Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Peroxyformic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Performic acid (PFA) is an organic compound with the formula CH2O3. It is an unstable colorless liquid which can be produced by mixing formic acid with hydrogen peroxide. Owing to its oxidizing and disinfecting action, it is used in the chemical, medical and food industries.

Compositions and methods of treating edible matter and substrates therefor

There are provided methods of treating edible matter comprising applying a composition comprising performic acid to the edible matter or a substrate therefor. Other embodiments are also disclosed.

Owner:BEN YEHUDA NIMROD

Process for the preparation of peroxy acids

ActiveUS20090221704A1Easy to controlIncrease powerBiocideOrganic compound preparationPeroxy acidCarboxylic acid

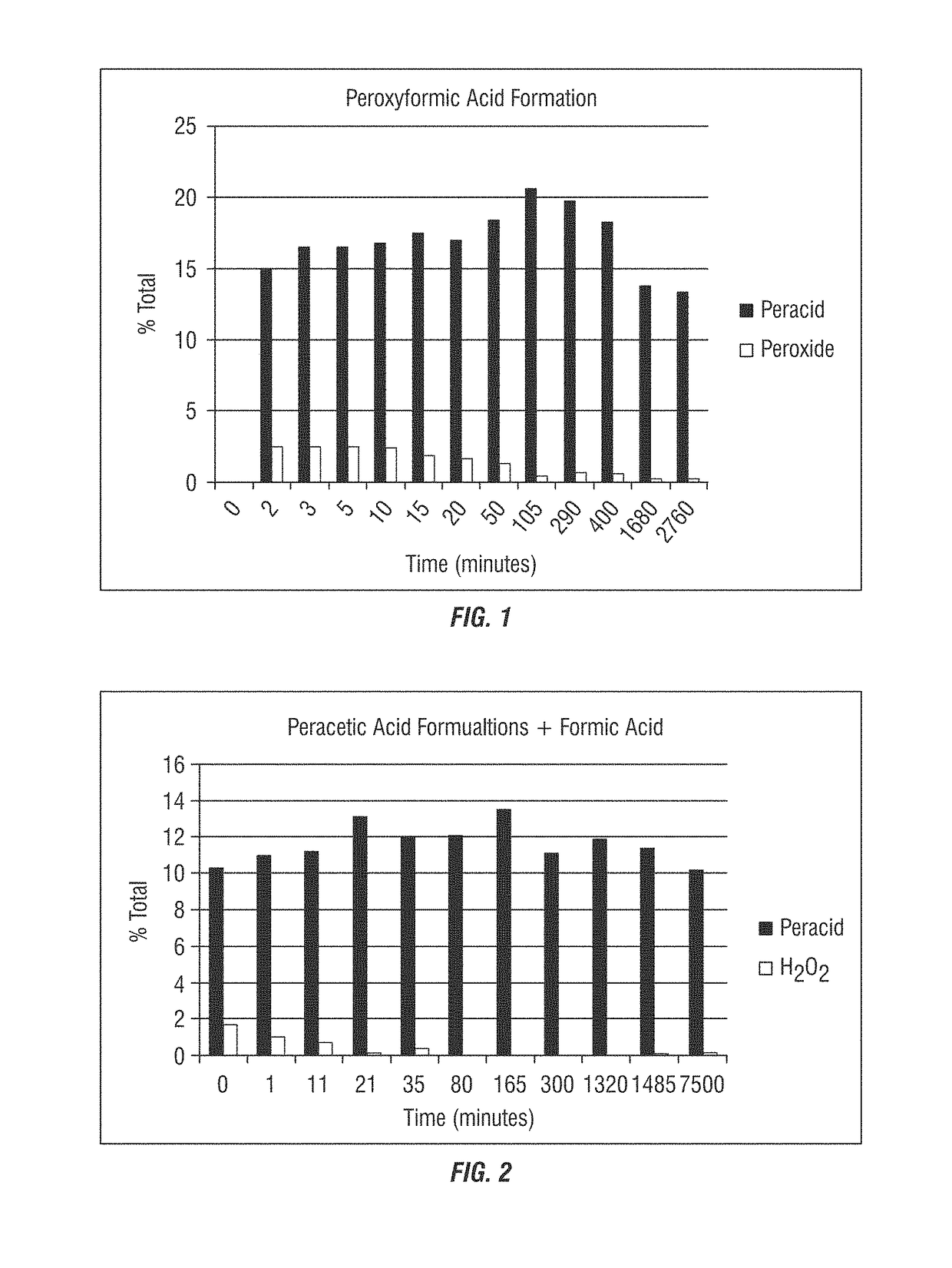

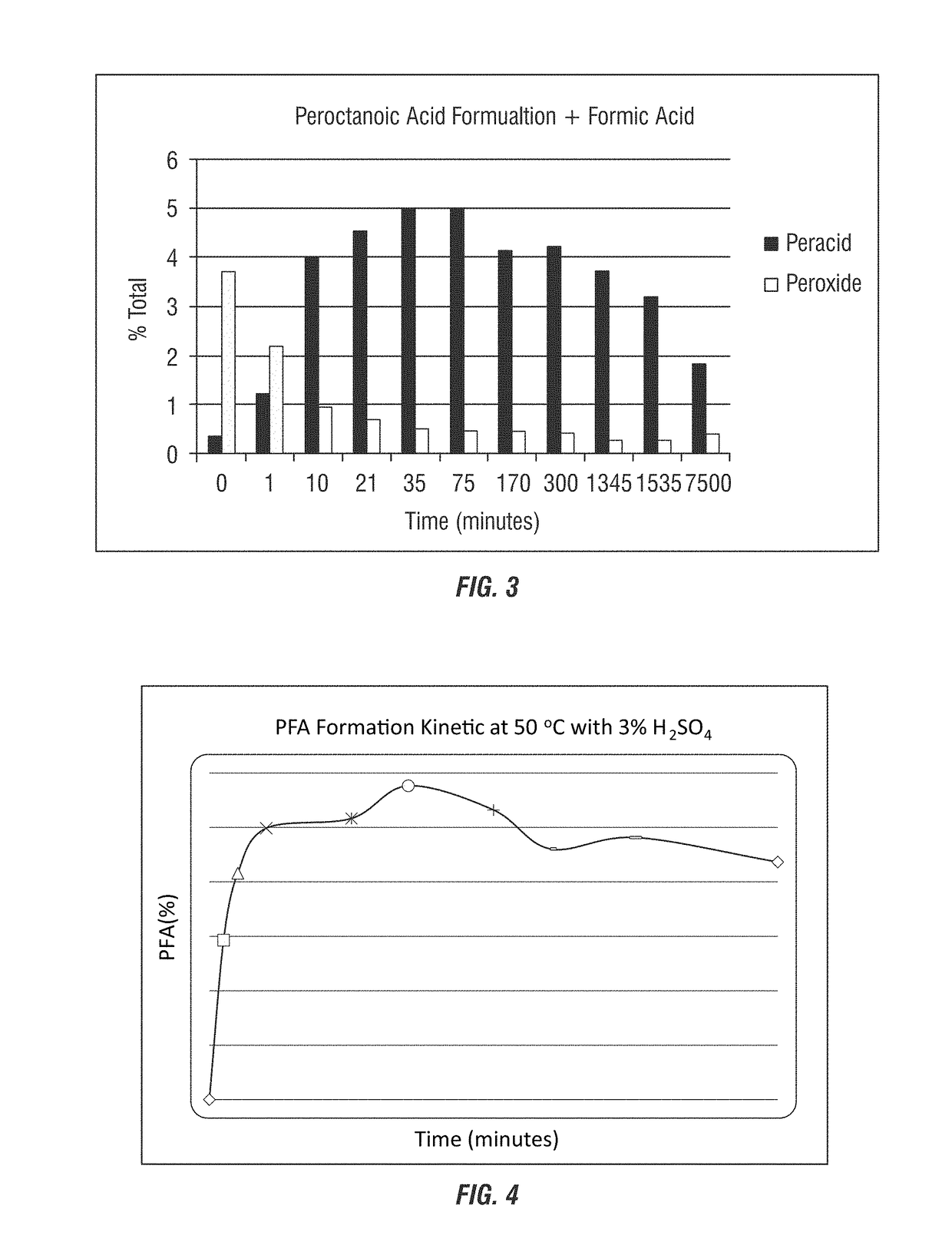

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

Process for the preparation of peroxy acids

ActiveUS8828910B2Easy to controlIncrease powerBiocideOrganic compound preparationCarboxylic acidPeroxy acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

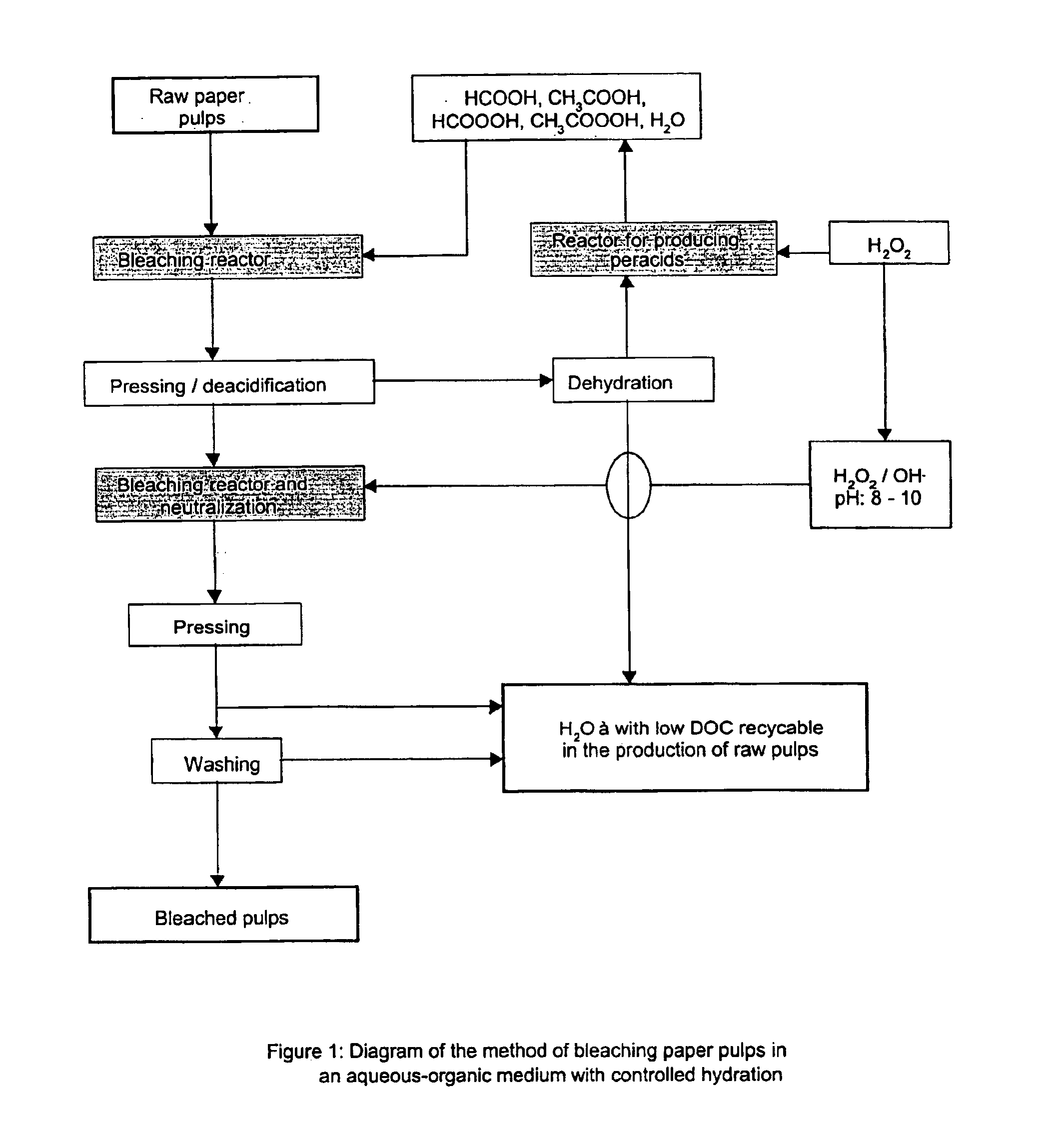

Method for bleaching paper pulp with organic peracids followed by peroxide and sodium hydroxide

InactiveUS6866749B2Stable and neutral and even slightlyReduce trimmingPulp bleachingPulping with organic solventsAcetic acidAtmospheric pressure

The invention concerns a method for bleaching different types of paper pulp in two steps at atmospheric pressure and at a temperature not higher than 100 DEG C. The first step consists in contacting the unbleached paste with a mixture of paracetic acid and performic acid. The second step consists in treating the bleached pulp derived from the first step, with a solution of soda and hydrogen peroxide. The resulting pulps exhibit a high index of whiteness and a degree of polymerisation close to unbleached pulps. The method is environmentally safe and non-polluting.

Owner:CIE IND DE LA MATIERE VEGETALE

Method of treating swimming pool water

A method of treating water for a swimming pool comprising chlorination of the water, and filtration of the water using a fixed-bed filter with periodic backflushing of the filter using wash water to which a disinfectant has been added. The disinfectant is a peroxycarboxylic acid with one to six carbon atoms is used as disinfectant, preferably a solution containing peroxyacetic acid and / or peroxyformic acid and hydrogen peroxide. The method results in an improvement of the quality of the swimming-pool water and of the used wash water.

Owner:DEGUSSA AG

Method for preparing epoxidized fatty acid methyl esters in continuous flow microchannel reactor

The invention relates to a method for preparing epoxidized fatty acid methyl esters by using a microchannel reactor. The method comprises the following specific steps of: preparing catalyst formic acid and concentrated hydrochloric acid in a certain proportion; pumping fatty acid methyl ester, a formic acid catalyst, and hydrogen peroxide into the microchannel reactor by using three metering pumps; and washing reaction products, separating and drying to obtain the final product epoxidized fatty acid methyl esters. The whole process is an exothermic reaction process, and peroxyformic acid and epoxidized fatty acid methyl esters are synthesized simultaneously. When the epoxidized fatty acid methyl esters are produced by the method, the temperature of the reaction process can be controlled effectively, high safety can be guaranteed, a module is good in mixing effect, and a product obtained through reaction is high in quality; and the continuous flow reaction is performed, the process is continuous, and high production efficiency is achieved.

Owner:CHANGZHOU UNIV

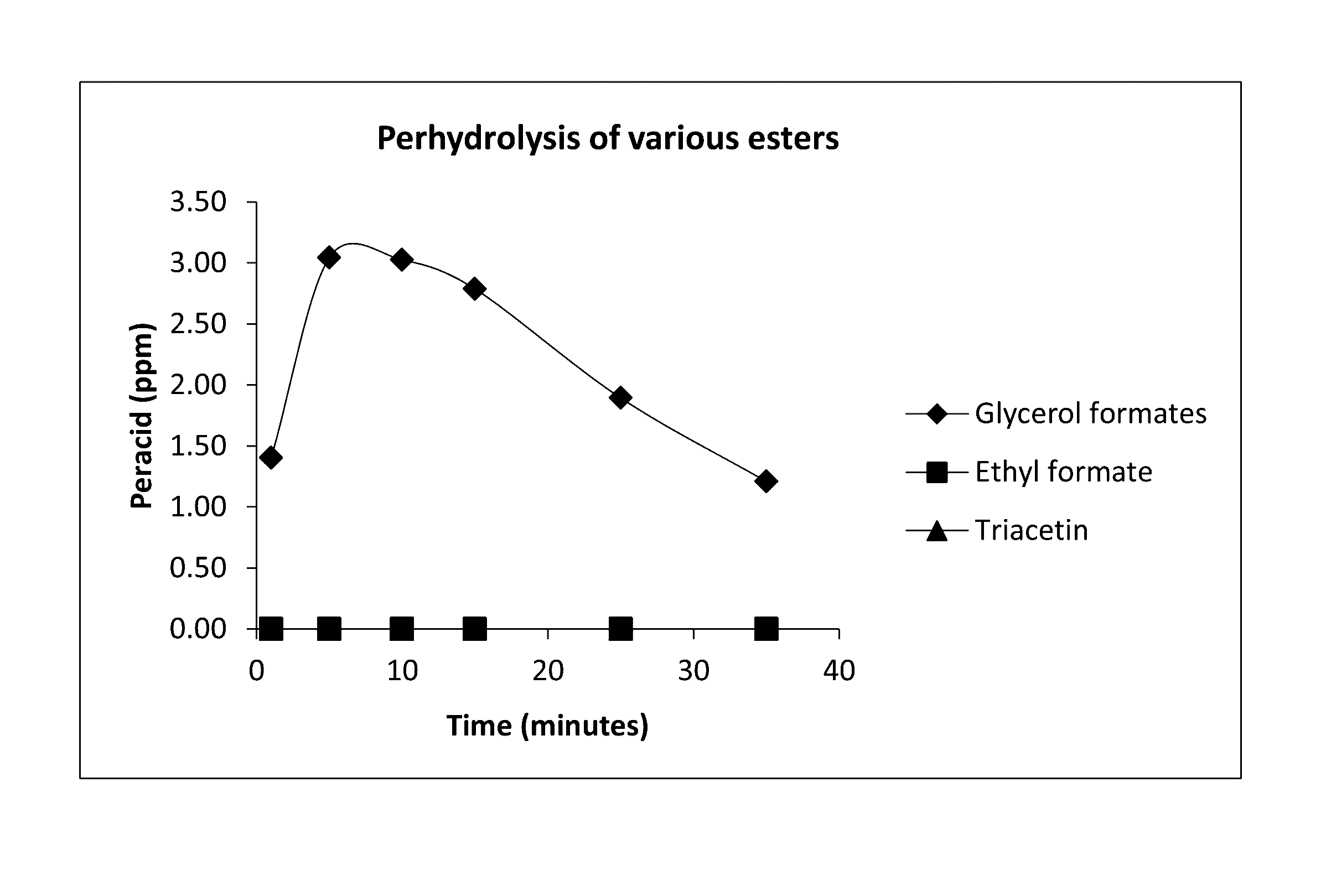

Generation of peroxyformic acid through polyhydric alcohol formate

ActiveUS9518013B2Eliminate needSufficient time to stabilize or reduce microbialAntibacterial agentsBiocideAlcoholFormate

Owner:ECOLAB USA INC

Method for eliminating sulfur compound contained in fuel oil by catalytic oxidation of phase transition

InactiveCN101050378AAvoid pollutionAbsorptiveOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhosphomolybdic acidQuaternary ammonium cation

This invention discloses a method for removing sulfur-containing compounds from fuel oil by phase-transfer catalytic oxidation. The method comprises: preparing six types of heteropolyacid quaternary ammonium salts as the phase-transfer catalysts from quaternary ammonium salts and phosphomolybdic acid / tungstophosphoric acid, mixing the phase-transfer catalysts, fuel oil, and peroxyformic acid oxidant (prepared from H2O2 and formic acid at a weight ratio of 3.5:(1-1.5)), reacting at 25-55 deg.C under ultrasonication for 1-2 h, and separating fuel oil and peroxyformic acid to obtain desulfurized fuel oil. The method avoids adsorption and extraction procedures due to the heteropolyacid quaternary ammonium salts phase-transfer catalysts, and has such advantages as simple process, and high reaction rate. The catalyst has such advantages as no toxicity and no pollution, and is recyclable and environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

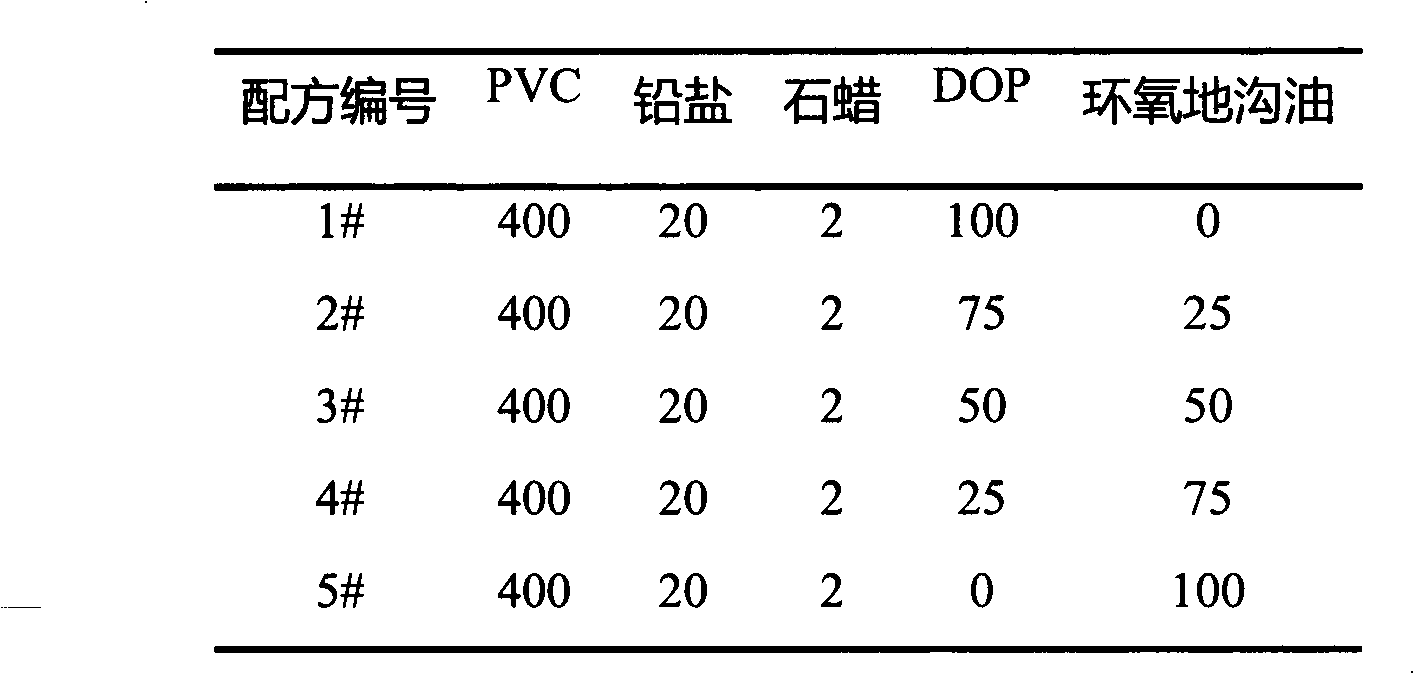

Formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride)

InactiveCN103013675ASimple processLow costFatty oils/acids recovery from wasteFatty acid chemical modificationEpoxyGutter oil

The invention relates to a formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride). In a test, sulfuric acid is taken as a catalyst, hydrogen peroxide is taken as an oxygen supply agent, formic acid is taken as an oxygen receiving agent, and the epoxidation reaction conditions of gutter oil are researched in one step by adopting performic acid. The method is suitable for industrial popularization and application. Therefore, the optimal processing formula of the epoxy gutter oil plasticized PVC is designed by taking the epoxy gutter oil as a plasticizer in the PVC production process instead of the conventional dioctyl phthalate.

Owner:SHIHEZI UNIVERSITY

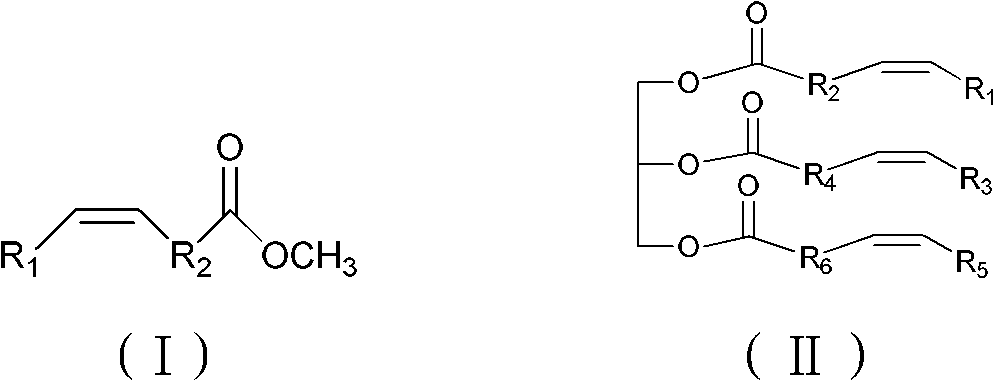

Synthesizing method of epoxy fatty acid ester

The invention relates to a synthesizing method of an epoxy fatty acid ester. According to the method, formic acid (acetic acid) contacts and is mixed with hydrogen peroxide in a first micro-reactor, such that a peroxidation reaction is initiated; when a material of the initiated peroxidation reaction flows out of the micro-reactor, the reaction of the material is continued for several minutes in an extension pipe (capillary or micro-channel) connected to the outlet of the first micro-reactor, such that peroxyformic acid (peroxyacetic acid) is produced; the in-situ produced peroxyformic acid (peroxyacetic acid) contacts and is mixed with non-reacted hydrogen peroxide and fatty acid ester in a second micro-reactor, such that an epoxidation reaction is initiated; the reaction of the material of the initiated epoxidation reaction is continued for several minutes in an extension pipe connected to the outlet of the second micro-reactor, or other kettle-type material storage devices, such that epoxy fatty acid ester is produced. According to the method, organic acid peroxidation and double-bond epoxidation reactions are integrated in series, such that epoxy fatty acid ester is obtained by continuous synthesis. The process is safe and controllable. Under the optimized condition, double bond conversion rate in fatty acid ester is higher than 90%, and epoxy fatty acid ester selectivity is higher than 80%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

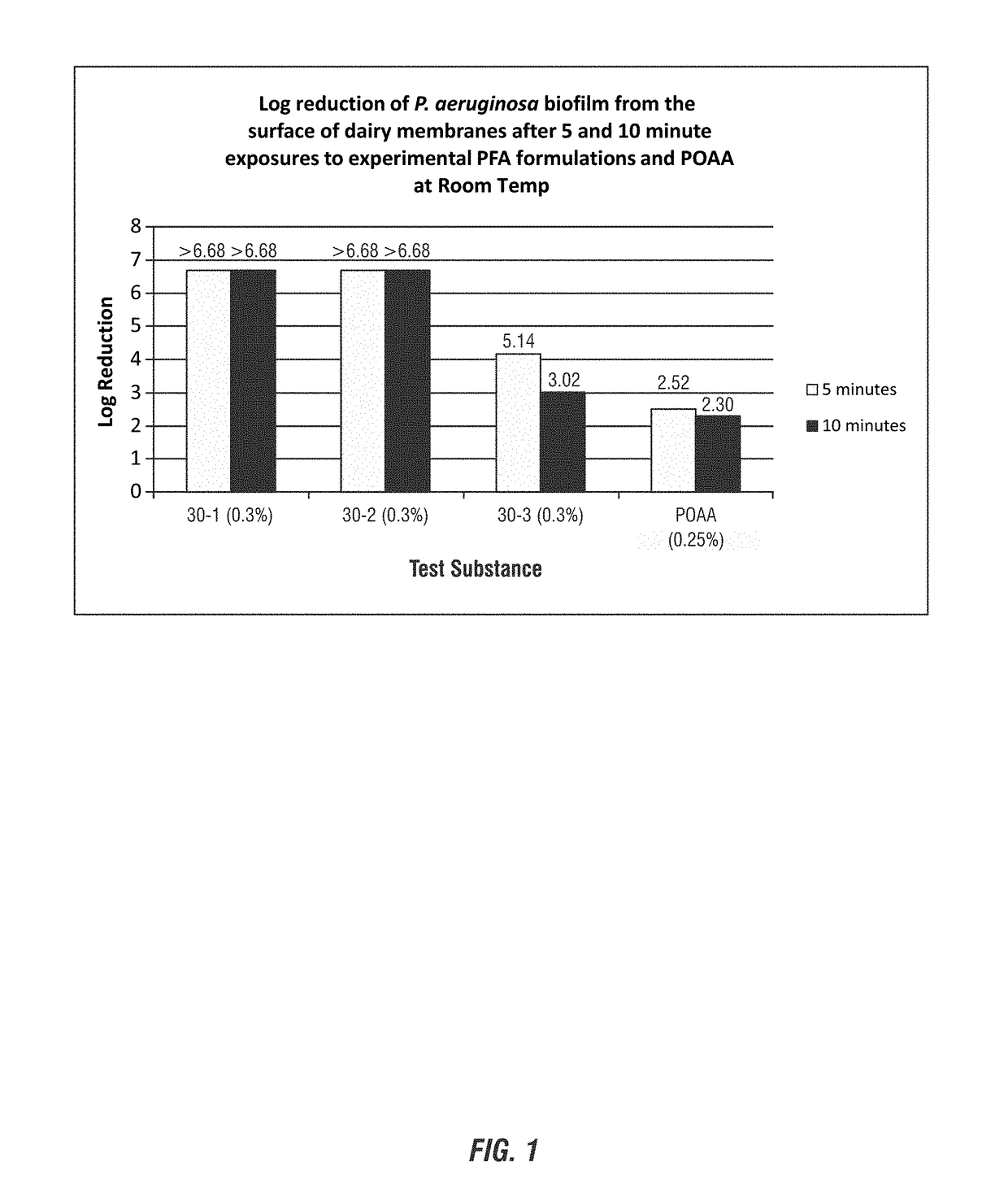

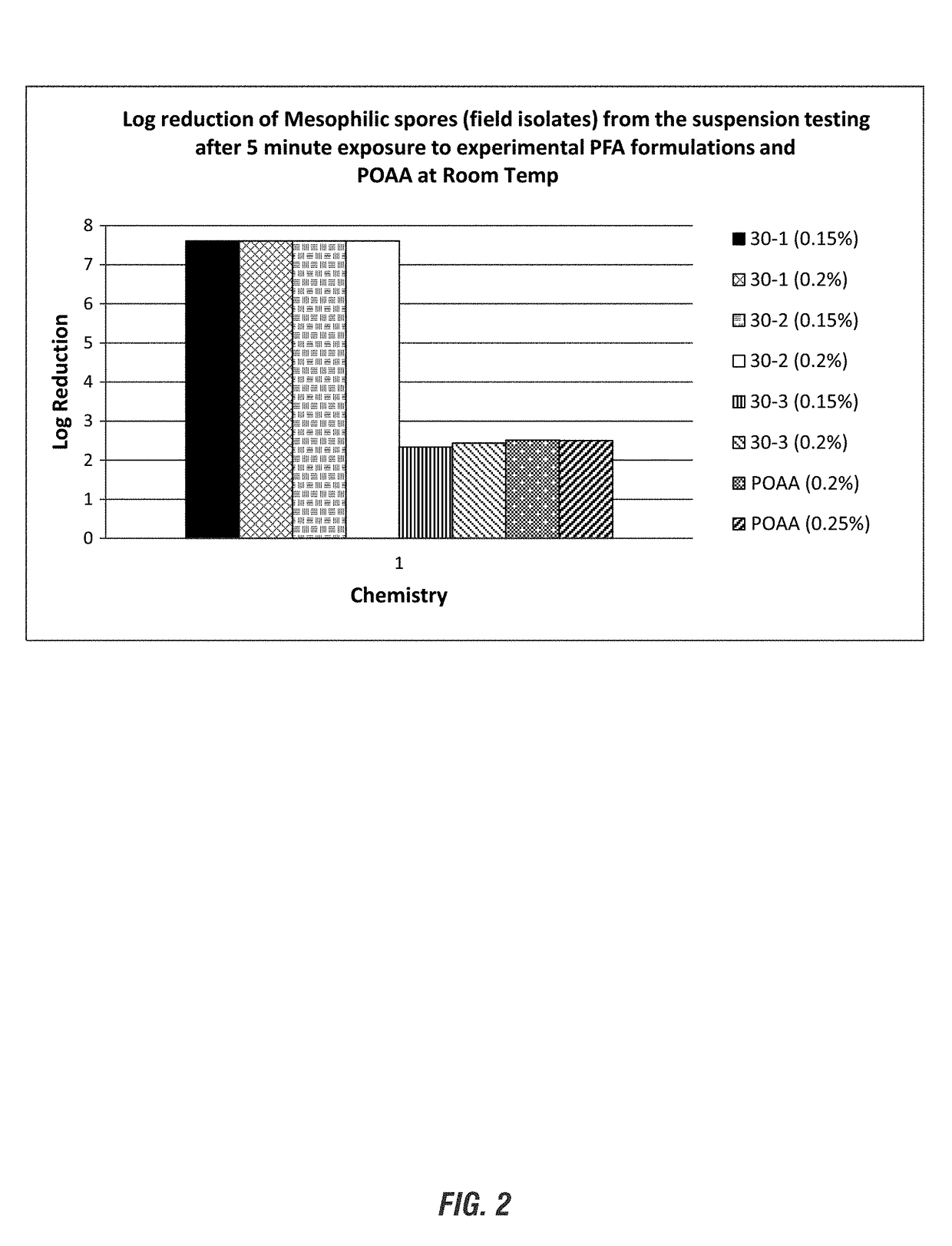

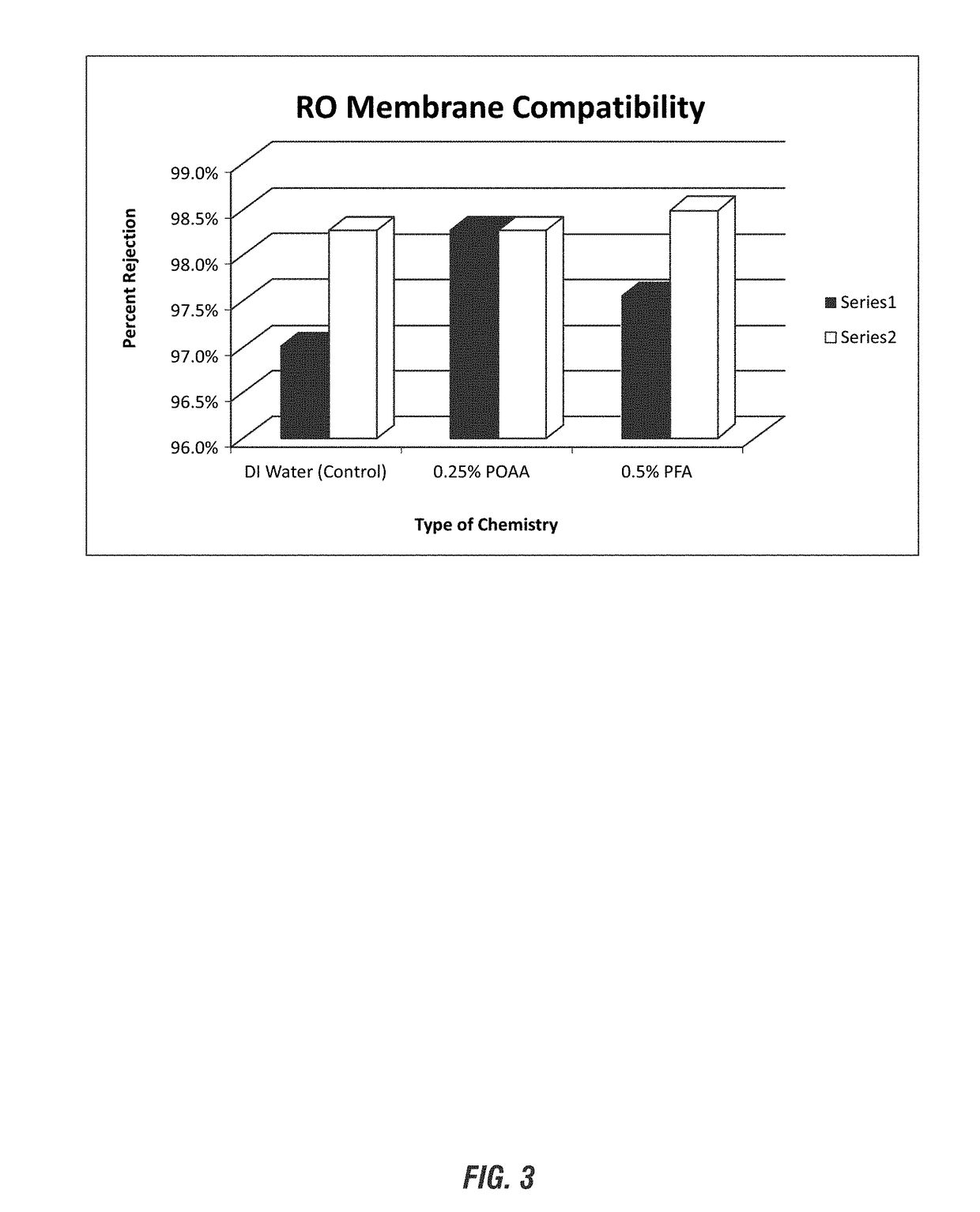

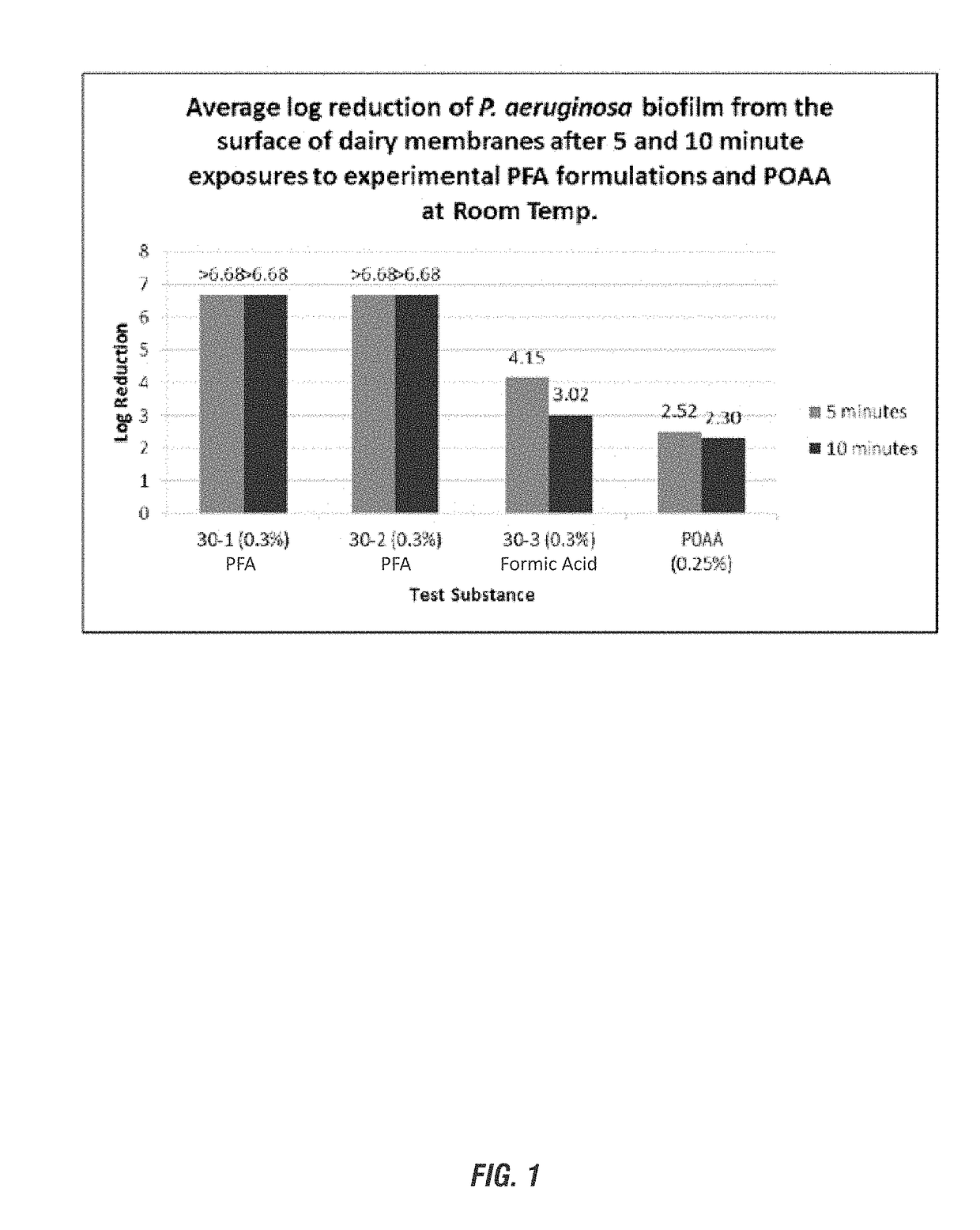

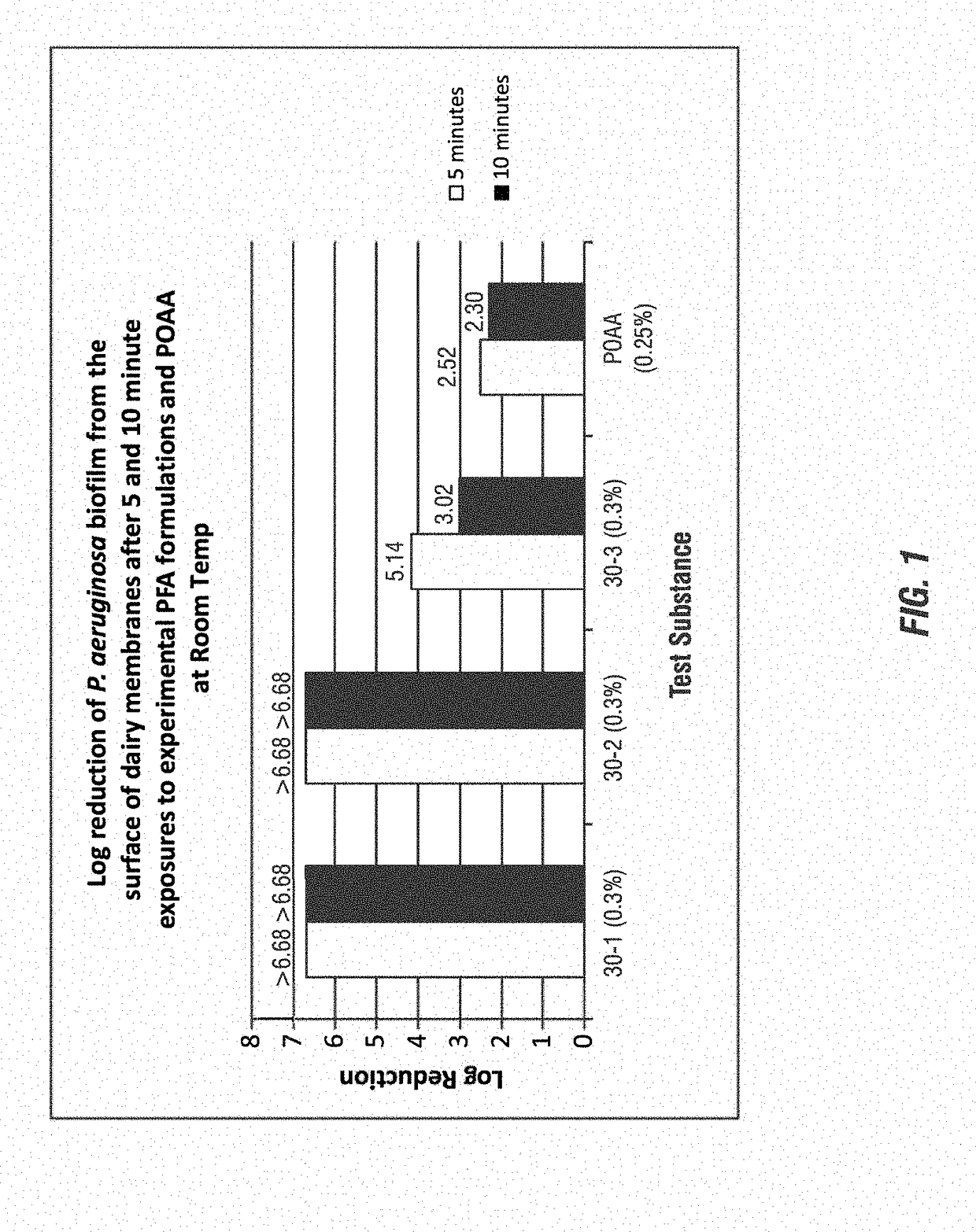

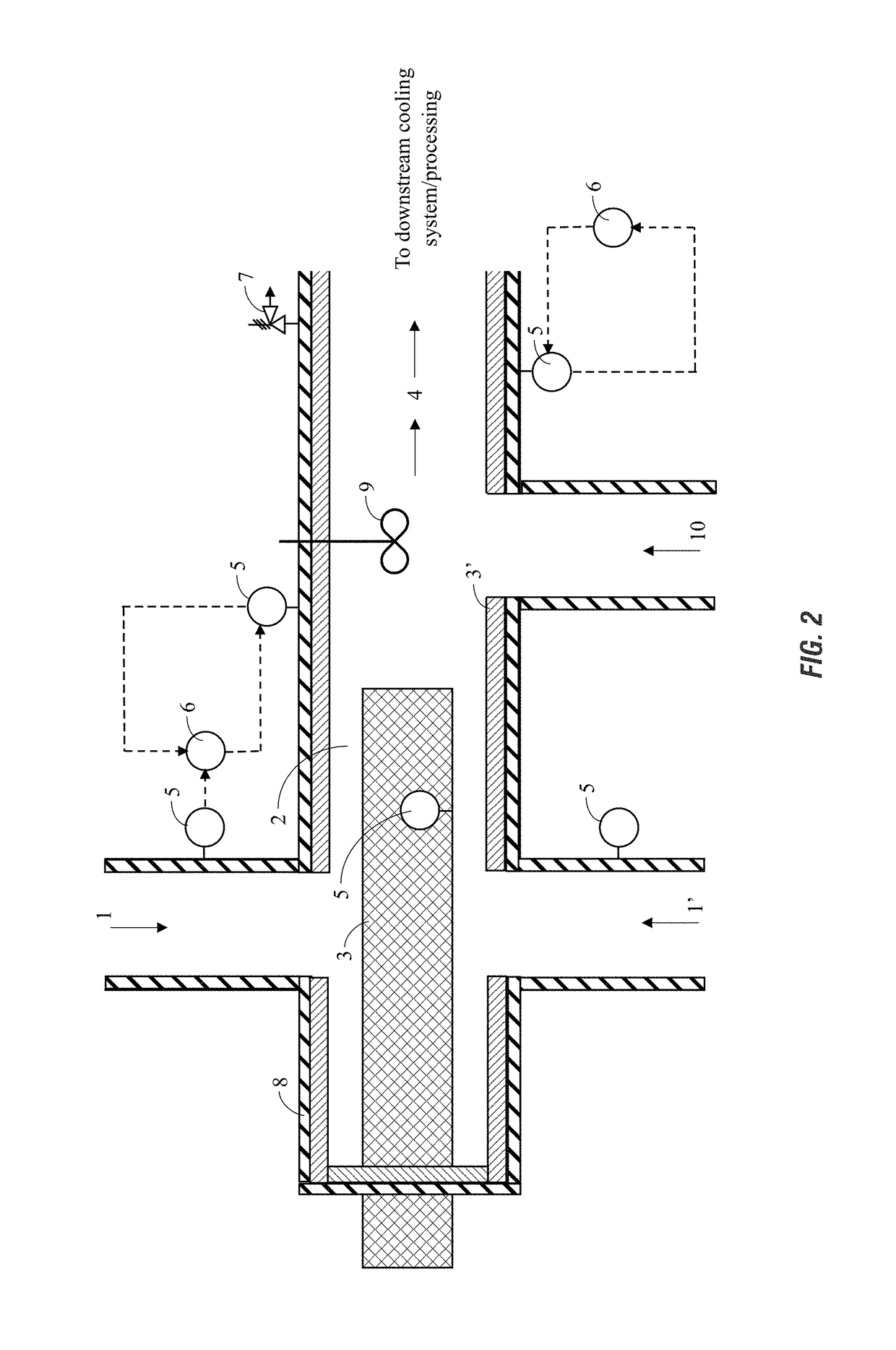

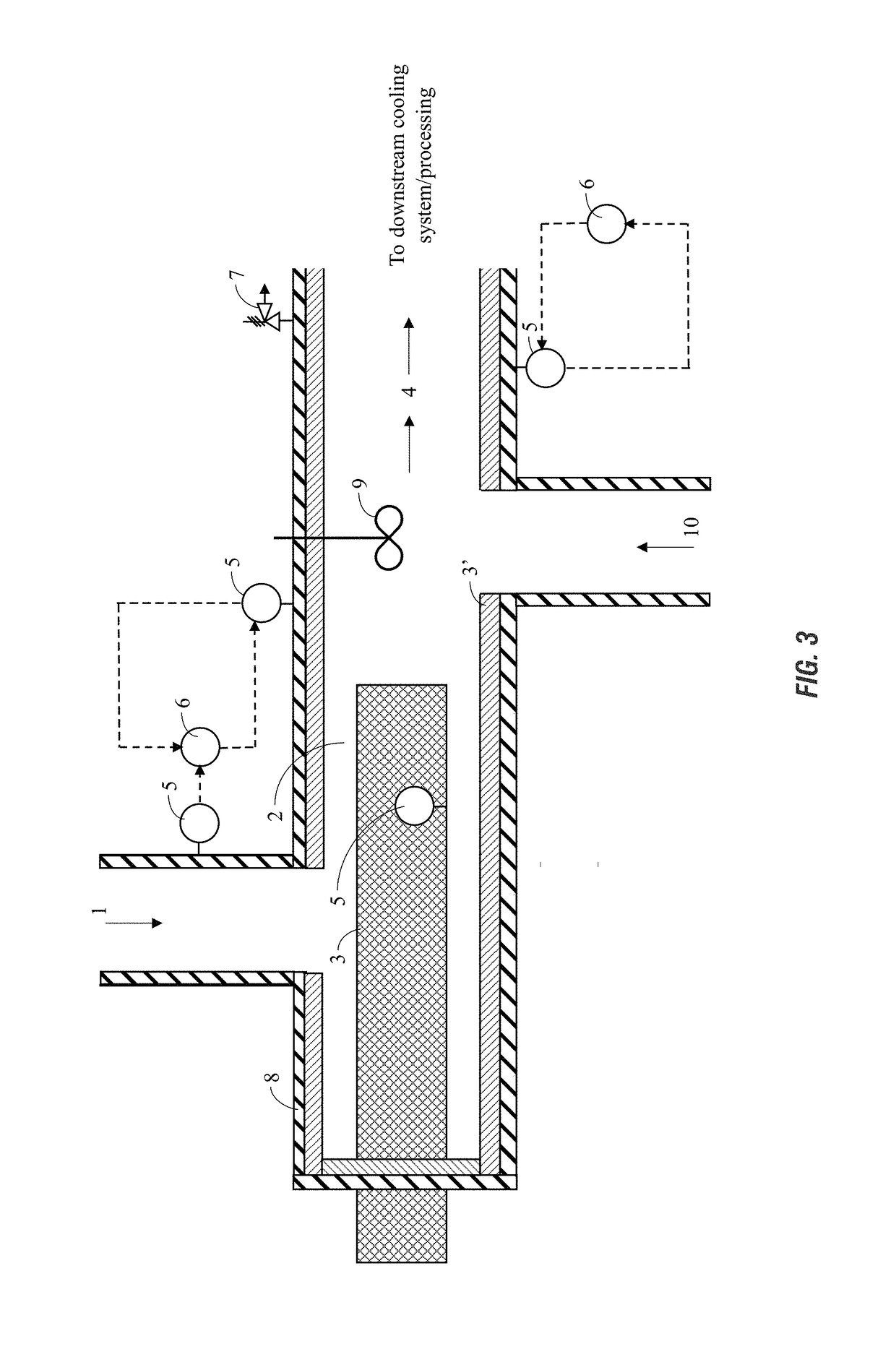

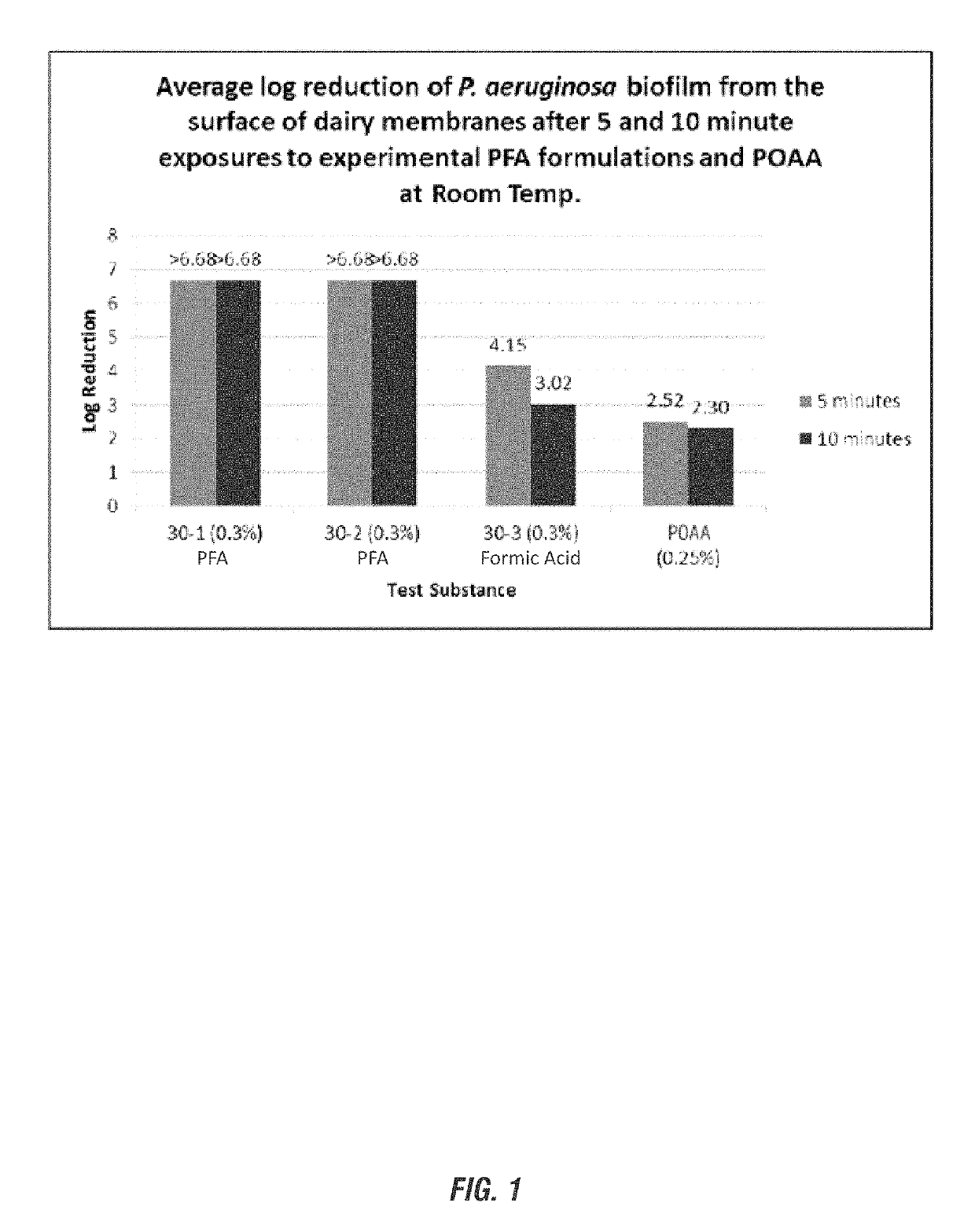

Peroxyformic acid compositions for membrane filtration cleaning

ActiveUS20170173642A1Promote growthEfficiently kill removalBiocideDetergent mixture composition preparationBiofilm growthFiltration

Peroxyformic acid compositions for removal of biofilm growth and mineral deposits on membranes are disclosed. In particular, peroxyformic acid compositions are generated in situ or on site generation for the reduction and prevention, of biofilms and the mitigation of mineral buildup on the membranes. The compositions according to the invention are compatible with the membranes under application of use conditions.

Owner:ECOLAB USA INC

Methods for forming peroxyformic acid and uses thereof

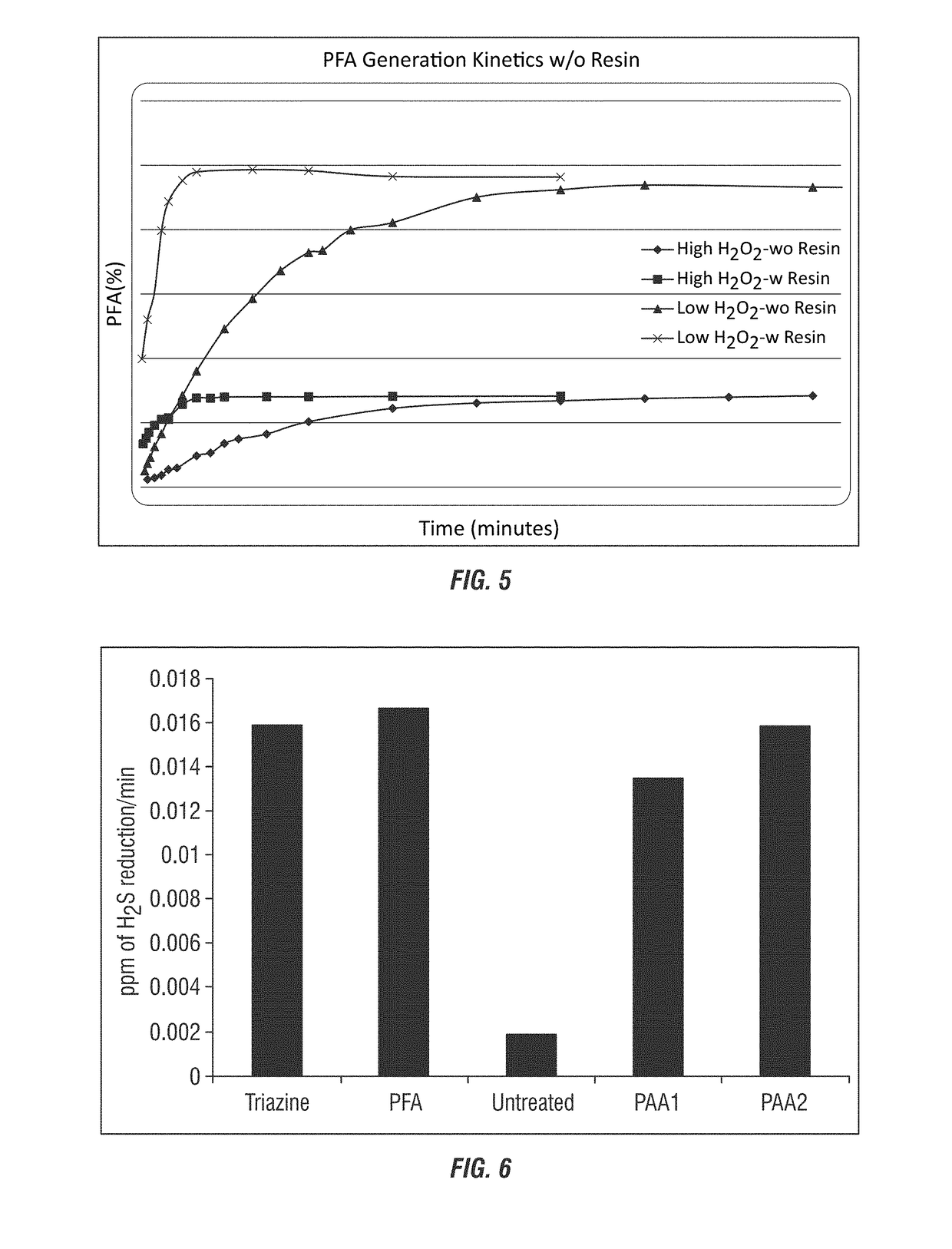

The present invention relates generally to methods for forming peroxyformic acid, comprising contacting formic acid with hydrogen peroxide. The methods for forming peroxyformic acid can include adding formic acid with a relatively lower concentration of hydrogen peroxide, or adding formic acid to a peroxycarboxylic acid composition or forming composition to react with hydrogen peroxide in the compositions. The present invention also relates to peroxyformic acid formed by the above methods. The present invention further relates to the uses of peroxyformic acid for treating a variety of targets, e.g., target water, including target water used in connection with oil- and gas-field operations. The present invention further relates to methods for reducing or removing H2S or iron sulfide in the treated water source, improving clarity of the treated water source, or reducing the total dissolved oxygen or corrosion in the treated water source, using peroxyformic acid, including peroxyformic acid generated in situ.

Owner:ECOLAB USA INC

Performic acid biofilm prevention for industrial co2 scrubbers

ActiveUS20170295784A1Broaden applicationExtension of timeBiocideAnimal repellantsAlcoholBiofilm growth

Peroxyformic acid compositions for removal of biofilm growth and other contaminants and impurities from industrial processing hard surfaces are disclosed. In particular, peroxyformic acid compositions may be dosed on site and / or generated in situ for the reduction and prevention of biofilms on the hard surfaces. Methods of employing the peroxyformic acid compositions for removal of biofilm growth and other impurities such as aldehydes and alcohols from industrial CO2 effluent are also disclosed which beneficially provide ambient biofilm control and break down more rapidly than other peracids, allowing for extended runs between CIP cleaning, including a reduction and / or elimination of cleaning of the scrubbers and other industrial surfaces.

Owner:ECOLAB USA INC

Peroxyformic acid compositions for membrane filtration cleaning in energy services

ActiveUS20180168150A1Broaden applicationPromote growthBiocideSpecific water treatment objectivesBiofilm growthPeroxyformic acid

Peroxyformic acid compositions for treatment and removal of biofilm growth and mineral deposits on membranes for energy services applications are disclosed. In particular, peroxyformic acid compositions are generated in situ or on site generation for the reduction and prevention, of biofilms and the mitigation of mineral buildup on the membranes. The compositions according to the invention are compatible with the membranes under application of use conditions.

Owner:ECOLAB USA INC

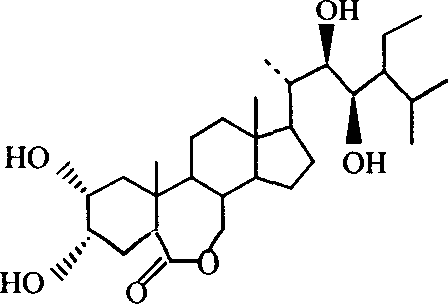

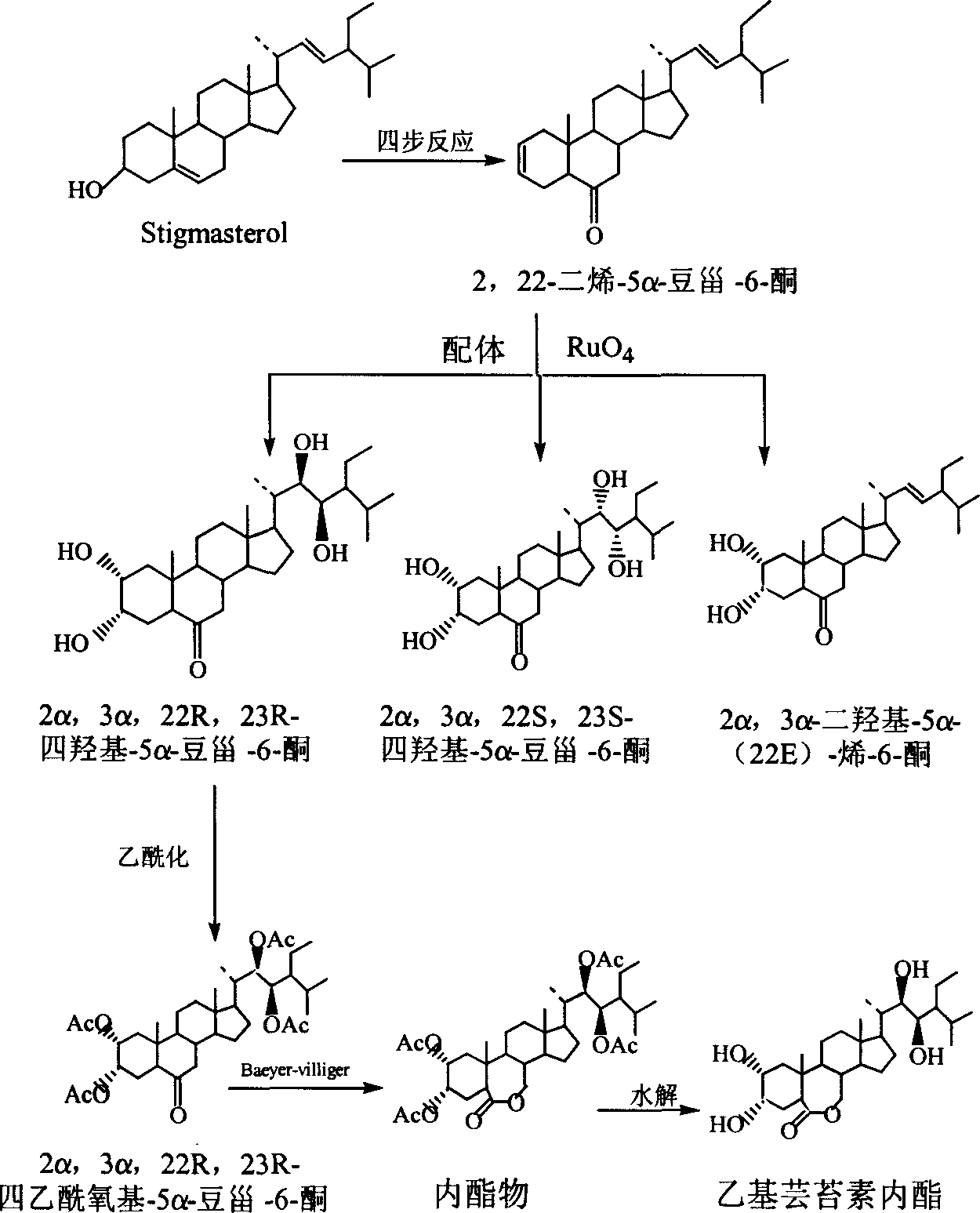

Manufacture method of ethyl brassinolide

The invention discloses a new preparing method of ethyl brassin lactone, which comprises the following steps: 1) preparing intermediate compound of 2, 22- diene -5a-stigma-6-ketone according to present technology; 2) adopting ruthenium tetroxide as oxidant, phenanthrene dihydrochinidin ether as ligand to control stereoscopic structure; proceeding asymmetric double-hydroxide for 2, 22-diene-5a- stigma-6-ketone to generate 2a, 3a, 22R, 23R-tetrahydroxy-5a- stigma-6-ketone; 3) making 2a, 3a, 22R, 23R-tetrahydroxy-5a- stigma-6-ketone to produce acetylate through acetylate protection; 4) using peroxyformic acid as agent to proceed Baeyer-Villiger reaction; lactonizing the acetylate to produce lactone: 2a, 3a, 22R, 23R-tetraace oxygen base-24S- ethyl group-B-high-7- oxa-5a-cholester-6-ketone; hydrolyzing the lactone to produce ethyl brassin lactone.

Owner:浙江来益生物技术有限公司 +1

Preparation method of epoxidized hydroxyl-terminated polybutadiene liquid rubber

The invention relates to a preparation method of epoxidized hydroxyl-terminated polybutadiene liquid rubber and belongs to the technical field of rubber. The preparation method of the epoxidized hydroxyl-terminated polybutadiene liquid rubber has the beneficial effects that epoxidizing modification can be carried out on hydroxyl-terminated polybutadiene liquid rubber (HTPB) by adopting a peroxyformic acid in-situ method for all the raw materials so as to prepare the epoxidized hydroxyl-terminated polybutadiene liquid rubber with excellent mechanical property.

Owner:CHENGDU JINHUI TECH

Preparation method of epoxidized solution polymerized styrene-butadiene rubber

The invention discloses a preparation method of epoxidized solution polymerized styrene-butadiene rubber. According to the preparation method, performic acid is generated in situ by H2O2 and HCOOH peracid system under a mild reaction condition, and the performic acid and double bonds on a solution polymerized styrene-butadiene rubber (SSBR) molecular chain undergo epoxidation reaction in an organic phase to obtain the epoxidized solution polymerized styrene-butadiene rubber. Epoxy groups introduced into SSBR have relatively strong reaction activity and can improve the polarity of the SSBR molecular chain, enhance the interaction between the SSBR molecular chain and the packing and improve the compatibility between an SSBR rubber matrix and a reinforcing agent.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

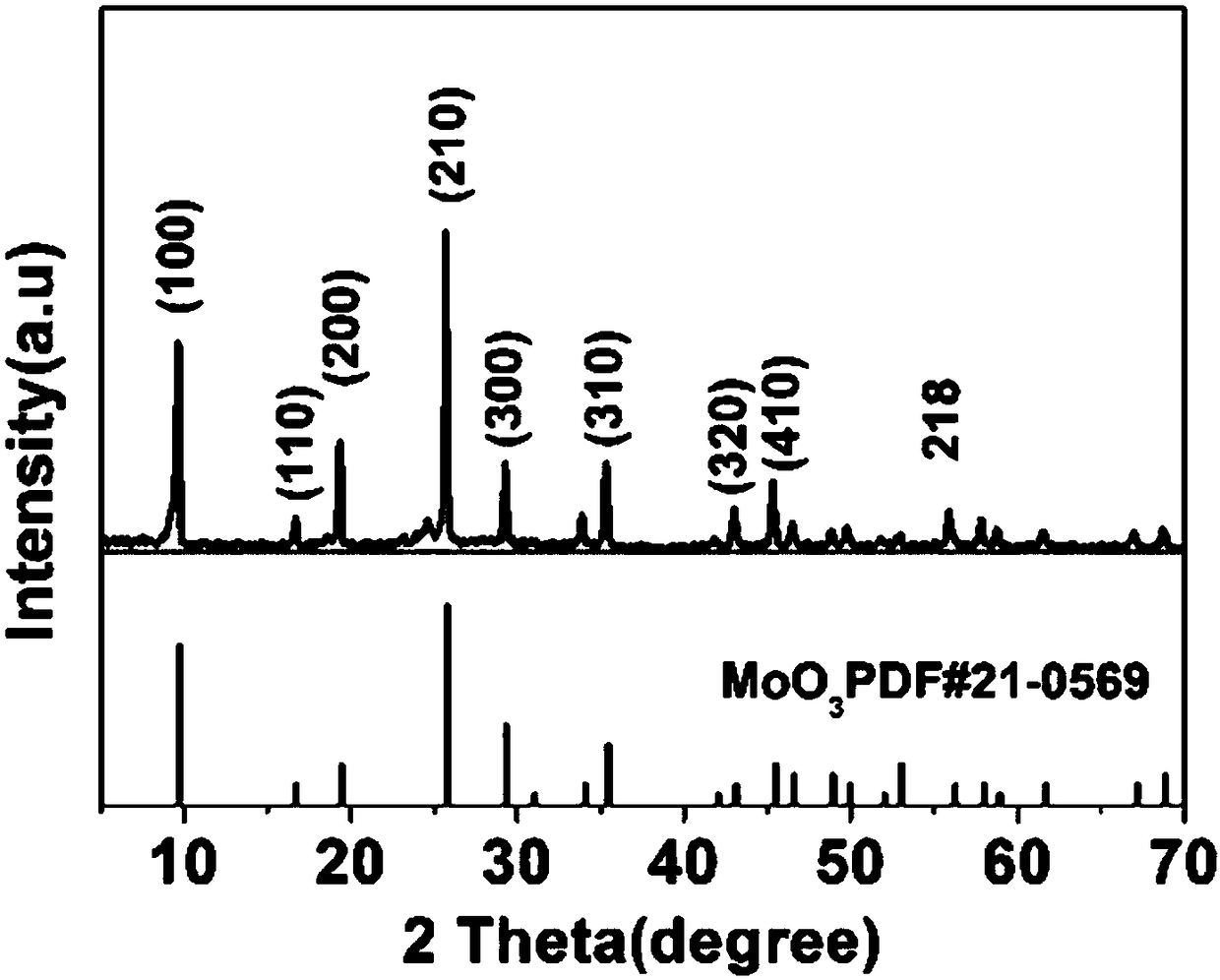

MoO3 composite carbon-dot lithium-ion battery anode material and preparation method thereof

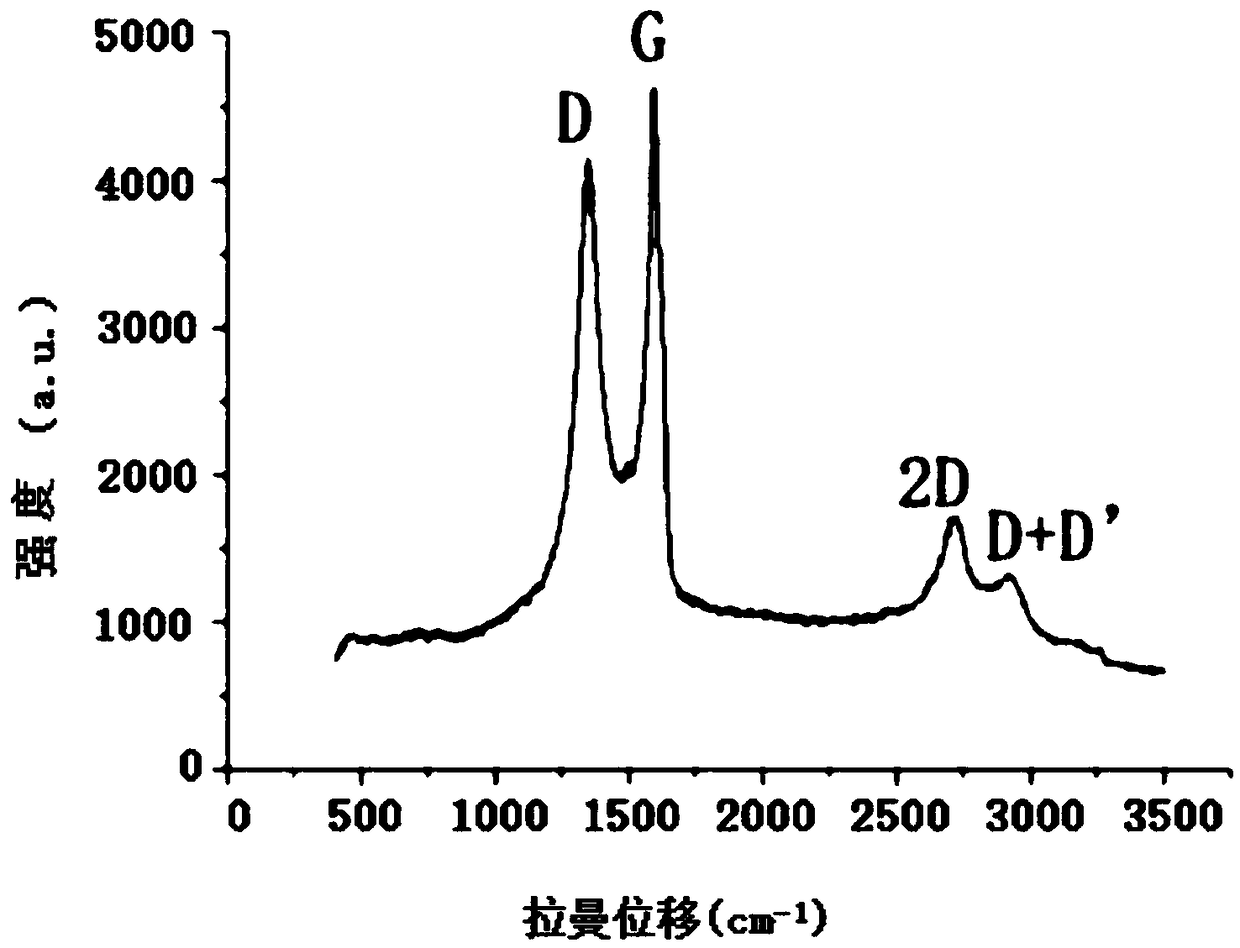

ActiveCN109301231AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsPerformic acidPeroxyformic acid

The invention discloses MoO3 composite carbon-dot lithium-ion battery anode material and a preparation method thereof. Ammonium molybdate is used as a material composite carbon dot to obtain a high-performance lithium-ion battery anode material; performic acid is used as an oxide to strip coal tar pitch to prepare a carbon dot, ammonium molybdate is then subjected as a raw material to the preparation of the MoO3 composite carbon-dot lithium-ion battery anode material by means of a hydrothermal process by using the carbon dot to induce oriented growth of molybdenum trioxide. The preparation method has the advantages of simplicity, short period, low energy consumption, good repeatability, high yield and the like; MoO3 composite prepared herein can relieve volumetric expansion and increase ion activated surface area, thereby increasing the specific capacity and cycle stability of a lithium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH +1

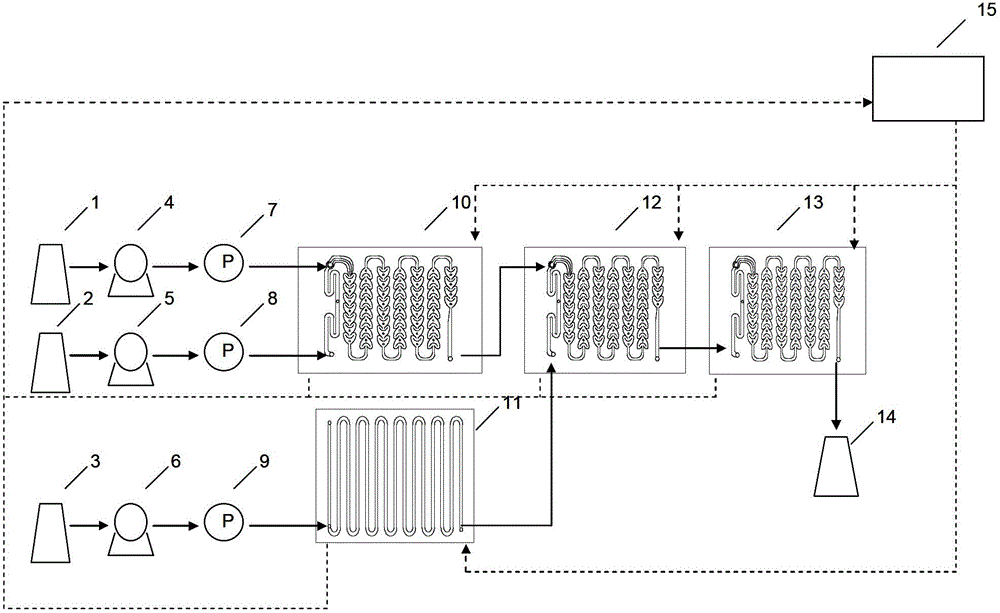

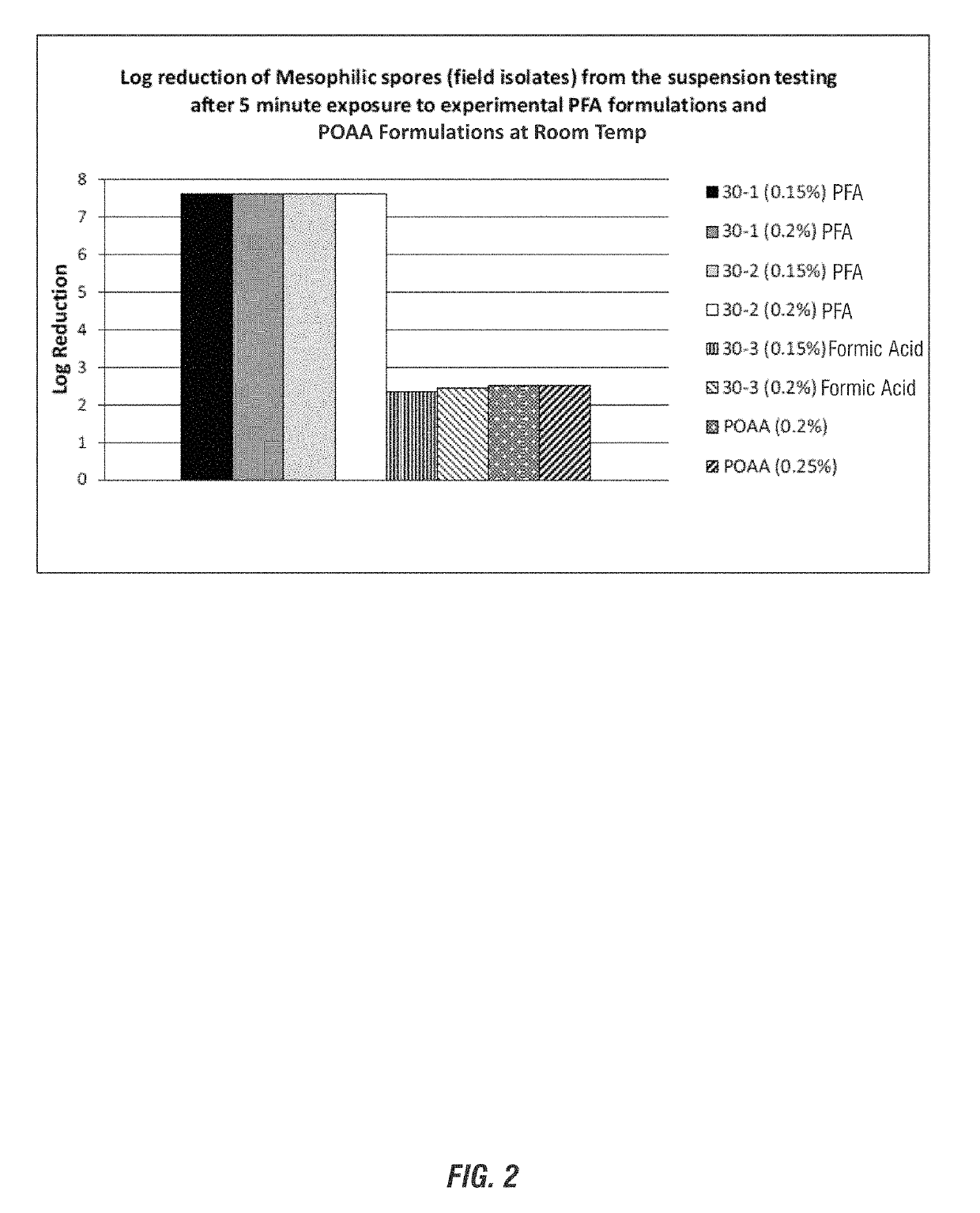

Performic acid on-site generator and formulator

Methods of generating performic acid by contacting aqueous oxidizing agent and aqueous formic acid source in liquid phase are disclosed. A system and apparatus for the in situ production of the performic acid chemistries is further disclosed. In particular, a continuous flow reactor is provided to generate performic acid at variable rates. Methods of employing the oxidizing biocide for various disinfection applications are also disclosed.

Owner:ECOLAB USA INC

Performic acid biofilm prevention for industrial CO2 scrubbers

Owner:ECOLAB USA INC

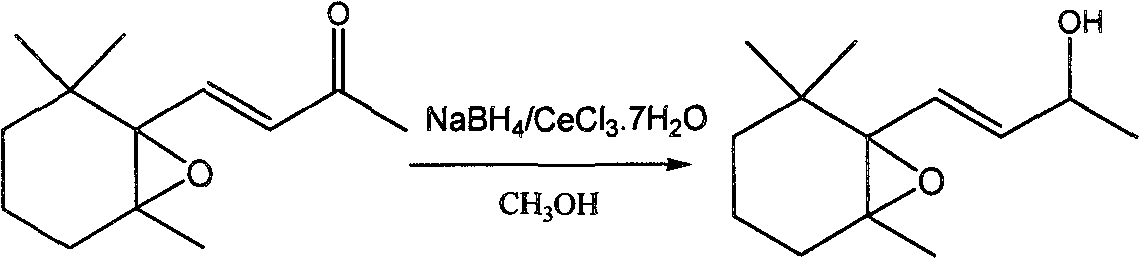

Preparation method of 5,6-epoxy-5,6-dihydro-beta-ionol

The invention provides a preparation method of 5,6-epoxy-5,6-dihydro-beta-ionol, comprising the following steps of: selectively reducing carbonyl in 5,6-epoxy-5,6-dihydro-beta-irisone used as raw material by using NaBH4 and CeCl3.7H2O, and synthesizing to obtain the 5,6-epoxy-5,6-dihydro-beta-ionol, wherein the yield reaches 87.8-91.84 percent. The purity is higher than 95.00 percent by silicagel column separation. Compared with a preparation method reported in the literature of carrying out the epoxidation reaction of beta-ionol by using m-chlorobenzene performic acid in sodium bicarbonate and methylene dichloride at room temperature to obtain the 5,6-epoxy-5,6-dihydro-beta-ionol, the reaction time is greatly shortened, and the yield is obviously increased.

Owner:SHANGHAI INST OF TECH

Protein regeneration composite fiber spinning solution and production method thereof

InactiveCN103388194AStrong color fastnessLow priceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyvinyl alcoholPotassium bisulfite

The invention relates to a regeneration animal-plant double-protein composite fiber spinning solution and a production method thereof. The protein regeneration composite fiber spinning solution includes an animal protein and / or a plant protein, the animal protein is sericin protein obtained by processing of reeling silk leftovers, and the plant protein is a protein obtained by extraction of multiploid locust leaves. The protein regeneration composite fiber spinning solution also includes the following components by weight: 0-40 parts of the animal sericin protein, 0-40 parts of the plant polyploid locust leaf protein, 58.6-74.4 parts of polyvinyl alcohol, 0.3-0.8 part of potassium sulfite or potassium bisulfite and 0.3-0.8 part of hydrogen peroxide, performic acid or peracetic acid; and then the composite spinning solution with the viscosity of 800-1200 centipoises is obtained by adding water and sodium hydroxide for copolymerization. According to the regeneration animal-plant double-protein composite fiber spinning solution and the production method thereof, the cost of fiber is reduced, the quality of products is improved, and the problems of chromaticity, color fastness, resistance to hot water and boiling water shrinkage of the fiber are solved.

Owner:郭洁清 +1

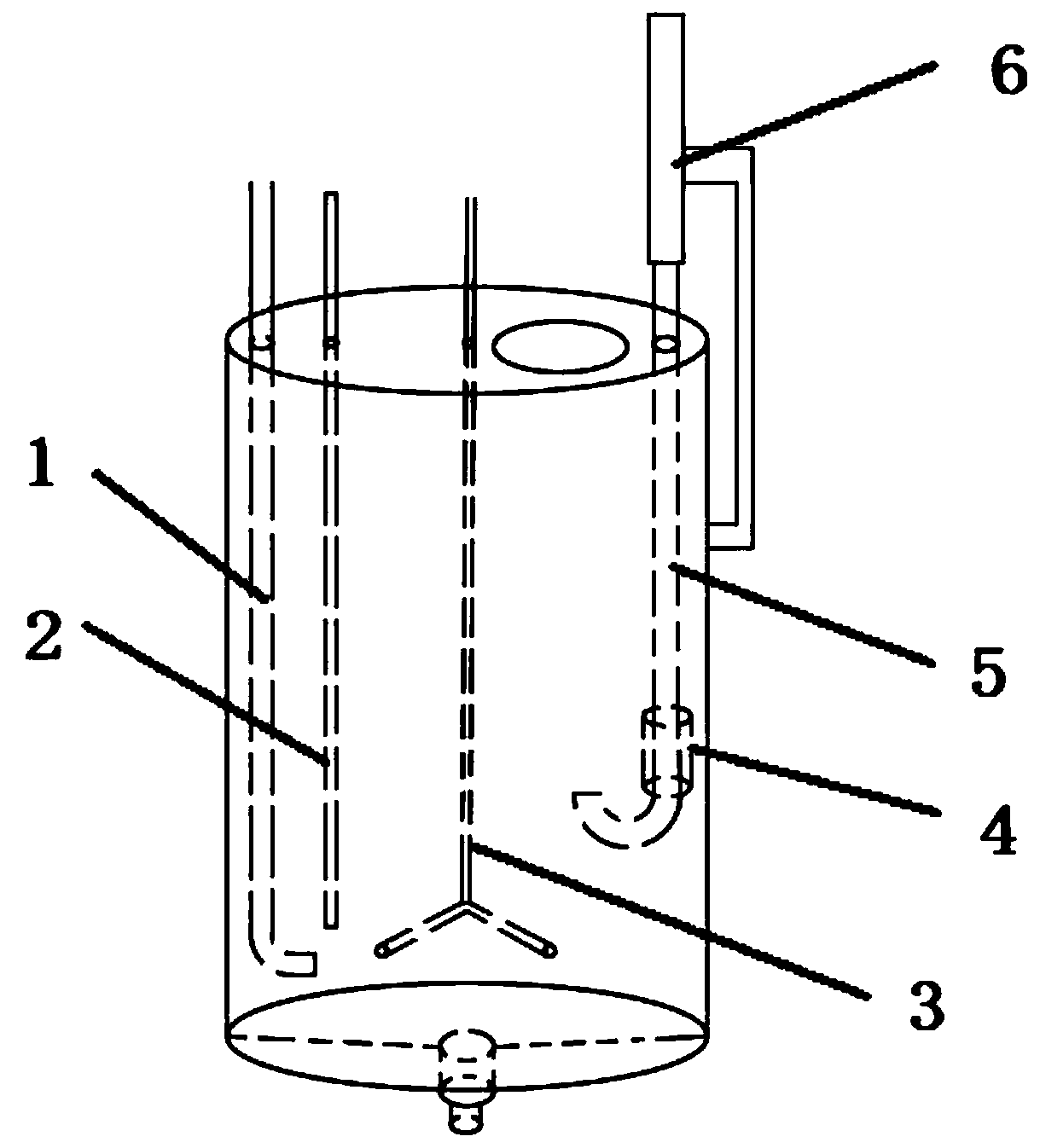

Grease epoxidation reactor

PendingCN108273452ARemove in timeEfficient mass transferOrganic chemistryLiquid-liquid reaction processesOil and greaseEngineering

The invention discloses a grease epoxidation reactor. The grease epoxidation reactor mainly comprises a reaction kettle, a circulating pump, a cavitator and a static mixing type heat exchanger. The grease epoxidation reactor is characterized in that initial microscopic mixing of an oil phase and a water phase is realized by the cavitator; the reaction kettle adopts an upper-lower overflowing structure, liquid passing through the static mixing type heat exchanger enters the reaction kettle by a liquid distributor, and liquid flowing out of the liquid distributor can maintain a mixed state stillin the middle area of the reaction kettle; after the auxiliary-reaction part, the oil phase and the water phase are gathered and layered into an upper part and a lower part, and the water phase can enrich peroxyformic acid; the water phase with the lower part enriching the peroxyformic acid and the upper-part oil phase enter next reaction cycle again by the cavitator. The grease epoxidation reactor disclosed by the invention has the beneficial effects that the microscopic mixing of the oil phase and the water phase is realized by the cavitator, a good mixing state of the oil and the water ismaintained by the static mixing type heat exchanger and the reaction kettle with the upper-lower overflowing structure, the heat generated in reaction can be removed in time, simultaneously, good masstransfer and good heat transfer are realized simultaneously and the requirement of industrial capacity is met.

Owner:ZHEJIANG UNIV OF TECH

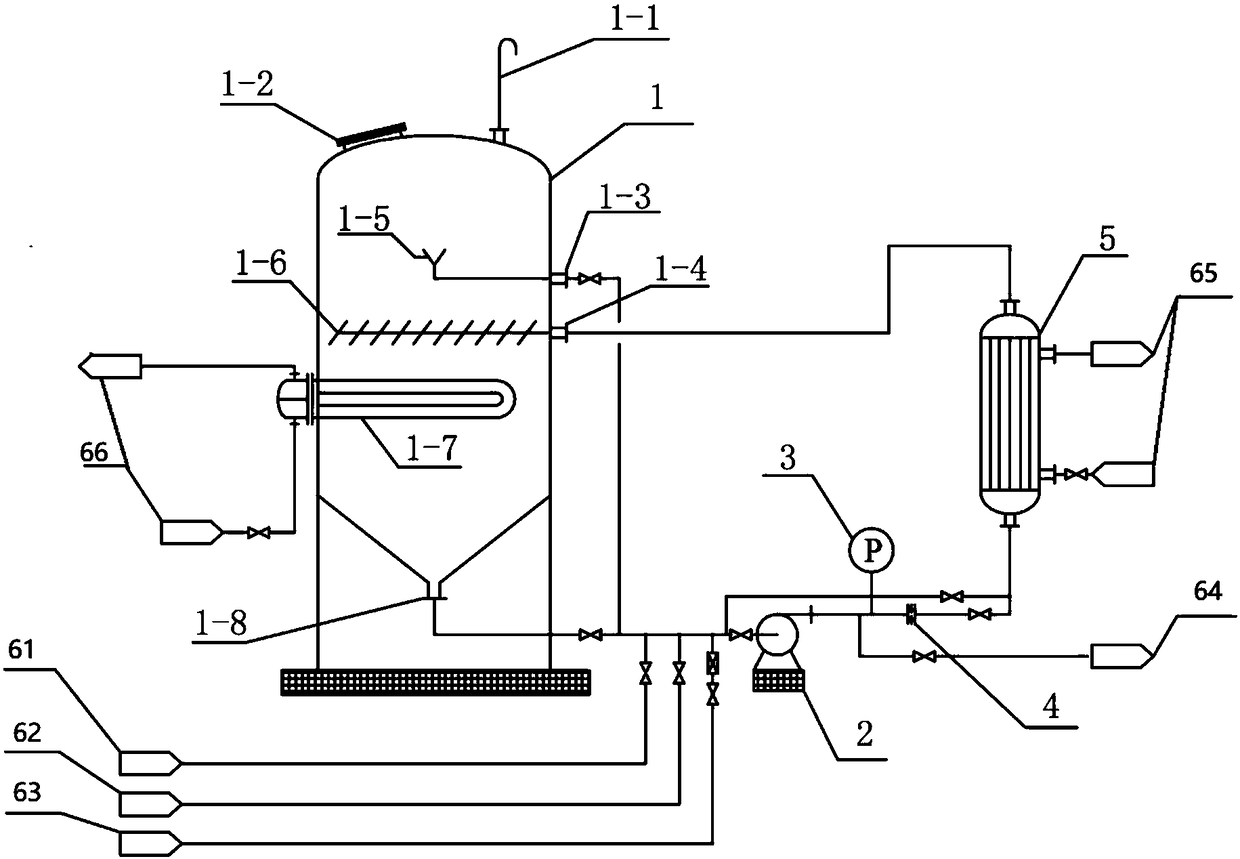

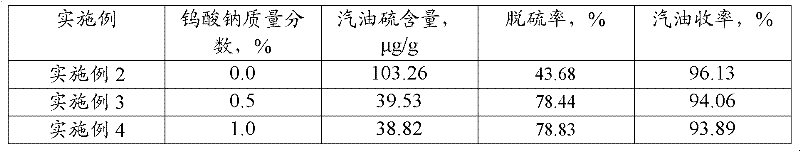

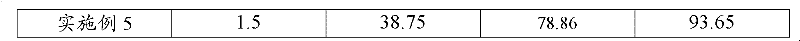

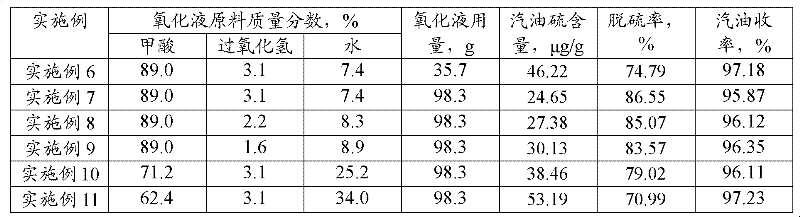

Method of peroxyformic acid of gasoline oxidation extraction and desulfurization

InactiveCN102311779AImprove desulfurization effectTreatment with plural serial refining stagesGasolineSolvent

The invention provides a method of peroxyformic acid of gasoline oxidation extraction and desulfurization. The method comprises the following steps: adding a tungstic acid oxidation catalyst or a tungstate oxidation catalyst into a mixed solution of formic acid and hydrogen peroxide, preparing an oxidation solution of peroxyformic acid; performing an oxidation treatment to the gasoline by the oxidation solution under the mild condition, then washing the gasoline by water to obtain the oxidized gasoline; then, extracting the oxidized gasoline by the extraction solvent, and washing the gasoline by water again to realize the desulphurization of gasoline. The invention has the characteristics of simple and feasible process, high gasoline desulfurization rate, high gasoline yield and the like.

Owner:ZHEJIANG UNIV OF TECH

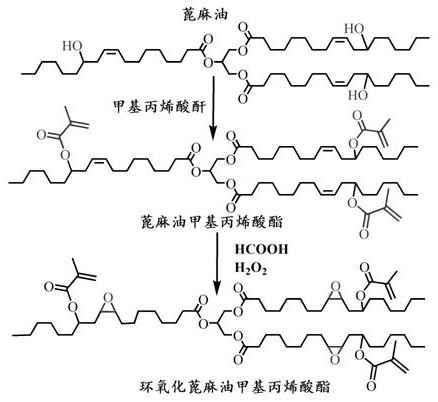

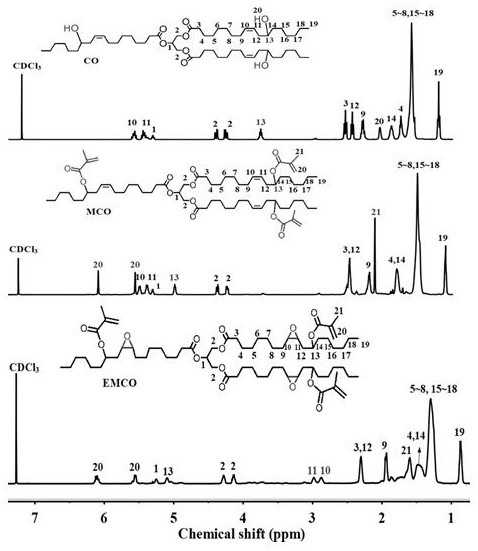

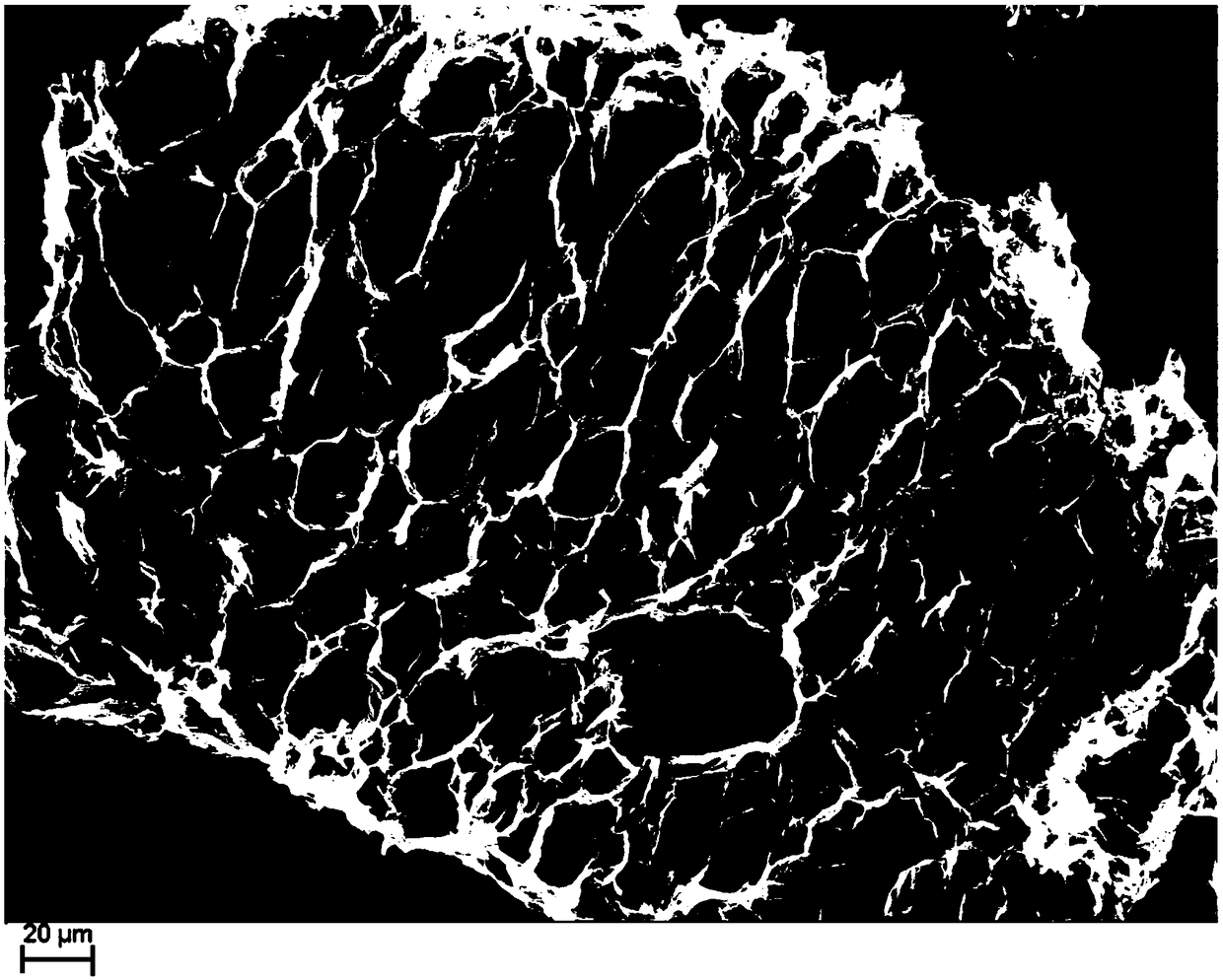

Recyclable castor oil-based unsaturated polyester Vitrimer material based on dynamic disulfide bond and preparation method of recyclable castor oil-based unsaturated polyester Vitrimer material

The invention provides a recyclable castor oil-based unsaturated polyester Vitrimer material based on dynamic disulfide bonds and a preparation method thereof. The preparation method comprises the following steps: firstly, synthesizing castor oil-based unsaturated polyester matrix resin from natural and renewable castor oil through a two-step method of methacrylic anhydride esterification and peroxyformic acid epoxidation; and allowing the castor oil-based unsaturated polyester Vitrimer material and a curing agent containing reversible dynamic disulfide bonds to be subjected to an epoxy ring-opening reaction by adopting a gradient curing strategy to obtain the castor oil-based unsaturated polyester Vitrimer material containing the dynamic disulfide bonds. The obtained material has sustainable cyclic utilization and excellent mechanical properties; and the problems that a traditional petroleum-based unsaturated polyester material cannot be recycled and raw materials are derived from non-renewable petroleum resources are solved, and the method has important significance on sustainable utilization of a thermosetting high polymer material.

Owner:SHAANXI UNIV OF SCI & TECH

Clean pulping catalyst and application technology thereof

InactiveCN108130771ASafe and Effective Tea BrewingSafe and effective methodPulp beating/refining methodsNon-woody plant/crop pulpSulfite saltPapermaking

The invention discloses a clean pulping catalyst and an application technology thereof. The clean pulping catalyst comprises 85% of pulping raw materials, 9% of catalytic solvent, 5% of solid catalyzer and 1% of preservative. The catalytic solvent is a mixed solution by mixing one aqueous solution of NaOH, KOH, Ca(OH)2, Na2CO3, K2CO3, NaHCO3, KHCO3 and Na2SiO3, of which the weight percentage concentration is 5-30% with an EDTA aqueous solution with the weight percentage concentration of 1-10% according to the weight ratio of 1:1; the solid catalyzer comprises an oxygen stabilizer and an additive, and the oxygen stabilizer comprises a mixture of one or two or more kinds of DMD, hydrogen peroxide, performic acid, peracetic acid, perpropionic acid, ozone, MgSO4 and MgC12 according to a randomproportion; the additive comprises ferrous sulfate and sodium sulfite. According to the technology, no waste medicine liquid is discharged, no waste water is discharged, and the technology is beneficial to environmental protection and has high innovation value in the papermaking industry.

Owner:QILU UNIV OF TECH

Preparation method of graphite oxide capable of being washed directly

The invention provides a preparation method of graphite oxide capable of being washed directly. The preparation method comprises the following steps that step one, crystalline flake graphite is takenas a raw material, a main intercalator and an auxiliary intercalator are added for intercalation treatment to obtain a graphite intercalation compound; the main intercalator is at least one of formicacid, acetic acid, phosphoric acid, concentrated nitric acid and concentrated sulfuric acid; the auxiliary intercalator is at least one of an aqueous hydrogen peroxide solution, performic acid and peracetic acid; step two, after redundant main intercalator and auxiliary intercalator of the graphite intercalation compound are filtered out, the filtered graphite intercalation compound is put into ice water, tiny impurity particles and water are filtered and washed off with a sieve, and the graphite intercalation compound with less impurities is obtained; step three, an oxidizing agent is added in the filtered graphite intercalation compound, oxidation is carried out for 0.5-50 hours under the condition of 0-45 DEG C, and the graphite oxide of which a PH value is 0-1 and capable of being washed directly by the water is obtained. By the method, the volume of the raw material is swelled to 300 times to 500 times or above.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

Epoxidized hydroxyl-terminated polybutadiene liquid rubber

InactiveCN108102009AGood mechanical propertiesImprove mechanical propertiesPolymer scienceHydroxyl-terminated polybutadiene

The invention relates to epoxidized hydroxyl-terminated polybutadiene liquid rubber and belongs to the technical field of rubber. The epoxidized hydroxyl-terminated polybutadiene liquid rubber is prepared from the following raw materials in parts by weight: 50-60 parts of hydroxyl-terminated polybutadiene, 150-200 parts of hydrogen peroxide, 30-50 parts of formic acid, 50-60 parts of methyl ethylketone, 3-5 parts of sodium sulfamate and 800-1000 parts of deionized water. The epoxidized hydroxyl-terminated polybutadiene liquid rubber has the beneficial effects that epoxidizing modification canbe carried out on hydroxyl-terminated polybutadiene liquid rubber (HTPB) by adopting a peroxyformic acid in-situ method for all the raw materials so as to prepare the epoxidized hydroxyl-terminated polybutadiene liquid rubber with excellent mechanical property.

Owner:CHENGDU JINHUI TECH

Production method of epoxidized soybean oil

ActiveCN109535104AReduce dosageReduce processing burdenOrganic chemistryState of artSynthesis methods

The invention discloses a production method of epoxidized soybean oil. The invention adopts a two-step synthesis method, and the method includes the steps of: (1) adding hydrogen peroxide, formic acidand a catalyst into a high-pressure reaction kettle, conducting stirring and cooling to obtain peroxyformic acid; (2) adding soybean oil dropwise into the peroxyformic acid obtained by step (1), introducing oxygen, performing stirring and carrying out pressurizing reaction to obtain a crude epoxidized soybean oil product; and (3) conducting alkali washing, water scrubbing and reduced pressure distillation on the crude epoxidized soybean oil product obtained by step (2) to obtain an epoxidized soybean oil finished product. Compared with the prior art, the method provided by the invention has the advantages of low cost, good reaction temperature controllability, fast reaction speed and few by-product, and the obtained product has good quality.

Owner:广东宏力达合成材料科技有限公司

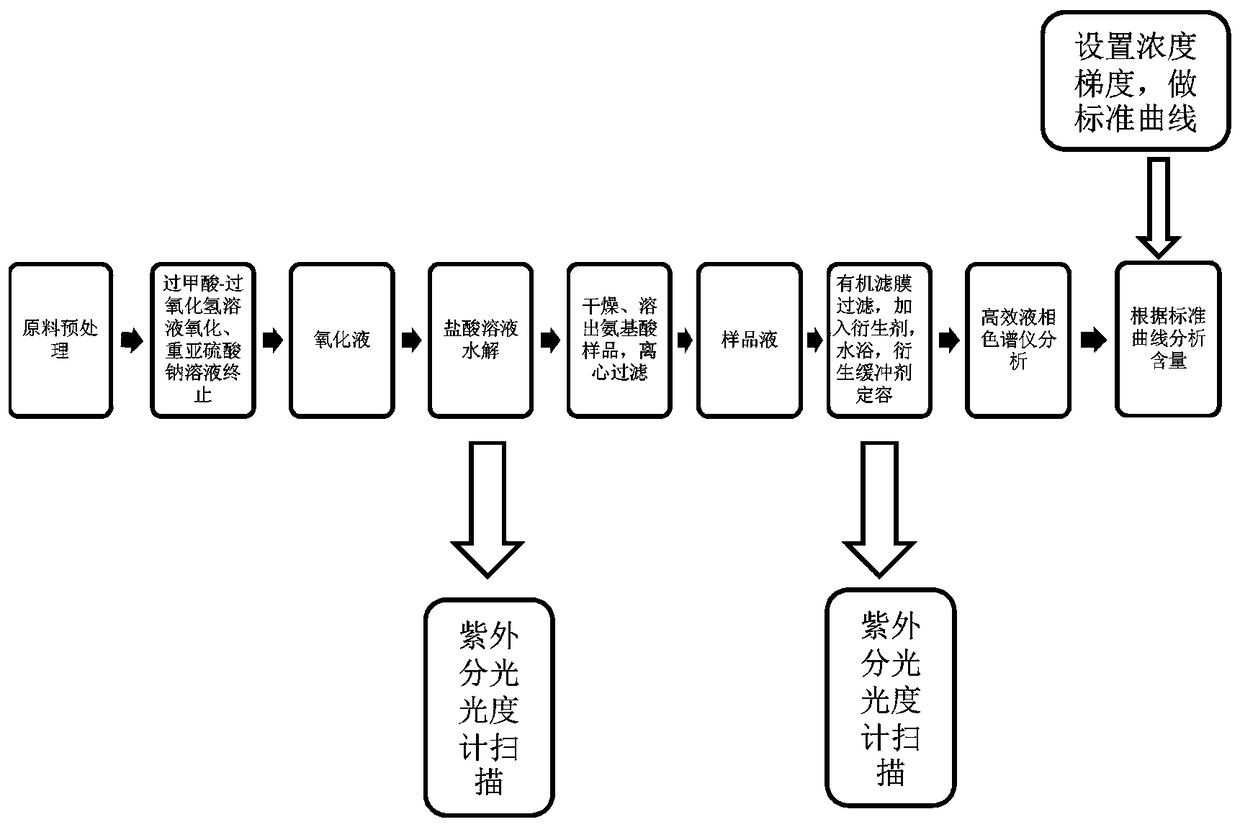

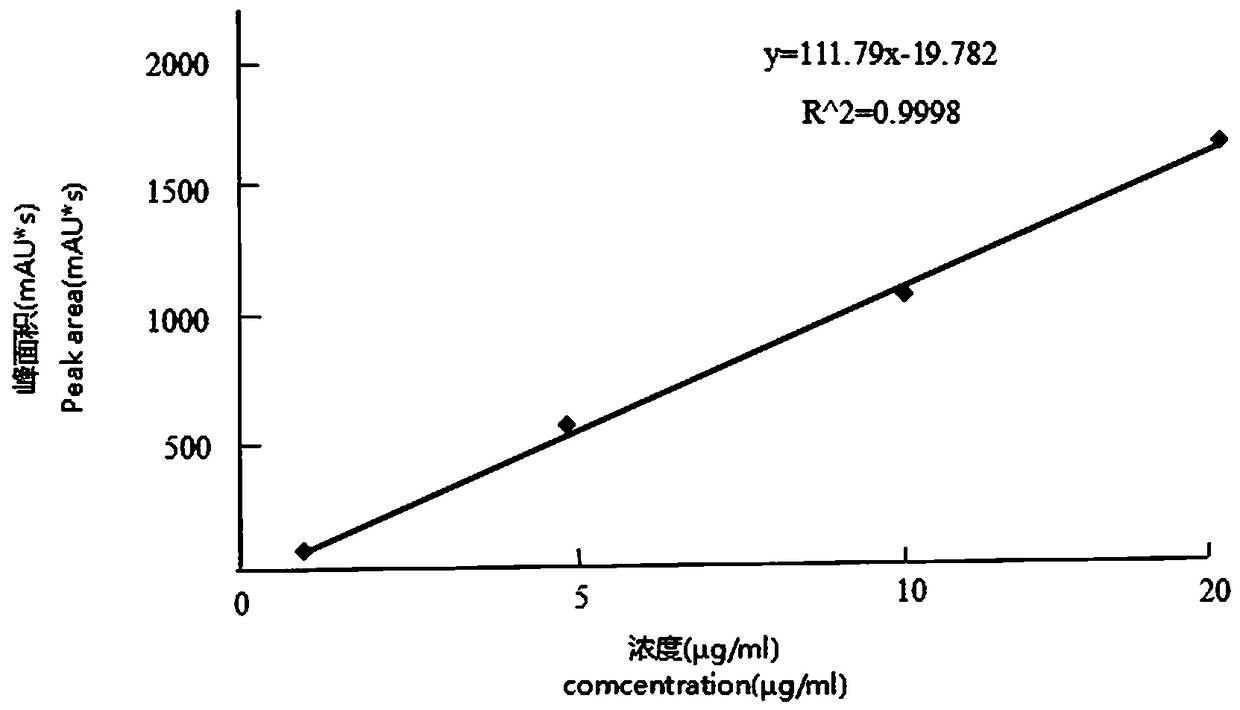

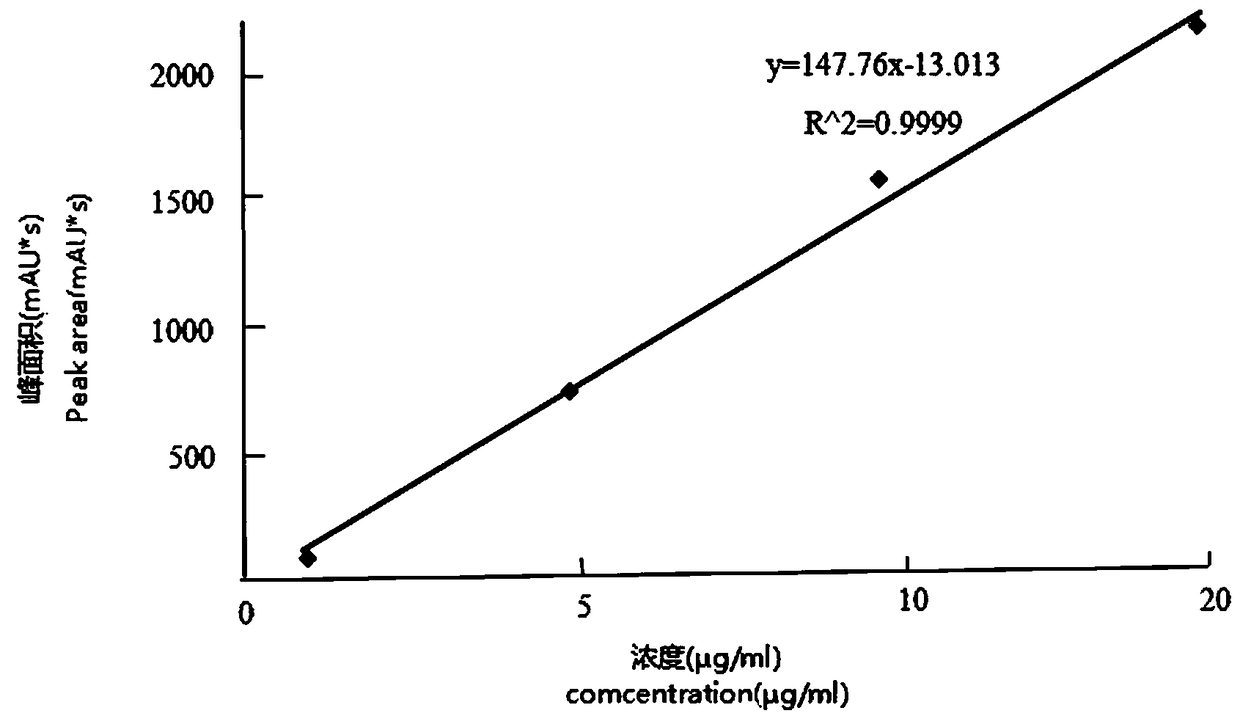

Method for measuring sulfur-containing amino acid content of Astragali mushroom

InactiveCN109164191AReduce distractionsEfficient methodComponent separationColor/spectral properties measurementsSodium acetateUltrafiltration

The invention discloses a method for measuring the sulfur-containing amino acid content of Astragali mushroom, and relates to the field of measurement of amino acid content of the Astragali mushroom.The method comprises the following steps: performing performic acid oxidation protection on the Astragali mushroom serving as a raw material, performing acid hydrolysis, performing ultrafiltration centrifugation, performing derivatization by taking 2,4-dinitrofluorobenzene as a derivatization reagent, performing gradient elution on the obtained derivative sample liquid through high performance liquid chromatography and by taking acetonitrile-water and sodium acetate as flowing phases, detecting under the wavelength of 360 nm, separating derivatives of cysteic acid and methionine sulfone, measuring the peak area of a cystine standard product and a methionine standard product under different concentration gradient, drawing a standard curve, and measuring the cystin content and the methioninecontent separately to obtain the sulfur-containing amino acid content. According to the method, the requirement on instruments is low, the reaction condition does not need to be strictly limited, thequantity of the needed samples is small, the samples are not damaged, single component can be analyzed, and the method is a measuring method which is efficient, accurate, simple, convenient and easyto operate and low in price.

Owner:LULIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com