Method of peroxyformic acid of gasoline oxidation extraction and desulfurization

A technology of peroxyformic acid and gasoline, which is applied in the field of peroxyformic acid oxidation, extraction and desulfurization of gasoline, which can solve the problems of low gasoline yield and achieve good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 60g of formic acid and 10g of hydrogen peroxide with a mass concentration of 30%, add tungstic acid to make the mass fraction of the mixed solution 1.0%, stir and mix at 25°C for 30min to prepare a peroxyformic acid oxidation solution. Under the conditions of reaction temperature 30°C and reaction time 30min, in a 250ml flask, oxidize 100.0ml of catalytically cracked gasoline with a sulfur content of 183.33μg / g in a 250ml flask, and place the mixture in a 250ml separatory funnel after oxidation Settled for 20 minutes, separated the oxidized liquid in the lower layer; then, at room temperature, under the condition that the volume ratio of deionized water to gasoline was 1:2, in a 250ml flask, washed the gasoline with 50.0ml deionized water for 15min, and the mixture was washed with water Settling in a 250ml separating funnel for 20min, the lower aqueous phase was separated to obtain the upper layer of oxidized gasoline. Then, under the conditions of extraction temper...

Embodiment 2~ Embodiment 5

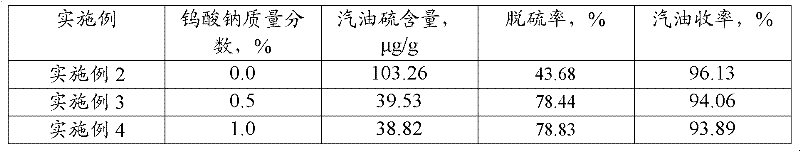

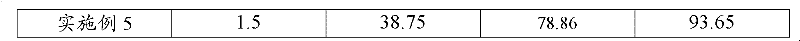

[0023] Mix 60g of formic acid and 10g of hydrogen peroxide with a mass concentration of 30%, respectively add sodium tungstate so that the mass fraction of the mixed solution is 0.0%, 0.5%, 1.0%, and 1.5%, and stir and mix at 25°C for 30 minutes to prepare Obtain peroxyformic acid oxidation solution. At a reaction temperature of 30°C and a reaction time of 30 minutes, in a 250ml flask, use these oxidation solutions to oxidize 100.0ml of FCC gasoline with a sulfur content of 183.33μg / g, and put the mixture in a 250ml separating funnel after oxidation. Settling for 20 minutes, the oxidation liquid in the lower layer was separated; then, water washing treatment, solvent extraction, and water washing treatment were carried out. The water washing treatment and solvent extraction conditions were the same as in Example 1. The desulfurization experiment results are listed in Table 1.

[0024] Table 1

[0025]

[0026]

[0027] It can be seen from the data in Table 1 that, compa...

Embodiment 6~ Embodiment 11

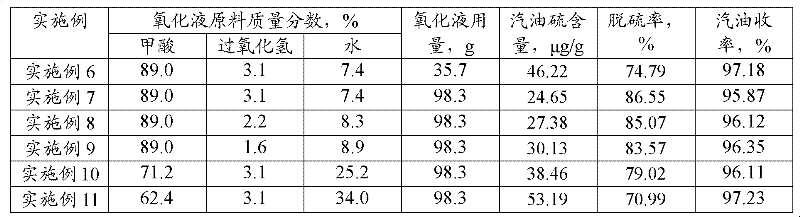

[0029] Mix different amounts of formic acid, hydrogen peroxide, and deionized water, and add sodium tungstate to prepare a peroxyformic acid oxidation solution with a mass fraction of sodium tungstate of 0.5%. Carry out oxidation treatment to the 100.0ml catalytic gasoline that sulfur content is 183.33 μ g / g, then carry out the washing of embodiment 1 condition, solvent extraction, washing treatment, investigate the influence of peroxyformic acid solution raw material composition and consumption on catalytic gasoline desulfurization, will corresponding The experimental results are listed in Table 2.

[0030] Table 2

[0031]

[0032] As can be seen from Table 2, under the certain situation of preparing the raw material ratio of peroxyformic acid solution, along with the increase of the peroxyformic acid solution consumption, the desulfurization rate improves to some extent, and the gasoline yield decreases to some extent; Under certain circumstances, with the increase of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com