Production method of modified nanometer SiO2 particles with CO2/N2 response

A responsive, nano-technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as low sweep efficiency, injectability problems, corrosion hazards of pipeline equipment, etc., to achieve improved oil displacement and enhanced recovery , good responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a CO 2 / N 2 Responsive modified nano-SiO 2 Granule preparation method:

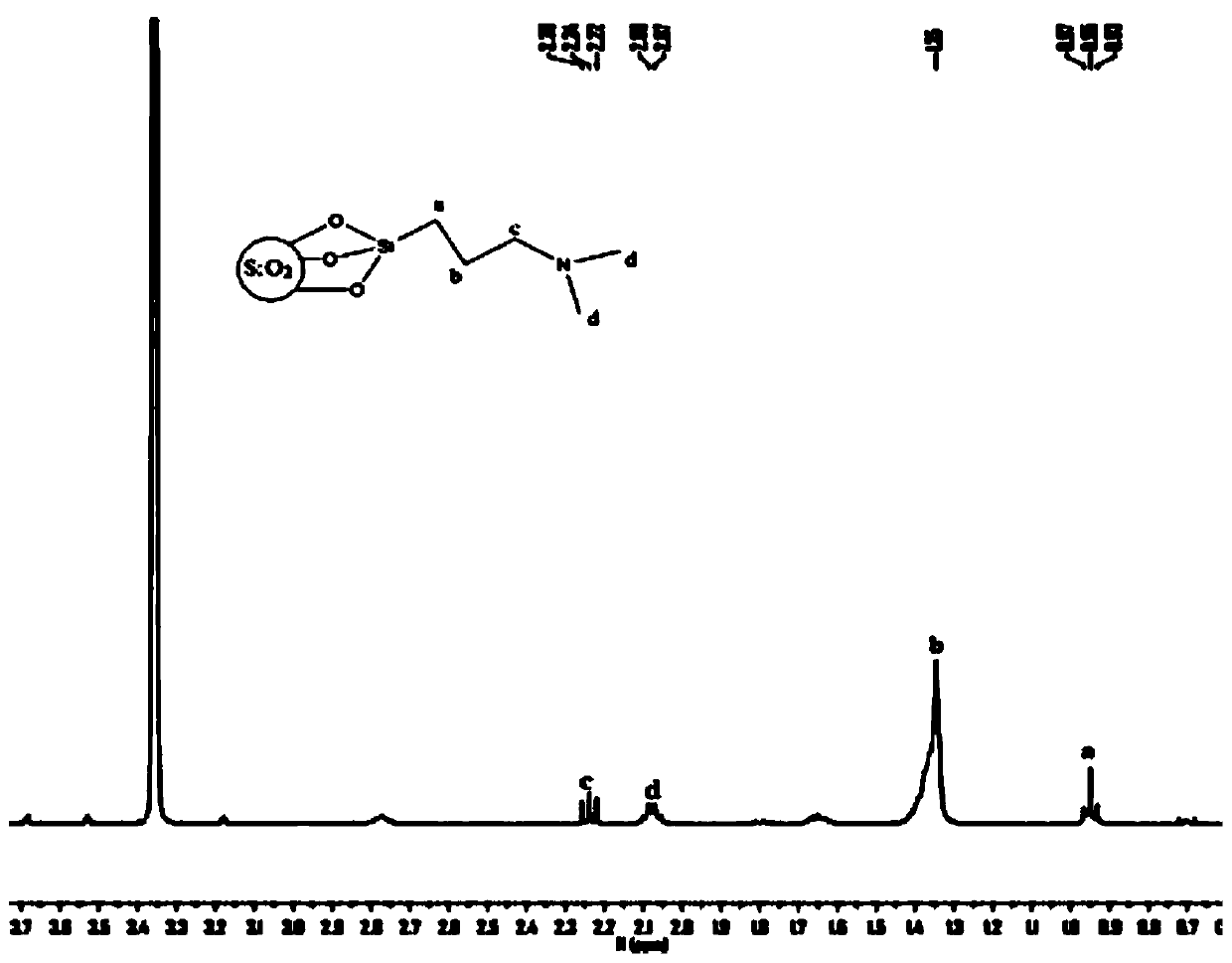

[0025] S1. Silane coupling agent modified nano-SiO 2 : In a nitrogen atmosphere, nano-SiO with a particle size of 20nm 2 Put the powder in toluene, stir for 10 minutes, then add 3-aminopropyltriethoxysilane, stir and react at 75°C for 8 hours, carry out suction filtration, wash with ethanol, and after three cycles, put it in a constant temperature oven for drying to obtain Silane Coupling Agent Modified Nano-SiO 2 ;

[0026] S2.CO 2 / N 2 Responsive modified nano-SiO 2 Particles: In a nitrogen atmosphere, the silane coupling agent is modified with nano-SiO 2 Place in N,N-dimethylformamide, stir for 10 minutes, then slowly add formic acid, then add formaldehyde while stirring, raise the temperature to 85°C for 6 hours, then filter with suction, wash with ethanol, and cycle three times , placed in a constant temperature oven for drying and storage, to obtain CO 2 / N 2 Responsive modified n...

Embodiment 2

[0029] a CO 2 / N 2 Responsive modified nano-SiO 2 Granule preparation method:

[0030] S1. Silane coupling agent modified nano-SiO 2 : In a nitrogen atmosphere, 30nm nano-SiO 2 Put the powder in toluene, stir for 12 minutes, then add 3-aminopropyltrimethoxysilane, stir and react at 80°C for 10 hours, then carry out suction filtration, wash with ethanol, and after three cycles, put it in a constant temperature oven for drying to obtain silane Coupled agent modified nano-SiO 2 ;

[0031] S2.CO 2 / N 2 Responsive modified nano-SiO 2 Particles: In a nitrogen atmosphere, the silane coupling agent is modified with nano-SiO 2 Place in N,N-dimethylformamide, stir for 12 minutes, then slowly add formic acid, then add formaldehyde while stirring, raise the temperature to 90°C for 10 hours, then filter with suction, wash with ethanol, and cycle three times , placed in a constant temperature oven for drying and storage, to obtain CO 2 / N 2 Responsive modified nano-SiO 2 partic...

Embodiment 3

[0034] a CO 2 / N 2 Responsive modified nano-SiO 2 Granule preparation method:

[0035] S1. Silane coupling agent modified nano-SiO 2 : In a nitrogen atmosphere, 40nm nano-SiO 2 Put the powder in toluene, stir for 15 minutes, then add 3-aminopropyltriethoxysilane, stir and react at 85°C for 14 hours, then carry out suction filtration, wash with ethanol, and after three cycles, put it in a constant temperature oven for drying to obtain silane Coupling agent modified nano-SiO 2 ;

[0036] S2.CO 2 / N 2 Responsive modified nano-SiO 2 Particles: In a nitrogen atmosphere, the silane coupling agent is modified with nano-SiO 2 Place in N,N-dimethylformamide, stir for 15 minutes, then slowly add formic acid, then add formaldehyde while stirring, raise the temperature to 95°C for 14 hours, then filter with suction, wash with ethanol, and cycle three times , placed in a constant temperature oven for drying and storage, to obtain CO 2 / N 2 Responsive modified nano-SiO 2 partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com