Preparation method of superabsorbent resin

A technology of superabsorbent resin and monomer, which is applied in the field of preparation of superabsorbent resin, can solve problems such as unsatisfactory liquid absorption rate, and achieve the effects of low cost, high efficiency and good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The impact of embodiment 1 monomer ratio on resin liquid absorption rate

[0028] Fix ω(NMBA)=0.022%, ω(KPS)=0.15%, the neutralization degree of AA and AMPS is 75%, the influence of different monomer molar ratios on the water absorption capacity of the resin is shown in Table 1, and Table 1 is the factor level. From Table 2, the optimal mole combination is: A 2 B 2 C 1 D. 1 , that is, the monomer ratio: n(AMPS):n(AA):n(AM)=1:2:0.5, when ω(starch)=3%, the liquid absorption rate of the water-absorbent resin reaches the maximum. The main reason is that with the increase of the ratio of AA to AM in the solution, the hydrophilic group -COO - When the ratio is too high, self-crosslinking occurs during copolymerization, and the expansion of the polymer network is limited during liquid absorption, so that the liquid absorption ratio decreases; when the amount of AMPS increases, the SO in the solution 3 -The number of AMPS increases and the charge density is higher, which ...

Embodiment 2

[0031] Example 2 The effect of the amount of crosslinking agent on the liquid absorption rate of superabsorbent resin

[0032] Fixed ω (KPS) = 0.15% (based on the total mass), the neutralization degree of AA and AMPS is 75%, n(AMPS):n(AA):n(AM)=1:2:0.5, ω( Starch) = 3%. The effect of the amount of cross-linking agent on the liquid absorption rate of superabsorbent resin is shown in Table 3. It can be seen from Table 3 that with the increase of the amount of cross-linking agent, the liquid absorption rate of the resin first increases and then decreases. When the amount of cross-linking agent is 0.023% of the total mass, the liquid absorption rate of the resin is the highest. The main reason is that when the amount of cross-linking agent is low, the cross-linking reaction is incomplete, the degree of cross-linking is weak, and the formed space network structure is not obvious, which reduces the water absorption rate of the resin; when the amount of cross-linking agent is too la...

Embodiment 3

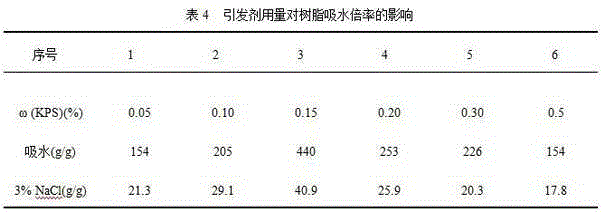

[0034] The influence of embodiment 3 initiator dosages on resin liquid absorption rate

[0035] Fixed ω(NMBA)=0.023% (based on the total mass), the neutralization degree of AA and AMPS is 75%, n(AMPS):n(AA):n(AM)=1:2:0.5, ω( Starch) = 3%. The effect of the amount of initiator on the liquid absorption rate of superabsorbent resin is shown in Table 4. It can be seen from Table 4 that when the amount of initiator is too small, the reaction speed is slow, the reactive points in the reaction system are less, and the resin cannot effectively form a three-dimensional space network structure, so the liquid absorption rate is low; when the amount of initiator is high, the polymerization rate Too fast, the resin forms a three-dimensional network space with more branched chains, so the liquid absorption rate decreases. Therefore, when the amount of initiator is 0.15%, the liquid absorption rate of the resin is the highest.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com