Temperature-resisting salt-tolerant foam adjusting displacing system prepared from high-salinity formation water

A high-salinity, temperature-resistant and salt-resistant technology, which is used in mining fluids, drilling compositions, chemical instruments and methods, etc. Difficulties and other problems to achieve the effect of improving oil washing efficiency, improving temperature and salt resistance, and increasing swept volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a temperature- and salt-tolerant foam profile control and flooding system prepared from high-salinity formation water. The steps are as follows:

[0043] (1) Under the condition of 25℃, add citrate in the water first, stir for 3-5 minutes to fully dissolve the citrate, and then add nano-SiO 2 Stir for 3-5 minutes and then ultrasonic for 60 minutes to make nano SiO 2 Disperse evenly in water to obtain nano SiO 2 Dispersed aqueous solution;

[0044] (2) In nano SiO 2 Add the surface active agent THSB to the dispersed aqueous solution, stir for 3-5 minutes to fully dissolve, and obtain the first mixed solution;

[0045] (3) Add partially hydrolyzed HPAM to the first mixed solution, and continue to stir the solution for 6 hours to obtain a temperature- and salt-tolerant foam profile control and flooding system prepared from high-salinity formation water.

[0046] An oil displacement method of a temperature-resistant, salt-tolerant foam profile control and disp...

Embodiment 1

[0057] This example evaluates the flocculation, foaming and foam stabilization performance of a temperature-tolerant and salt-tolerant foam profile control and flooding system prepared from high-salinity formation water.

[0058] At 25℃, prepare nano SiO 2 The mass fraction of 1%, the mass fraction of THSB is 0.05%, the mass fraction of partially hydrolyzed HPAM is 0.1%, the average molecular weight is 4 million, the degree of hydrolysis is 6%, the mass fraction of sodium citrate is 0.1%, and the balance is water. , The water is simulated mineralized water prepared according to reservoir conditions, with a total salinity of 220,000 mg / L, of which Ca 2+ With Mg 2+ The ion concentration is 2000mg / L.

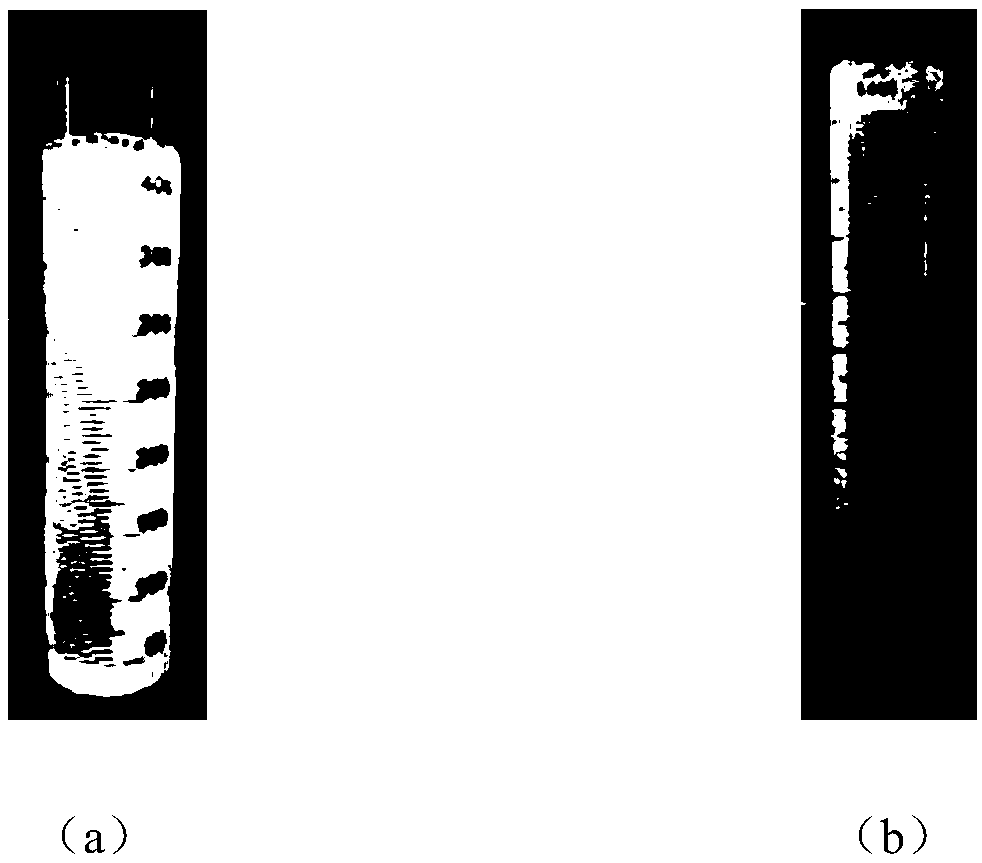

[0059] Such as figure 1 As shown, under unstirred conditions, the control and flooding system flocculates less at 25°C and 220,000 mg / L. After aging under high temperature conditions, such as figure 2 As shown, when the solution is placed in an ampoule and sealed in a thermostatic oven ...

Embodiment 2

[0064] A temperature-resistant and salt-resistant foam profile control and flooding system prepared from high-salinity formation water, including the following mass fraction components: 1.5% nano-SiO 2 , 0.1% THSB, 0.15% partially hydrolyzed polyacrylamide (HPAM), the average molecular weight is 6 million, the degree of hydrolysis is 8%, 0.1% potassium citrate, the balance is water, and the total mass fraction of each component is 100% , The water is simulated mineralized water prepared according to reservoir conditions, with a total salinity of 220,000 mg / L, of which Ca 2+ With Mg 2+ The ion concentration is 2000mg / L.

[0065] A method for preparing a temperature- and salt-tolerant foam profile control and flooding system prepared from high-salinity formation water. The steps are as follows:

[0066] (1) Under the condition of 25℃, add 0.15g potassium citrate to 99.25g simulated mineralized water, stir to fully dissolve potassium citrate, and then add 1.5g nano-SiO 2 Stir for 3-5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com