Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Performic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Performic acid (PFA) is an organic compound with the formula CH₂O₃. It is an unstable colorless liquid which can be produced by mixing formic acid with hydrogen peroxide. Owing to its oxidizing and disinfecting action, it is used in the chemical, medical and food industries.

Compositions and methods of treating edible matter and substrates therefor

There are provided methods of treating edible matter comprising applying a composition comprising performic acid to the edible matter or a substrate therefor. Other embodiments are also disclosed.

Owner:BEN YEHUDA NIMROD

Process for the preparation of peroxy acids

ActiveUS20090221704A1Easy to controlIncrease powerBiocideOrganic compound preparationPeroxy acidCarboxylic acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

Process for the preparation of peroxy acids

ActiveUS8828910B2Easy to controlIncrease powerBiocideOrganic compound preparationCarboxylic acidPeroxy acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

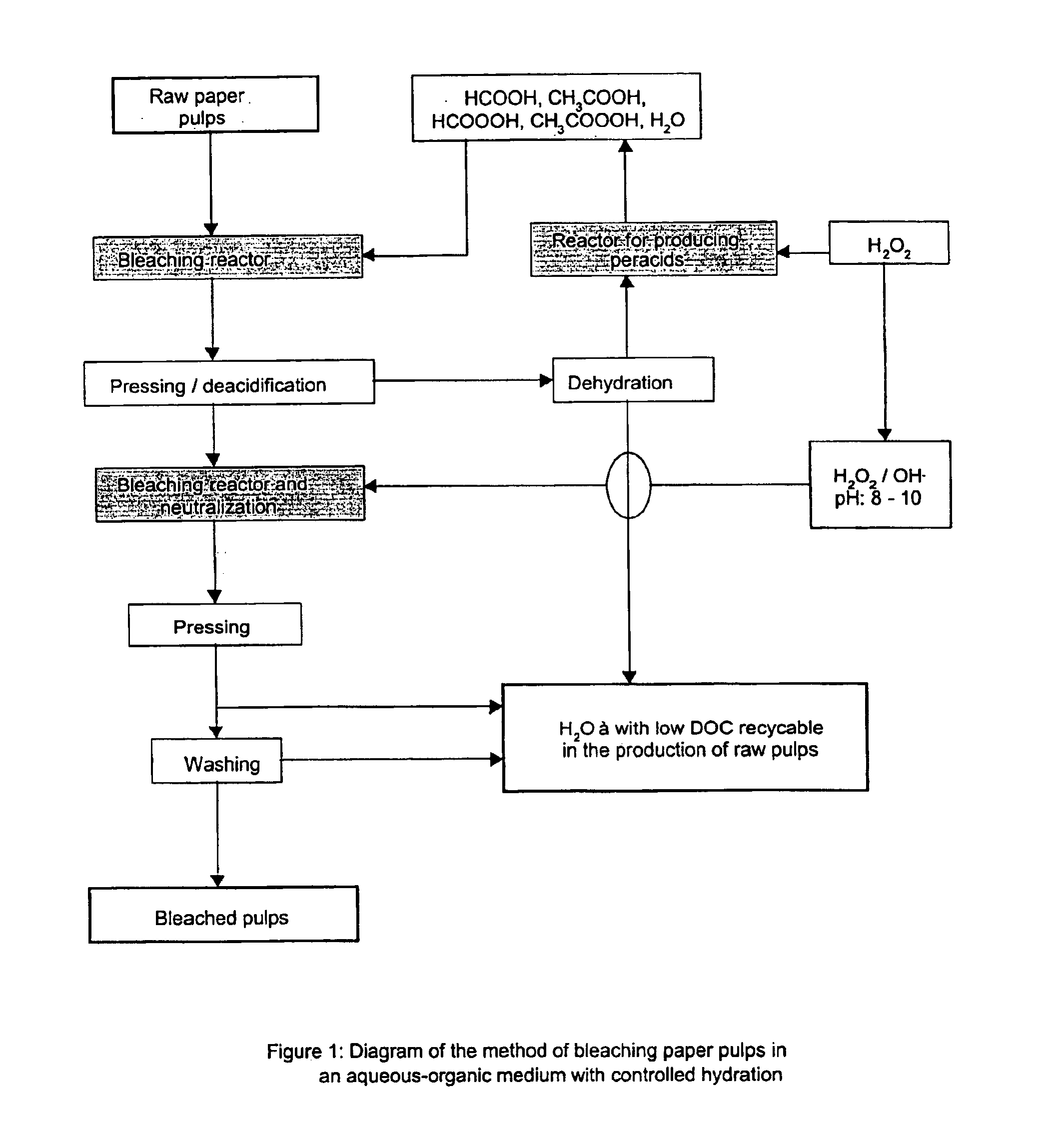

Method for bleaching paper pulp with organic peracids followed by peroxide and sodium hydroxide

InactiveUS6866749B2Stable and neutral and even slightlyReduce trimmingPulp bleachingPulping with organic solventsAcetic acidAtmospheric pressure

The invention concerns a method for bleaching different types of paper pulp in two steps at atmospheric pressure and at a temperature not higher than 100 DEG C. The first step consists in contacting the unbleached paste with a mixture of paracetic acid and performic acid. The second step consists in treating the bleached pulp derived from the first step, with a solution of soda and hydrogen peroxide. The resulting pulps exhibit a high index of whiteness and a degree of polymerisation close to unbleached pulps. The method is environmentally safe and non-polluting.

Owner:CIE IND DE LA MATIERE VEGETALE

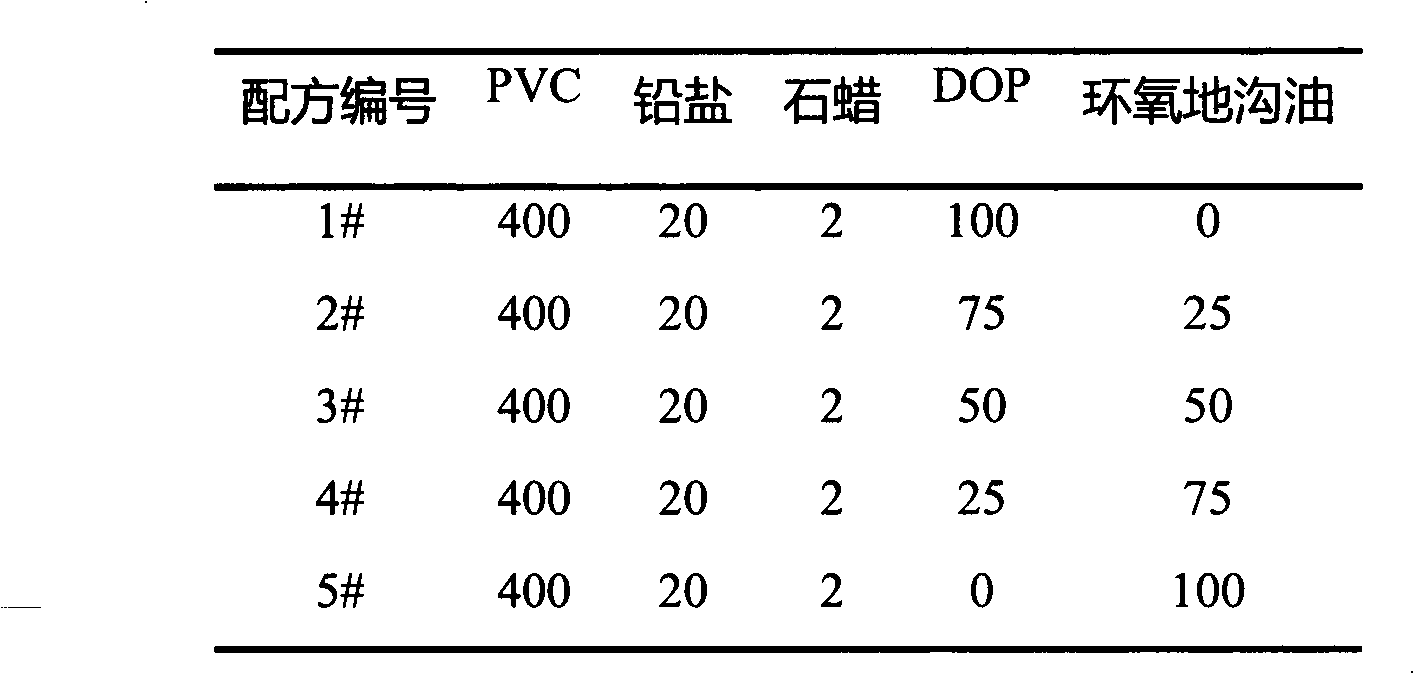

Formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride)

InactiveCN103013675ASimple processLow costFatty oils/acids recovery from wasteFatty acid chemical modificationEpoxyGutter oil

The invention relates to a formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride). In a test, sulfuric acid is taken as a catalyst, hydrogen peroxide is taken as an oxygen supply agent, formic acid is taken as an oxygen receiving agent, and the epoxidation reaction conditions of gutter oil are researched in one step by adopting performic acid. The method is suitable for industrial popularization and application. Therefore, the optimal processing formula of the epoxy gutter oil plasticized PVC is designed by taking the epoxy gutter oil as a plasticizer in the PVC production process instead of the conventional dioctyl phthalate.

Owner:SHIHEZI UNIVERSITY

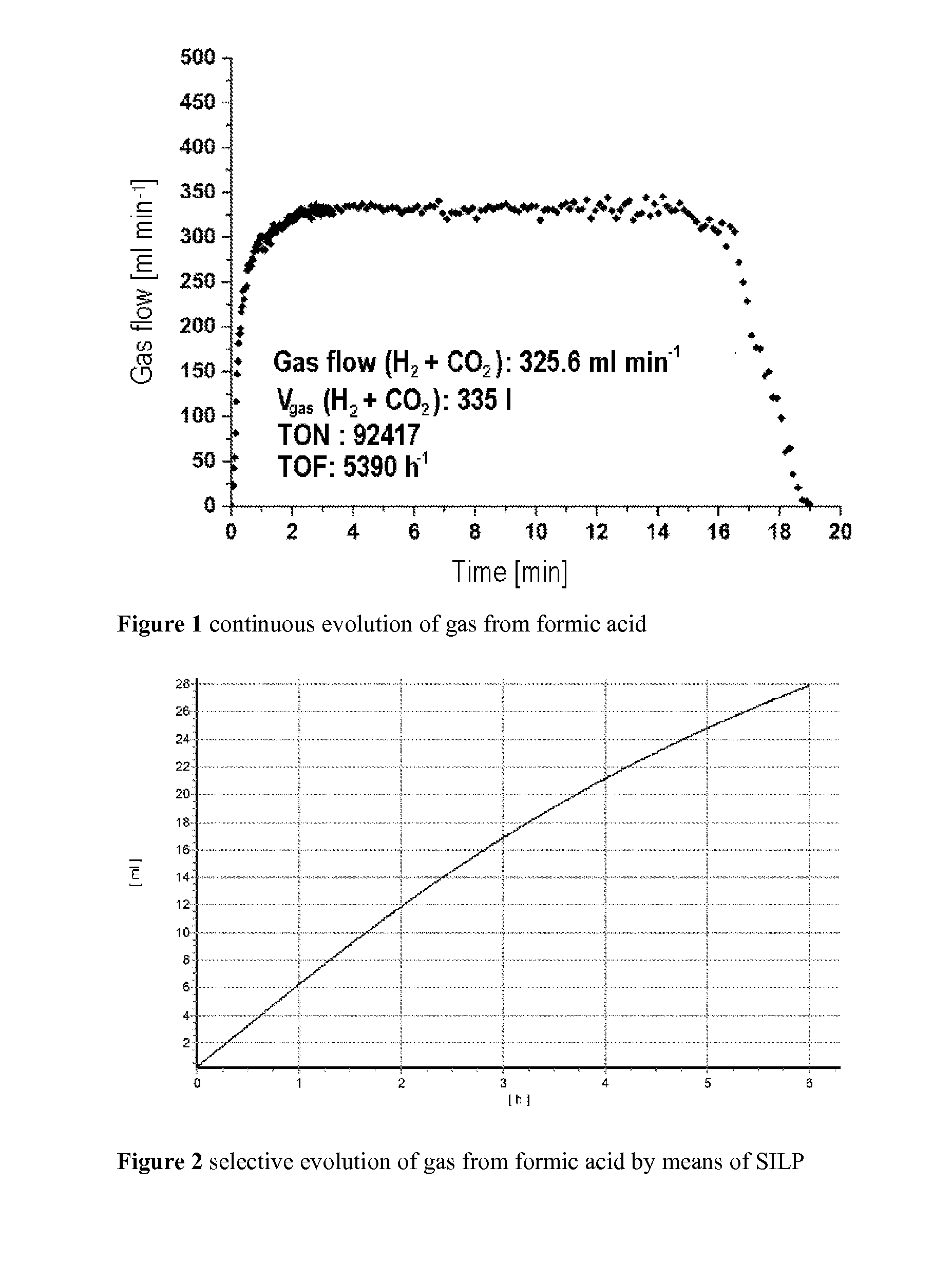

Method for obtaining hydrogen by catalytic decomposition of formic acid

InactiveUS20140255296A1Hydrogen productionHydrogen/synthetic gas productionHydrogenCatalytic decomposition

The invention relates to a method for producing hydrogen by selective dehydration of formic acid using a catalytic system consisting of a transition metal complex of transition metal salt and at least one tripodal, tetradentate ligand, wherein the transition metal is selected from the group comprising Ir, Pd, Pt, Ru, Rh, Co and Fe. The transition metal complex can be used either as a homogeneous catalyst or a heterogenised metal complex, which has been applied to a carrier.

Owner:BAYER TECH SERVICES GMBH

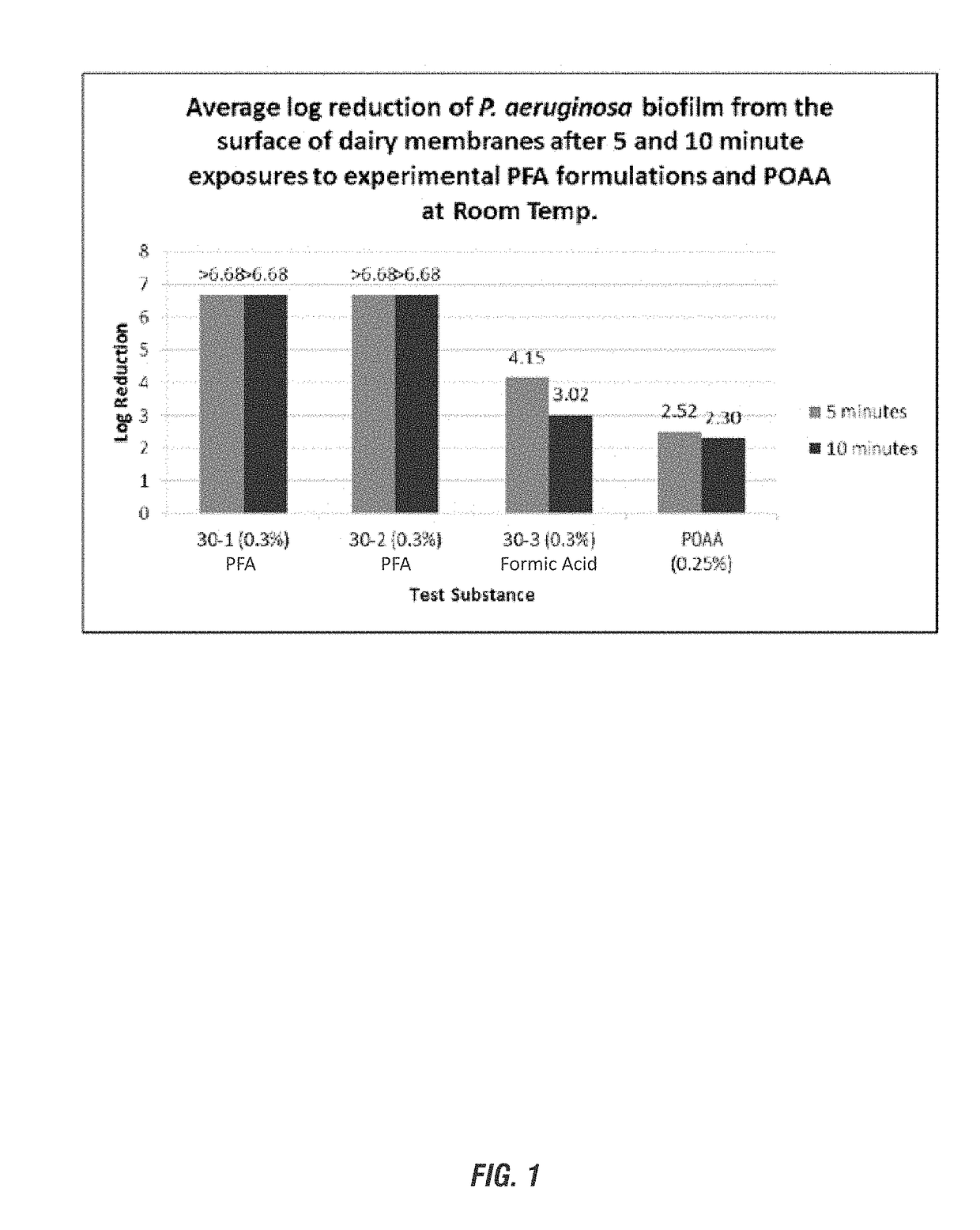

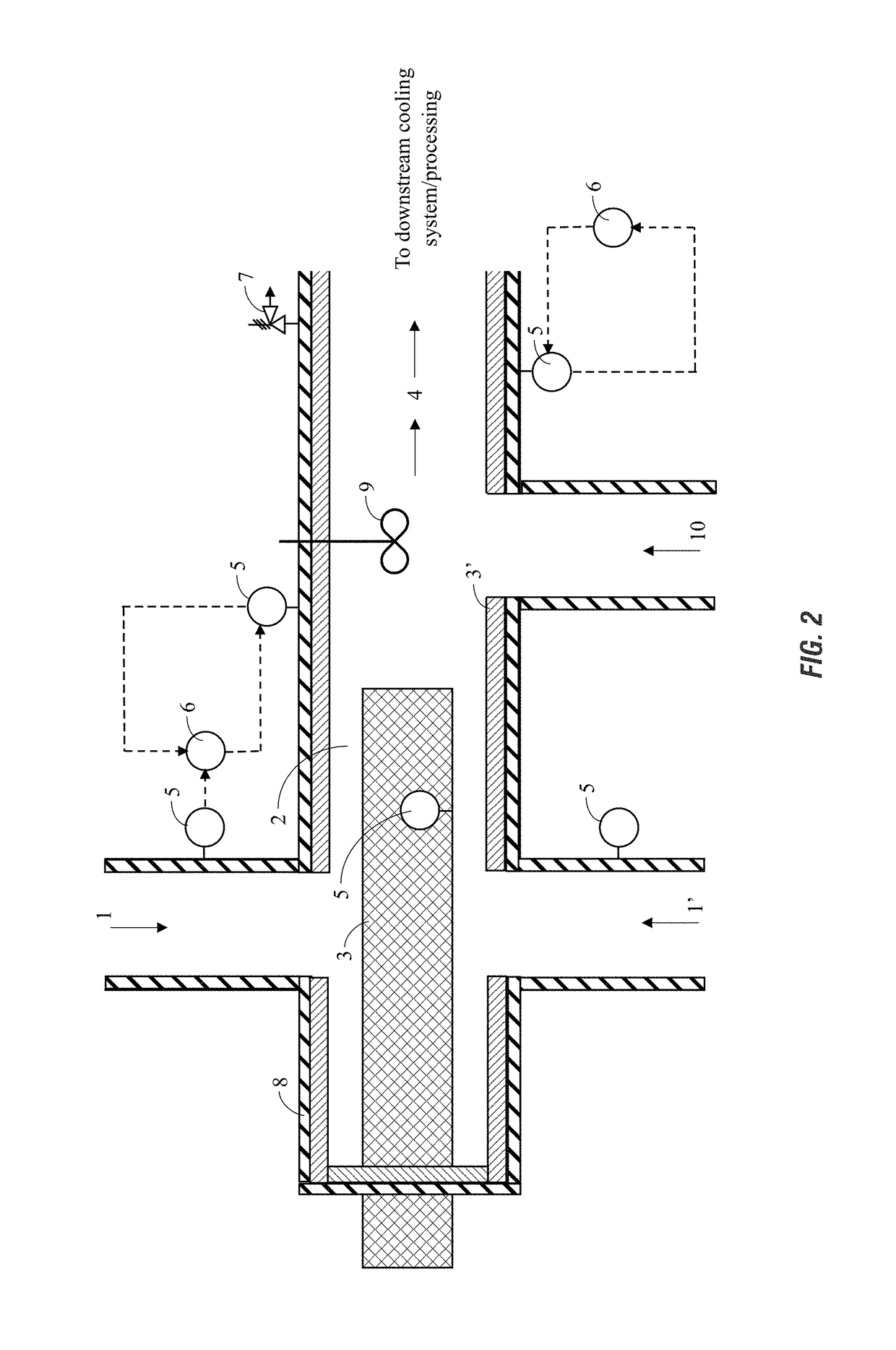

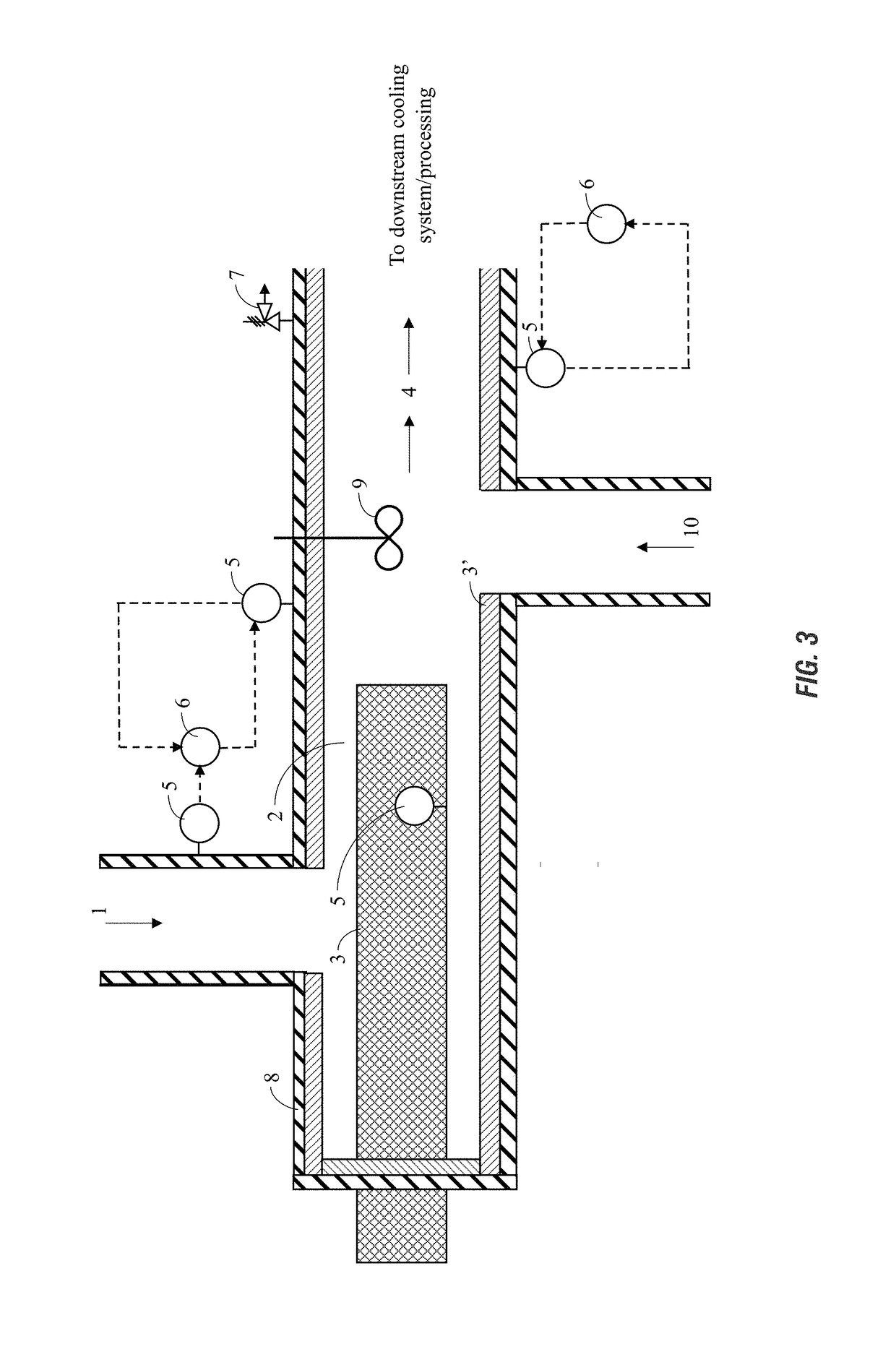

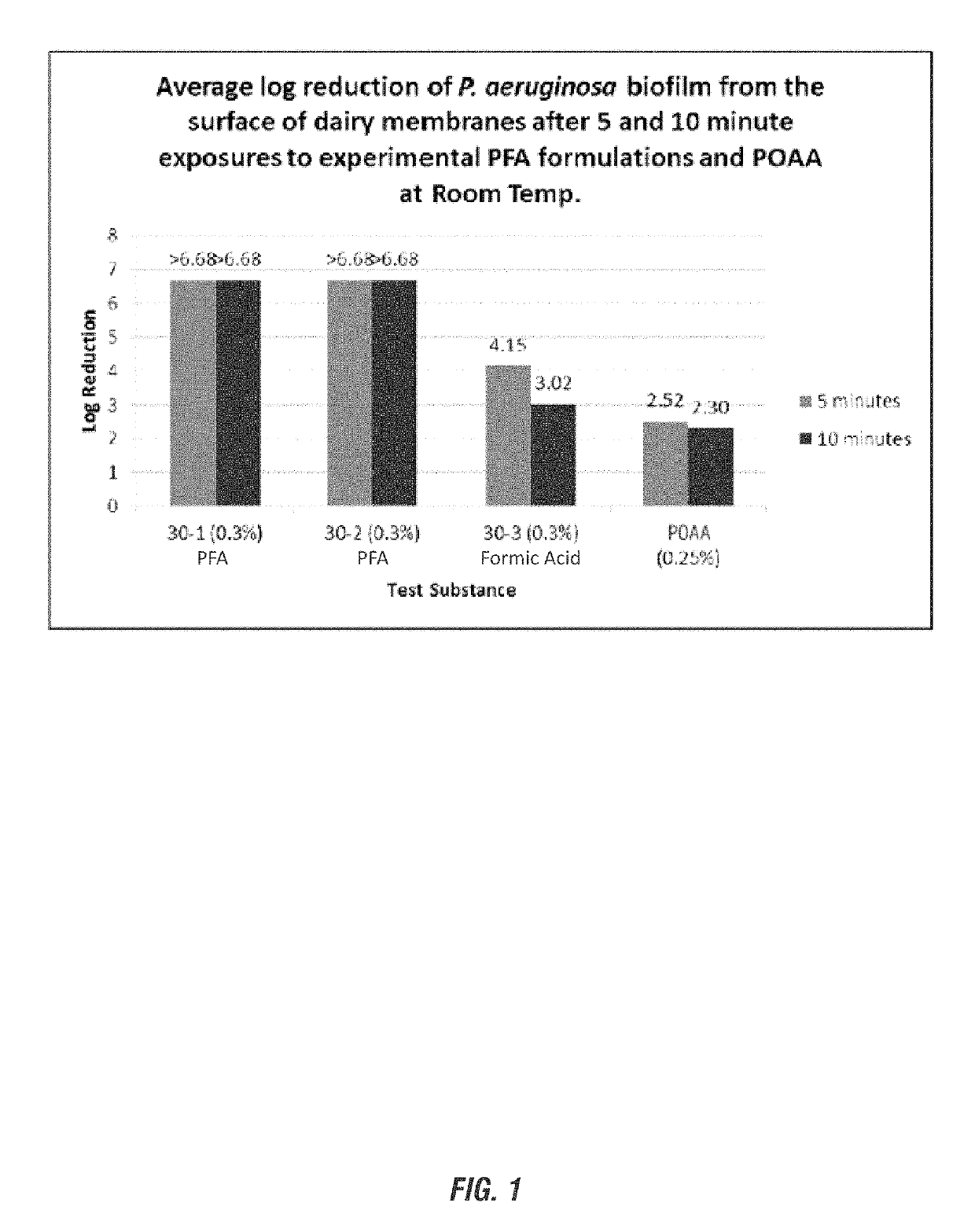

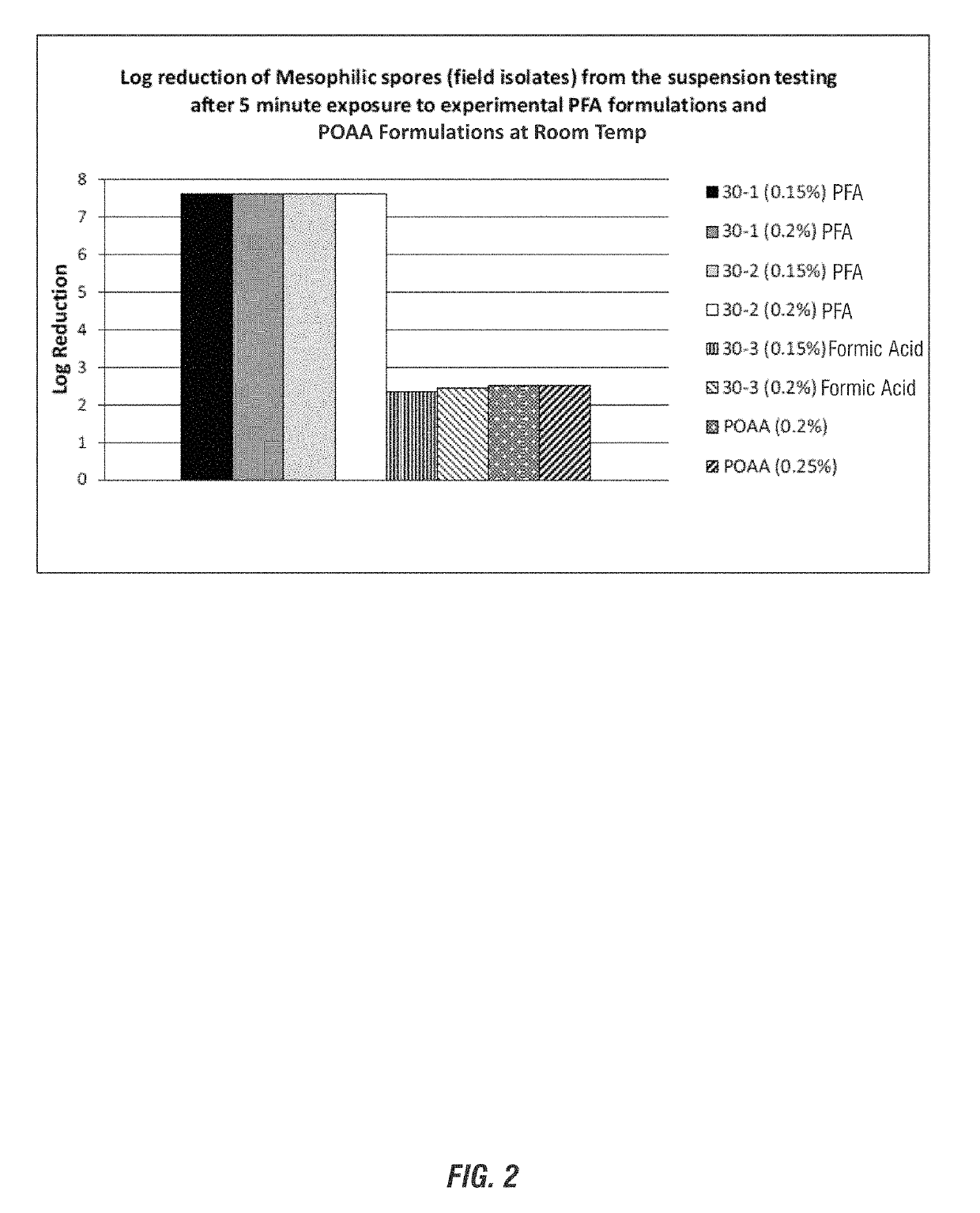

Performic acid biofilm prevention for industrial co2 scrubbers

ActiveUS20170295784A1Broaden applicationExtension of timeBiocideAnimal repellantsAlcoholBiofilm growth

Peroxyformic acid compositions for removal of biofilm growth and other contaminants and impurities from industrial processing hard surfaces are disclosed. In particular, peroxyformic acid compositions may be dosed on site and / or generated in situ for the reduction and prevention of biofilms on the hard surfaces. Methods of employing the peroxyformic acid compositions for removal of biofilm growth and other impurities such as aldehydes and alcohols from industrial CO2 effluent are also disclosed which beneficially provide ambient biofilm control and break down more rapidly than other peracids, allowing for extended runs between CIP cleaning, including a reduction and / or elimination of cleaning of the scrubbers and other industrial surfaces.

Owner:ECOLAB USA INC

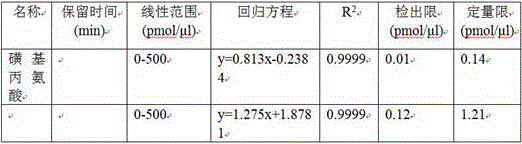

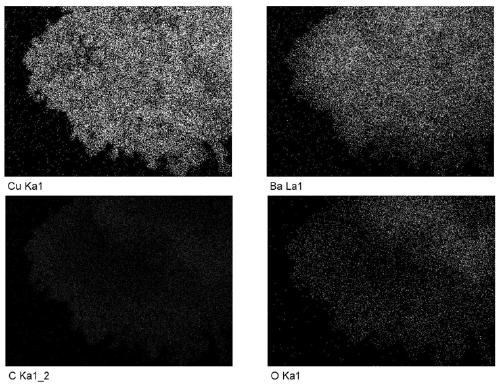

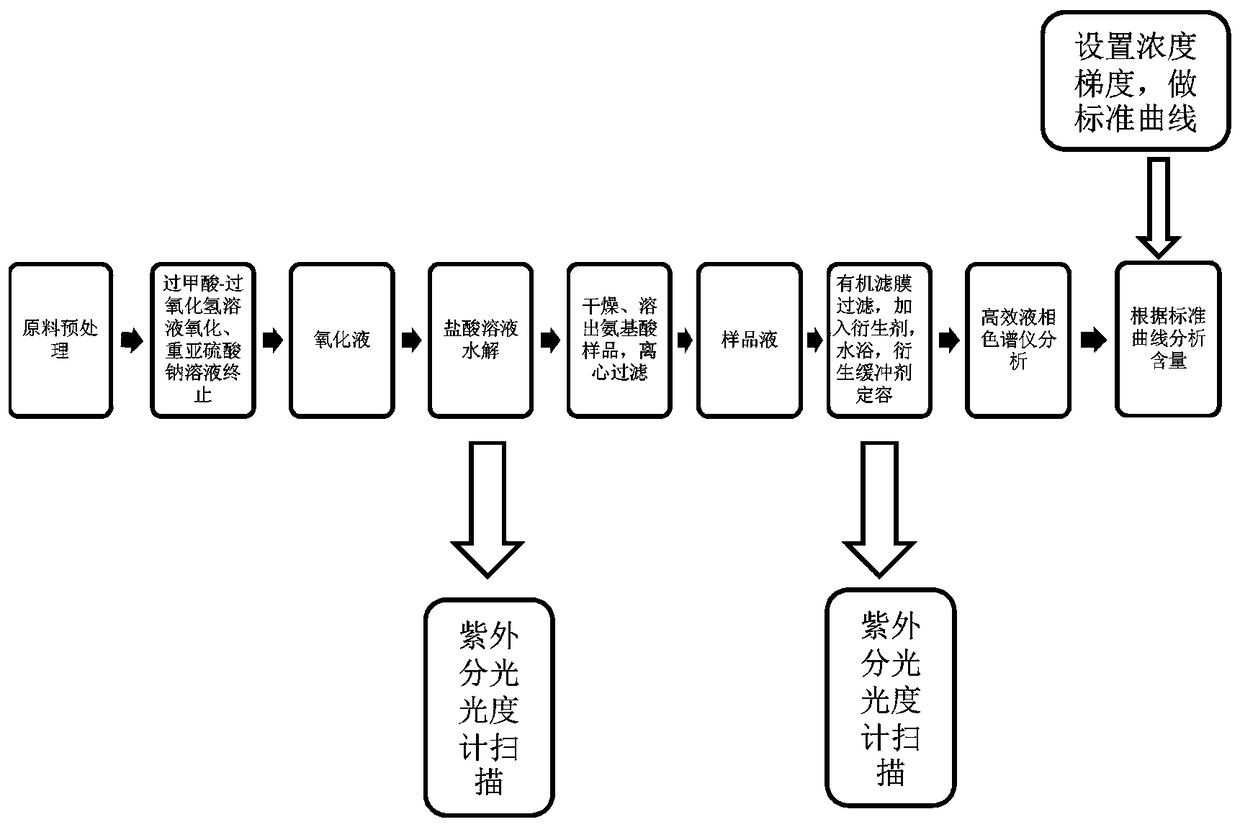

Method for quantitatively detecting sulfur-containing amino acid in sludge

The invention discloses a method for quantitatively detecting sulfur-containing amino acid in sludge. The method includes: performing freezing drying, grinding and sieving on the sludge to obtain a sample; using formic acid to convert the sulfur-containing amino acid in the sludge into cysteic acid and methionine sulfone; using concentrated hydrochloric acid to hydrolyze protein, and using a 3kD filter membrane to perform ultrafiltration, immunity removing and purification on hydrolysate; using phthalic dicarboxaldehyde as the derivative agent to allow the sulfur-containing amino acid derivatives to have fluorescent characteristics; using high-performance liquid chromatography to perform quantitative analysis on the derivatives. Compared with a conventional method, the method has the advantages that the method is simple and convenient to operation, low in toxicity, high in detection accuracy, high in sensitivity and good in repeatability, an expansive amino acid analyzer is not needed, and the like.

Owner:TONGJI UNIV

Method for preparing epoxy flax oil plasticizers

The invention relates to a method for preparing epoxy flax oil plasticizers, and belongs to the technical field of material additives. The defects that in the existing epoxy flax oil preparing process, hydrogen peroxide is used as main oxidizing agents, devices are prone to being corroded, and the temperature performance of the synthesized product is low are overcome. The method includes the steps that ozonized ice is prepared to serve as oxidizing agents, then catalysis is carried out through formic acid, and the epoxy flax oil is prepared from flax oil. According to the method, as the common oxidizing agents are replaced by the ozonized ice, cost is saved, and meanwhile the devices are prevented from being corroded; the prepared epoxy flax oil is good in plasticity, and breaking elongation and impacting strength are improved by 30% to 50%; the production steps are simple, and cost is saved.

Owner:CHANGZHOU OPTICAL MATERIAL

Preparation method of epoxidized solution polymerized styrene-butadiene rubber

The invention discloses a preparation method of epoxidized solution polymerized styrene-butadiene rubber. According to the preparation method, performic acid is generated in situ by H2O2 and HCOOH peracid system under a mild reaction condition, and the performic acid and double bonds on a solution polymerized styrene-butadiene rubber (SSBR) molecular chain undergo epoxidation reaction in an organic phase to obtain the epoxidized solution polymerized styrene-butadiene rubber. Epoxy groups introduced into SSBR have relatively strong reaction activity and can improve the polarity of the SSBR molecular chain, enhance the interaction between the SSBR molecular chain and the packing and improve the compatibility between an SSBR rubber matrix and a reinforcing agent.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

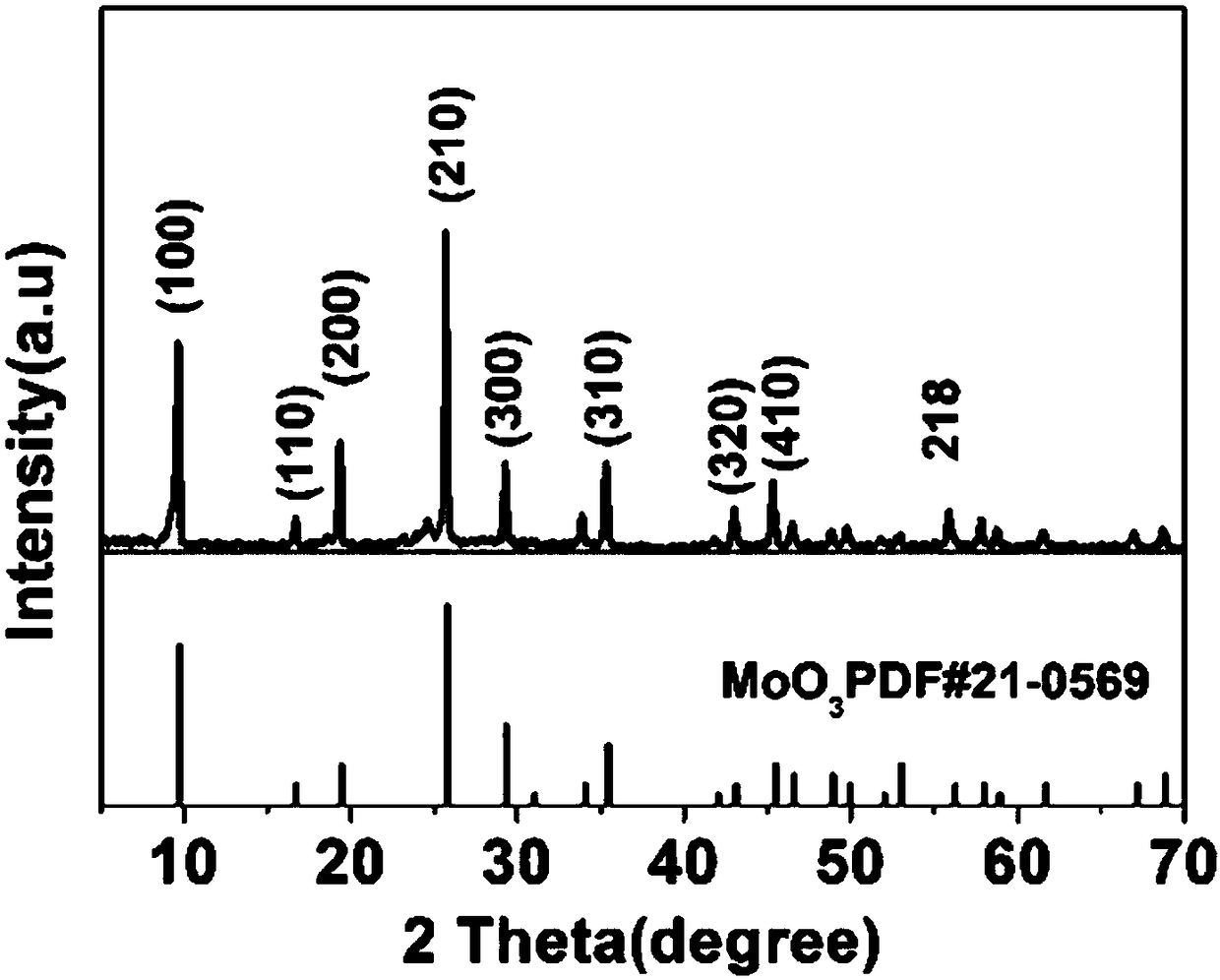

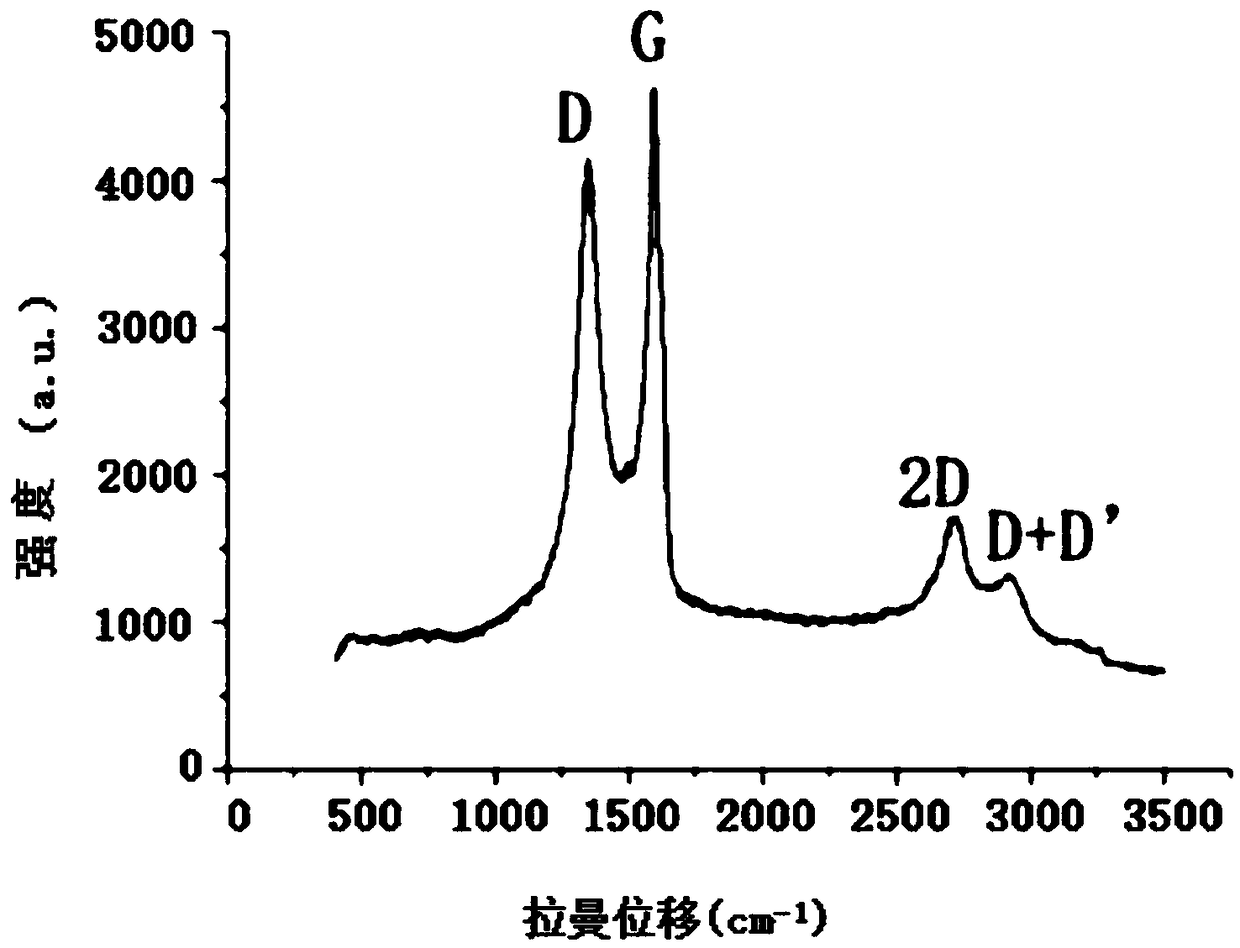

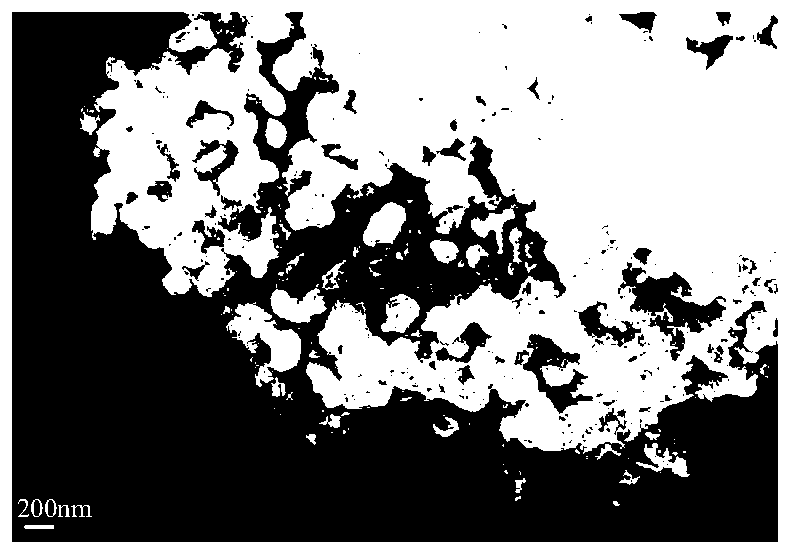

MoO3 composite carbon-dot lithium-ion battery anode material and preparation method thereof

ActiveCN109301231AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsPerformic acidPeroxyformic acid

The invention discloses MoO3 composite carbon-dot lithium-ion battery anode material and a preparation method thereof. Ammonium molybdate is used as a material composite carbon dot to obtain a high-performance lithium-ion battery anode material; performic acid is used as an oxide to strip coal tar pitch to prepare a carbon dot, ammonium molybdate is then subjected as a raw material to the preparation of the MoO3 composite carbon-dot lithium-ion battery anode material by means of a hydrothermal process by using the carbon dot to induce oriented growth of molybdenum trioxide. The preparation method has the advantages of simplicity, short period, low energy consumption, good repeatability, high yield and the like; MoO3 composite prepared herein can relieve volumetric expansion and increase ion activated surface area, thereby increasing the specific capacity and cycle stability of a lithium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH +1

Performic acid on-site generator and formulator

Methods of generating performic acid by contacting aqueous oxidizing agent and aqueous formic acid source in liquid phase are disclosed. A system and apparatus for the in situ production of the performic acid chemistries is further disclosed. In particular, a continuous flow reactor is provided to generate performic acid at variable rates. Methods of employing the oxidizing biocide for various disinfection applications are also disclosed.

Owner:ECOLAB USA INC

Synthetic method of 24-methylene-cholesterol-3 beta, 5 alpha, 6 beta,19-tetraalcohol

The synthesis process of natural product 24-methene-cholest-3beta, 5alpha, 6beta, 19-tetrol (Nephalserol A) with antitumor and antiseptic activity includes the steps of: synthesis of 3beta-acetoxy-cholest-5-ene-24-one with easy-to-obtain stigmacholest; reaction of 3beta-acetoxy-cholest-5-ene-24-one with N-bromoacetamide in the catalysis of water solution of perchloric acid to produce 3beta-acetoxy-cholest-5alpha-bromo-6beta-hydroxy-24-one; photoannulation reaction to produce 3beta-acetoxy-cholest-5alpha-bromo-6, 19-epoxy-24-one; epoxy ring-opening reaction to produce 3beta-acetoxy-cholest-5-ene-19-hydroxy-24-one; oxidation of 5, 6-double bond with formic acid to obtain 3beta, 5alpha, 6beta, 19-tetrahydroxy-cholest-24-one; and final transforming the carbonyl group in 24-th place of branch chain into methane to obtain the destination product. The present invention has total yield of 9.3 %.

Owner:SUN YAT SEN UNIV

Performic acid biofilm prevention for industrial CO2 scrubbers

Owner:ECOLAB USA INC

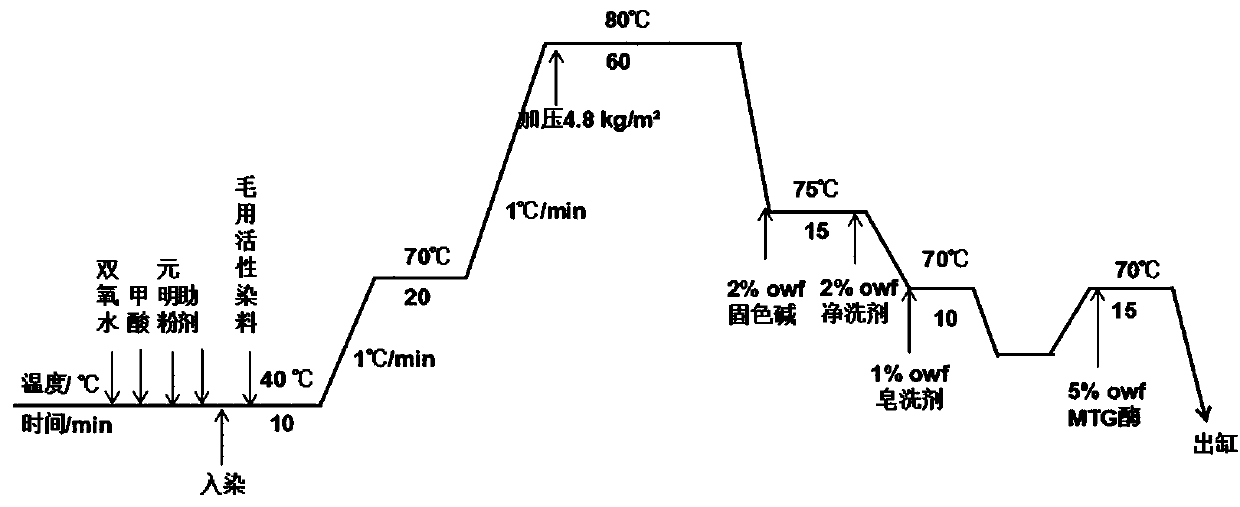

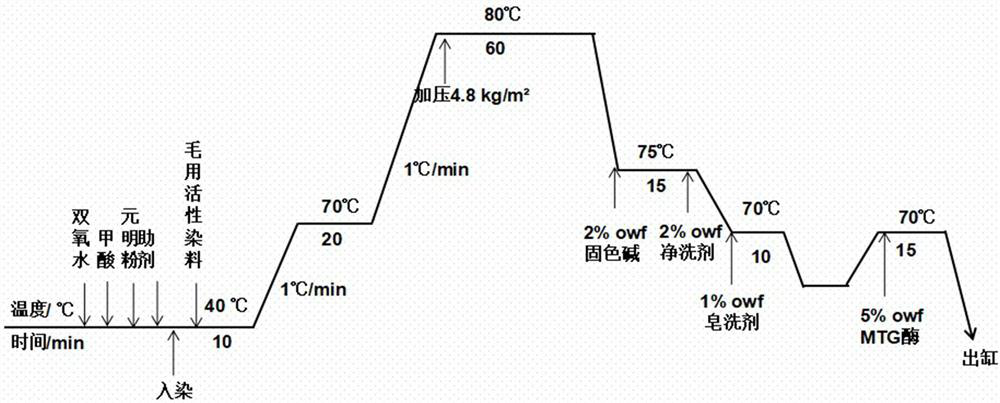

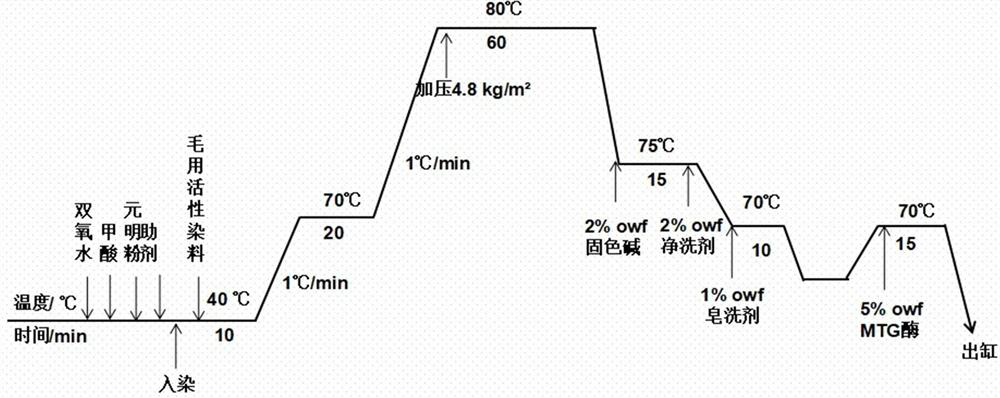

Low-temperature weak-damage wool dyeing process

The invention relates to the field of textile technology, and provides a low-temperature weak-damage wool dyeing process. The low-temperature weak-damage wool dyeing process comprises the following steps of (1) carrying out pretreatment; (2) performing hydrogen peroxide-formic acid oxidation pretreatment; (3) carrying out dyeing; (4) performing pressure relief; (5) carrying out alkali color fixingtreatment; (6) carrying out soaping; (7) carrying out water washing; and (8) performing repairing treatment, and taking out of a cylinder. The process has the beneficial effects that (1) through a triple swelling synergistic effect of the formic acid-hydrogen peroxide oxidization system, dyeing under pressure and glutamine transaminase repairing, low-temperature dyeing can be realized and the damage to the wool fibers is reduced, the dyeing can be performed at the dyeing temperature of 75-80 DEG C, the dyeing time is shortened by 30-35%, and the problem of yellowing caused by long-term boiling dyeing of wools at a high temperature can be avoided; and 2) through the process, the dye uptake and the dyeing fastness are both improved by 5-6% compared with those in the conventional dyeing method, the fiber strength, breaking elongation, and the moisture regain rate are all improved in a relatively high degree, the use amount of dye is highly reduced, and the enterprise production cost is lowered.

Owner:JIANGSU DANMAO TEXTILE

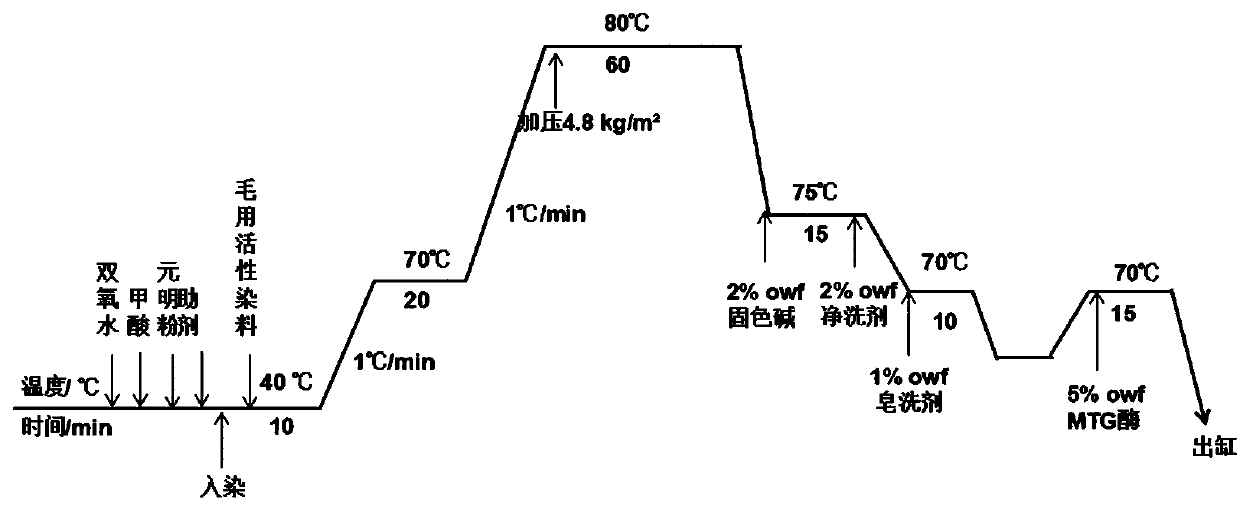

Preparation method of 5,6-epoxy-5,6-dihydro-beta-ionol

The invention provides a preparation method of 5,6-epoxy-5,6-dihydro-beta-ionol, comprising the following steps of: selectively reducing carbonyl in 5,6-epoxy-5,6-dihydro-beta-irisone used as raw material by using NaBH4 and CeCl3.7H2O, and synthesizing to obtain the 5,6-epoxy-5,6-dihydro-beta-ionol, wherein the yield reaches 87.8-91.84 percent. The purity is higher than 95.00 percent by silicagel column separation. Compared with a preparation method reported in the literature of carrying out the epoxidation reaction of beta-ionol by using m-chlorobenzene performic acid in sodium bicarbonate and methylene dichloride at room temperature to obtain the 5,6-epoxy-5,6-dihydro-beta-ionol, the reaction time is greatly shortened, and the yield is obviously increased.

Owner:SHANGHAI INST OF TECH

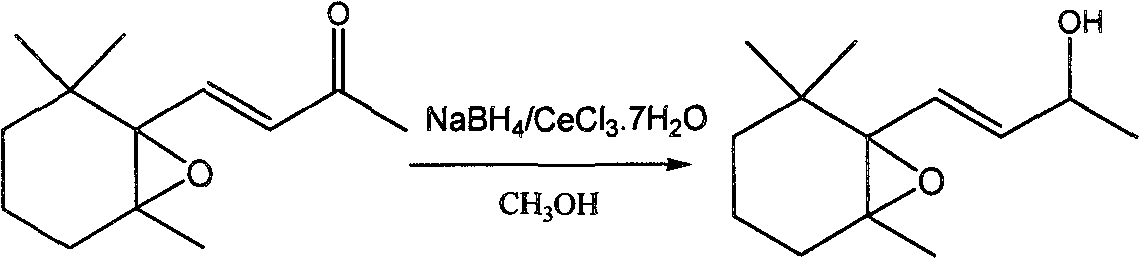

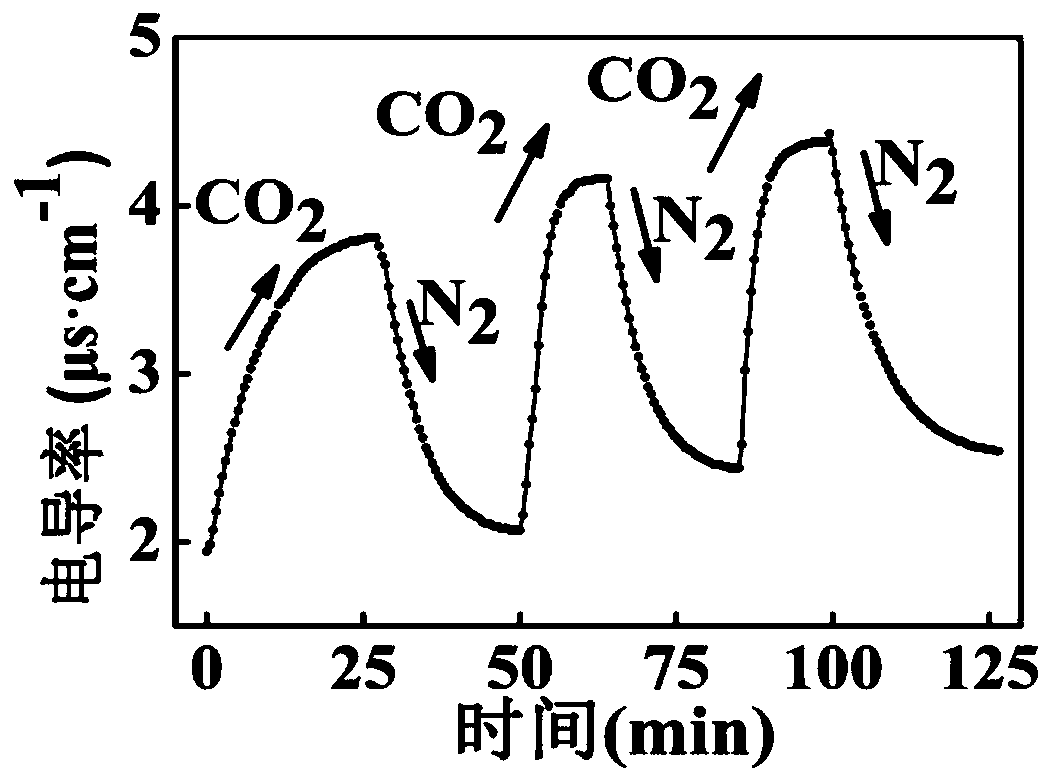

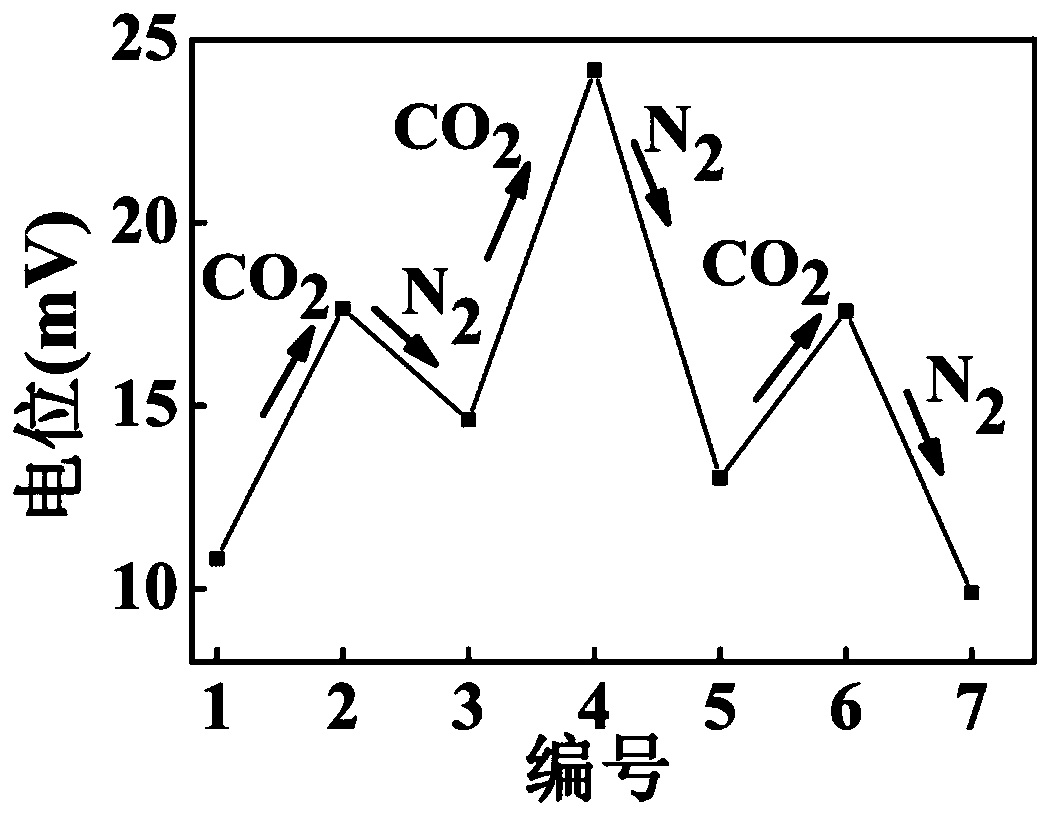

Production method of modified nanometer SiO2 particles with CO2/N2 response

InactiveCN110746954AOil displacement effect is goodImprove responsivenessDrilling compositionSweep efficiencySilanes

The invention discloses a production method of modified nanometer SiO2 particles with CO2 / N2 response, and belongs to the field of oilfield chemistry. The production method of the modified nanometer SiO2 particles with CO2 / N2 response comprises the two steps: firstly, in a nitrogen atmosphere, through a silane coupling agent, modifying nanometer SiO2 powder to obtain silane-coupling-agent-modifiednanometer SiO2; and secondly, in the nitrogen atmosphere, through formic acid and formaldehyde, at 85-95 DEG C, further modifying the silane-coupling-agent-modified nanometer SiO2 to obtain the modified nanometer SiO2 particles with CO2 / N2 response. The modified nanometer SiO2 particles have excellent response to CO2 / N2 gas, can be recycled, and can adsorb CO2 when injected, and then N2 is introduced in time to desorb CO2, so that the sweep efficiency is improved, and the modified nanometer SiO2 particles with CO2 / N2 response have values and prospects of improving the oil recovery efficiencyof unconventional oil reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

Protein regeneration composite fiber spinning solution and production method thereof

InactiveCN103388194AStrong color fastnessLow priceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyvinyl alcoholPotassium bisulfite

The invention relates to a regeneration animal-plant double-protein composite fiber spinning solution and a production method thereof. The protein regeneration composite fiber spinning solution includes an animal protein and / or a plant protein, the animal protein is sericin protein obtained by processing of reeling silk leftovers, and the plant protein is a protein obtained by extraction of multiploid locust leaves. The protein regeneration composite fiber spinning solution also includes the following components by weight: 0-40 parts of the animal sericin protein, 0-40 parts of the plant polyploid locust leaf protein, 58.6-74.4 parts of polyvinyl alcohol, 0.3-0.8 part of potassium sulfite or potassium bisulfite and 0.3-0.8 part of hydrogen peroxide, performic acid or peracetic acid; and then the composite spinning solution with the viscosity of 800-1200 centipoises is obtained by adding water and sodium hydroxide for copolymerization. According to the regeneration animal-plant double-protein composite fiber spinning solution and the production method thereof, the cost of fiber is reduced, the quality of products is improved, and the problems of chromaticity, color fastness, resistance to hot water and boiling water shrinkage of the fiber are solved.

Owner:郭洁清 +1

Clean pulping catalyst and application technology thereof

InactiveCN108130771ASafe and Effective Tea BrewingSafe and effective methodPulp beating/refining methodsNon-woody plant/crop pulpSulfite saltPapermaking

The invention discloses a clean pulping catalyst and an application technology thereof. The clean pulping catalyst comprises 85% of pulping raw materials, 9% of catalytic solvent, 5% of solid catalyzer and 1% of preservative. The catalytic solvent is a mixed solution by mixing one aqueous solution of NaOH, KOH, Ca(OH)2, Na2CO3, K2CO3, NaHCO3, KHCO3 and Na2SiO3, of which the weight percentage concentration is 5-30% with an EDTA aqueous solution with the weight percentage concentration of 1-10% according to the weight ratio of 1:1; the solid catalyzer comprises an oxygen stabilizer and an additive, and the oxygen stabilizer comprises a mixture of one or two or more kinds of DMD, hydrogen peroxide, performic acid, peracetic acid, perpropionic acid, ozone, MgSO4 and MgC12 according to a randomproportion; the additive comprises ferrous sulfate and sodium sulfite. According to the technology, no waste medicine liquid is discharged, no waste water is discharged, and the technology is beneficial to environmental protection and has high innovation value in the papermaking industry.

Owner:QILU UNIV OF TECH

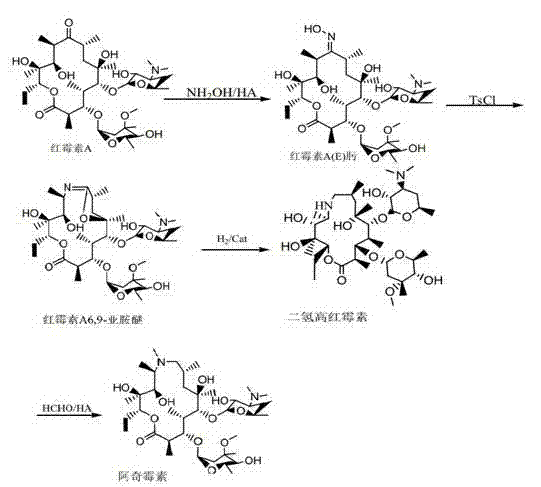

One-pot process for preparing azithromycin

ActiveCN103087125AEmission reductionShorten production timeSugar derivativesSugar derivatives preparationPtru catalystFormate

The invention mainly discloses a one-pot process for preparing azithromycin. The method which allows azithromycin to be prepared through using erythromycin imino ether without an extraction intermediate comprises the following steps: carrying out catalytic hydrogenation of erythromycin imino ether, filtering out a catalyst, adding formate, fully reacting, filtering, recovering to dryness, adding acetone for dissolving, adding the formate, adding formaldehyde and formic acid in a dropwise manner, carrying out a methylation reaction under an acidic condition to obtain azithromycin, and re-crystallizing to obtain azithromycin dihydrate. The process which realizes one-pot of a reduction reaction and the methylation reaction through the application of the formate has the advantages of substantial shortening of the erythromycin imino ether-to-azithromycin production time, operation reduction, and reduction of the discharge of three wastes, has a yield 1-5% higher than original processes, and allows the product content to be 0.5-1.5% higher than that of the original processes.

Owner:ZHEJIANG GUOBANG PHARMA

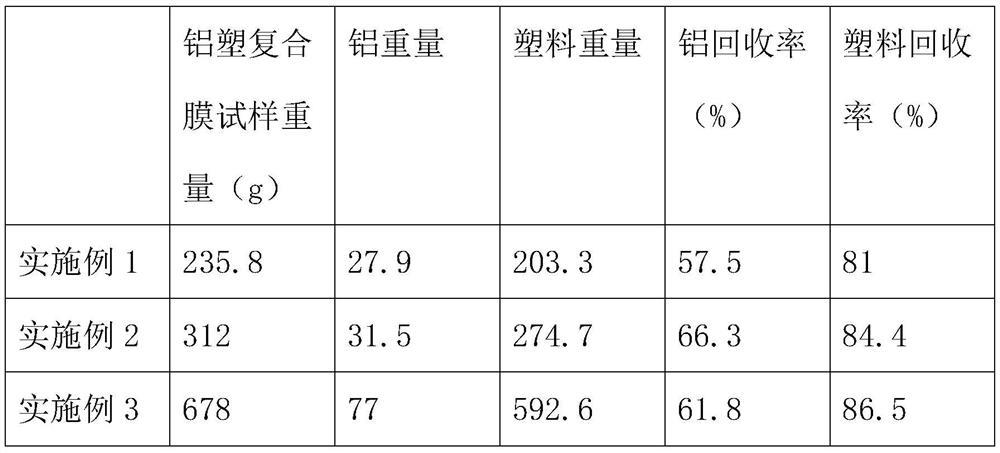

Aluminum-plastic separating agent and aluminum-plastic separating method

InactiveCN113105667AImprove permeabilityImprove surface activityProductsReagentsCelluloseAluminum Ion

The invention discloses an aluminum-plastic separating agent, which is prepared from the following raw materials in parts by weight: 1 to 2 parts of hydroxyethyl cellulose, 10 to 16 parts of formic acid, 1 to 2 parts of fatty acid diethanolamide, 2 to 4 parts of ethylenediamine tetraacetic acid, 20 to 30 parts of methyl methacrylate and 0.6 to 0.7 part of initiator. The polymer emulsion is obtained bypolymerization under the action of the initiator by taking ethylene diamine tetraacetic acid as adoping agent and blending the doping agent with methyl methacrylate monomer. The polymer emulsion has good permeability and surface activity, a small amount of aluminum oxide on an aluminum surface layer can be dissolved by formic acid, and obtained aluminum ions can be reacted and compounded with ethylenediaminetetraacetic acid, so that the dissolution of an aluminum oxide film on the plastic surface is promoted, and the separation effect is improved; according to the separation method disclosed by the invention, most of aluminum and plastic materials can be obtained, the loss is relatively less, and the requirement on equipment is also low.

Owner:江苏澄奥环保科技有限公司

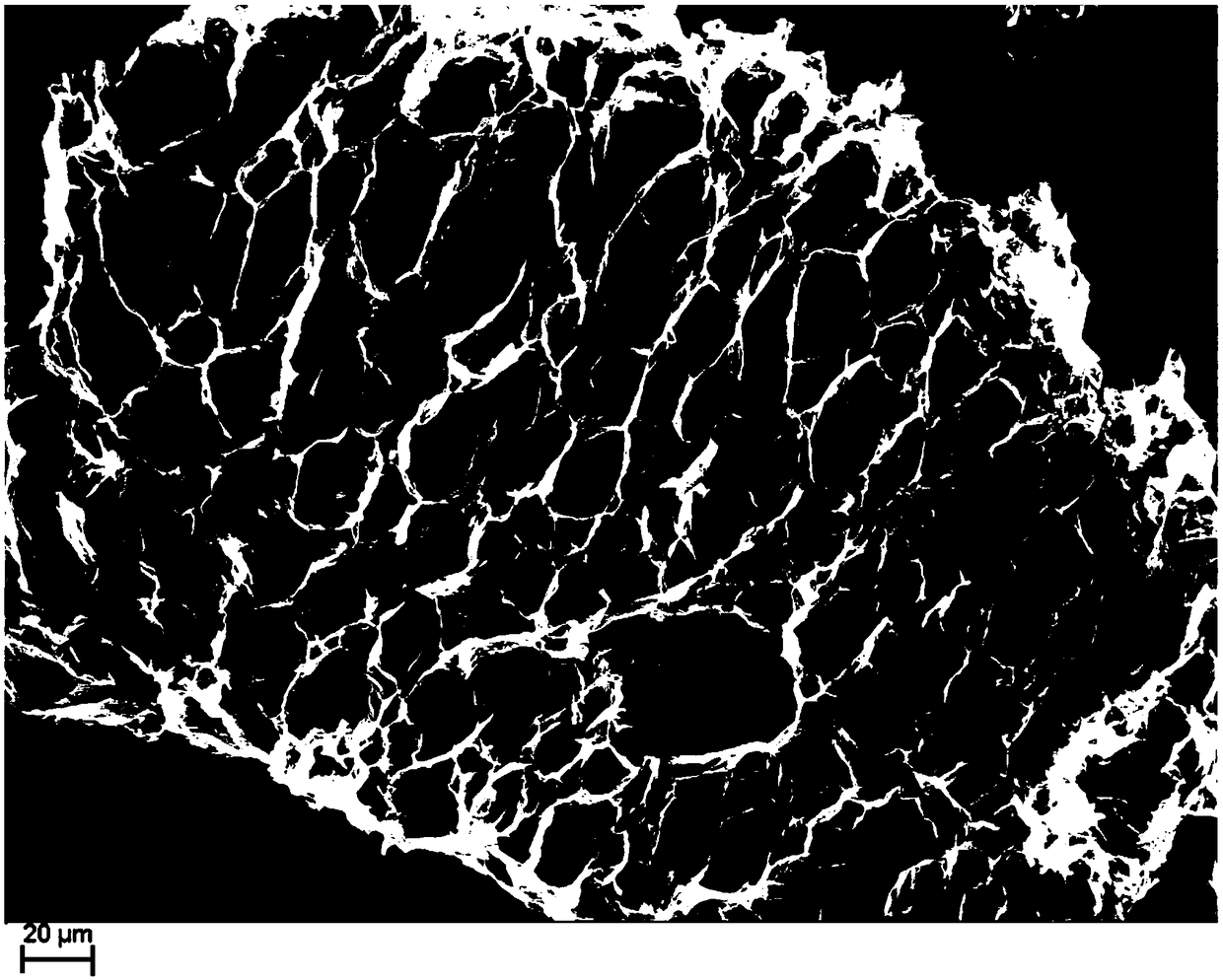

Preparation method of graphite oxide capable of being washed directly

The invention provides a preparation method of graphite oxide capable of being washed directly. The preparation method comprises the following steps that step one, crystalline flake graphite is takenas a raw material, a main intercalator and an auxiliary intercalator are added for intercalation treatment to obtain a graphite intercalation compound; the main intercalator is at least one of formicacid, acetic acid, phosphoric acid, concentrated nitric acid and concentrated sulfuric acid; the auxiliary intercalator is at least one of an aqueous hydrogen peroxide solution, performic acid and peracetic acid; step two, after redundant main intercalator and auxiliary intercalator of the graphite intercalation compound are filtered out, the filtered graphite intercalation compound is put into ice water, tiny impurity particles and water are filtered and washed off with a sieve, and the graphite intercalation compound with less impurities is obtained; step three, an oxidizing agent is added in the filtered graphite intercalation compound, oxidation is carried out for 0.5-50 hours under the condition of 0-45 DEG C, and the graphite oxide of which a PH value is 0-1 and capable of being washed directly by the water is obtained. By the method, the volume of the raw material is swelled to 300 times to 500 times or above.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

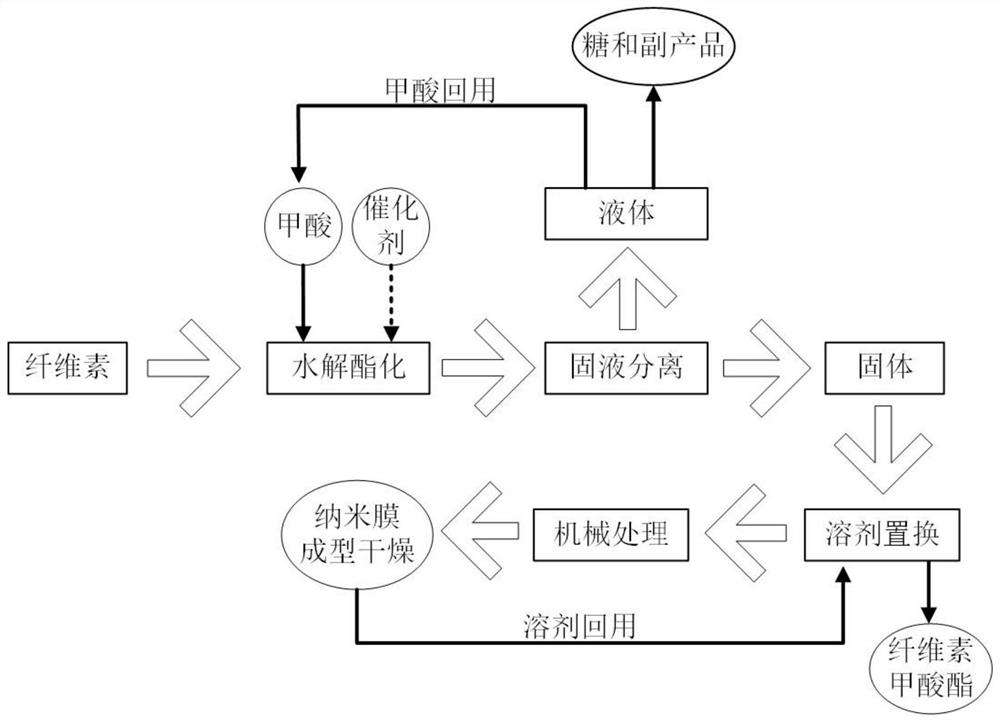

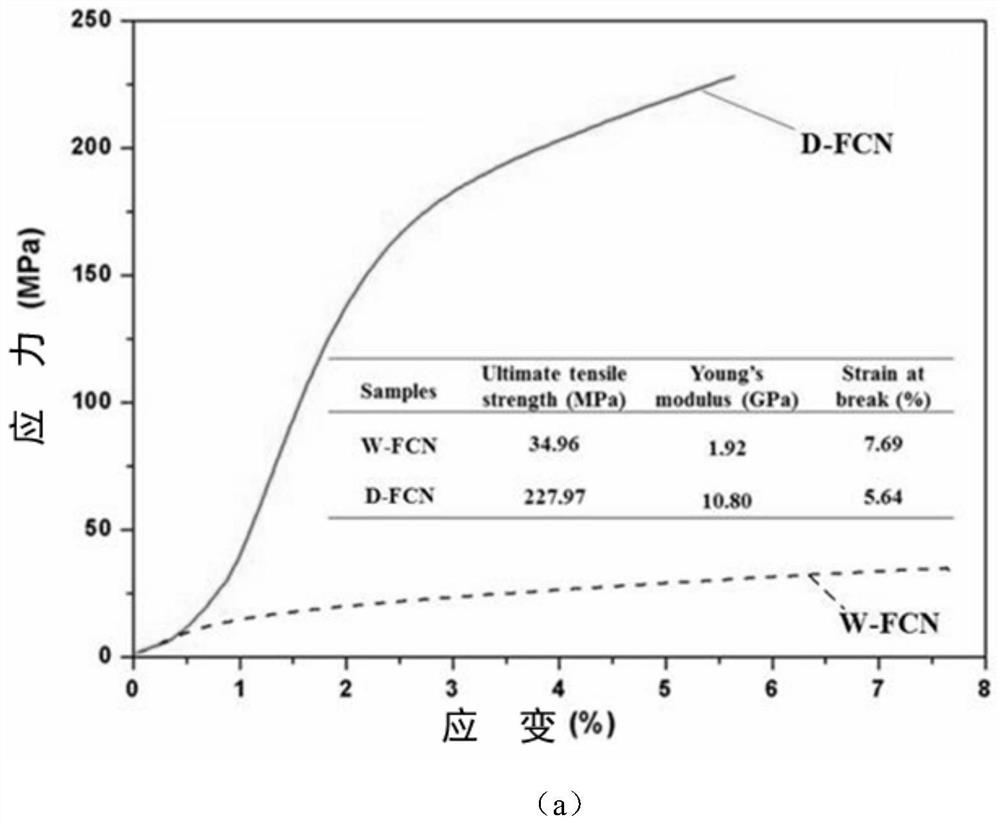

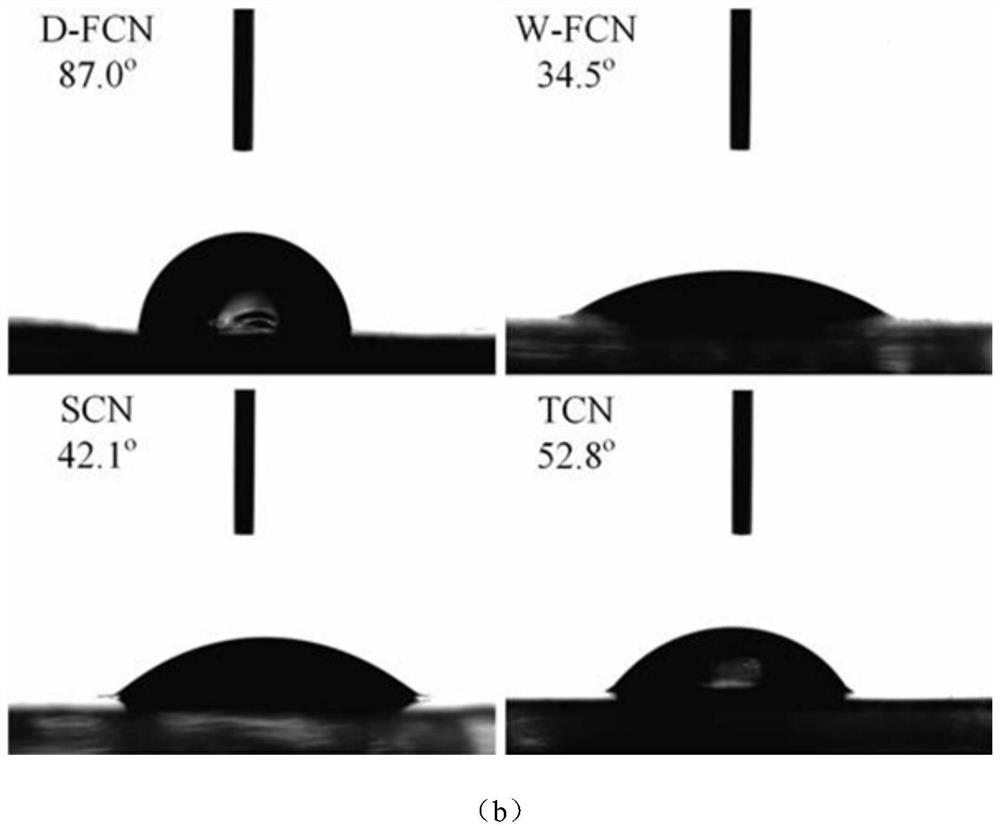

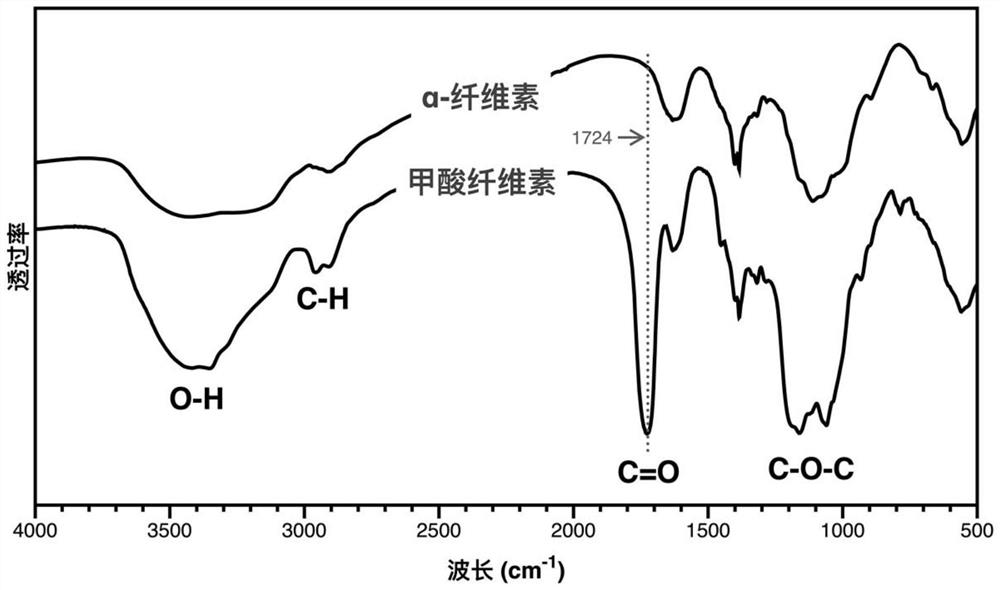

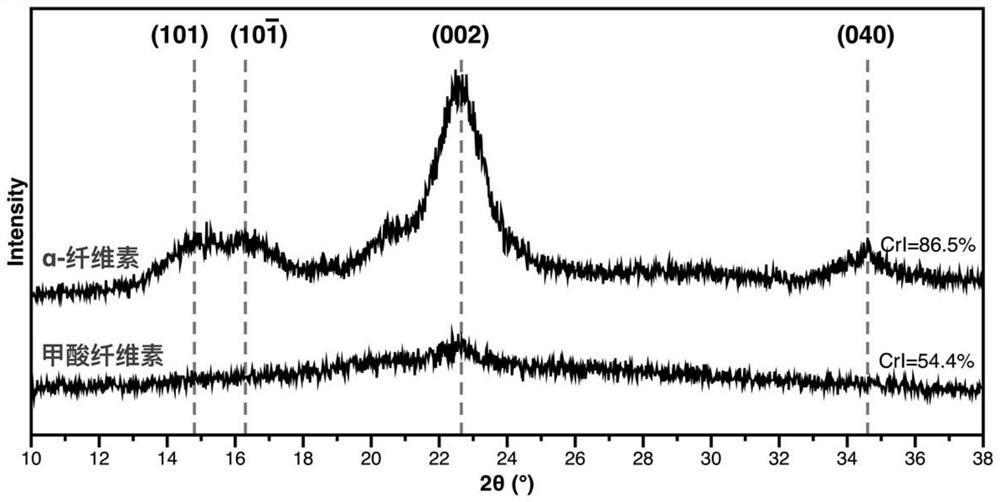

A kind of high-strength transparent hydrophobic cellulose nano film and preparation method thereof

The invention discloses a high-strength transparent hydrophobic cellulose nano film and a preparation method thereof, belonging to the field of green cellulose materials and environment-friendly nano materials. The method of the invention uses natural cellulose as a raw material, firstly hydrolyzes the cellulose raw material with formic acid, and the separated cellulose solid is sequentially subjected to solvent replacement, mechanical treatment and drying to obtain the high-strength transparent hydrophobic cellulose nano film. The nanocellulose film prepared by the method of the present invention has excellent properties, compact structure, high strength and high transparency, the tensile strength of the film can be greater than 200MPa, and the transparency can reach 95%; the hydrophobic modification process of the present invention does not require complex chemical reactions and expensive Chemical reagents, molecular rearrangement and recrystallization can occur on the surface of cellulose during mechanical treatment and film formation; the water contact angle of the obtained nanocellulose film can reach 99°, and the original shape can still be maintained after long-term immersion in water. It has good water resistance and can be used in high humidity environment.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Synthetic process of 3-methoxydiphenylamine

InactiveCN104058978AEasy to useEasy to prepareOrganic compound preparationAmino-hyroxy compound preparationIodinePotassium hydroxide

The invention discloses a synthetic process of 3-methoxydiphenylamine, relating to the technical field of chemical engineering. The process comprises the following steps: reacting formic acid with phenylamine to prepare N-formanilide at first, and then reacting N-formanilide, potassium carbonate, copper powder, iodine, potassium hydroxide and ethanol to prepare 3-methoxydiphenylamine. The process has the beneficial effects that the 3-methoxydiphenylamine is convenient and simple to prepare, environment-friendly, pollution-free, high in purity, convenient to operate, safe and reliable, and has a good use effect; raw materials are easily available and the equipment investment is low.

Owner:安徽佑骏商品混凝土有限公司

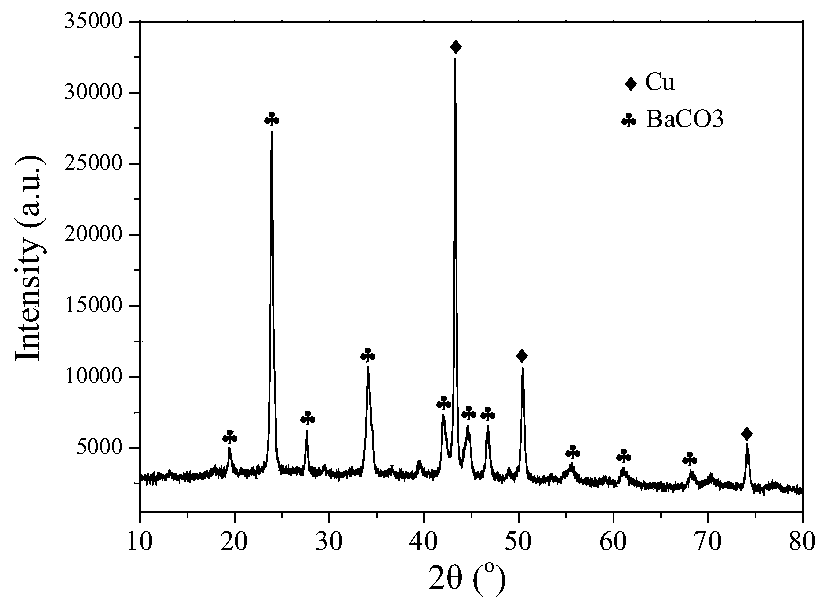

Preparation method of modified copper-based catalyst for furfural hydrogenation to furfuryl alcohol

ActiveCN109731596BReduce manufacturing costEasy to makeOrganic chemistryPhysical/chemical process catalystsPtru catalystEngineering

Owner:XIAMEN UNIV

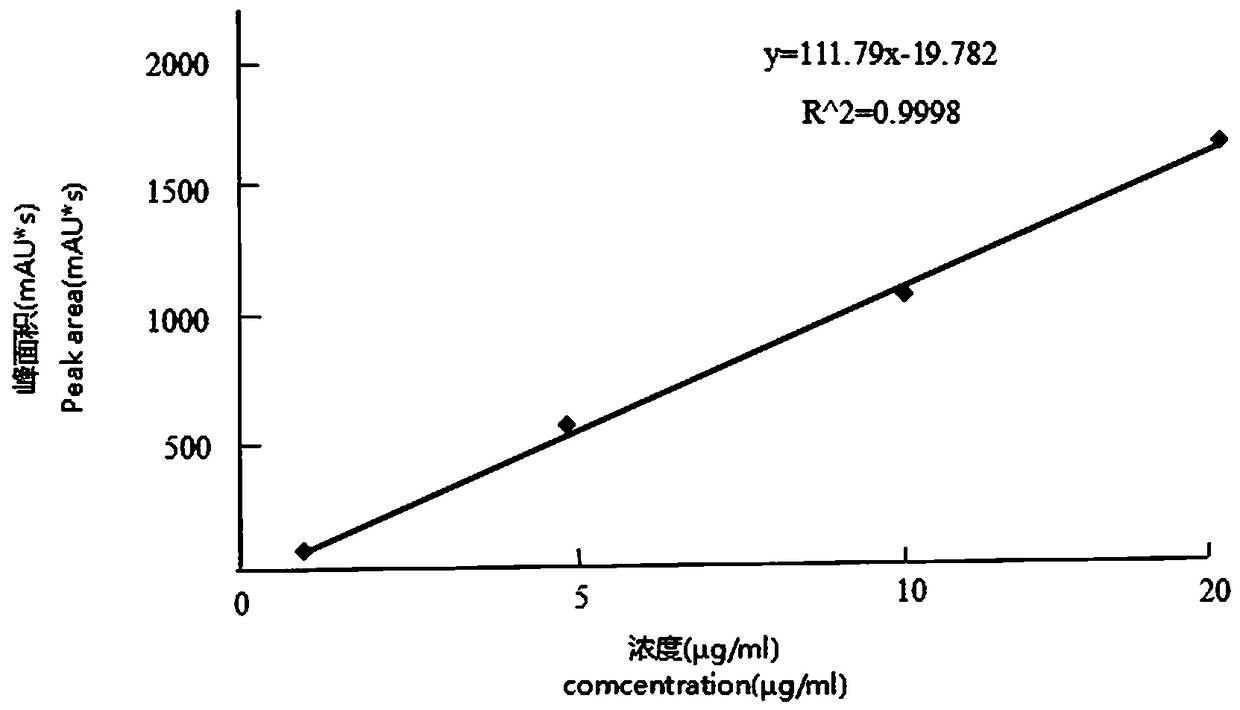

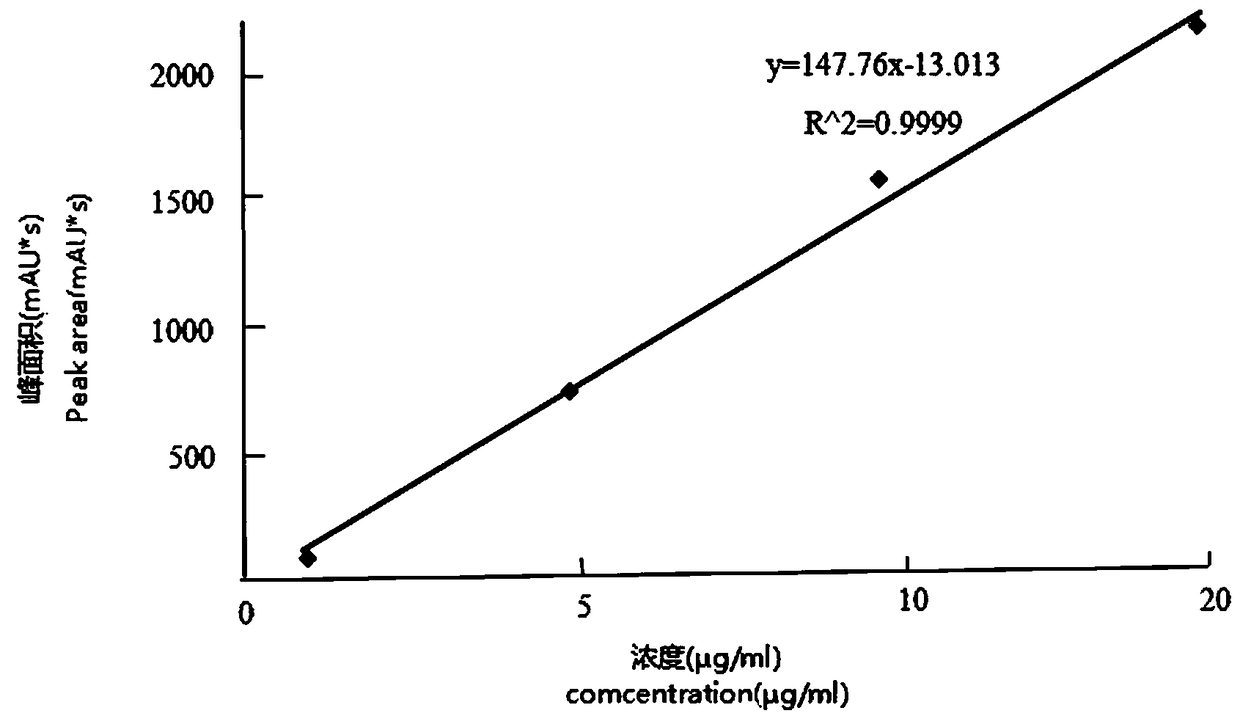

Method for measuring sulfur-containing amino acid content of Astragali mushroom

InactiveCN109164191AReduce distractionsEfficient methodComponent separationColor/spectral properties measurementsSodium acetateUltrafiltration

The invention discloses a method for measuring the sulfur-containing amino acid content of Astragali mushroom, and relates to the field of measurement of amino acid content of the Astragali mushroom.The method comprises the following steps: performing performic acid oxidation protection on the Astragali mushroom serving as a raw material, performing acid hydrolysis, performing ultrafiltration centrifugation, performing derivatization by taking 2,4-dinitrofluorobenzene as a derivatization reagent, performing gradient elution on the obtained derivative sample liquid through high performance liquid chromatography and by taking acetonitrile-water and sodium acetate as flowing phases, detecting under the wavelength of 360 nm, separating derivatives of cysteic acid and methionine sulfone, measuring the peak area of a cystine standard product and a methionine standard product under different concentration gradient, drawing a standard curve, and measuring the cystin content and the methioninecontent separately to obtain the sulfur-containing amino acid content. According to the method, the requirement on instruments is low, the reaction condition does not need to be strictly limited, thequantity of the needed samples is small, the samples are not damaged, single component can be analyzed, and the method is a measuring method which is efficient, accurate, simple, convenient and easyto operate and low in price.

Owner:LULIANG UNIV

Method for preparing 5-hydroxymethylfurfural by catalyzing cellulose formate with dimethyl sulfoxide-water cosolvent system

The invention discloses a method for preparing 5-hydroxymethylfurfural by catalyzing cellulose formate with a dimethyl sulfoxide-water cosolvent system. The method comprises the following steps: firstly, adding alpha-cellulose into a formic acid solution for oil-bath heating, and carrying out centrifugal filtration to obtain a reaction filtrate; carrying out rotary evaporation and concentration onthe reaction filtrate, pouring the filtrate into an ethanol solution, and carrying out centrifugal filtration to obtain a white precipitate; pouring the white precipitate into an ethanol solution, carrying out centrifuging and filtering, repeating the operation for three times, and implementing freeze-drying to obtain cellulose formate; finally, performing microwave catalytic conversion in a dimethyl sulfoxide water cosolvent system by taking alpha-cellulose or cellulose formate as a substrate, and hydrochloric acid and aluminum chloride as catalysts to obtain the 5-hydroxymethylfurfural. Cellulose is treated with formic acid for acidolysis and formylation to obtain cellulose formate, and aluminum chloride hydrochloride is used as a combined catalyst to directly and efficiently catalyze cellulose formate in a dimethyl sulfoxide water cosolvent system to prepare 5-hydroxymethylfurfural.

Owner:ZHEJIANG UNIV

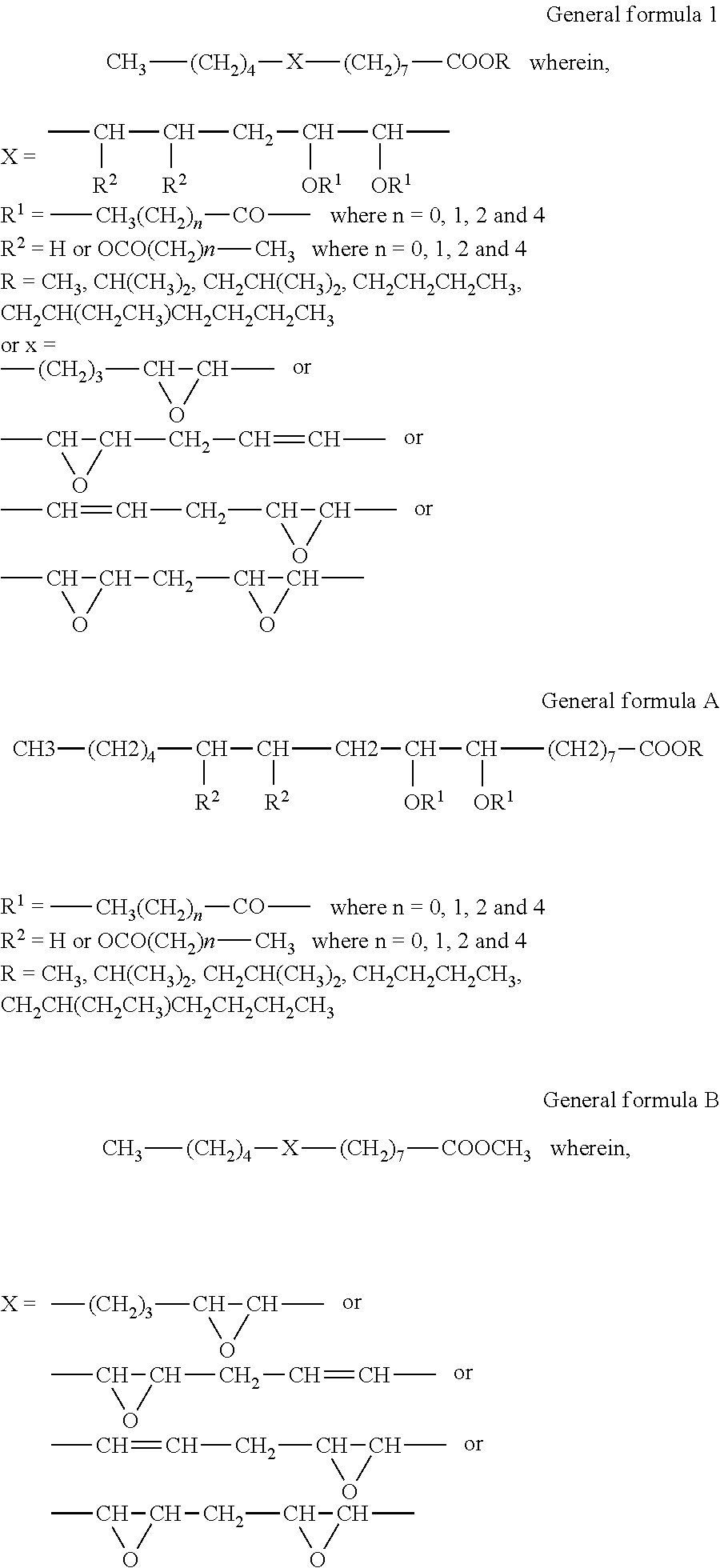

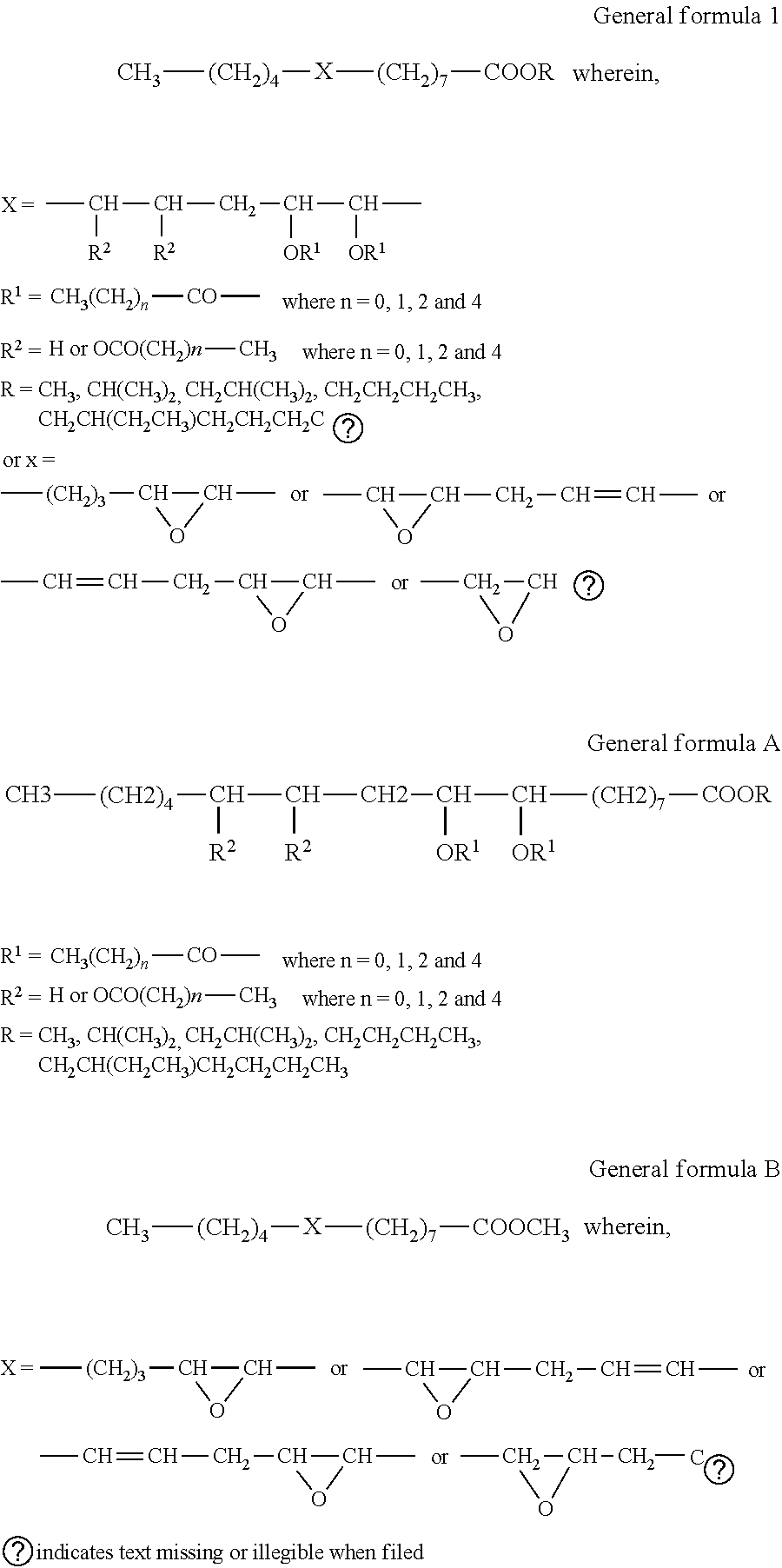

Process for the preparation of karanja oil-based epoxy and acyloxy compounds as lubricant basestocks

ActiveUS20150191441A1Promote degradationImprove the lubrication effectOrganic compound preparationPreparation by ester-hydroxy reactionEpoxyMetal working fluid

The present invention relates to preparation of epoxy karanja oil, epoxy karanja fatty acid methyl esters and their acylated derivatives. Accordingly karanja oil and karanja fatty acid methyl esters were epoxidised using performic acid method. Karanja oil and its fatty acid methyl esters were also hydroxylated to prepare their acyloxy derivatives (C3, C4 & C6). Both the epoxy and acyloxy derivatives of karanja oil and its methyl esters were characterized by 1H NMR and IR studies. The products were evaluated for acid value (A.V.), hydroxyl value (H. V.), iodine value (I. V.), viscosity, viscosity index (V.I.), pour point, flash point and copper strip corrosion and lubricant properties like oxidation stability, air release value, evaporation loss, rust prevention characteristics, hydrolytic stability, foam stability and load carrying capacity and found to be potential base stocks for hydraulic, metal working fluids and other industrial fluids.

Owner:COUNCIL OF SCI & IND RES

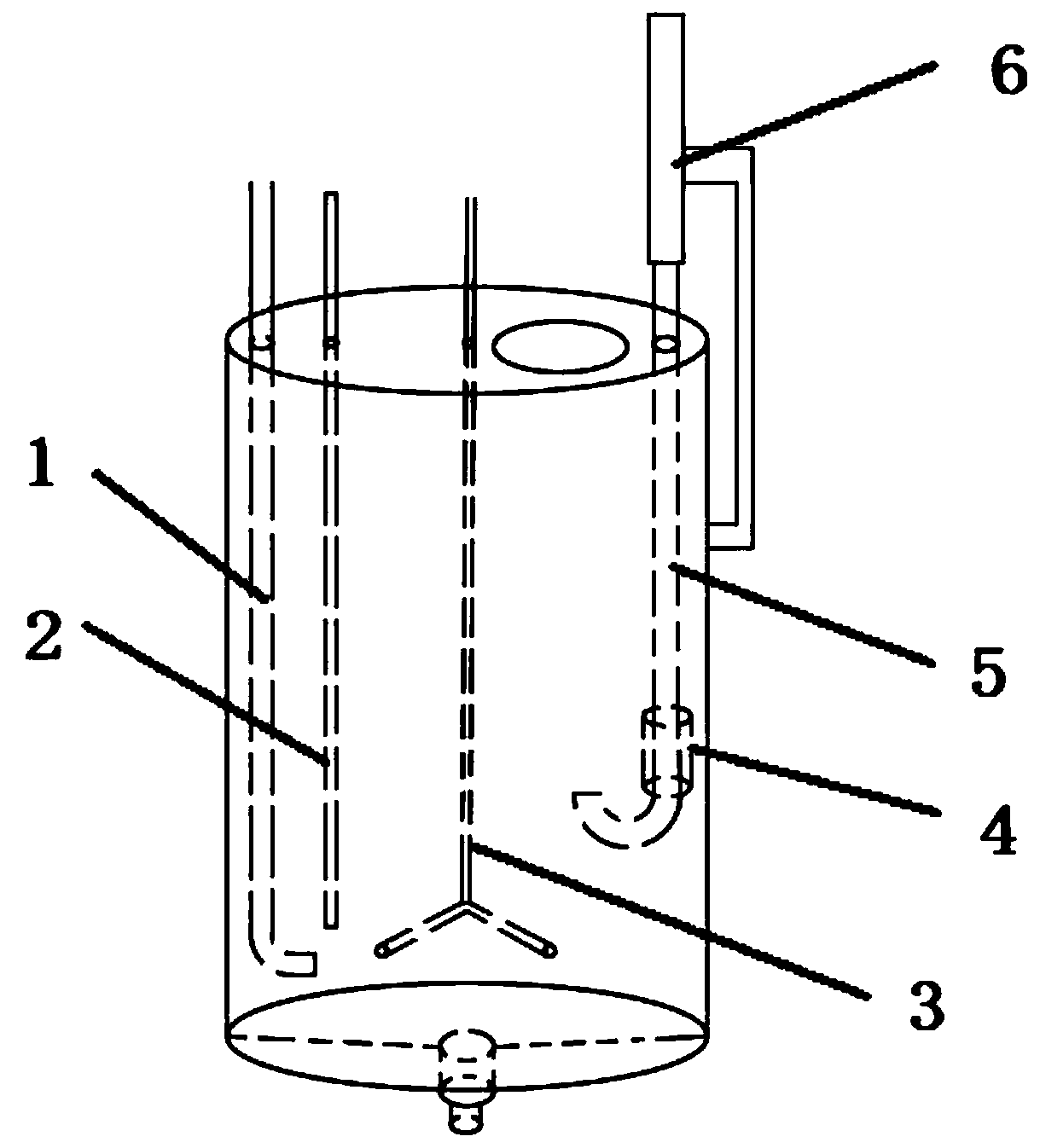

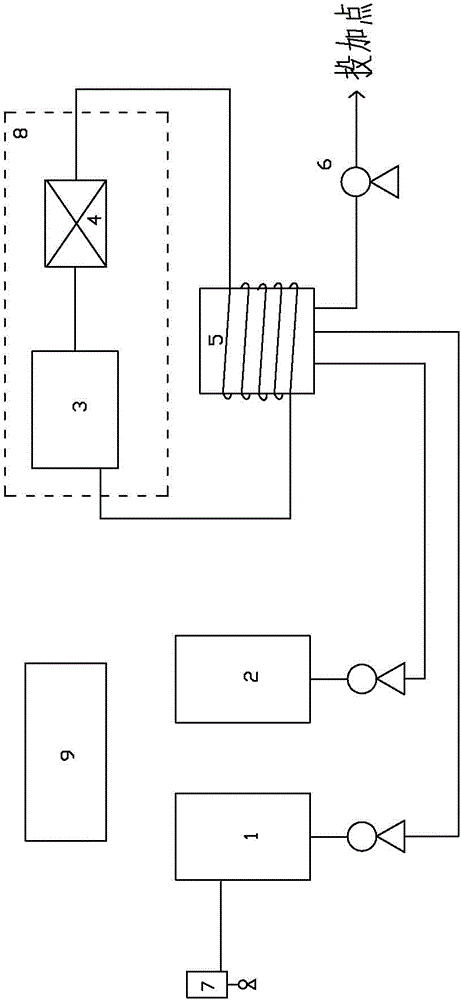

Intelligent disinfection and sterilization system for chloride-free tap water

InactiveCN104944540AImprove disinfection and sterilization efficiencyProduce corrosionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationEngineeringChloride

The invention discloses an intelligent disinfection and sterilization system and method for chloride-free tap water. The system is characterized by comprising a formic acid storage box (1), a hydrogen peroxide storage box (2), a reaction box (5), an addition metering pump (6), a cooling device and an intelligent control device, wherein the input end of the addition metering pump (6) is connected with the output end of the reaction box (5), the output end of the addition metering pump (6) extends into a water outlet of a tap water plant through a water pipe, performic acid with low dosage is rapidly dissolved into water, achieves disinfection and sterilization within 60 s and rapidly decomposed into water and carbon dioxide, and the input end of the reaction box (5) is connected with the output end of the formic acid storage box (1) and the output end of the hydrogen peroxide storage box (2). The intelligent disinfection and sterilization system is high in disinfection and sterilization efficiency, has no residue, and is low in running cost and convenient to maintain.

Owner:江苏鸿佑环保有限公司

A low temperature weak damage dyeing process for wool

The present invention relates to the field of textile technology. The present invention provides a low-temperature and weak-damage dyeing process for wool, which is carried out according to the following process steps: (1) pretreatment; (2) hydrogen peroxide-formic acid oxidation pretreatment; (3) dyeing; (4) unloading (5) Alkali color fixing treatment; (6) Soaping; (7) Water washing; (8) Restoration treatment, out of the tank. The beneficial effects of the present invention are: 1) Through the triple swelling synergistic effect of formic acid-hydrogen peroxide oxidation system, pressure dyeing, and transglutaminase repair, low-temperature dyeing can be realized and wool fiber damage can be reduced, and the dyeing temperature can be dyed at 75-80°C , the dyeing time is shortened by 30%-35%, avoiding the yellowing problem caused by high temperature and long-term boiling of wool; 2) Through the process of the present invention, the dyeing rate and color fastness are both increased by 5%-6% compared with traditional dyeing methods, and the fiber The strength, elongation at break and moisture regain are all greatly improved, which greatly reduces the amount of dyes used and reduces the production cost of the enterprise.

Owner:JIANGSU DANMAO TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com