Nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes/tin dioxide

A technology of multi-walled carbon nanotubes and nanocomposite materials, applied in the fields of nanocomposite materials and wave absorbing materials, can solve the problems of uncertainty of wave absorption performance of composite materials, uneven size of nanoparticles, and difficulty in guaranteeing magnetic metals, etc. Excellent absorbing performance, low reaction cost, light weight and load-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

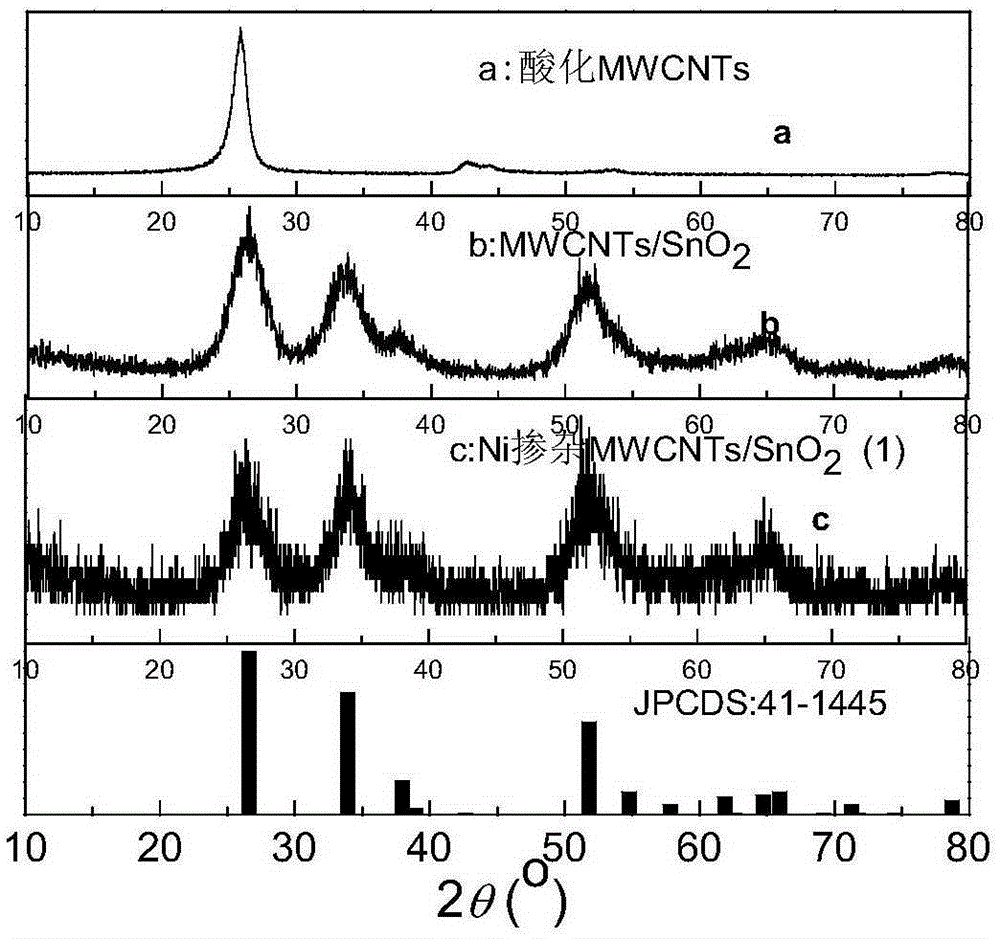

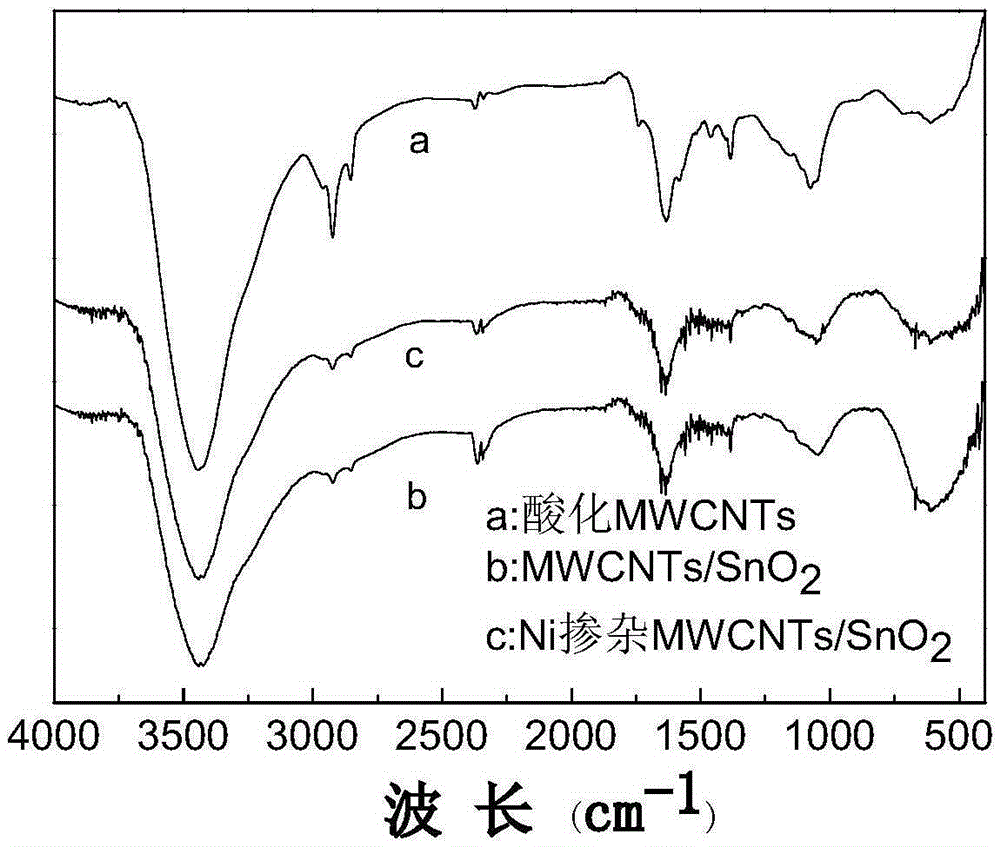

[0041] Ni-doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO 2 ) lightweight absorbing material:

[0042] 1) Take 1g of multi-walled carbon nanotubes (MWCNTs) (>95%) in a three-necked flask, add 100mL of concentrated nitric acid (65wt%), and stir at room temperature for 15 minutes. After the stirring is completed, the three-necked flask is transferred to an oil bath, Connect the condensing tube, set the temperature of the oil bath to 140°C after the device interface is sealed, and react for 6 hours. After the reaction, the crude product is suction-filtered, washed until neutral, and dried in a vacuum oven at 60°C for 24 hour, obtain acidified multi-walled carbon nanotubes (MWCNTs);

[0043] 2) 40 mg of the multi-walled carbon nanotubes (MWCNTs) treated in step 1) was placed in 40 mL of water, and ultrasonically dispersed, and the dispersion of the multi-walled carbon nanotubes (MWCNTs) was transferred to a 50 mL reactor, and 2 g of tetrahydrate Tin chloride (SnCl ...

Embodiment 2

[0048] Magnetic metal-doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO2) prepared by the present invention 2 ) nanocomposite is only the wave absorbing agent of the wave absorbing material, and the wave absorbing material is composed of the base material and the wave absorbing agent, and paraffin is the base material in the present invention.

[0049] Multi-walled carbon nanotubes (MWCNTs) and paraffin were mixed evenly at a mass ratio of 3:1, pressed into pellets, and their absorbing properties were tested with a vector network analyzer.

[0050] Tin dioxide (SnO 2 ) nanoparticles and paraffin with a mass ratio of 3:1 were mixed evenly, pressed into tablets, and the wave-absorbing performance was tested with a vector network analyzer. Tin dioxide (SnO 2 ) nanoparticles are prepared according to the following method: step 2) does not add nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), all the other are with embodiment 1, obtain pure tin dioxide (SnO 2 )Nan...

Embodiment 3

[0053] Magnetic metal Ni doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO2) prepared by the present invention 2 ) nanocomposite is only the wave absorbing agent of the wave absorbing material, and the wave absorbing material is composed of the base material and the wave absorbing agent, and paraffin is the base material in the present invention. Magnetic Ni-doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO 2 ) nanocomposite material and paraffin with a mass ratio of 3:1 were mixed evenly, pressed into tablets, and the wave-absorbing performance was tested with a vector network analyzer.

[0054] Ni-doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO 2 ) nanocomposite material: nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (2) is 1.5g, all the other are with embodiment 1, and the product obtained is recorded as Ni-doped multi-walled carbon nanotubes (MWCNTs) / tin dioxide (SnO 2 )(2).

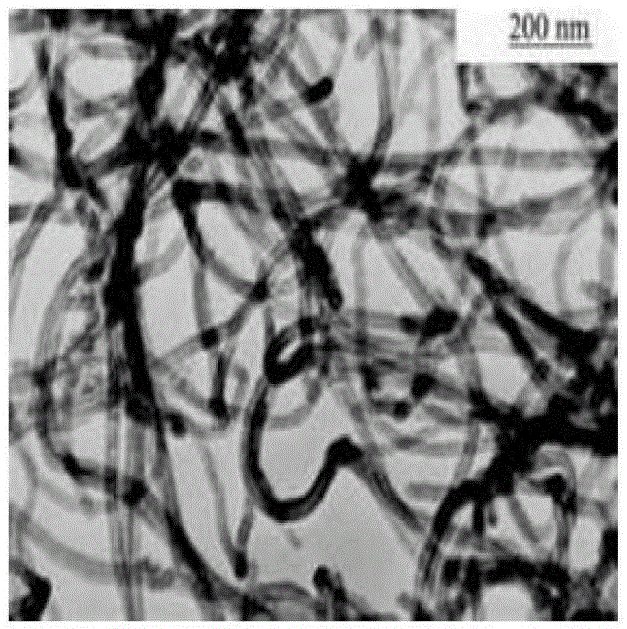

[0055] Figure 4c Ni-doped multi-walled carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com