Method for preparing epoxidized fatty acid methyl esters in continuous flow microchannel reactor

A technology of epoxy fatty acid methyl ester and microchannel reactor, which is applied in the direction of organic chemistry, etc., can solve the problems of long process time, low epoxy value, difficult safety control, etc., to improve epoxy value, increase conversion rate, The effect of constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

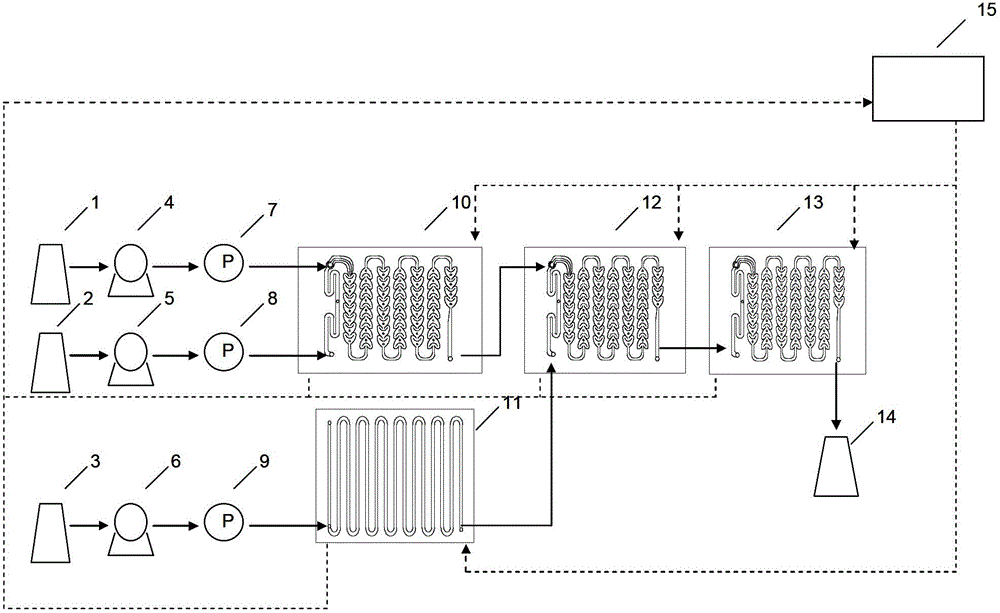

[0029] (1) Device: Corning high-throughput microchannel reactor, the number of straight channel modules is determined according to the number of material stocks, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the module connection method refers to image 3 Make sure that the heat exchange medium is heat transfer oil.

[0030] (2) Catalyst preparation: Accurately weigh 640g of formic acid and 40g of concentrated hydrochloric acid, pour them into a beaker, stir evenly, and seal them for future use.

[0031] (3) Set the volume flow rate ratio of pump 1, pump 2, and pump 3 as formic acid catalyst: fatty acid methyl ester: hydrogen peroxide = 0.5:1:1. After the three materials are preheated and mixed by module 10 and module 11 respectively, they will enter module 12 when used To carry out the reaction, the circulating cooler set the reaction temperature to 42°C, and at this time, the molar ratio of fatty acid methyl es...

Embodiment 2

[0034] (1) Device: Corning high-throughput microchannel reactor, the number of straight channel modules is determined according to the number of material stocks, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the module connection method refers to image 3 Make sure that the heat exchange medium is heat transfer oil.

[0035] (2) Catalyst preparation: Accurately weigh 640g of formic acid and 40g of concentrated hydrochloric acid, pour them into a beaker, stir evenly, and seal them for future use.

[0036] (3) Set the volume flow rate ratio of pump 1, pump 2, and pump 3 as formic acid catalyst: fatty acid methyl ester: hydrogen peroxide = 0.5:1:1.5. After the three materials are preheated and mixed by module 10 and module 11 respectively, they will enter module 12 when used To carry out the reaction, the circulating cooler set the reaction temperature at 42°C, and at this time the molar ratio of fatty acid methyl e...

Embodiment 3

[0039] (1) Device: Corning high-throughput microchannel reactor, the number of straight channel modules is determined according to the number of material stocks, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the module connection method refers to image 3 Make sure that the heat exchange medium is heat transfer oil.

[0040] (2) Catalyst preparation: Accurately weigh 640g of formic acid and 40g of concentrated hydrochloric acid, pour them into a beaker, stir evenly, and seal them for future use.

[0041] (3) Set the volume flow rate ratio of pump 1, pump 2, and pump 3 as formic acid catalyst: fatty acid methyl ester: hydrogen peroxide = 1.0:1:2.5. After the three materials are preheated and mixed by module 10 and module 11 respectively, they will enter module 12 when used To carry out the reaction, set the reaction temperature to 42°C, and the molar ratio of fatty acid methyl ester to hydrogen peroxide is 1:2.5. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com