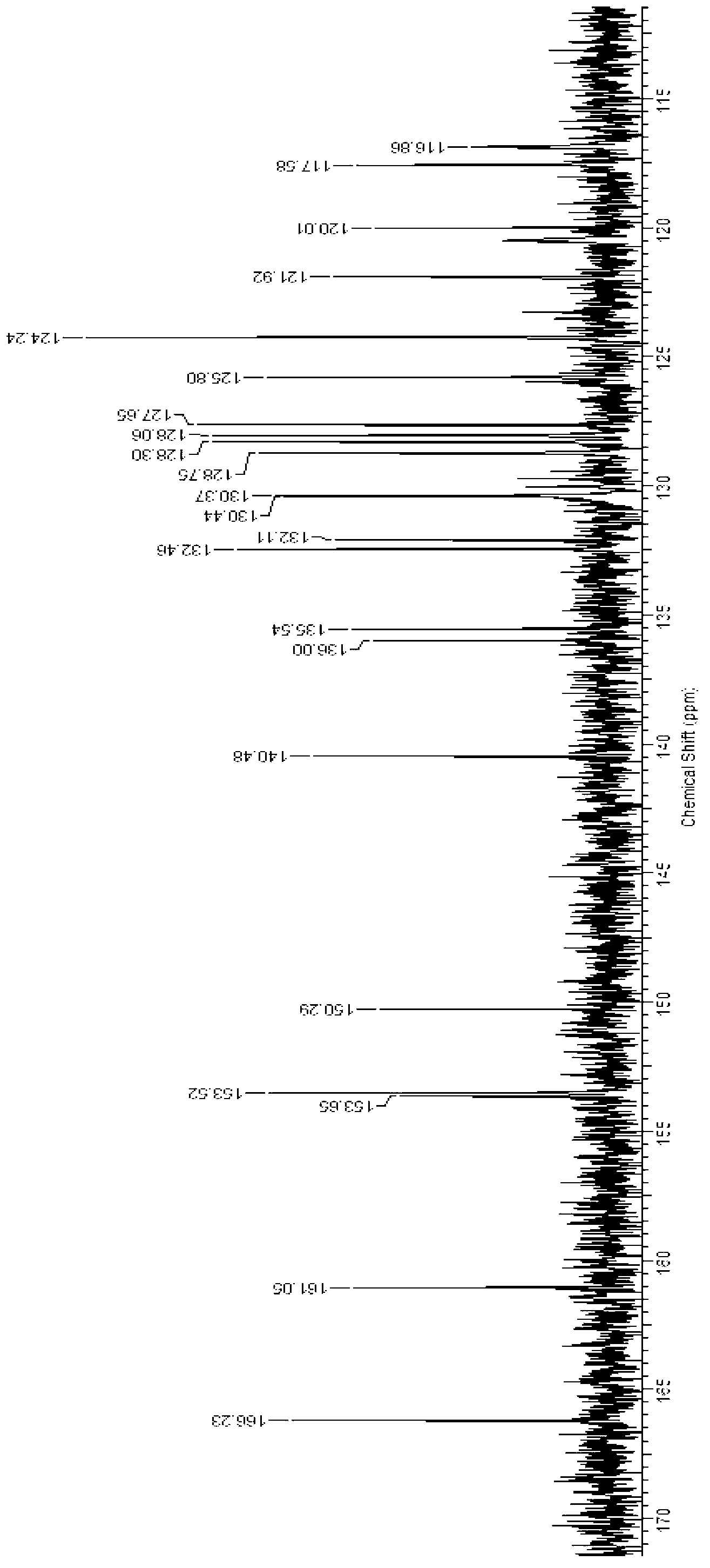

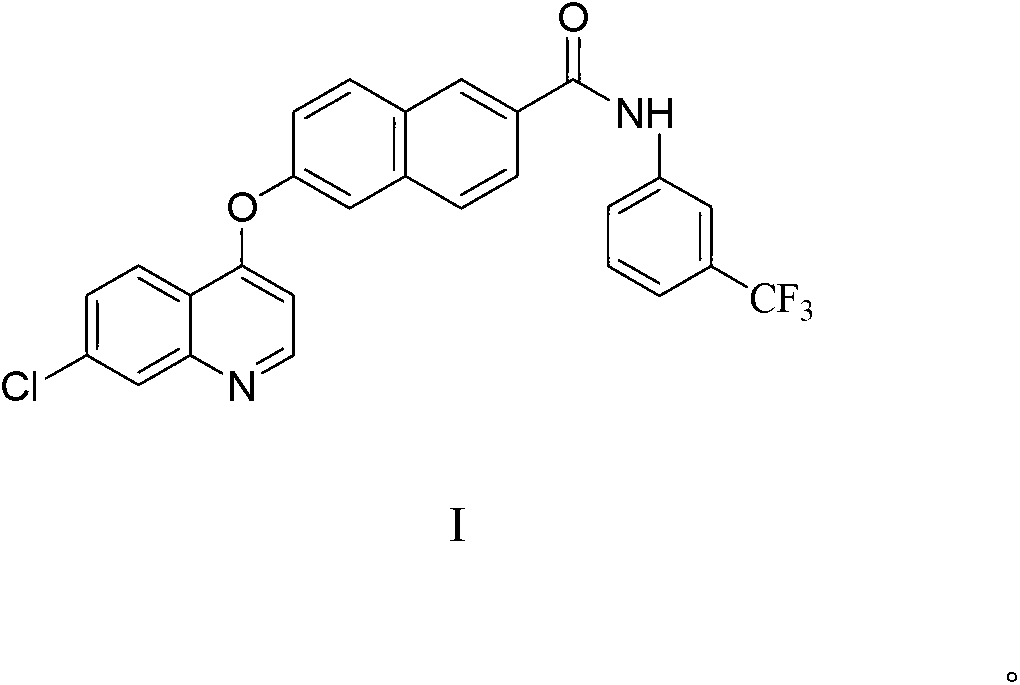

Naphthoyl amine derivative, and preparation method and application thereof

InactiveCN103288728ALower reaction costHigh yieldOrganic chemistryMetabolism disorderPTK InhibitorsEther

The invention provides a naphthoyl amine derivative, and a preparation method and an application of the same. The naphthoyl amine derivative is N-(3- trifluoromethyl phenyl)-6-[(7- chloroquinoline-4-oxo) phenolic ether]-2- naphthoyl amine; the N-(3- trifluoromethyl phenyl)-6-[(7- chloroquinoline-4-oxo) phenolic ether]-2- naphthoyl amine can be used as protein kinase inhibitor and histone deacetylase inhibitor, and can be used for treating diseases caused by protein kinase dysregulation. The naphthoyl amine derivative can effectively treat the diseases caused by protein kinase dysregulation, and has the advantages of high bioavailability, obvious antitumor activity and low toxicity; moreover, the naphthoyl amine derivative is low in preparation reaction cost and higher in yield, the reaction process is simple and easy to control, so that the naphthoyl amine derivative is suitable for industrial production.

Owner:HUAQIAO UNIVERSITY

Selective oxidative light catalyst and preparing method thereof

InactiveCN1552524AShort lifeLower reaction costOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic reactionBipyridine

A photocatalyst for selective oxidization is prepared from the inorganic carrier including NaX and NaY molecular sieves, ZSM-5 molecular sieve, mesopore molecular sieve, SO2, and Al2O3, the transition metal ions chosen from Fe, Mn, Ni and Co and the organic ligand chosen from alpha, alpha'-bipyridine, 1-(2-pyridineazo)-2-naphthol (PAN), schiff base, etc through complexing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing iron modified SBA-15 mesoporous molecular sieve

InactiveCN101837988AIncrease surface areaIncrease mass transfer rateCrystalline aluminosilicate zeolitesMolecular sieveRoom temperature

The invention relates to a method for preparing an iron modified SBA-15 mesoporous molecular sieve, which comprises the following steps of: 1) adding nonionic surfactant and ferric nitrate nonahydrate into solution prepared from hydrochloric acid and deionized water in a volume ratio of 1 to 10 with pH of about 1, and stirring the solution at the room temperature till the solution is clear and transparent; 2) adding tetraethoxysilane into the mixed solution obtained in the step 1), placing the mixed solution into an ultrasonic pool, acting ultrasonic wave on the mixed solution for 2 hours, adjusting the pH of the mixed solution to between 3 and 4, transferring the mixed solution to a reaction kettle, and hydro-thermally crystallizing the mixed solution for 24 hours at the temperature of 100 DEG C to form the iron modified SBA-15 mesoporous molecular sieve; and 3) filtering the reaction solution obtained in the step 2), repeatedly washing a filtered substance by using water and drying the filtered substance, and calcining the filtered substance for 6 hours at the temperature of 550 DEG C to obtain the SBA-15 mesoporous molecular sieve of which iron ions are high dispersed inside and outside a skeleton. The method reduces the reactive ageing time to 2 hours from 20 hours, does not need to use a mineralizing agent NH4F, greatly shortens the reaction period, and reduces the reaction cost.

Owner:CHONGQING UNIV OF TECH

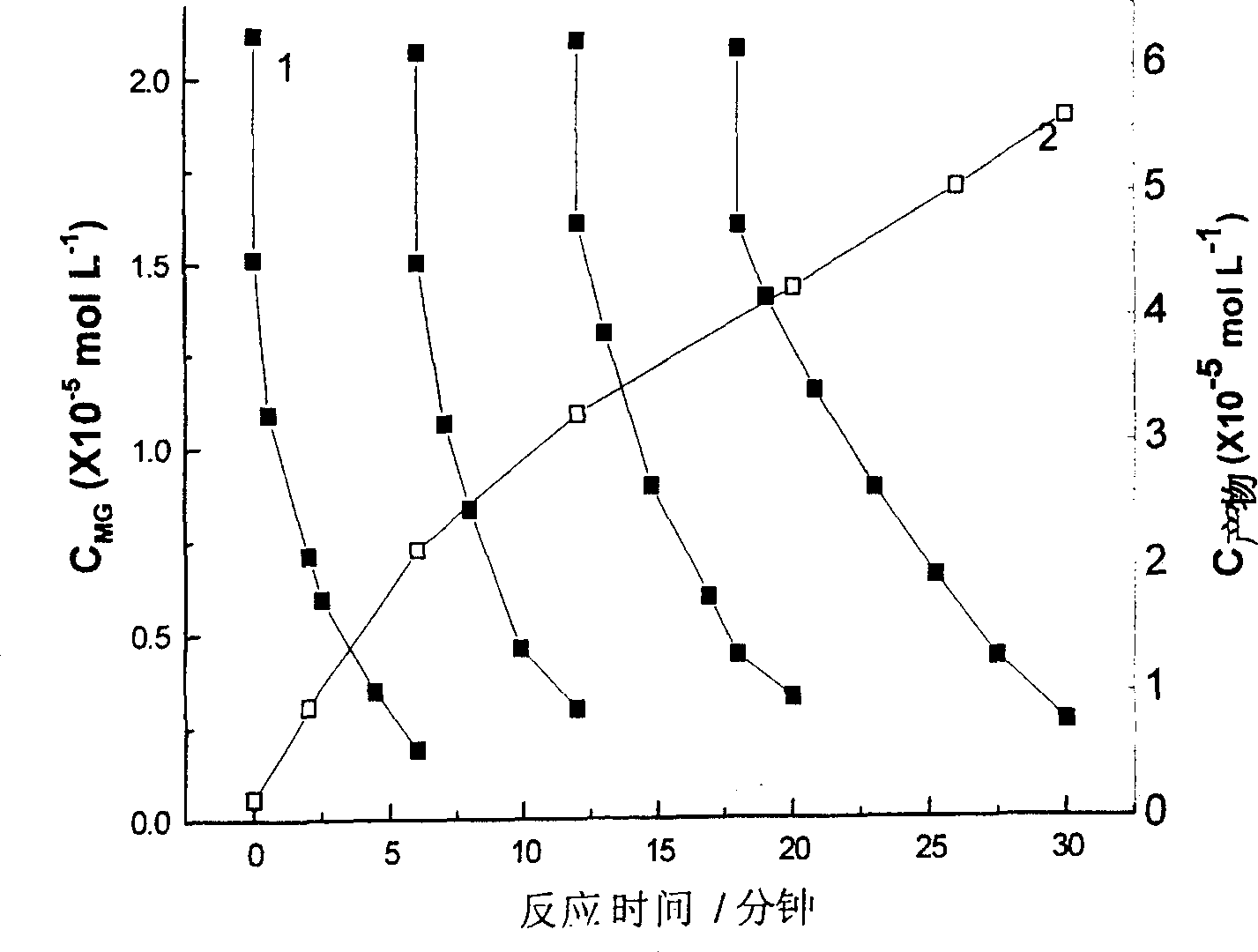

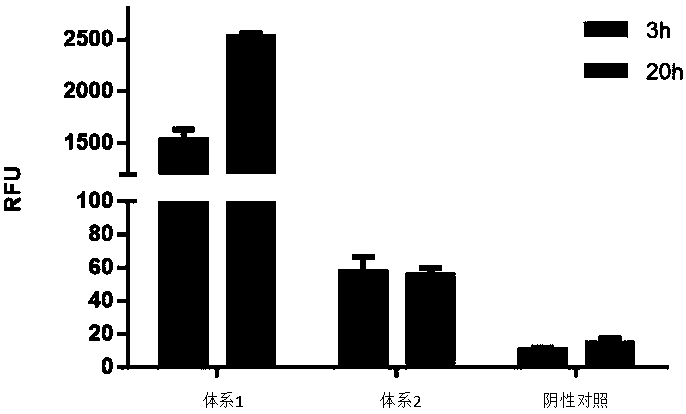

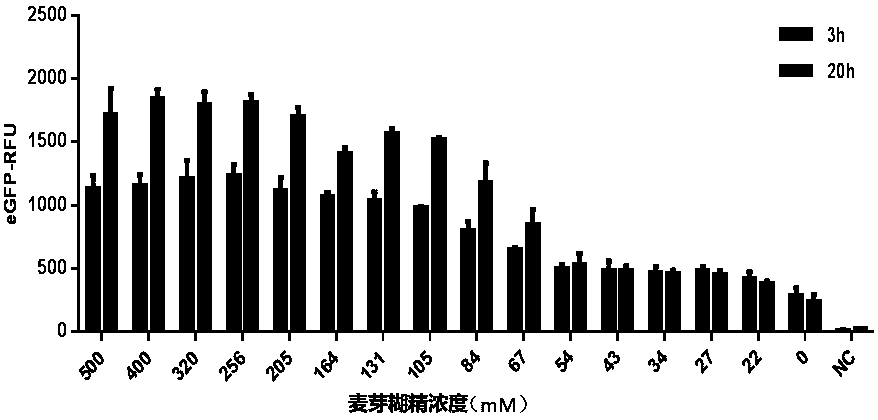

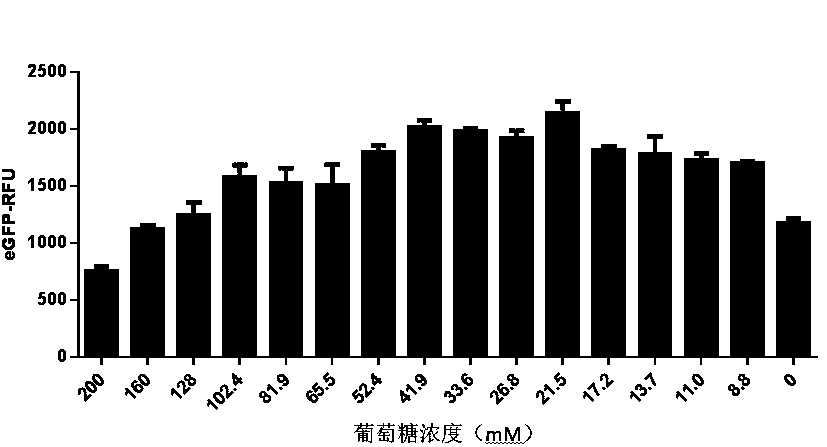

Optimized in vitro cell-free protein synthesis system and application

ActiveCN111378708AIncrease productionLow costFermentationVector-based foreign material introductionProtein targetCell free

The invention discloses an optimized in vitro cell-free protein synthesis system. The system comprises a cell extract, a carbohydrate material, a phosphate compound, a buffering agent and a DNA molecular template for encoding an exogenous protein, wherein the cell extract is a yeast cell extract inserted into a T7 RNA polymerase gene; the carbohydrate material is a mixture of glucose and maltodextrin; the buffering agent is a trihydroxymethyl aminomethane buffering agent; and the DNA molecule template is prepared by a nucleic acid isothermal amplification method, and a sequence as shown in SEQID NO.1 is inserted into the upstream of the coding sequence of the exogenous protein in the DNA molecular template. By optimizing, the cost of in vitro protein synthesis is reduced and the yield ofthe target protein is increased.

Owner:KANGMA SHANGHAI BIOTECH LTD

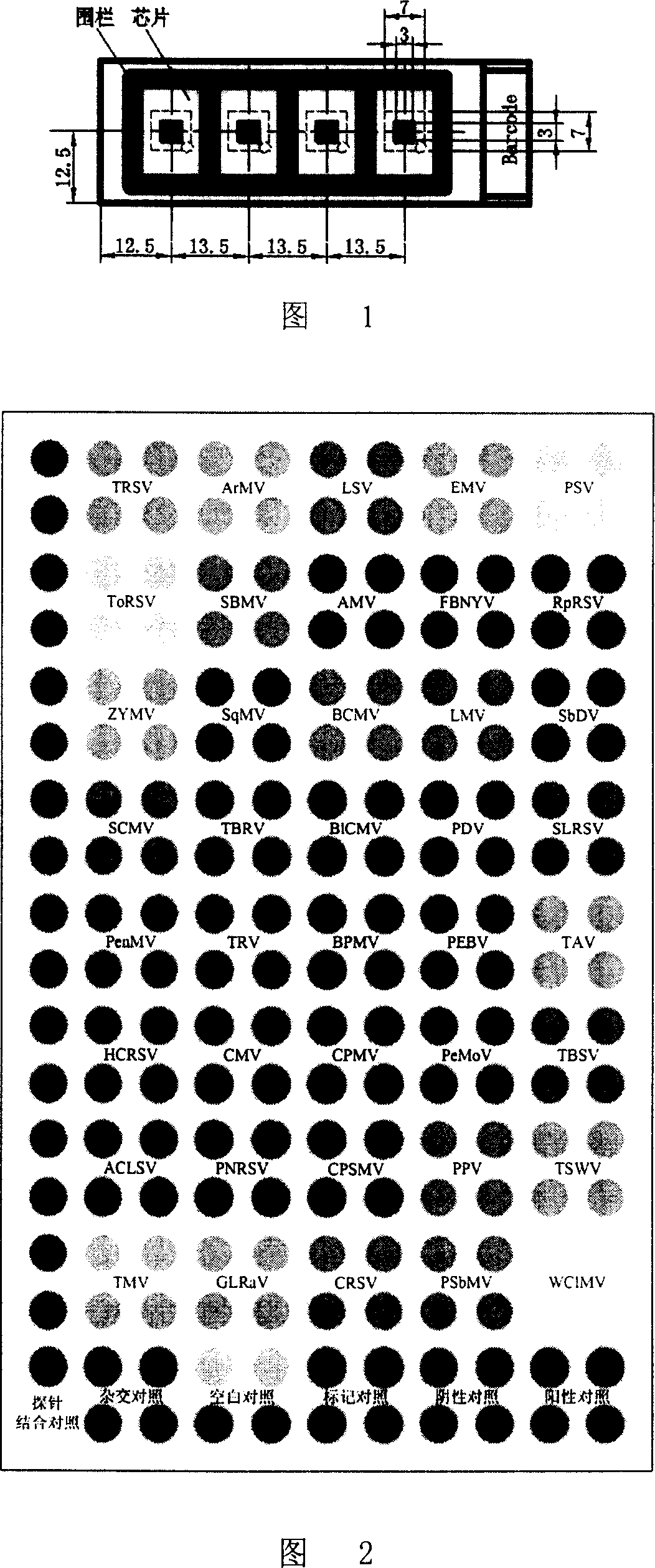

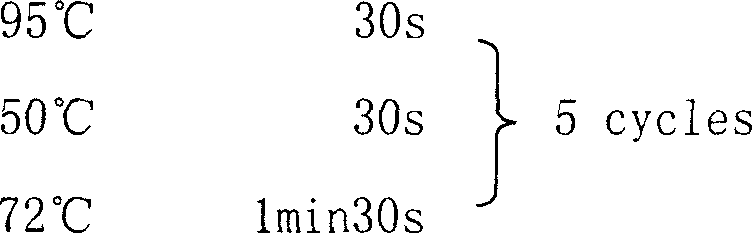

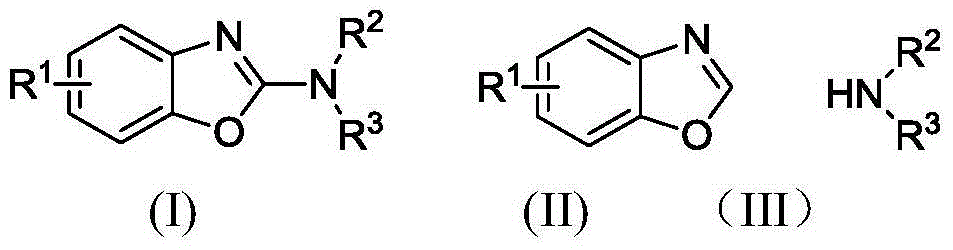

A gene chip, nucleotide sequence and reagent kit for detecting virus of leguminous plant

InactiveCN1952648AAchieving Simultaneous DetectionPracticalMicrobiological testing/measurementFluorescence/phosphorescencePlant virusFluorescence

A gene chip for detecting viruses of leguminous plant is disclosed, several probes and nature-control collations are fixed on surface of solidoid carrier, the probes has the nucleotide sequence showed on from SEQ ID No.1 to SEQ ID No.80; the nature-control collations consists of the surface chemistry LUT, fluorescence labeling LUT, positive LUT, negative LUT, cross LUT and blank control. The advantages and innovations of the invention are following: practicability, quick-speed, and idiocrasy, and sensitivity, low activity cost, repeatability, stable and reliable results. The testing system can guarantee the repeatability and accuracy of results that is proofed by the repeatability and stability test, the system can be widely used in area of plant quarantine of the outbound and enter the country test and quarantine system, the safety supervision of plant source food, the diagnosis of plant virus in plant protecting station and the authenticate of pathogenesis in research of plant taxonomic virology. The gene chip testing call for detecting viruses of leguminous plant can be used in about 600 daily quarantine pursuits of leguminous plant source food.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU +3

Synthesis of pyridine-N-oxide

Synthesis of pyridine-N-oxide is carried out by preparing sodium tungstate into carrier phosphate-tungstic acid by wetting method, vacuum drying to generate anhydrous product, putting anhydrous product and carrier into container, formulating solution by deionized water, agitating to remove water content, drying at high-temperature, activating to obtain catalyst, putting catalyst and pyridine into flask, oxidation reacting by hydrogen peroxide, filtering out catalyst and decompress distilling to obtain the final product. It's simple, fast and cheap and has less solvent.

Owner:天津维智精细化工有限公司

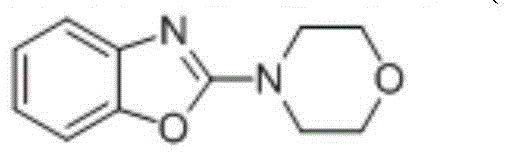

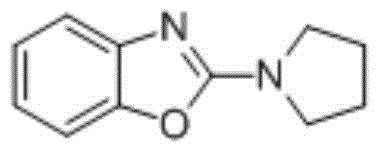

Electrochemical catalytic synthesis method of 2-N-substituted benzoxazole compounds

ActiveCN103603007AReduce usageLower reaction costElectrolysis componentsElectrolytic organic productionSupporting electrolyteBenzoxazole

The invention relates to an electrochemical preparation method of 2-N-substituted benzoxazole compounds. The 2-N-substituted benzoxazole compounds are obtained by constant current electrolysis in a single-chamber electrolytic cell by utilizing benzoxazole compounds and amine as raw materials and utilizing a halide as an electrocatalyst, wherein the dosage of the catalyst is 5-20% (mol), an organic solvent serves as electrolyte, glacial acetic acid serves as an additive, the reaction temperature is 0-40 DEG C and the current density is 2-10mA / cm<2>. According to the method provided by the invention, an indirect electrolytic method is used for the first time to synthesize the 2-N-substituted benzoxazole compounds, thereby avoiding the use of excessive organic hypervalent iodine reagent with high price and potential explosiveness or other co-oxidants and avoiding the generation of reduction wastes resulting from the use of the excessive oxidant or co-oxidant as well. According to the method provided by the invention, common industrial reagents and conventional production conditions, instead of supporting electrolyte, are used, and the reaction conditions are mild, so that the method is more suitable for industrial production.

Owner:BEIJING UNIV OF TECH

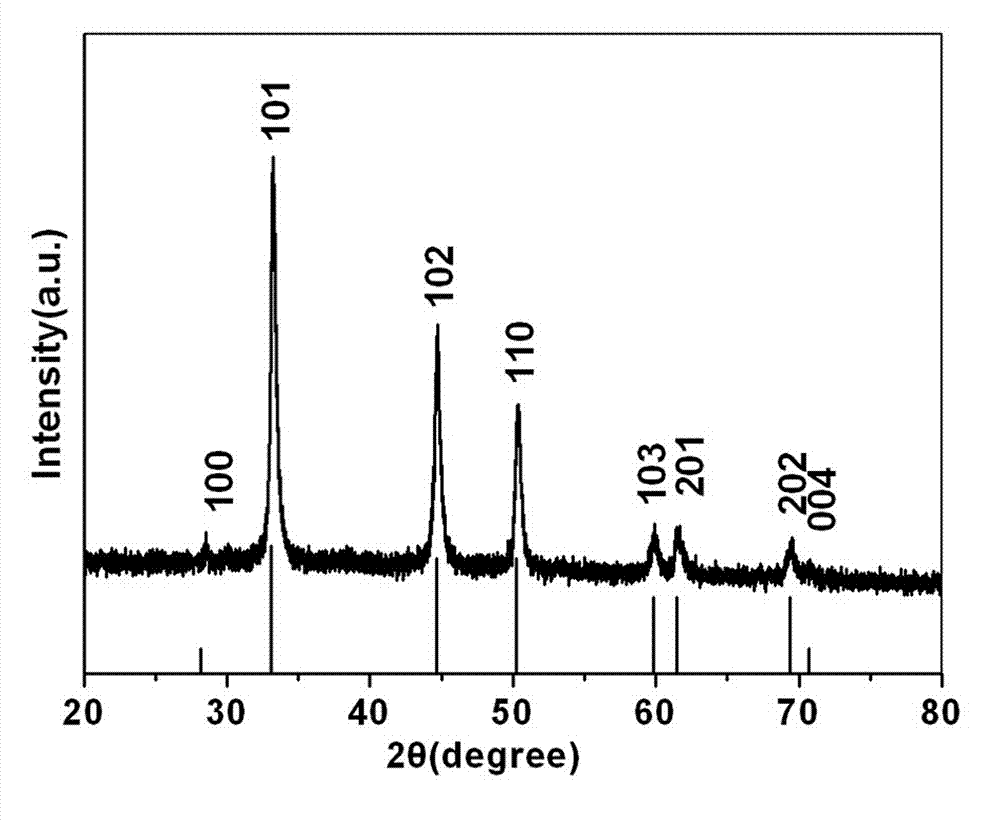

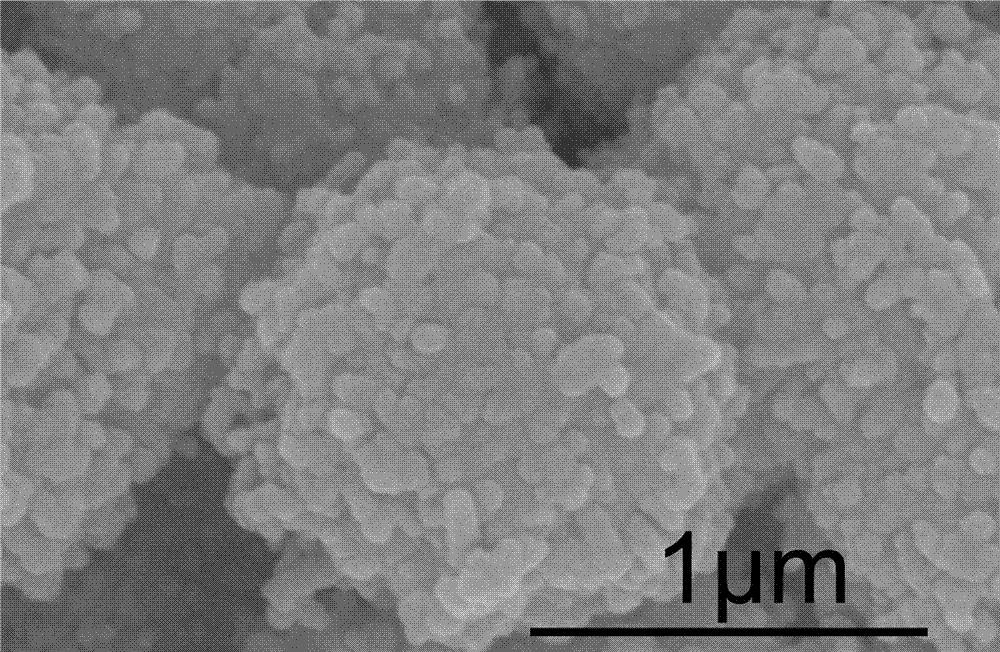

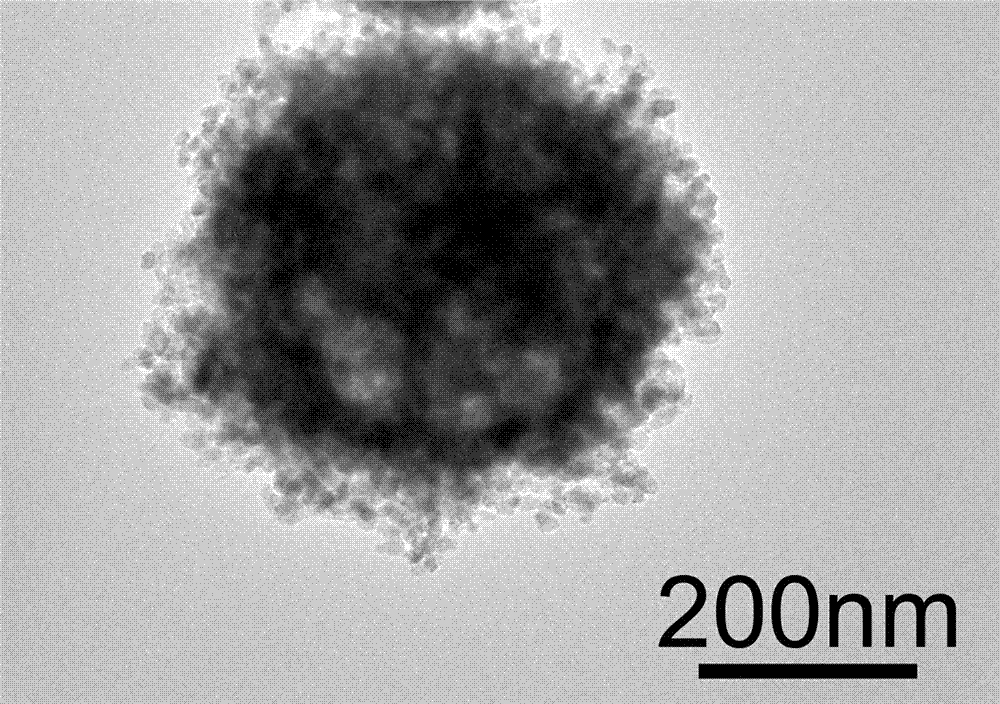

Preparation method of porous nickel selenide hollow nanospheres

ActiveCN102874773AGood chemical stabilityMeets friendly requirementsMaterial nanotechnologyBinary selenium/tellurium compoundsEngineeringSelenium Oxide

The invention belongs to the technical field of nanometer material, relates to a synthetic method for preparing porous hollow nanospheres with uniform appearance through a hydrothermal process, and particularly relates to a preparation method of porous nickel selenide hollow nanospheres. The preparation method comprises the steps as follows: positioning selenium dioxide and nickel nitrate into alkaline aqueous solution of ammonia water; and preparing the porous hollow nanospheres through the hydrothermal process under the reduction effect of hydrazine hydrate. The nickel selenide hollow nanospheres prepared by the preparation method provided by the invention have the diameter of 300 to 400nm, and are formed by self-assembling 30 to 50nm of porous nickel selenide. The preparation method provided by the invention is simple in technology, and high in repeatability; and the used nickel source and selenium source are the inorganic compounds, low in cost, easy to obtain, low in cost, and meets the environment-friendly requirement; the method can be conducted without pre-processing such as ageing and roasting; the resultant temperature is low, therefore, the energy consumption and the reacting cost are reduced; and the mass production can be conveniently conducted.

Owner:指南者品牌管理(苏州)有限公司

Fuel oil desulfurization process by ionic liquid extraction-photocatalytic oxidation method

InactiveCN101338221ALower reaction costSimple and fast operationTreatment with plural serial refining stagesHydrocarbon oils refiningQuaternary ammonium ionsFuel oil

The present invention discloses a desulfurization method for ionic liquid extraction-photocatalytic oxide fuel oil. The fuel oil and the ionic liquid are mixed and stirred into a reaction system according to the volume proportion of 1:10 to 1:0.1; one of H2O2, Fenton agent and O2 in the air is used as the oxidant and nano TiO2 is used as the photocatalyst; the oxidant and the photocatalyst are added into the mixed system of the ionic liquid and the fuel oil; a high-pressure mercury lamp is used as the light source for radiation; after reacting for 5 to 60 minutes, the fuel and the ionic liquid separate; the sulfocompound in the fuel oil is oxidized into polar substance and transferred into the ionic liquid for desulfurization from the fuel oil. The present invention adopts the cheap quaternary ammonium ion as the extractant and the ionic liquid can be recycled, thus reducing the reaction cost; the present invention is operated under normal temperature and pressure with simple equipment and convenient operation; the reaction time of the present invention is short, which is conducive to the industrial production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

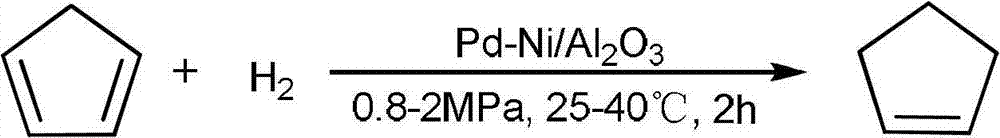

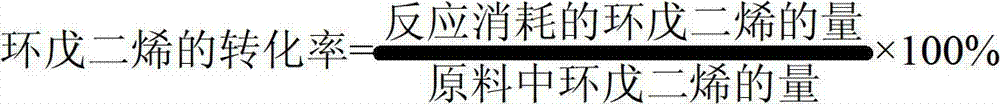

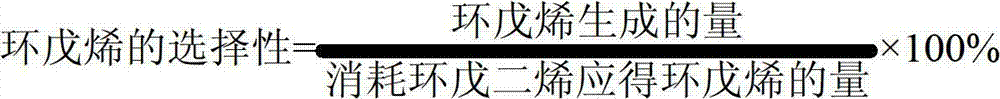

Pd-Ni/Al2O3 catalyst, its preparation method and application thereof

ActiveCN102728386AEasy to separateReduce generationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCyclopenteneActive component

The invention discloses a Pd-Ni / Al2O3 catalyst, its preparation method and an application thereof. With PdCl2 and Ni(NO3)2 being used as active components and Al2O3.H2O being used as a catalyst carrier, the Pd-Ni / Al2O3 catalyst is prepared by loading the active components onto the catalyst carrier, wherein the gross mass of PdCl2 and Ni(NO3)2 is 0.5-1 wt% of the weight of Al2O3.H2O and the mass ratio of Pd to Ni in the active components is 1:0.5-3. The Pd-Ni / Al2O3 catalyst can be used as a selective catalyst in cyclopentadiene selective hydrogenation for synthesis of cyclopentene. By the adoption of the catalyst, hydrogenation reaction can be conducted at normal temperature; the reaction condition is mild; conversion rate and selectivity are very good; the conversion rate is 98-99.5%; and the selectivity of cyclopentene also reaches 97-98.5%.

Owner:HEFEI UNIV OF TECH

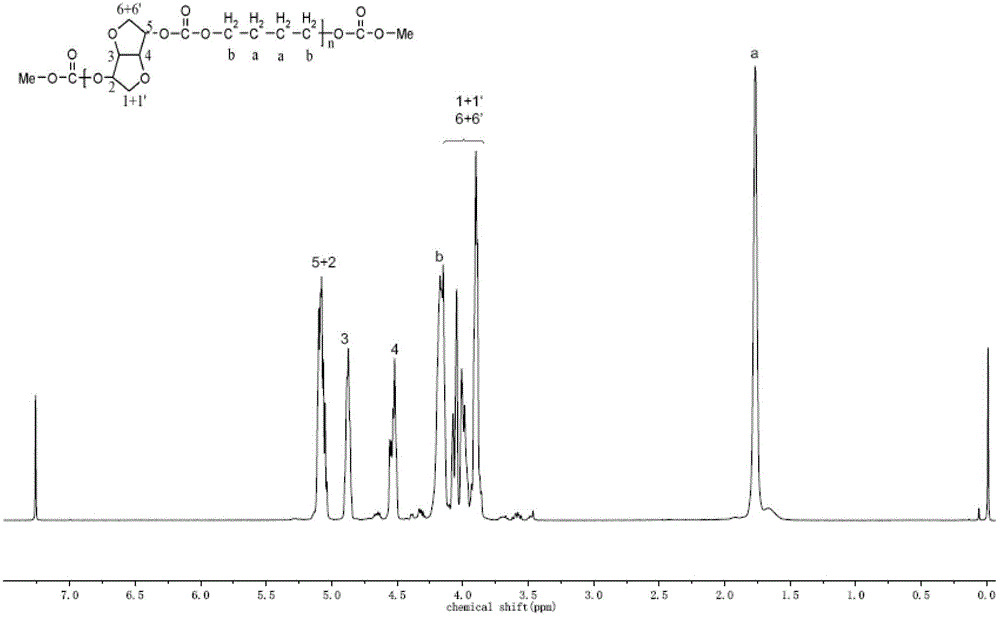

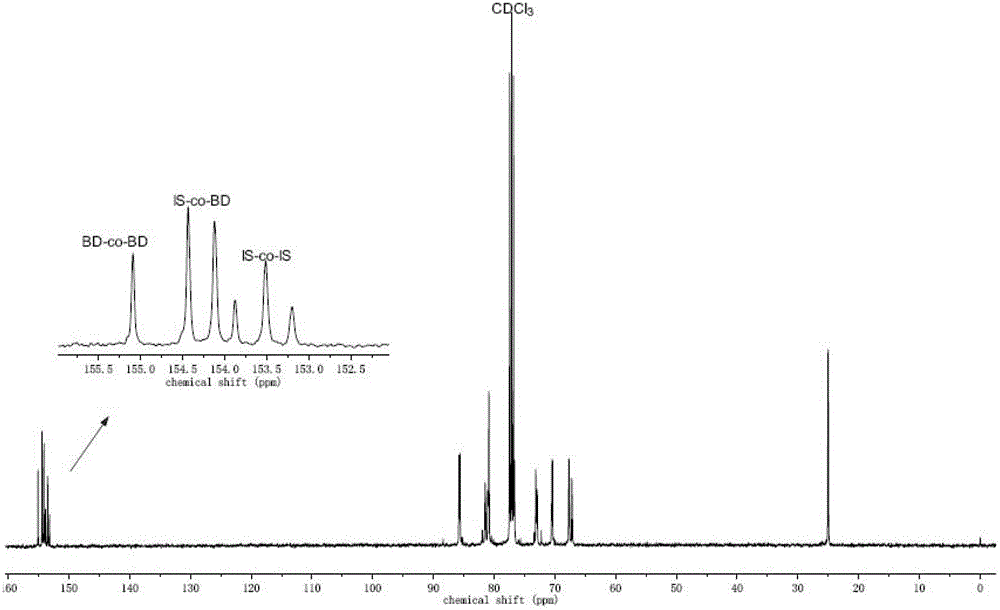

High-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and preparation method and application thereof

The invention discloses high-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and a preparation method and application thereof. According to the method, 1,4:3,6-dianhydro-hexanehexol and aliphatic diol respectively react with, or are mixed and then react with carbonic ester under the action of a catalyst in an inert gas atmosphere to realize ester interchange, and a resultant prepolymer undergoes polycondensation under the action of a polycondensation catalyst so as to obtain a product. The method costs little, can effectively improve transparency and the color of 1,4:3,6-dianhydro-hexanehexol type polycarbonate, uses a small amount of catalysts during reaction process and avoids complex separating process for the catalysts. The obtained product is a colorless or faint yellow transparent solid and has a number-average molecular weight of 1.5*10<4> to 2.0*10<5> and a glass-transition temperature of 100 to 175 DEG C. Prepared from biological raw materials and aliphatic diol, the product does not contain any residual phenyl ring and has no toxicity, usable as a food package material like a water cup and a water bottle or as a medical material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

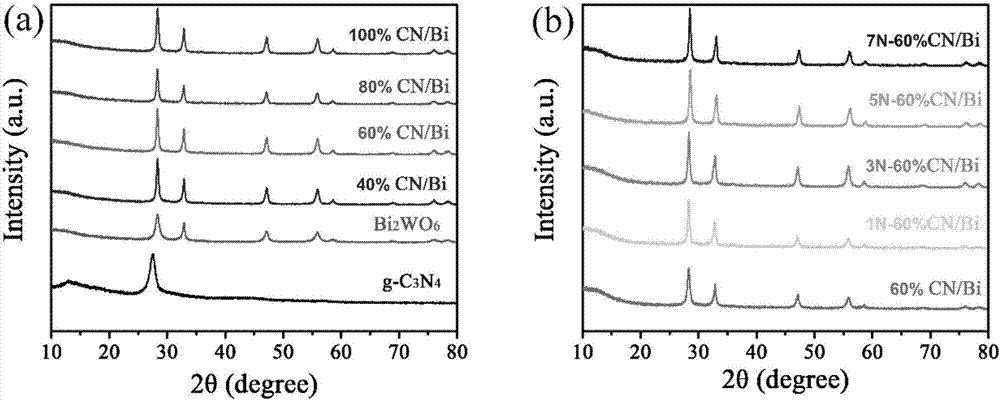

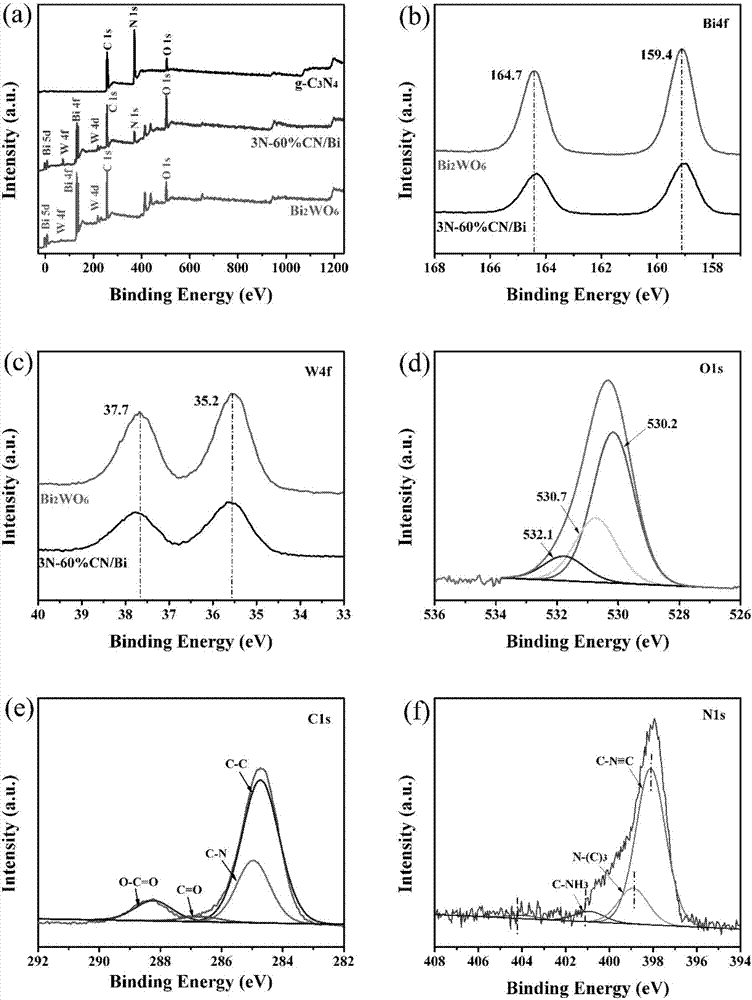

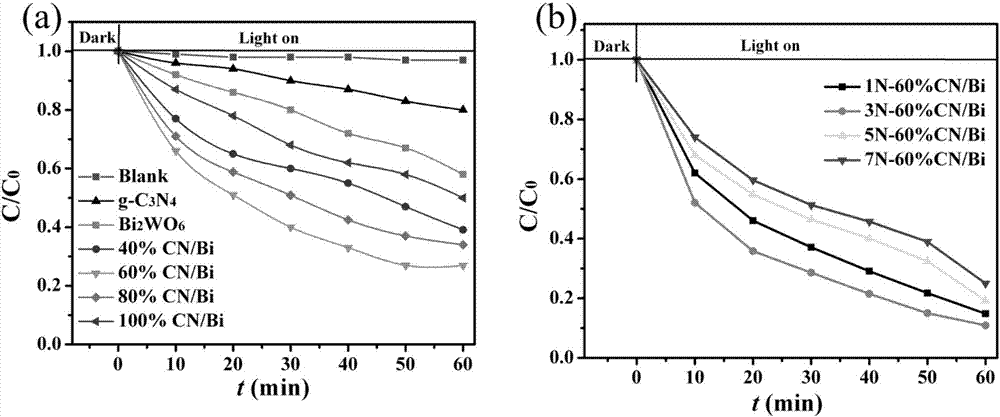

Preparation method and application of visible-light responsive ternary composite photocatalyst

InactiveCN107020143AMeets friendly requirementsImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsElectron transferLight responsive

The invention belongs to the technical field of photocatalysis, in particular to a preparation method and application of a visible-light responsive ternary composite photocatalyst. The method comprises the following steps: dissolving NGQDs and g-C3N4 / Bi2WO6 into deionized water, stirring at a room temperature to obtain an NGQDs@g-C3N4 / Bi2WO6 composite nano-material. The introduced NGQDs is used as a collector of dual-function electrons-holes, so that electrons produced by visible-light induced g-C3N4 are transferred to NGQDs, and holes produced by visible-light induced Bi2WO6 are transferred to NGQDs; oxidation-reduction reaction on the electrons-holes is further carried out, so that the separation efficiency of the electrons-holes is improved finally, and the photocatalytic activity is enhanced.

Owner:JIANGSU UNIV

Method for preparing 2,2'-di(trifluoromethyl)-4,4'-benzidine

ActiveCN101337895AHigh reaction yieldLower reaction costOrganic compound preparationAmino compound preparationHydrogen atmospherePhysical chemistry

The invention relates to a method for preparing 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl capable of being used as a liquid crystal material from 2,2'-bis(trifluoromethyl)-4,4'-dinitrobiphenyl by reduction reaction. According to the specific technical scheme, the method comprises the following steps: carrying out coupling reaction of 2-bromo-5-nitrobenzotrifluoride in the presence of a transition metal (Pd, Cu, Ni) catalyst to obtain 2,2'-bis(trifluoromethyl)-4,4'-dinitrobiphenyl; and catalyzing by a Cu oxide or metal Pa in the hydrogen atmosphere to obtain 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl. The process for preparing 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl has the advantages of less emission of the three wastes and high yield.

Owner:河北君瑞沣新材料有限公司

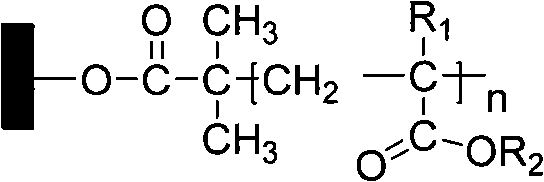

Surface material with protein adsorption resistant property and preparation method thereof

The invention relates to a surface material with protein adsorption resistant property and a preparation method thereof, belonging to the technical field of biological materials. The surface material is an organic silicon surface material polymerized by monomer molecules with diionic property and organic silicon, has good protein adsorption resistant property and can be extensively applied to the fields of marine antifouling materials and biomedical materials. The surface material which has the protein adsorption resistant property through surface modification is prepared by carrying out graft polymerization on the monomer molecules with the diionic property on the surface of an organic silicon substrate; the surface material is combined with water molecules in a marine environment to form a water film on the surface of the material and can prevent the adsorption of proteins on the surface of the material because the water molecules contained in the water film are compactly arranged, thereby inhibiting the further adhesion of marine fouling organisms on the surface of the material and achieving the effect of effectively preventing and removing the fouling of marine organisms; in addition, the invention has wide application prospect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method for benzoic acid

InactiveCN103910623AEasy to cleanImprove economyOrganic compound preparationCarboxylic compound preparationAir atmosphereBenzoic acid

The invention relates to a preparation method for benzoic acid. The preparation method comprises the following concrete steps: adding toluene into a reactor; carrying out a reaction under magnetic stirring at a temperature of 25 DEG C in air an atmosphere; and carrying out a full reaction under 300 W Xelamp illumination conditions so as to obtain desired benzoic acid. The method provided by the invention avoids usage of reagents with high corrosivity, high toxicity and easy production of toxicity used in traditional synthetic methods, improves cleanness of an industrial synthesis reaction and reduces environmental pollution and energy consumption. Benzophenone is used as a reaction catalyst in the method, so cost is decreased. The method is completed in one step and uses a single kind of raw material, so the method has improved process economical efficiency.

Owner:FUDAN UNIV

Preparation method of composite adsorption purifying agent

InactiveCN103071455ASufficient sourceLow priceOther chemical processesWater/sewage treatment by sorptionActivated carbonPtru catalyst

The invention provides a preparation method of a composite adsorption purifying agent. The method comprises the following steps of: washing a dead catalyst with water to remove impurities, and drying at the temperature of 100-120 DEG C for three hours; introducing a protective gas, and raising the temperature to 700-900 DEG C by microwave heating; and stopping introducing the protective gas, simultaneously introducing activating gas for activating for 20-40 minutes, cooling to the room temperature, and drying to obtain the composite adsorption purifying agent. The composite adsorption purifying agent has the advantages of rich source, low price, great reduction in the production cost, protection of the environment, saving of resources and realization of recycling. A production method is simpler, is easy to operate, has low energy consumption, contributes to reducing the emission of pollutants in a production process and no secondary pollution. The reaction rate is increased, the reaction time is shortened, and the reaction cost is reduced. A produced ZnO / active carbon composite adsorption purifying agent has ideal effects on the degradation of organic dyes, treatment of heavy metal ions in waste water and photocatalysis sterilization, and plays an important role in comprehensively treating environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

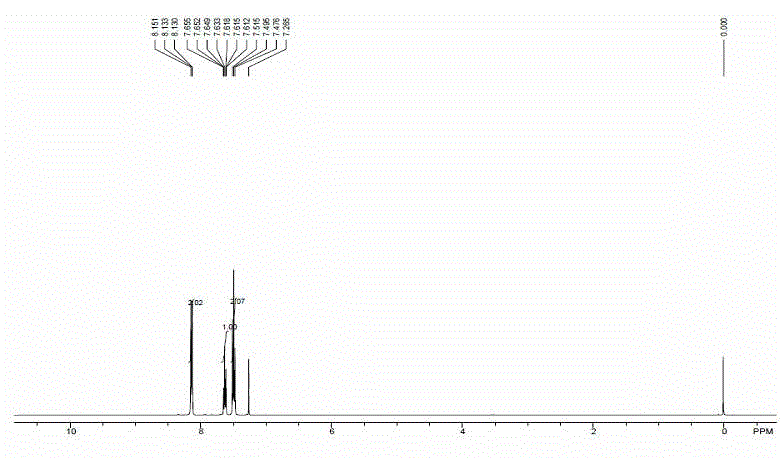

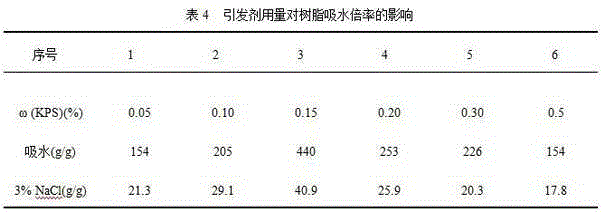

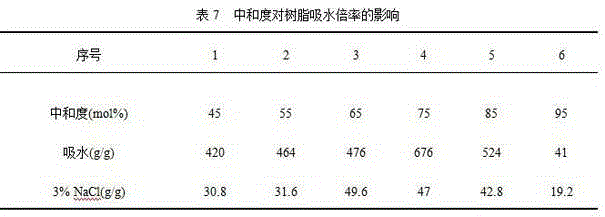

Preparation method of superabsorbent resin

The present invention discloses a preparation method of a superabsorbent resin containing starch grafted acrylic acid (AA), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The preparation method of the superabsorbent resin is as below: adding an initiator into gelatinized starch to conduct initiation; then neutralizing the AA and AMPS solution with NaOH or KOH solution under the condition of sufficient cooling; then adding the monomer mixture of AA, AM and AMPS into the starch solution to conduct a starch graft polymerization reaction. The method uses starch as a graft monomer material, which is widely available, inexpensive, biodegradable, environmentally friendly and easy to operate and more friendly to the environment; the obtained resin has good salt resistance and high water absorption rate, and can reach imbibition equilibrium within 5 min.

Owner:LANZHOU UNIVERSITY +1

Method for synthesizing acetylacetone metallic compound

InactiveCN101503343AOmit washingOmit drynessPreparation of aldehyde/ketone chelatesRoom temperatureMembrane reactor

The invention provides a method for preparing acetylacetone metallic compound, comprising soluble metal salt solution and aqueous alkali are quickly mixed together through a full back-mixing liquid membrane reactor to prepare precipitation grout of hydroxide with nanometer level, the precipitation of hydroxide is not needed to be separated and directly added with acetylacetone to react at the normal temperature to obtain the acetylacetone metallic compound. The method adopts the full back-mixing liquid membrane reactor to synthesize hydroxide with nanometer level, thus shortening the reaction time between the hydroxide and the acetylacetone and improving the preparation efficiency; meanwhile, by controlling the adding quantity of alkali and the acetylacetone in the crystal-transformation process, the reaction yield is greatly improved. The preparation method is simple in technique, convenient in operation and short in reaction time, and the obtained product has the yield being more than 95%.

Owner:BEIJING UNIV OF CHEM TECH

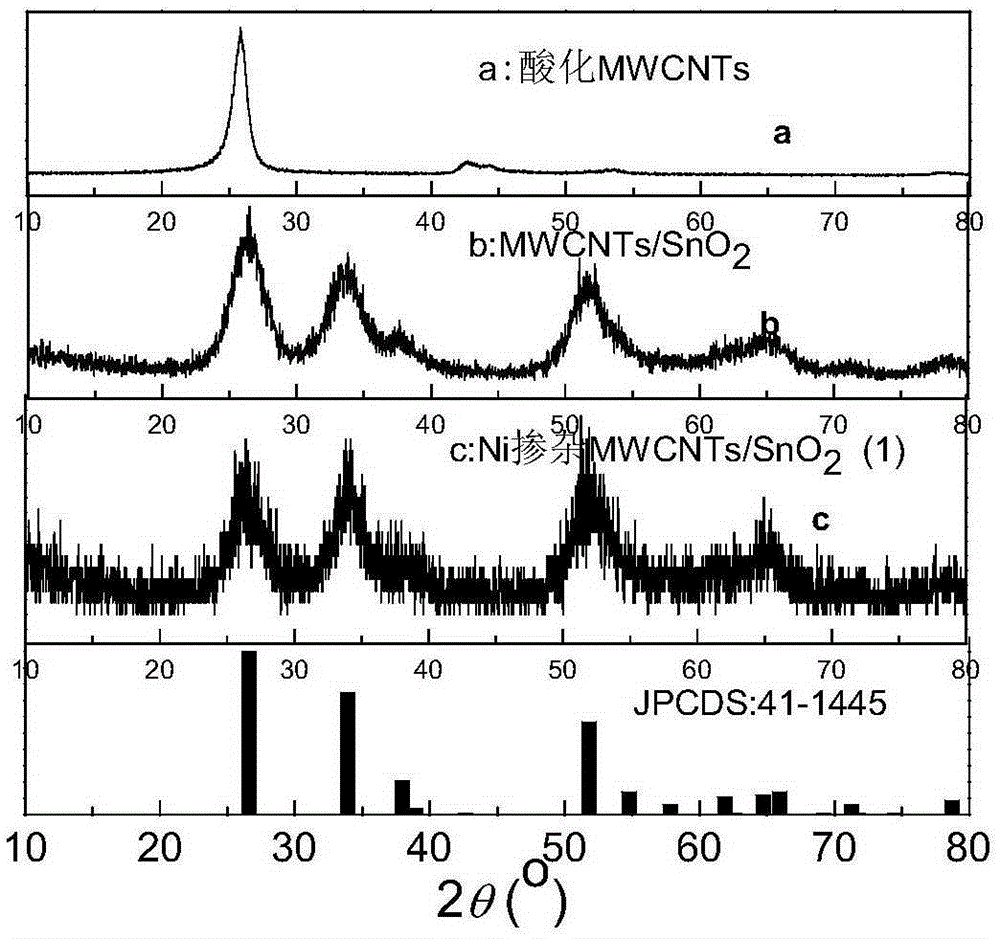

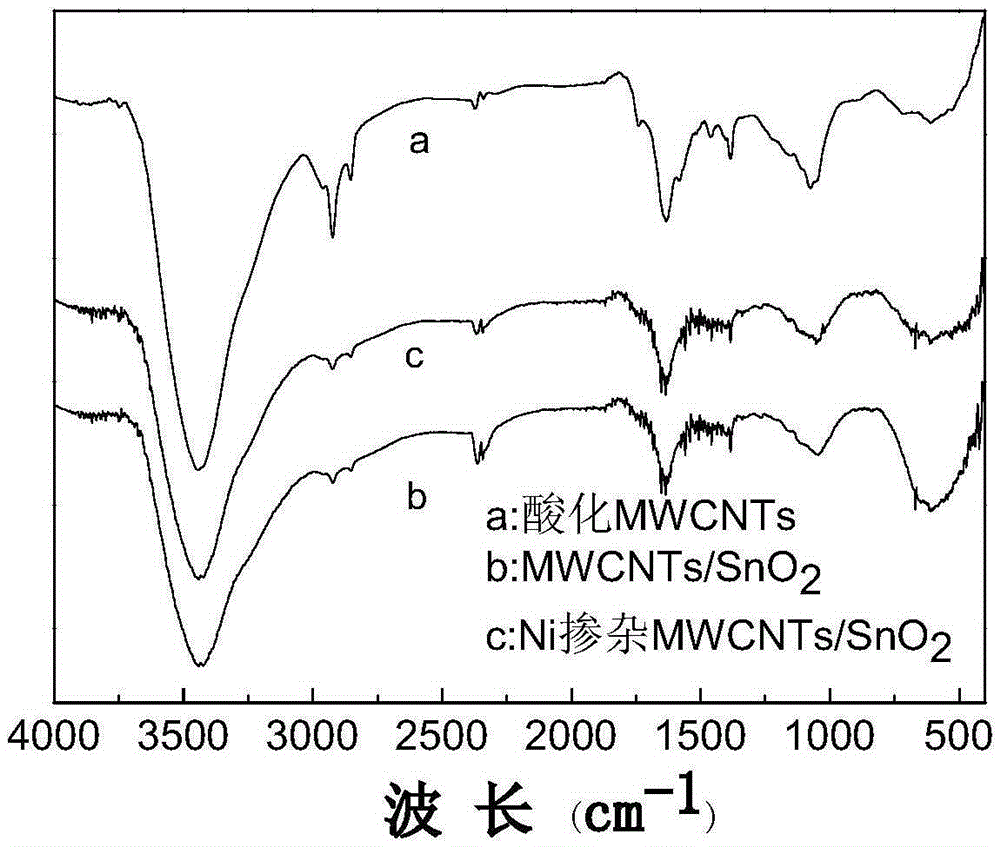

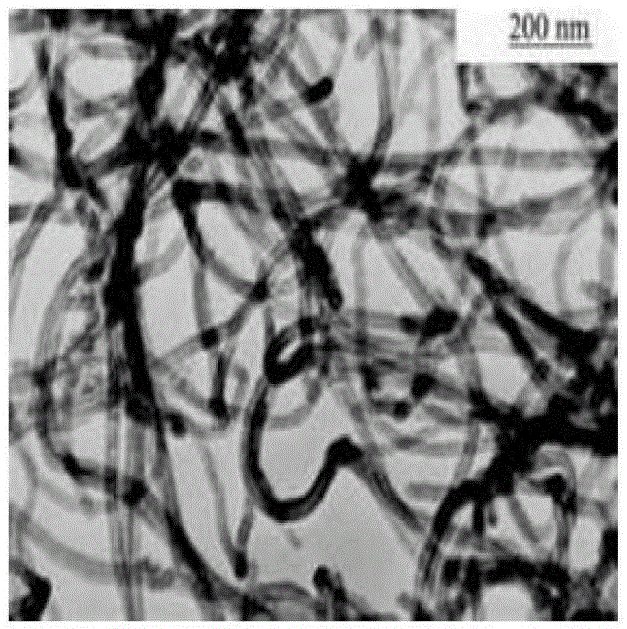

Nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes/tin dioxide

ActiveCN105338799ALight weightImprove conductivityMagnetic/electric field screeningTin dioxideNanocomposite

The invention discloses a nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes / tin dioxide, and the nanocomposite can be widely applied to the aspect of electromagnetic wave absorption. A preparation method of the nanocomposite comprises the following steps: 1, conducting acidificaiton on multiwalled carbon nanotubes; 2, dispersing the acidified multiwalled carbon nanotubes treated in step 1 into water, obtaining dispersion liquid of the multiwalled carbon nanotubes, adding tin tetrachloride pentahydrate, then adding nickel nitrate hexahydrate or ferric nitrate nonahydrate or cobalt nitrate hexahydrate, then adding acid, then slowly adding stronger ammonia water, adjusting pH to be 7-10, conducting a reaction for 8-24 hours at the temperature of 120-180 DEG C, and obtaining the nanocomposite made of the magnetic-metal (M)-doped multiwalled carbon nanotubes / tin dioxide through aftertreatment, wherein M represents Fe, Co and Ni, and the massic volume ratio of the acidified multiwalled carbon nanotubes to the tin tetrachloride pentahydrate to the nickel nitrate hexahydrate or the ferric nitrate nonahydrate or the cobalt nitrate hexahydrate to the acid is 0.04 g: 1-4 g: 0.5-3 g: 0.5-4 mL.

Owner:ANHUI UNIV OF SCI & TECH

Method for eliminating sulfur compound contained in fuel oil by catalytic oxidation of phase transition

InactiveCN101050378AAvoid pollutionAbsorptiveOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhosphomolybdic acidQuaternary ammonium cation

This invention discloses a method for removing sulfur-containing compounds from fuel oil by phase-transfer catalytic oxidation. The method comprises: preparing six types of heteropolyacid quaternary ammonium salts as the phase-transfer catalysts from quaternary ammonium salts and phosphomolybdic acid / tungstophosphoric acid, mixing the phase-transfer catalysts, fuel oil, and peroxyformic acid oxidant (prepared from H2O2 and formic acid at a weight ratio of 3.5:(1-1.5)), reacting at 25-55 deg.C under ultrasonication for 1-2 h, and separating fuel oil and peroxyformic acid to obtain desulfurized fuel oil. The method avoids adsorption and extraction procedures due to the heteropolyacid quaternary ammonium salts phase-transfer catalysts, and has such advantages as simple process, and high reaction rate. The catalyst has such advantages as no toxicity and no pollution, and is recyclable and environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

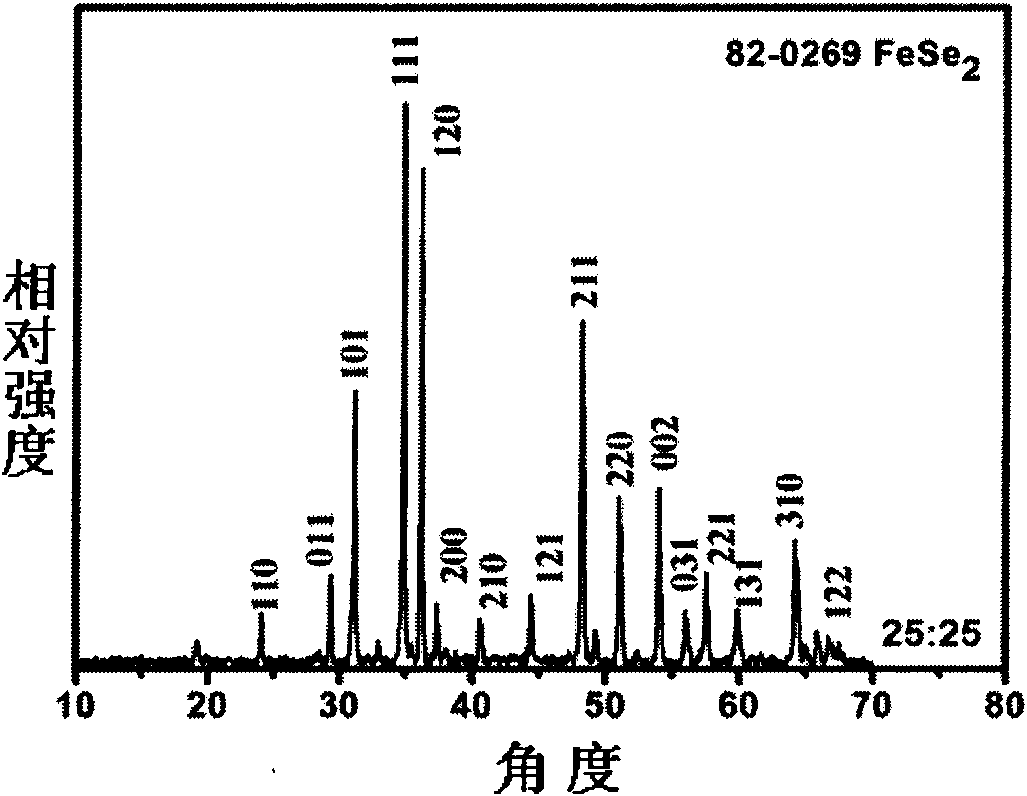

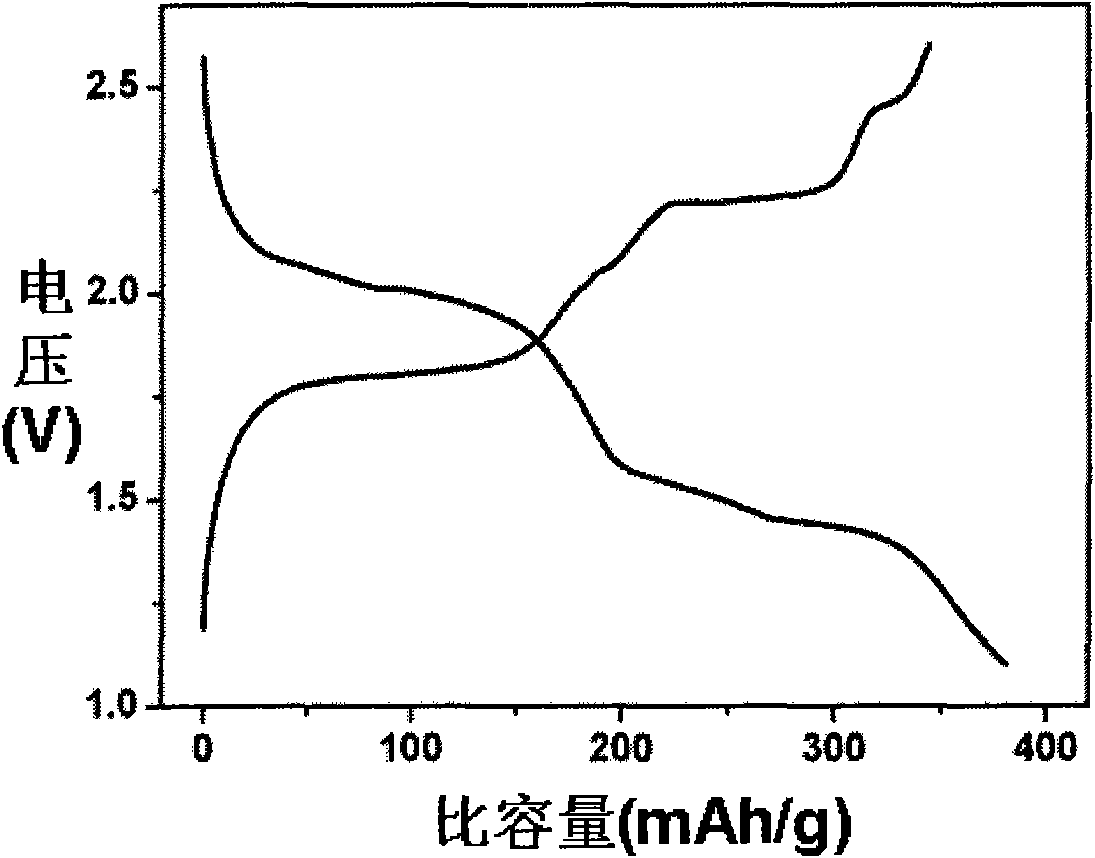

Method for preparing selenide ferrous iron nanometer flower

InactiveCN101559931AGood chemical stabilityGood reproducibilityCell electrodesIndividual molecule manipulationPolyvinyl alcoholSulfite salt

The invention relates to a method for preparing a selenide ferrous iron nanometer flower. The material can be used as an active material of an anode of a lithium ion battery. The method for preparing the selenide ferrous iron nanometer flower comprises the following steps that: according to the ratio of 0.1 mol:0.1 mol:100 mL, selenium powder, sodium sulfite and deionized water are picked up, heated and stirred to obtain a solution of Na2SeSO3; 2) according to the ratio of 10g:100 mL, polyvinyl alcohol and distilled water are picked up, heated and stirred to obtain a water solution of polyvinyl alcohol; 3) according to the ratio of 2.5 mmol:5 mL:20 to 30 mL : 20 to 30 mL, F3C2O4, citric acid with the concentration of 1 M, the solution of Na2SeSO3 and the water solution of polyvinyl alcohol are picked up, mixed and stirred, and by adjusting the pH value of the system to be 8-10, an even rheological phase matter is obtained; 4) the obtained matter is kept at a temperature of between 160 and 180 for 10 to 24 hours and then naturally cooled to obtain a hydrothermal product; 5) the hydrothermal product is subjected to centrifugal separation; and 6) the hydrothermal product is dried to obtain the red brown selenide ferrous iron nanometer flower. The method has the characteristics of simple process and low synthetic temperature.

Owner:武汉理工力强能源有限公司

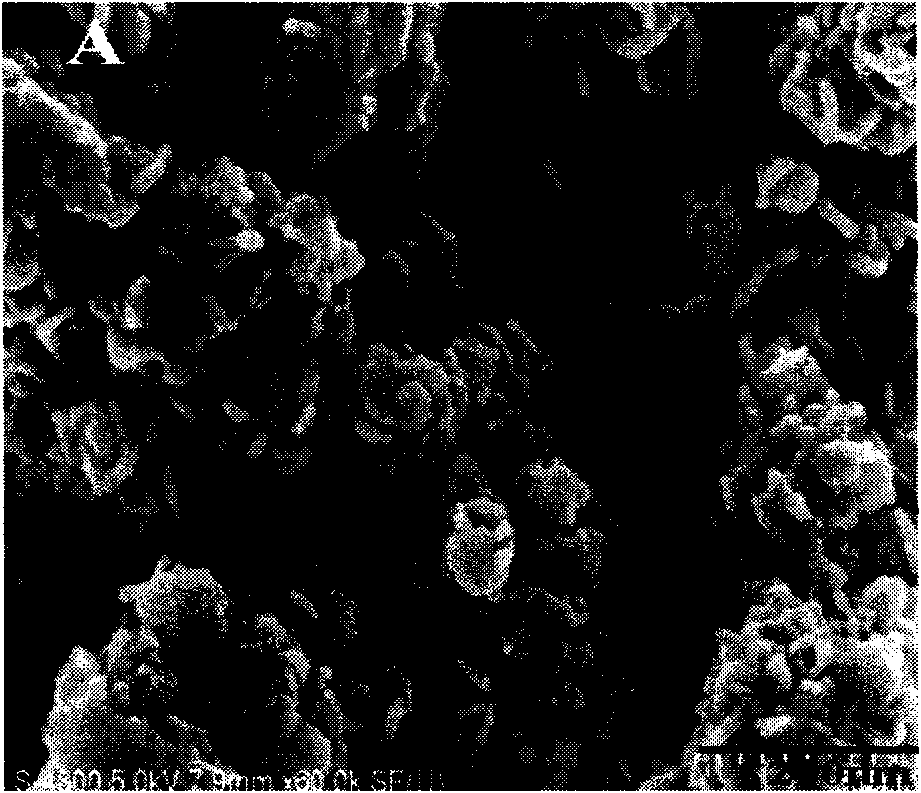

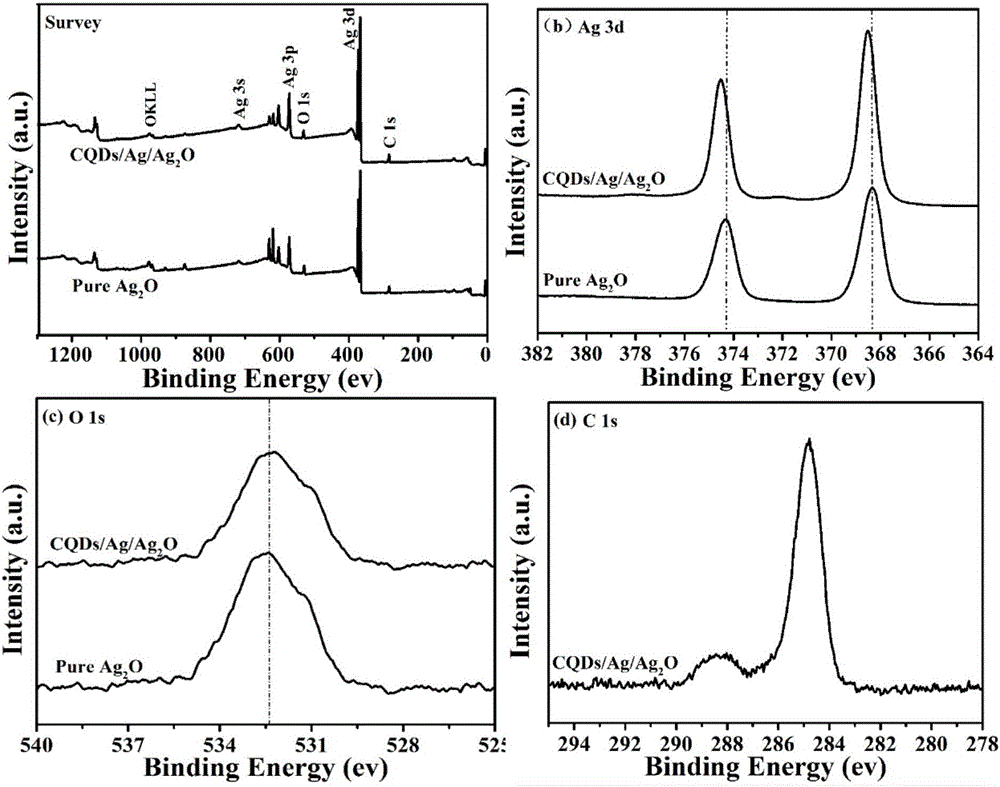

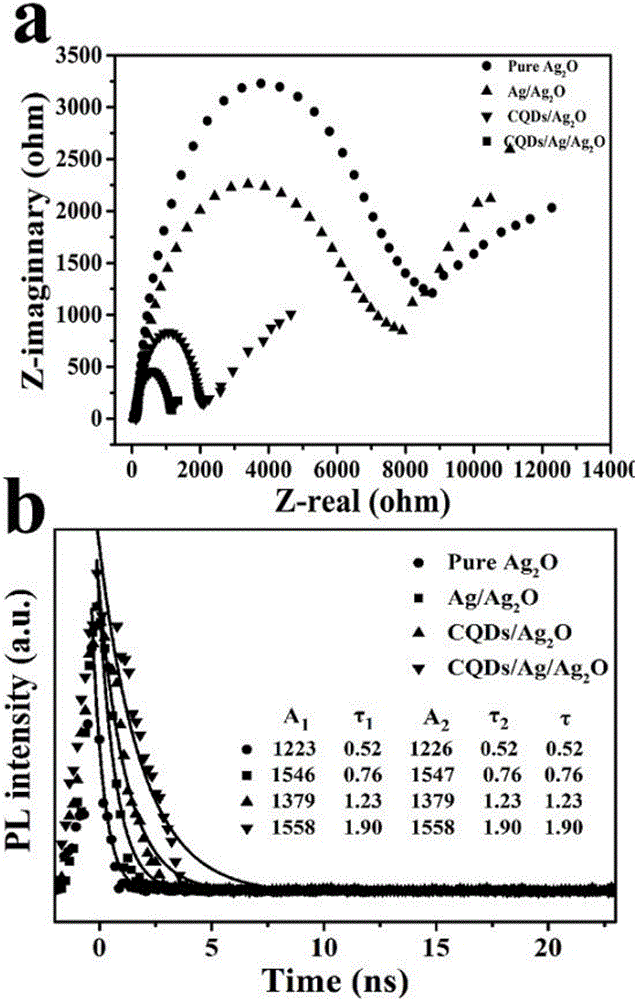

Preparation method and application for ternary composite photocatalyst

InactiveCN105688899ASimple processImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsOctahedronMaterial synthesis

The invention belongs to the technical field of nano-material synthesis, and particularly relates to a preparation method and the application of a ternary composite photocatalyst. The preparation method comprises the following steps: first, synthesizing CQDs (Carbon Quantum Dots) with a remarkable up-conversion fluorescence effect by utilizing a simple one-step alkali auxiliary ultrasonic processing method; then, generating silver oxide (Ag2O) with an octahedral structure in CQDs solution by a wet-chemical method to obtain a CQDs / Ag2O compound with a CQDs coating layer; finally, loading silver (Ag) nano-particles on the surface of the CQDs / Ag2O by using chemical deposition and photo-deposition methods. The ternary composite photocatalyst can be used for degrading organic pollutants, such as rhodamine B, under full spectrum.

Owner:JIANGSU UNIV

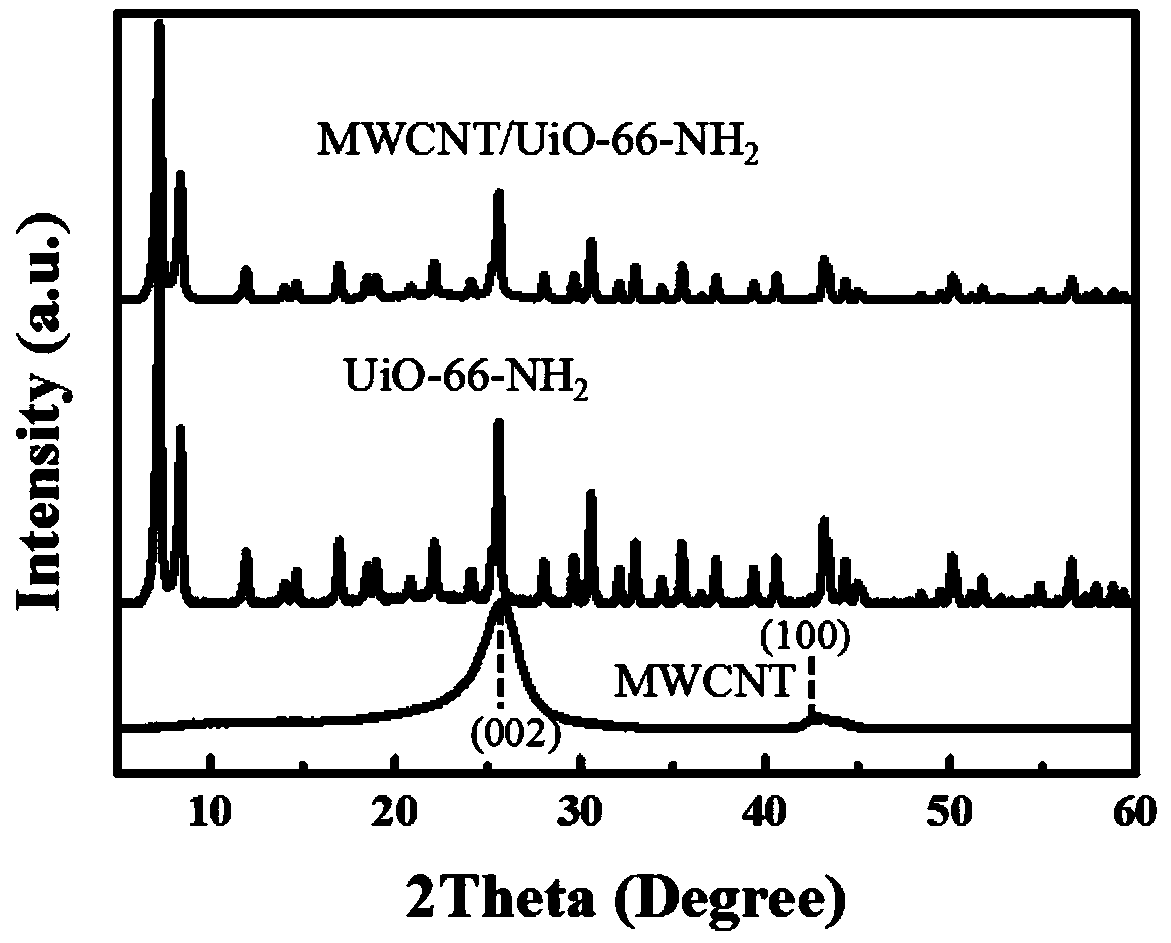

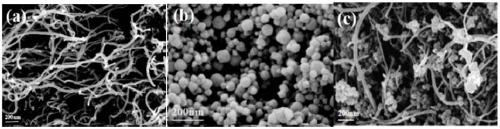

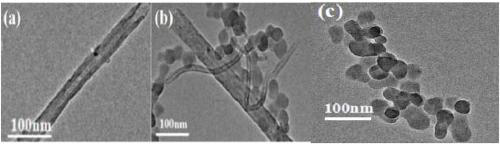

Preparation method of carbon nanotube/UiO-66-NH2 nano-composite material

ActiveCN109589932AReduce degradationImprove adsorption capacityOther chemical processesWater contaminantsMetal-organic frameworkCarbon nanotube

The invention belongs to the field of preparation of a metal organic framework material, and relates to a preparation method of a novel adsorption material carbon nano-tube / UiO-66-NH2. The preparationmethod comprises the following steps: firstly, performing acidizing treatment on a multi-wall carbon nano-tube to ensure that carboxyl located at the defect sites of the carbon nano-tube is functionalized and then a coordinate bond is formed by simultaneously an organic ligand and metal ions, and performing self-assembly to form a nano-composite material. The carbon nano-tube participates in theUiO-66-NH2 material in a form of physical blending, and the carbon nano-tube / UiO-66-NH2 composite material is also formed in a form of chemical bond. Because addition of the carbon nano-tube, the water stability of the metal organic framework material is obviously improved, and the heat stability, the specific surface area and the pore volume aperture of the composite material are all improved toa certain extent, and thus, the composite material has more excellent adsorption performance. The preparation method is simple and effective, and a new way is provided for preparing the nano-tube / MOFscomposite material.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com