Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389 results about "N-Propanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-assisted lithographic process using photosensitive sol-gel derived glass for depositing ridge waveguides on silicon

InactiveUS6054253ARapid thermal annealingSimple wayPhotomechanical apparatusOriginals for photomechanical treatmentRidge waveguidesSolvent

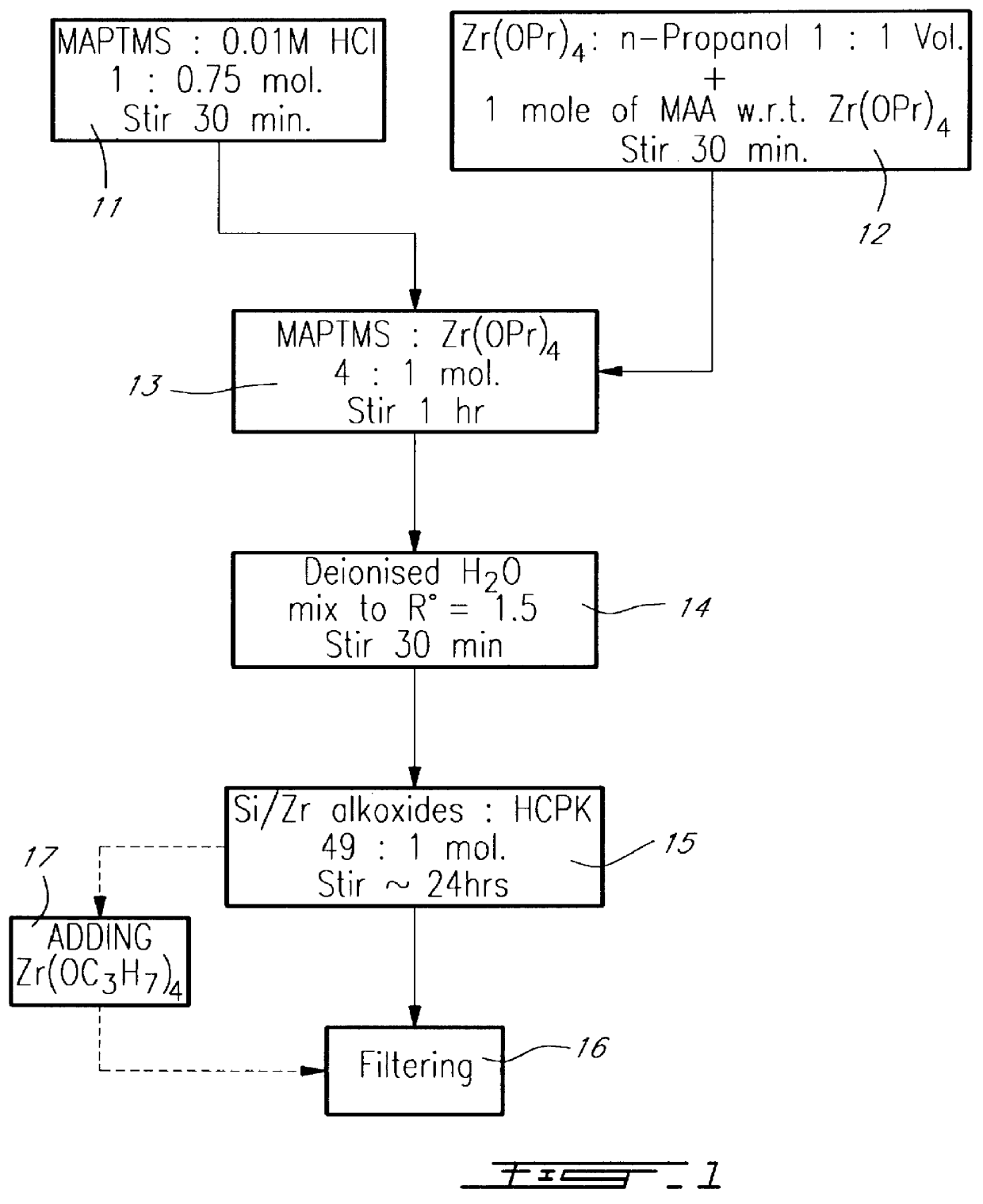

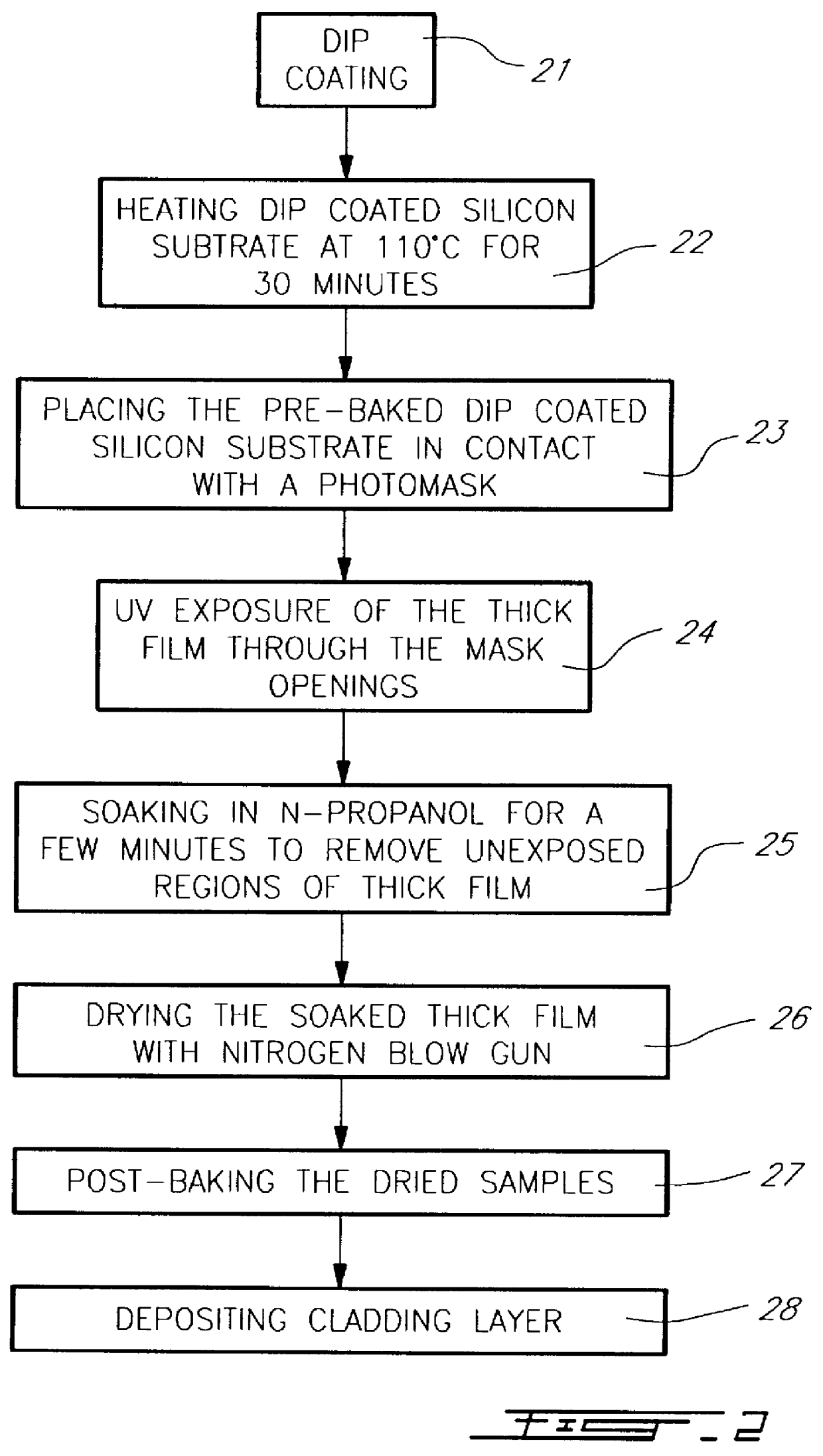

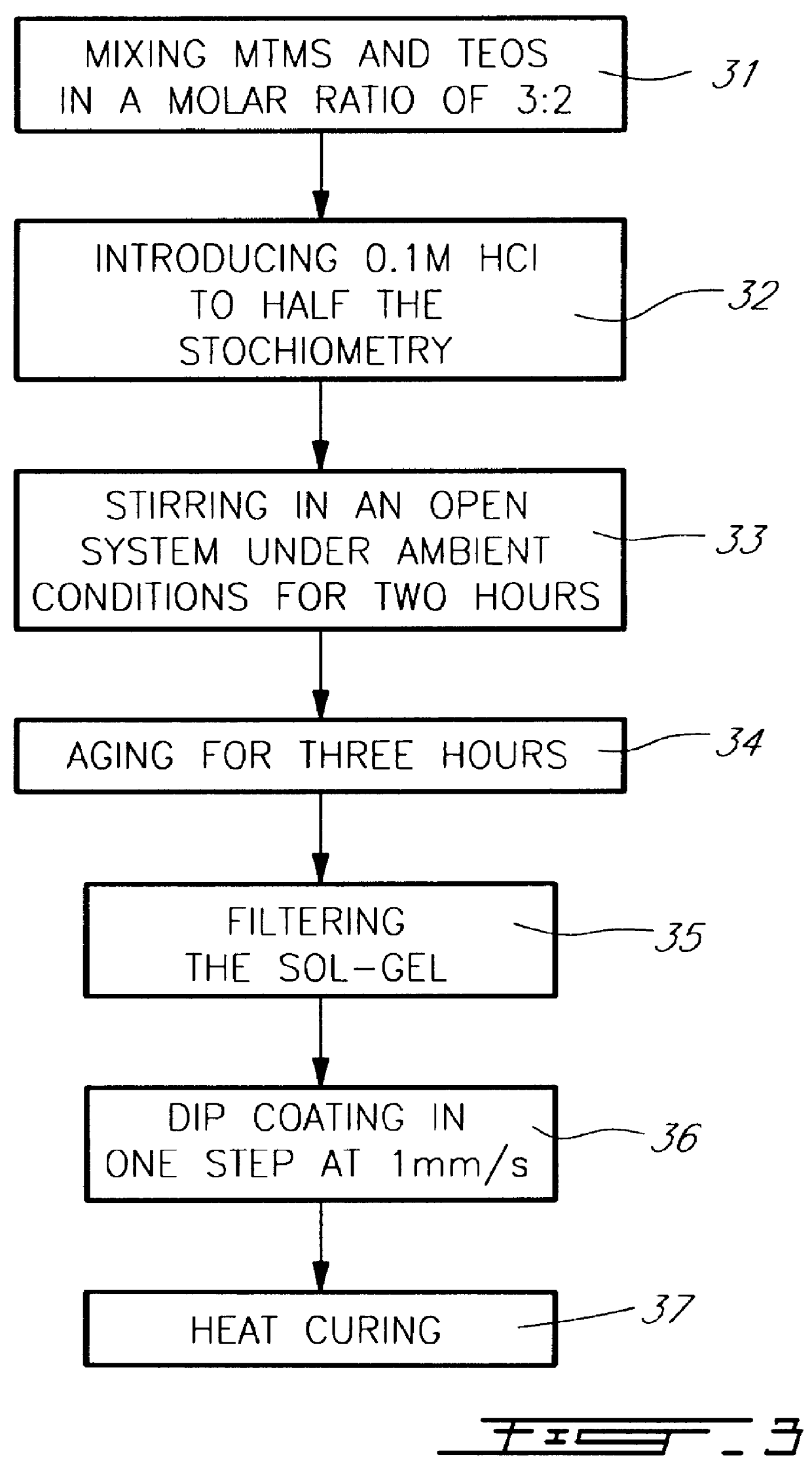

The process for fabricating a ridge waveguide on a substrate uses a photosensitive sol-gel glass material prepared, according to a first embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) and methacrylic acid (H2C=C(CH3)COOH) or, according to a second embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) with bis(s-butoxy)aluminoxytriethoxysilane. A thick film of photosensitive sol-gel glass material is first dip coated on at least a portion of the substrate. A photomask is applied to the film of photosensitive sol-gel glass material, and this sol-gel material is exposed to ultraviolet radiation through the opening(s) of the photomask to render a portion of the film insoluble to a given solvent and thereby imprint the ridge waveguide in that film. The thick film is then soaked in this solvent, for example n-propanol to dissolve the unexposed portion of the sol-gel film and leave on the substrate the exposed film portion and therefore the ridge waveguide. The ridge waveguide is heat cured and the heat cured ridge waveguide is covered with a cladding layer.

Owner:MCGILL UNIV - THE ROYAL INSTION FOR THE ADVANCEMENT OF LEARNING

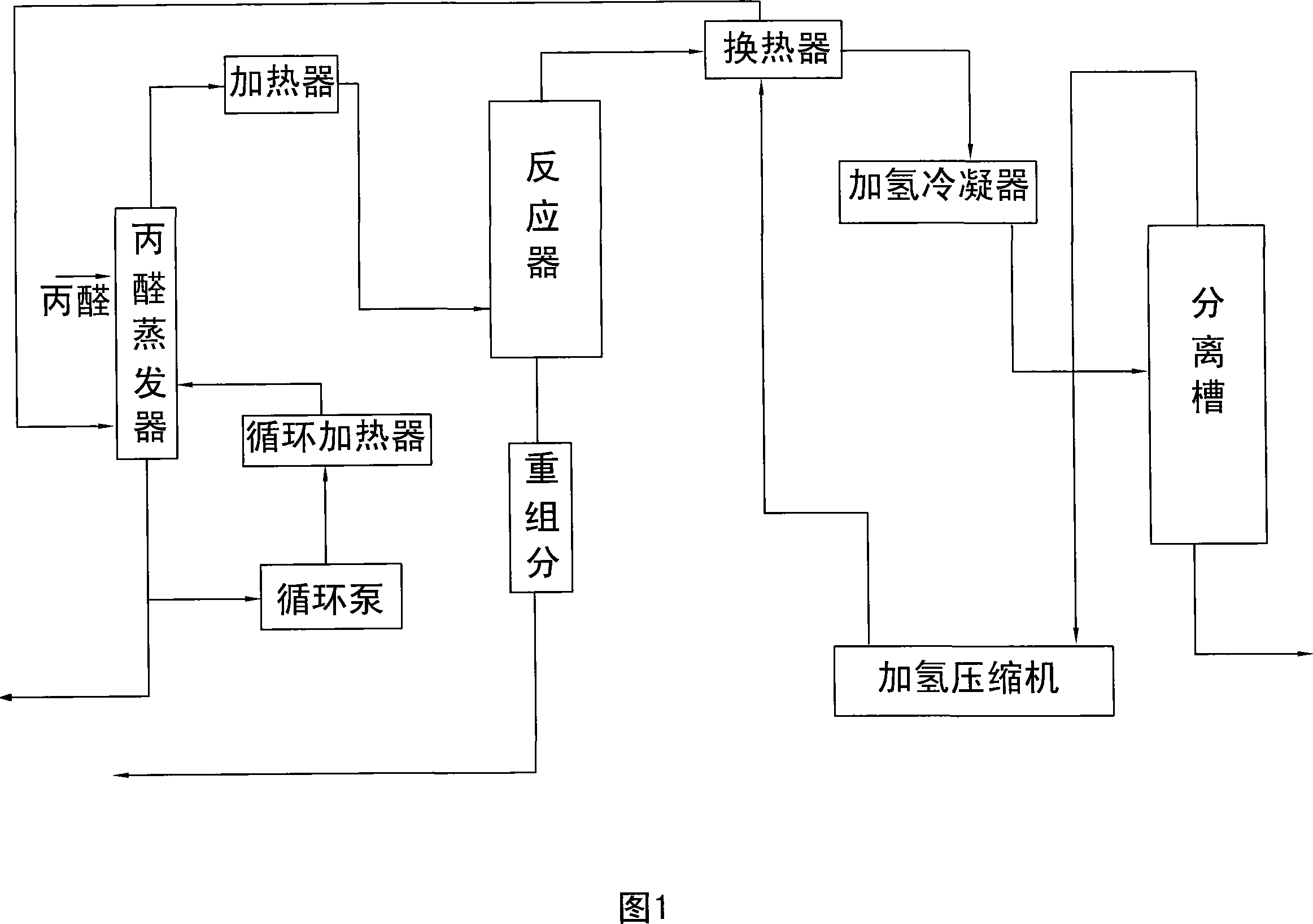

Process for preparing n-propanol by hydrogenating glycerol

ActiveCN101054339AHigh selectivityOvercome the disadvantage of low selectivityOrganic compound preparationHydroxy compound preparationChemical industryBiodiesel

The invention provides a method for preparing normal propyl alcohol by glycerol hydrogenation, wherein glycerite or biodiesel byproduct glycerol which is diluted by glycerol or solvent reacting with hydrogen or gaseous mixture containing hydrogen to generatenormal propyl alcohol, which provides a new way for synthesizing normal propyl alcohol. The present invention can enhance activity of glycerol hydrogenation and selectively generates normal propyl alcohol, also can make normal propyl alcohol united generating with 1,2-propanediol, ethandiol, methylic alcohol and ethyl hydrate, thus its product process program is very flexible. The present invention is characterized in that its technological condition is geniality, raw material is cheap and can be obtained easily and the cost of manufacture is low, which belongs to environment friendly green chemical industry technique.

Owner:SHANGHAI HUAYI NEW MATERIAL

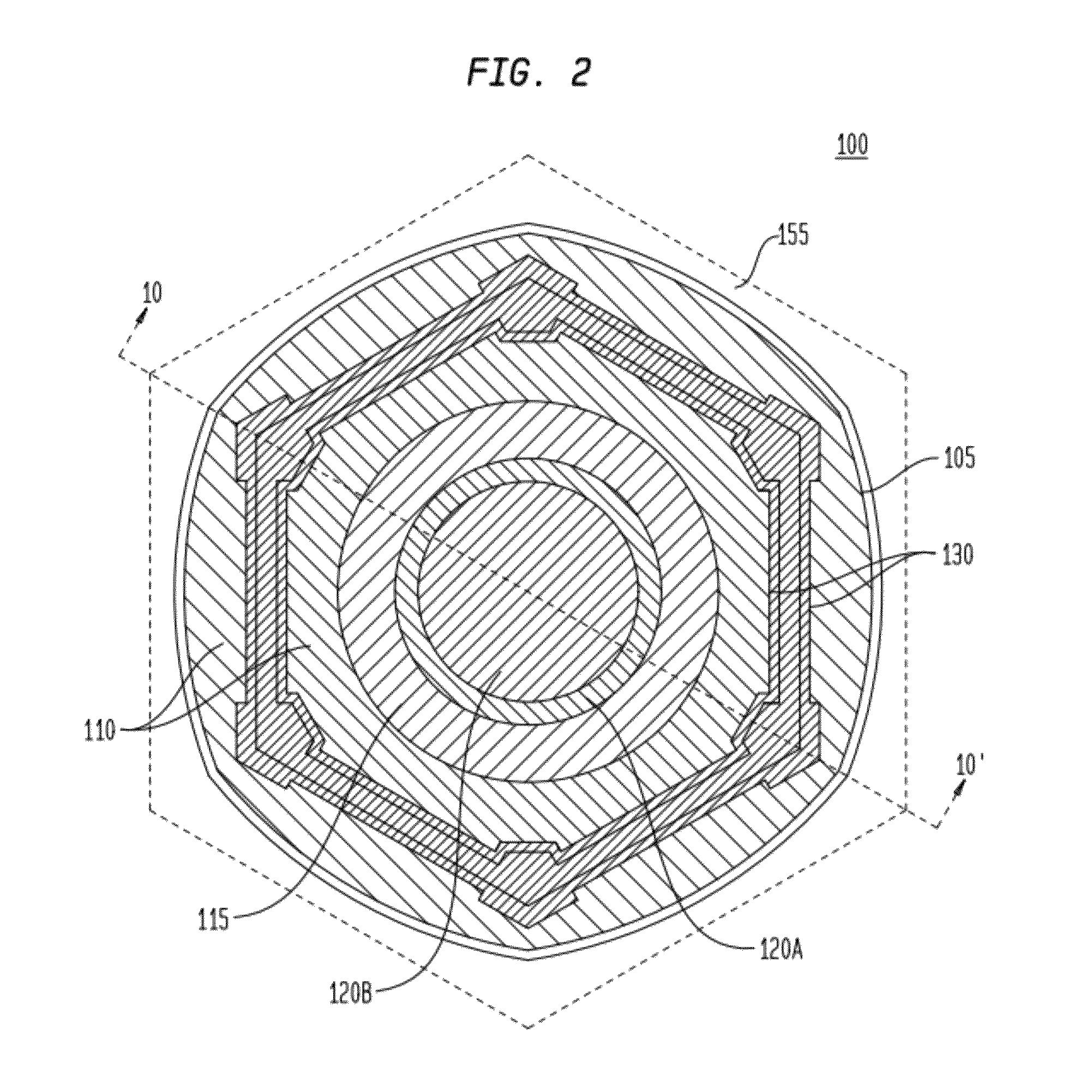

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

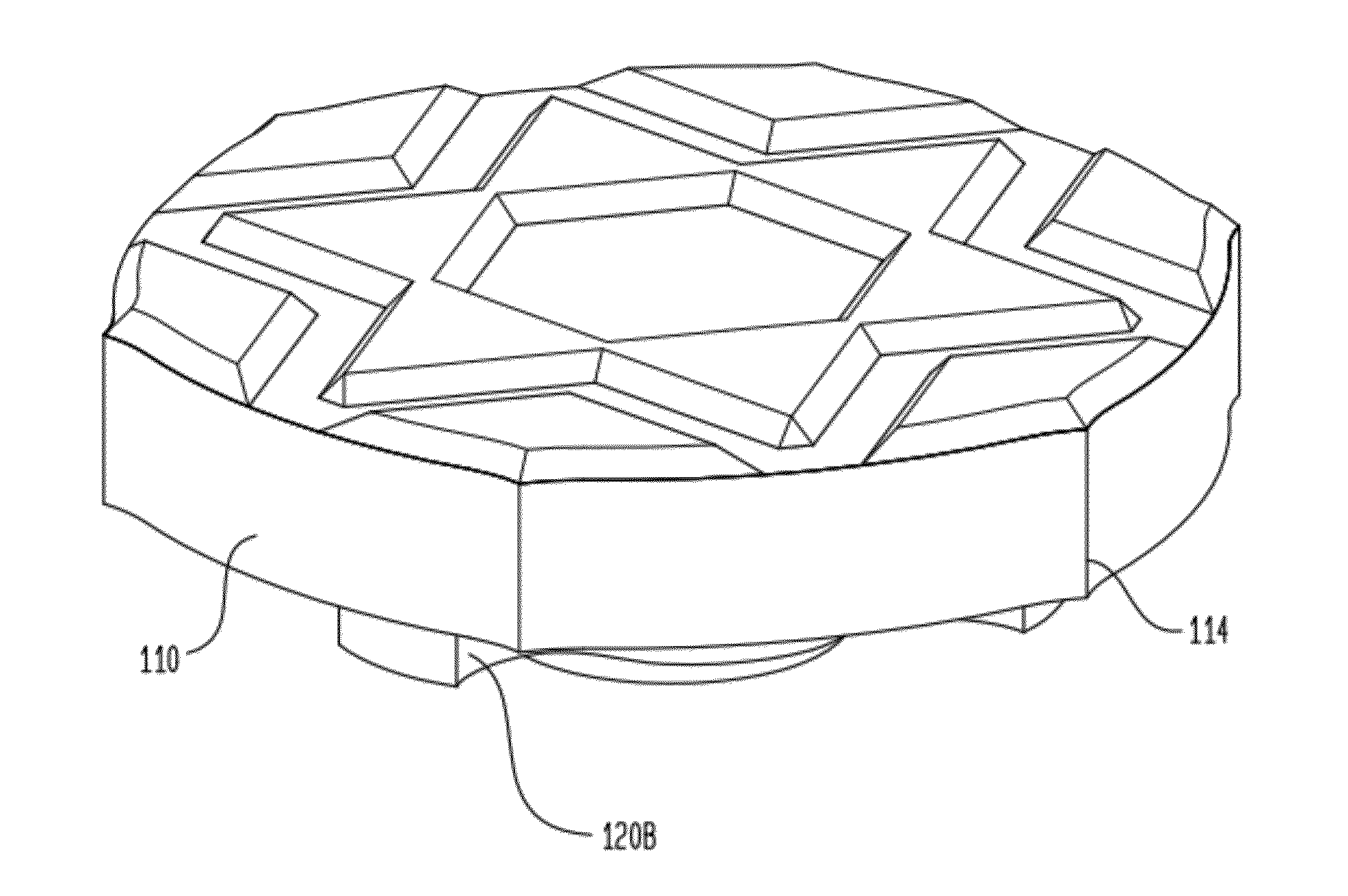

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

Printable composition of a liquid or gel suspension of diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

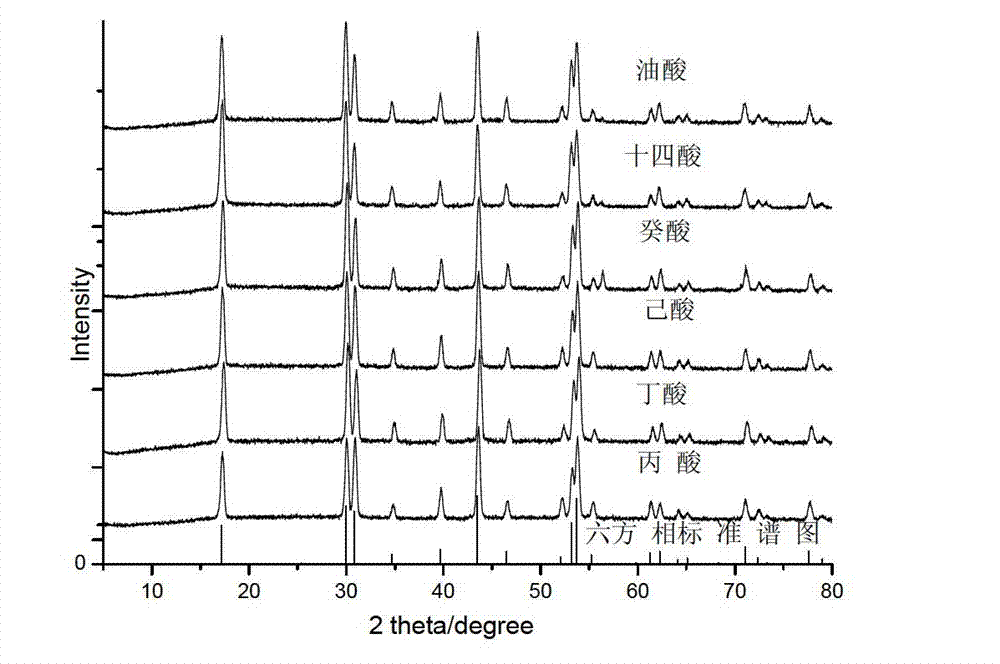

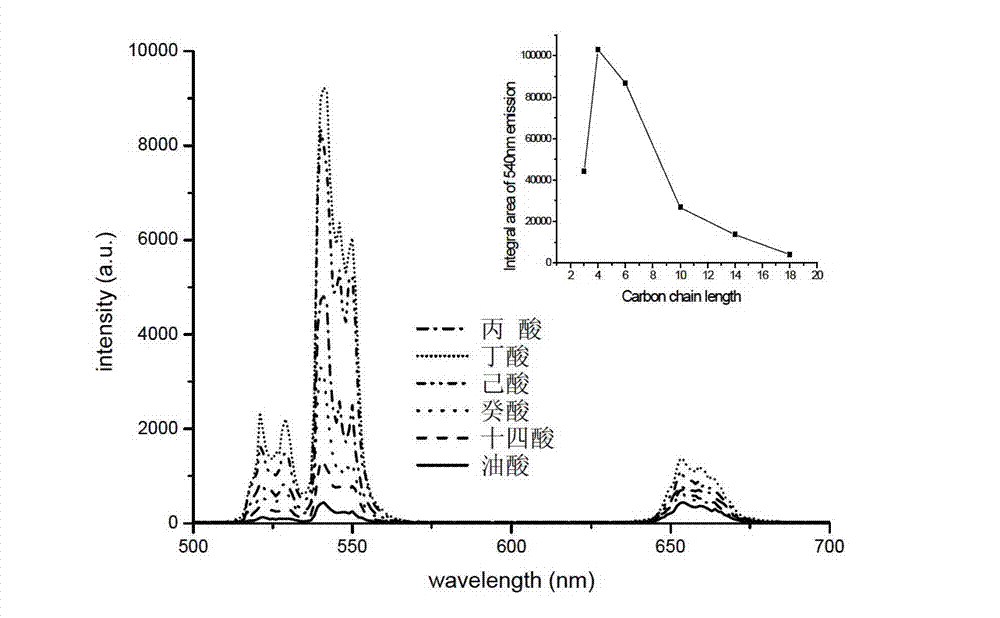

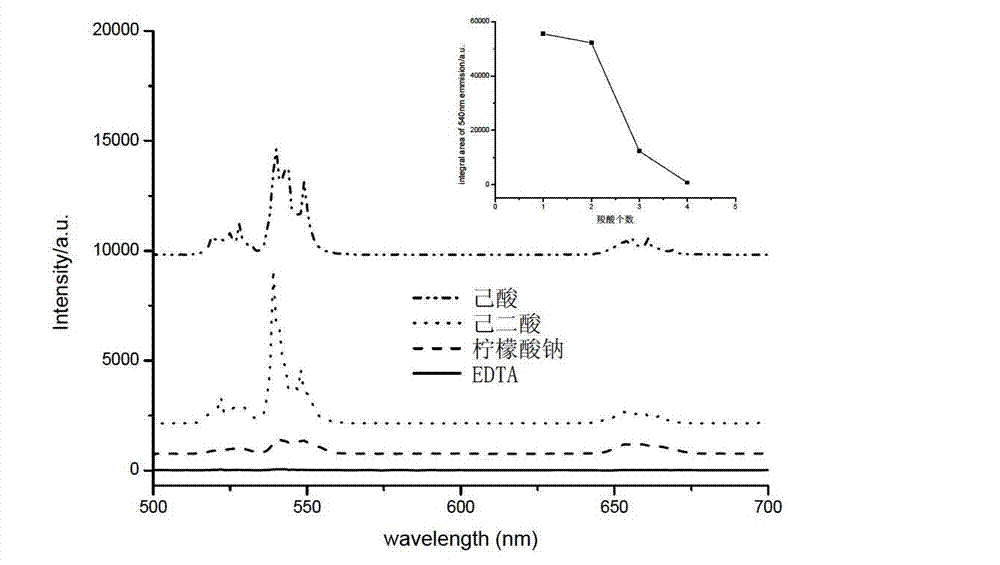

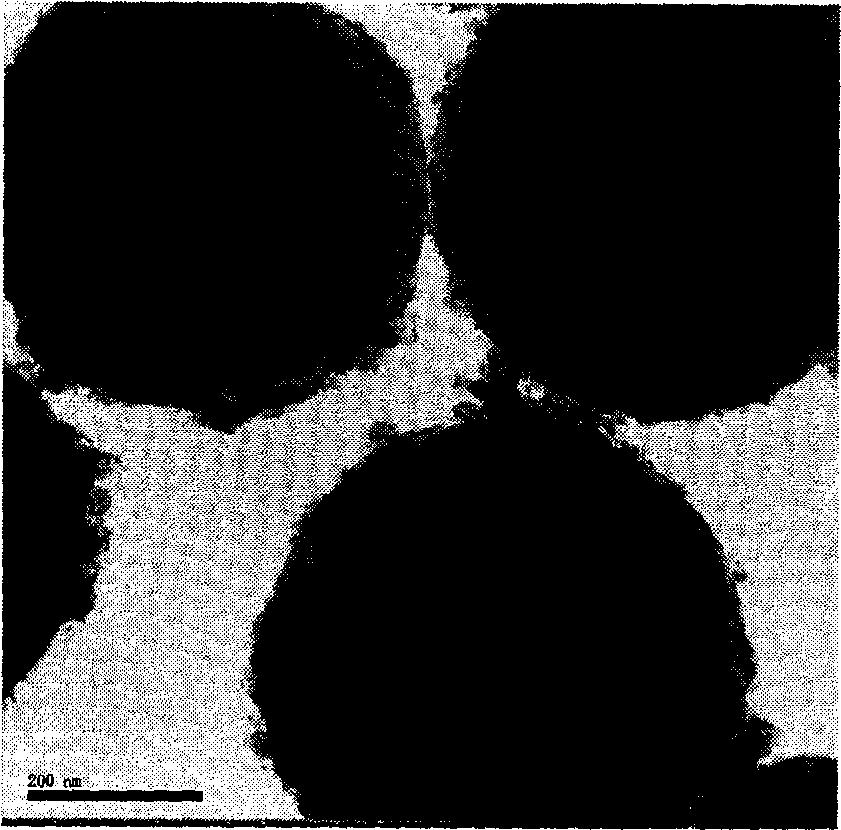

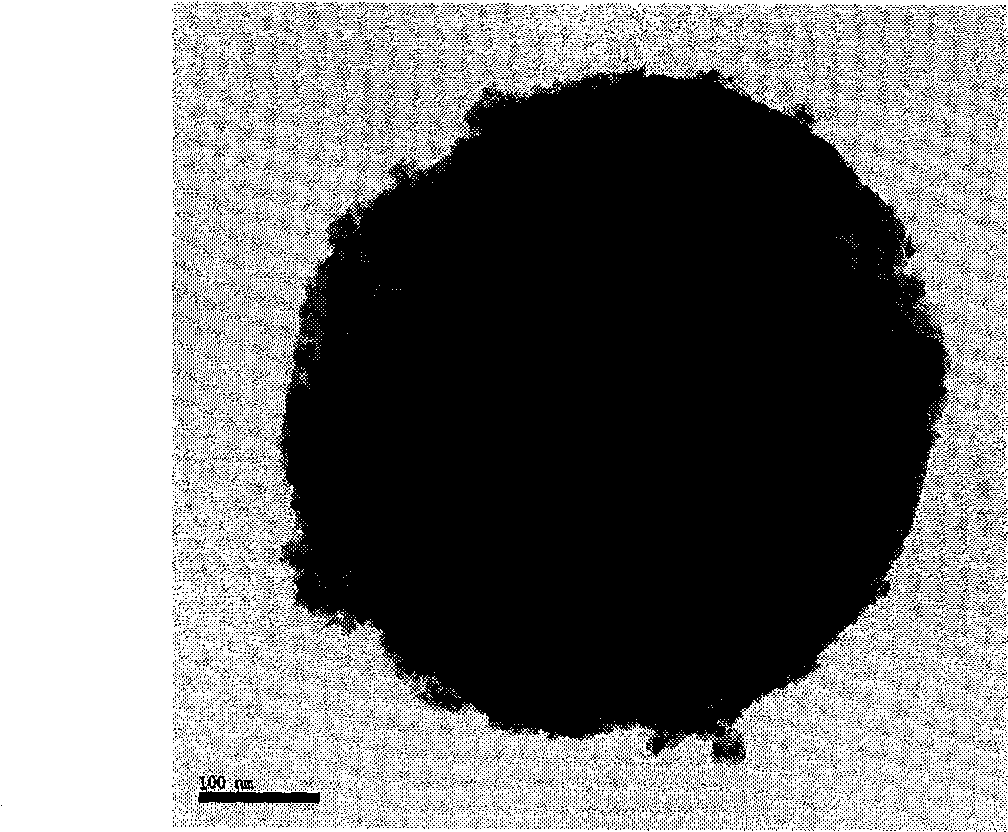

High-strength rare earth-doped up-conversion luminescence nanometer material and preparation method thereof

The invention provides a method of improving luminous efficiency of a rare earth-doped up-conversion luminescence nanometer material through changing the usage of a ligand. According to the method, the synthesis adopts a hydrothermal-solvothermal method, an organic ligand is an organic compound such as monocarboxylic acid, dicarboxylic acid or polycarboxylic acid, and amine, the molar ratio of rare earth ions to the ligand is 2:1-1:100, the molar ratio of NaOH to the ligand is 0:1-1:1, water / alcohol, water / n-propanol alcohol, water / isopropyl alcohol, water / n-butyl alcohol, water / acetone or water / ethylene glycol is used as a solvent, the temperature ranges from 180-240 DEG C, the reaction time is 2-24h, and the F<-> / Re value ranges from 4-12. With the method, the problems of selecting various ligands for synthesizing the up-conversion luminescence nanometer material, improving the luminous efficiency of the rare earth-doped up-conversion luminescence nanometer material, synthesizing the water-soluble up-conversion luminescence nanometer material, and the like can be mainly solved.

Owner:DALIAN UNIV OF TECH

Fuel blends

A fuel additive composition containing ethanol, n-propanol or mixtures thereof together with a non-hydroxy fatty acid and organic ester is described. A miscible fuel blend composition containing the fuel additive composition and diesel oil, gas oil or a mixture thereof, as well as a process for preparing the fuel blend composition is also described.

Owner:VICTORIAN CHEM INT

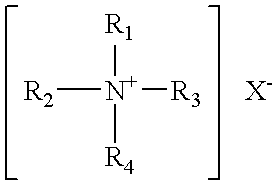

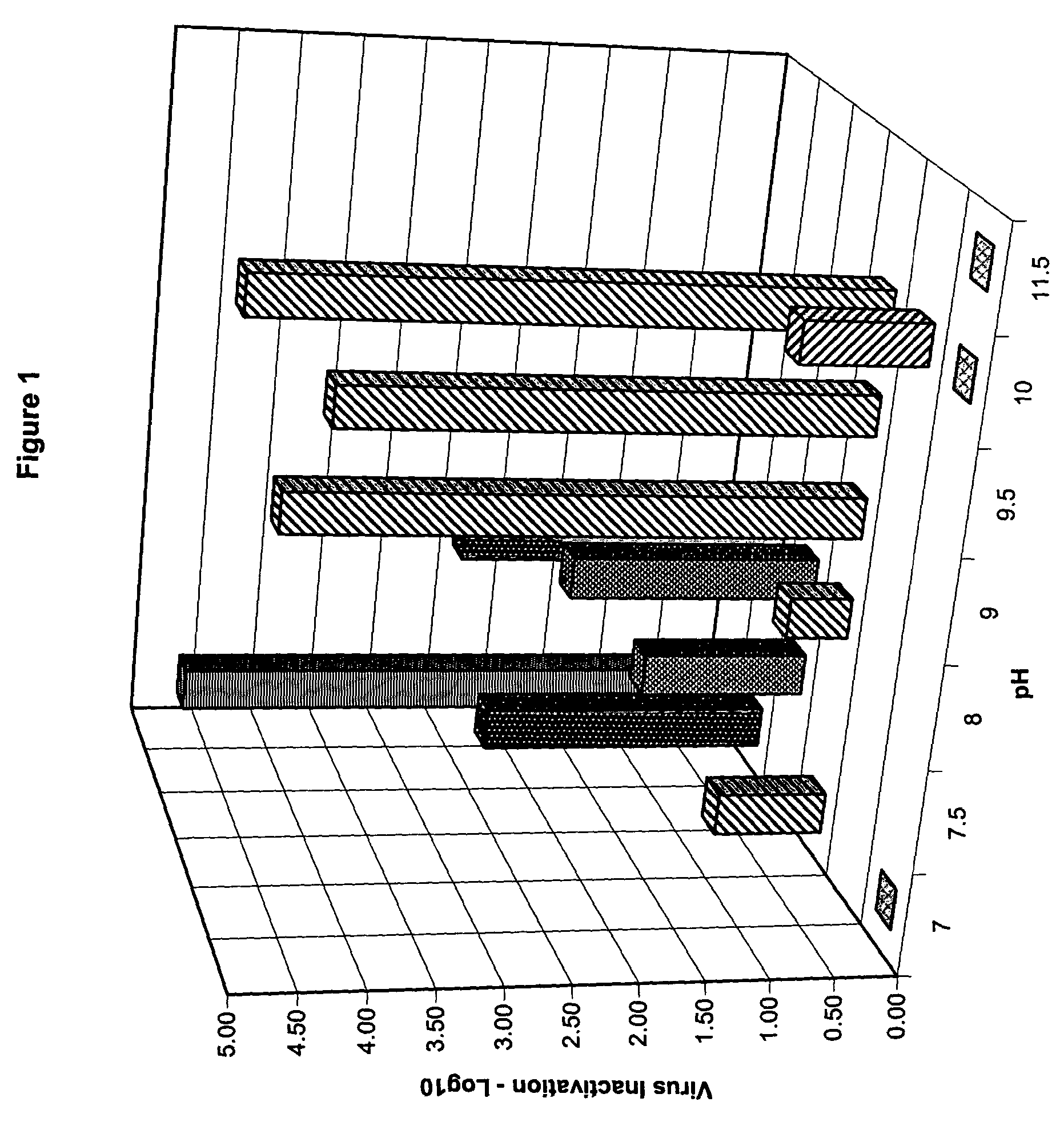

Method and Composition for Disinfecting Hard Surfaces

Aqueous hard surface treatment compositions necessarily comprise an alcohol constituent selected from the group consisting of methanol, ethanol, n-propanol, isopropanol, n-butanol, benzyl alcohol, and mixtures thereof which alcohol constituent comprises from about 40 and 70 weight percent (“% wt”) of the total weight of the composition of which it forms a part. Preferably however the alcohol constituent is present in an amount of from about 50% wt to about 70% wt, more preferably is present in amounts of from about 60% wt to about 70% wt.

Owner:RECKITT BENCKISER INC

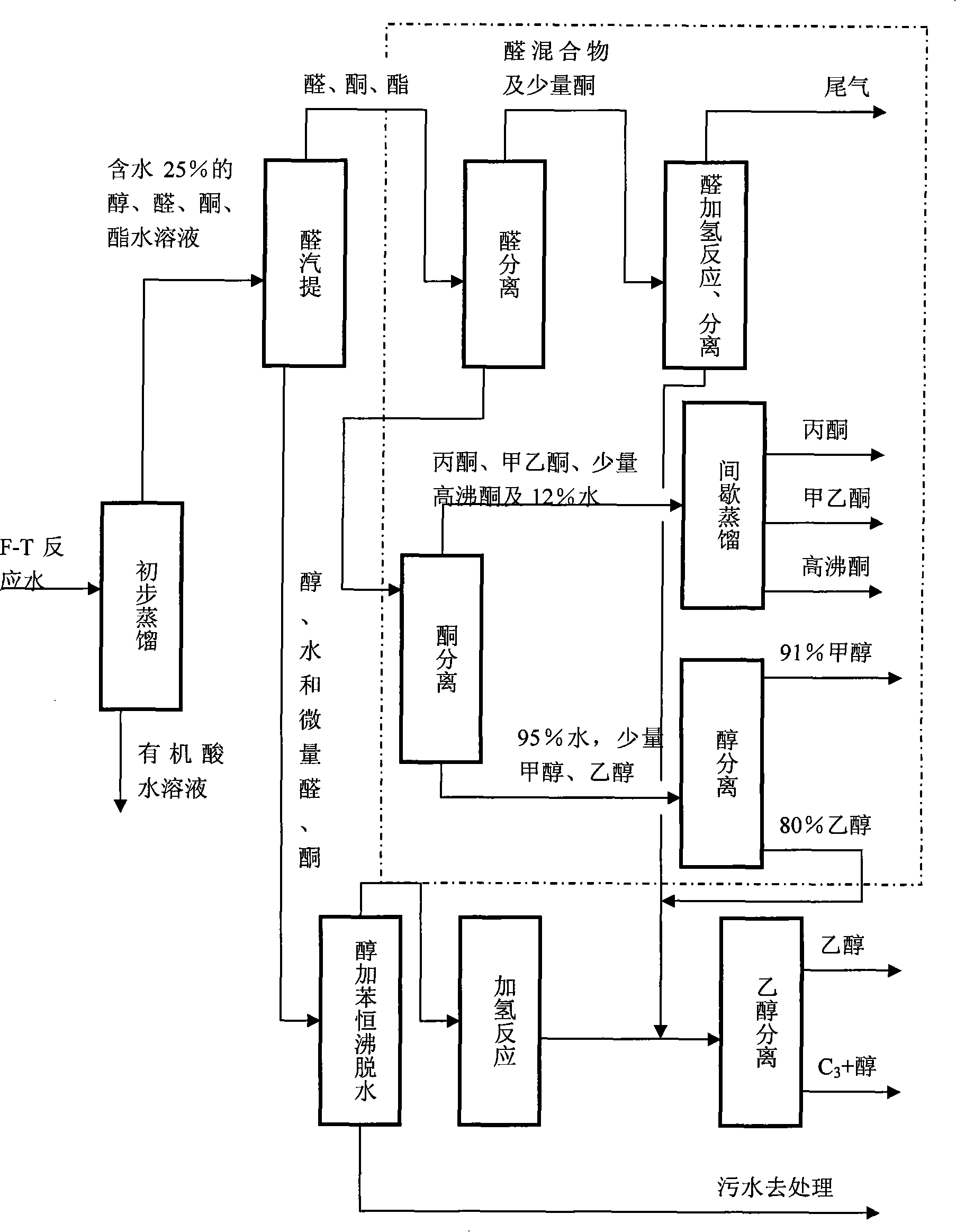

Method for separating and reclaiming organic matter from high-temperature Fischer-Tropsch synthesis reaction water

ActiveCN101239886AEffective and orderly separation and recoveryOrderly separation and recoveryOrganic compound preparationHydroxy compound preparationRecovery methodKetone

The invention relates to a separation and recovery method of organic matters in high-temperature Fischer-Tropsch synthesis reaction water. The method comprises steps of: (1) separating and recoverying aldehyde after rectifying and removing organic acid; (2) rectifying and separating ketone / n-propanol; (3) rectifying and separating acetone / butanone; (4) refining acetone; (5) extracting and separating butanone / ethanol; (6) rectifying and separating ethanol / n-propanol; further rectifying alcohol-containing aqueous sollution obatained from the bottom of a column for rectifying and separating ketone / n-propanol, ethanol containing little water and obtained from the top of the column, and n-propanol alcohol-containing aqueous sollution obatained from the bottom of the column; (7) azeotropic rectifying ethanol sollution obtained by exaction and separation, and ethanol sollution with n-propanol separated to prepare anhydrous ethanol; (8) adding calces in n-propanol aqueous sollution, distilling to obtain n-propanol products; the invention effectively and orderly separates and recoveries aldehyde, acetone, butanone, ethanol and n-propanol, the purity of each product is above 95% and the yield is above 90%.

Owner:YANKUANG ENERGY R&D CO LTD

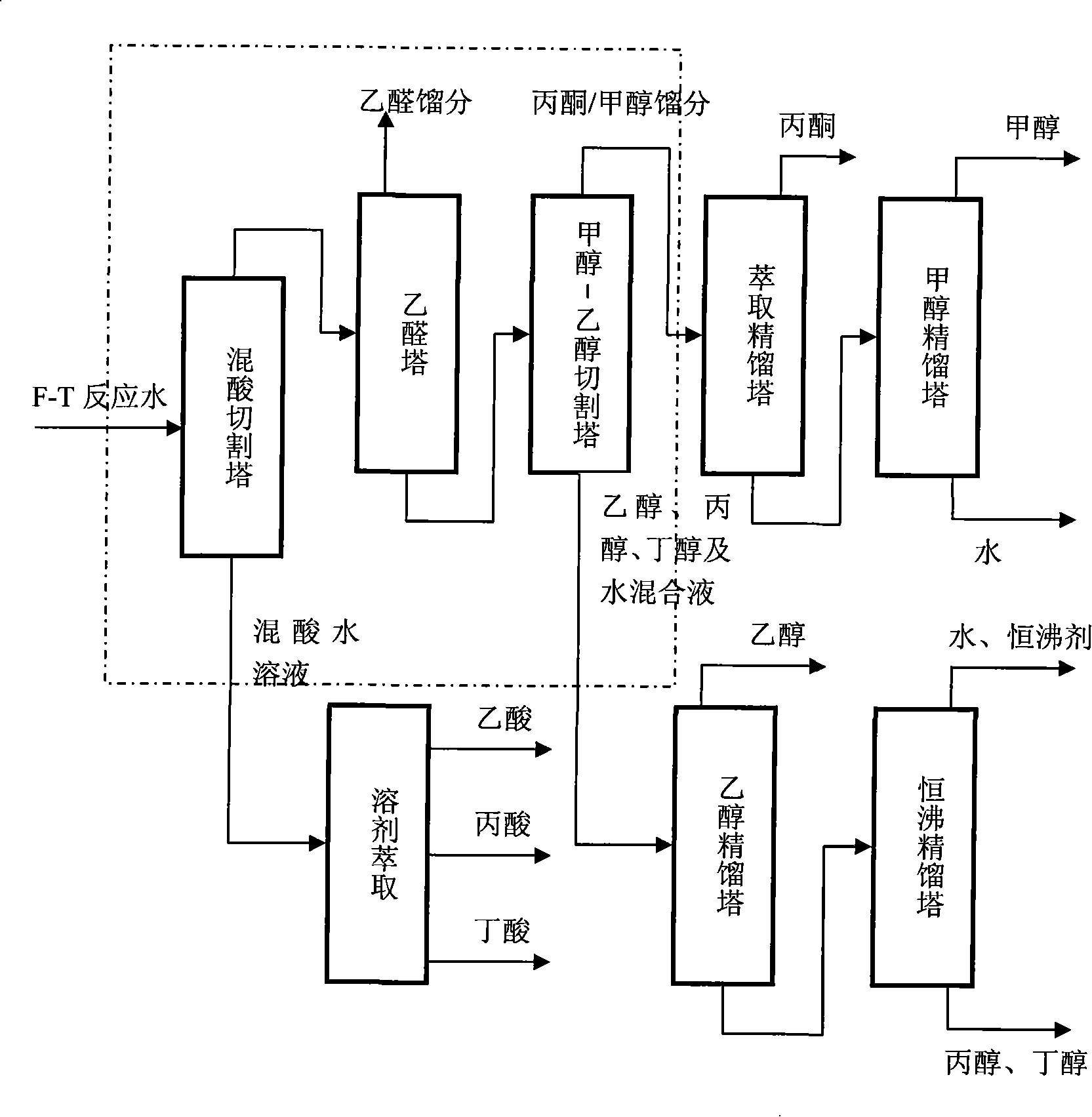

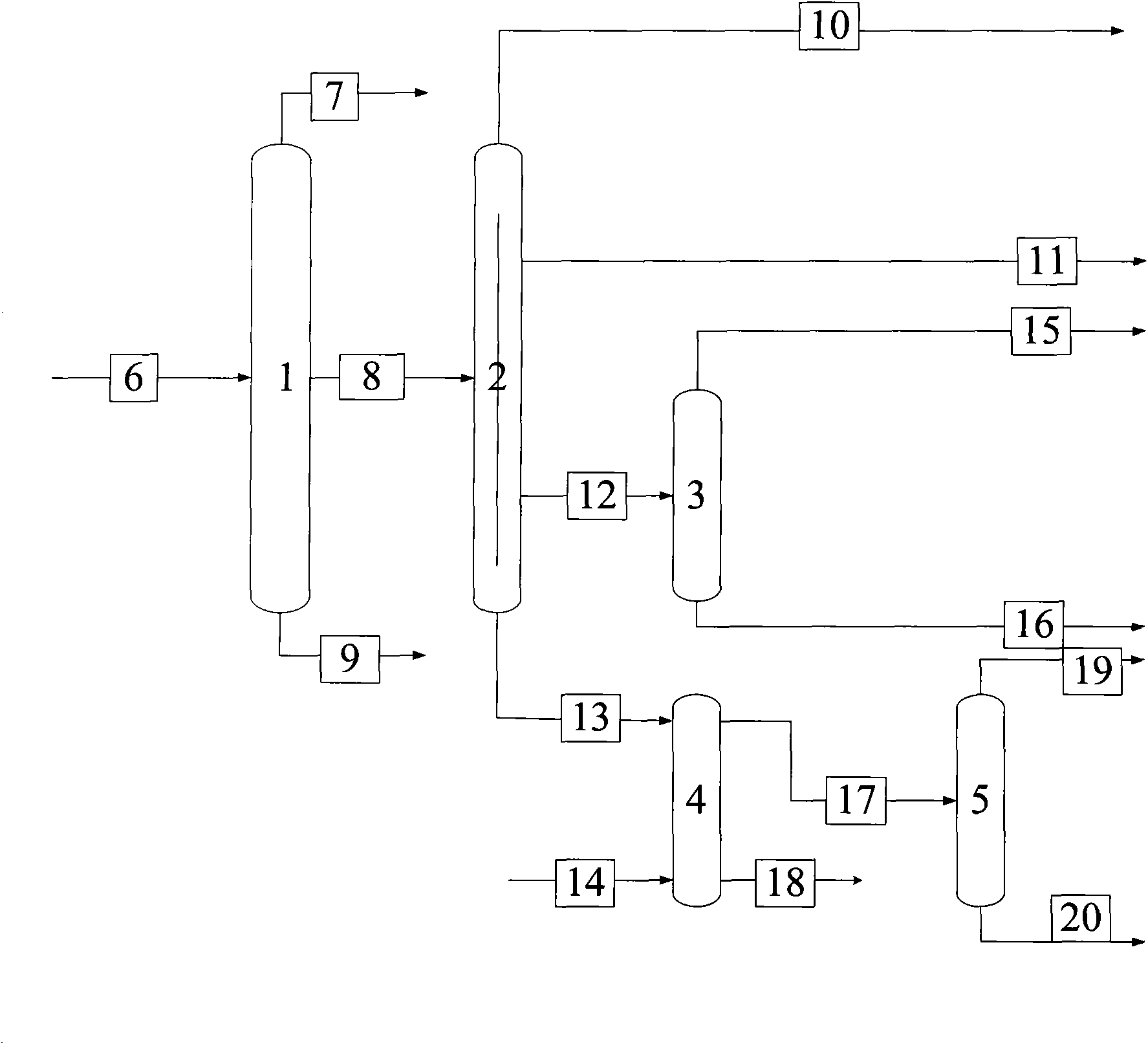

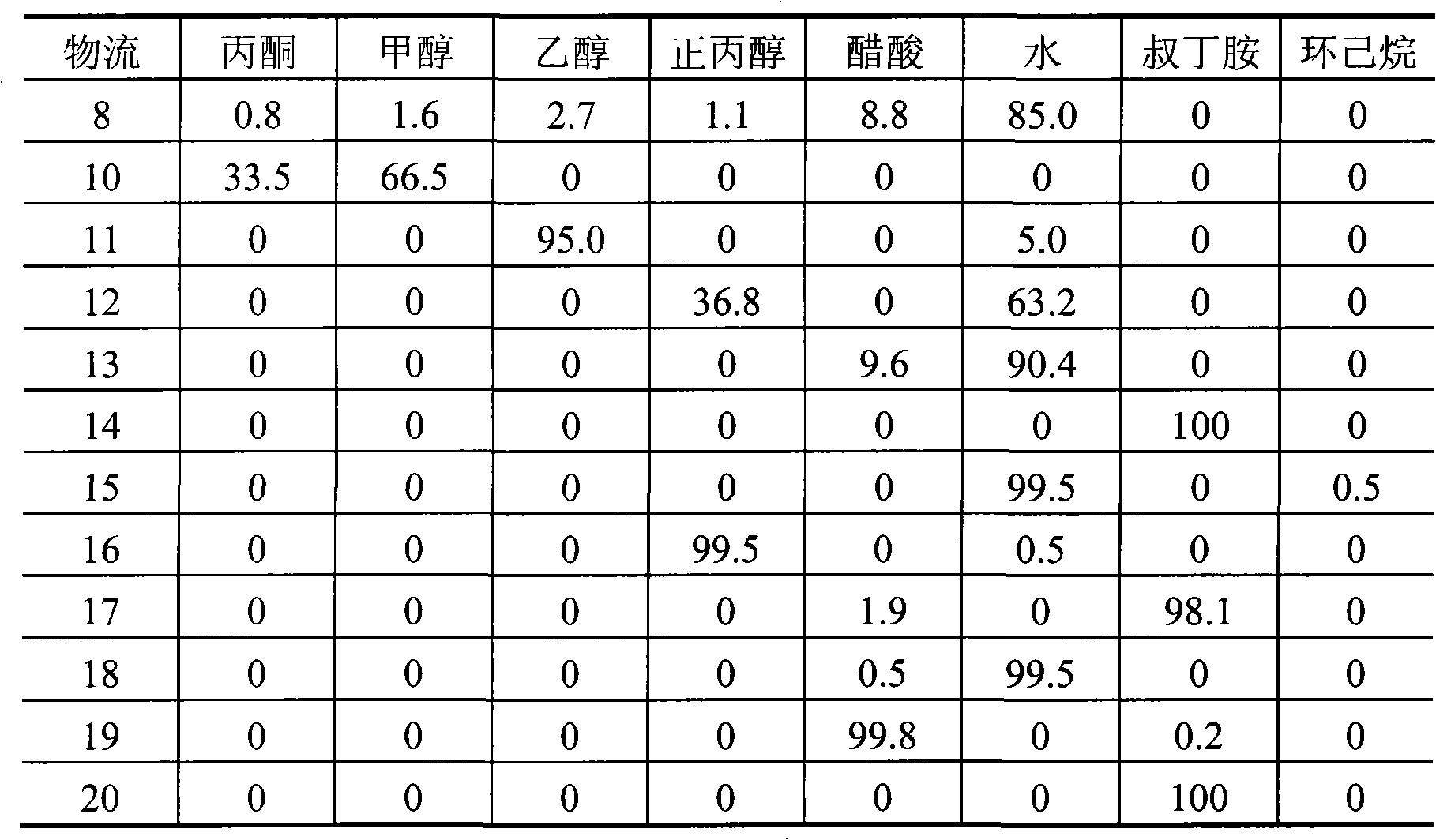

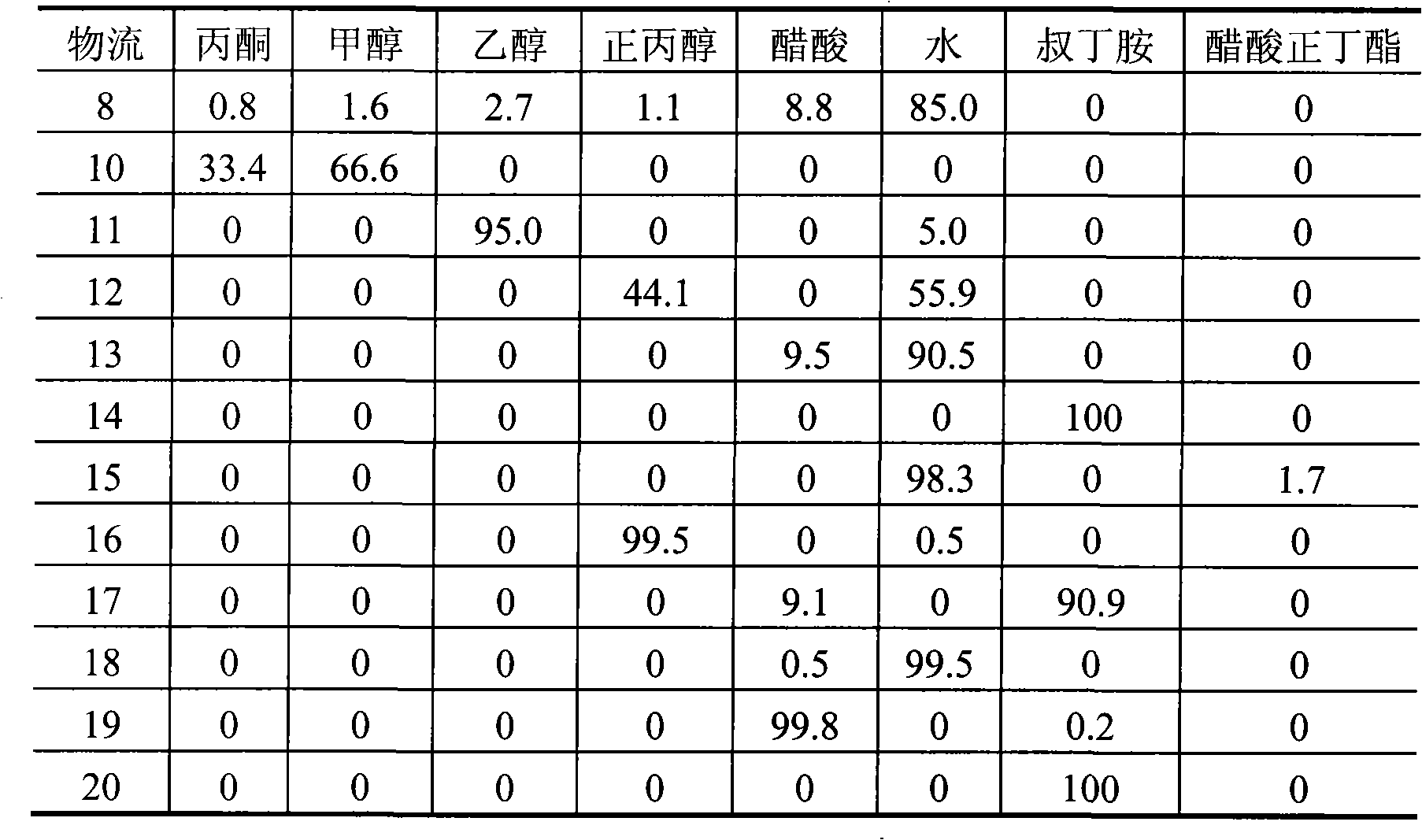

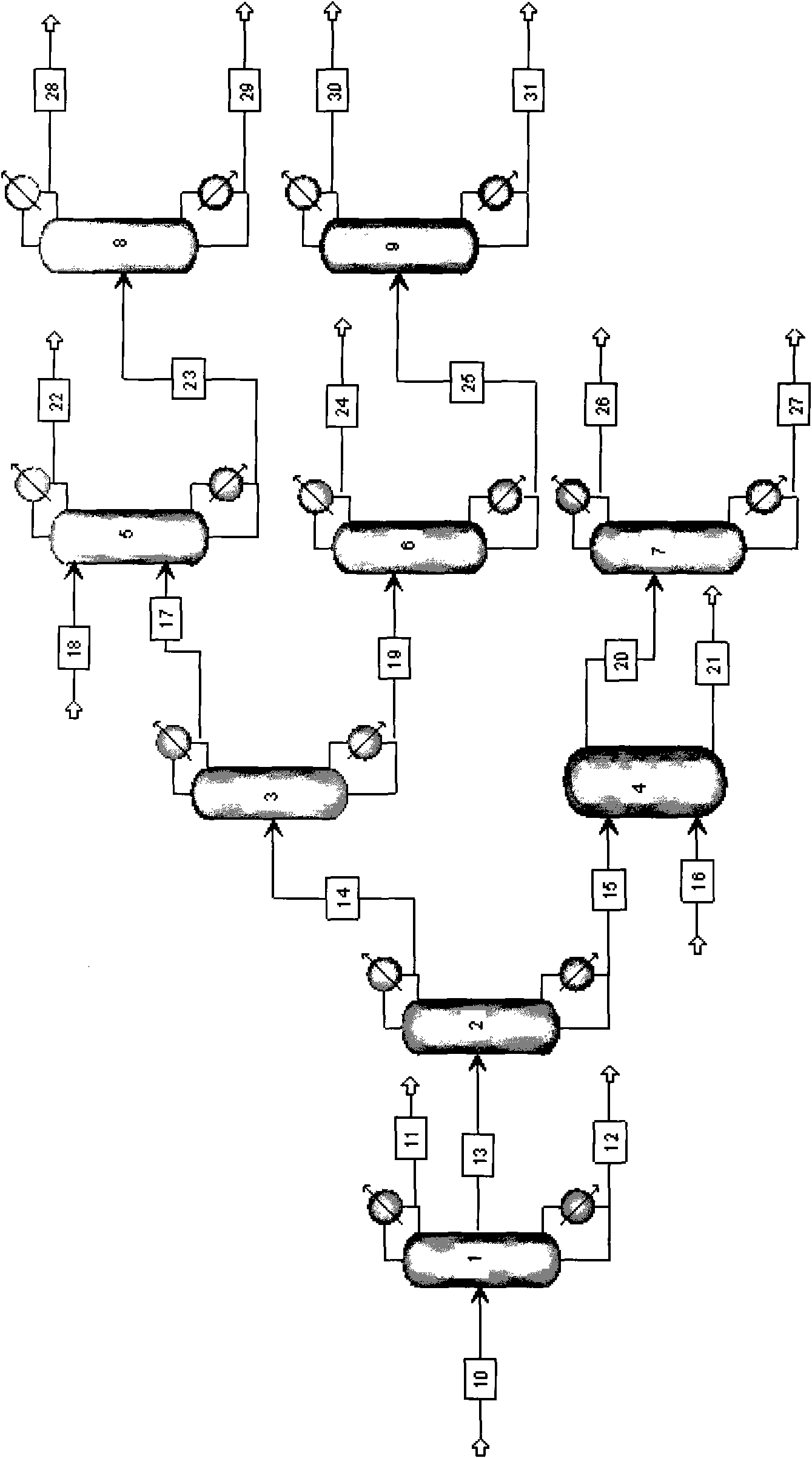

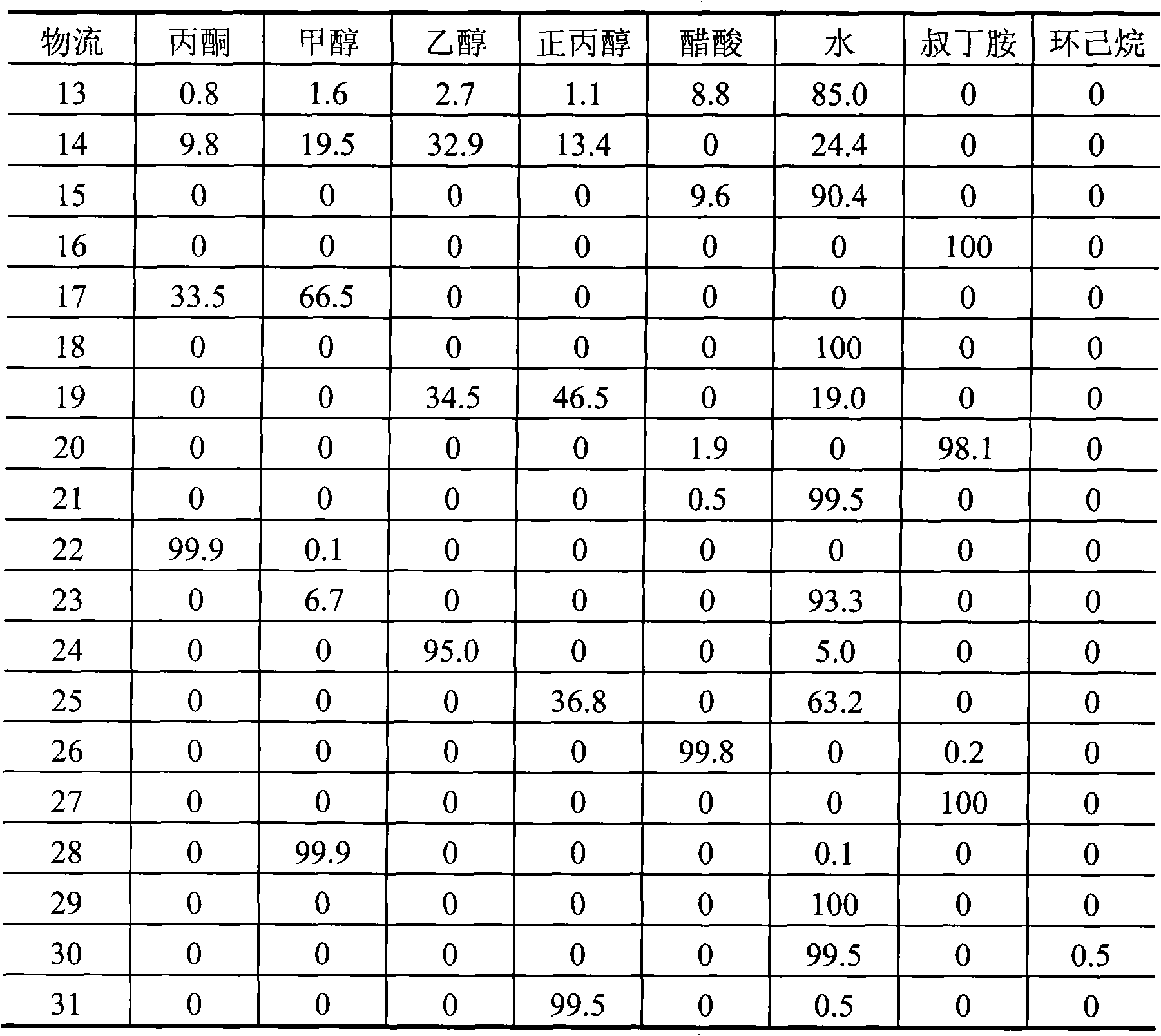

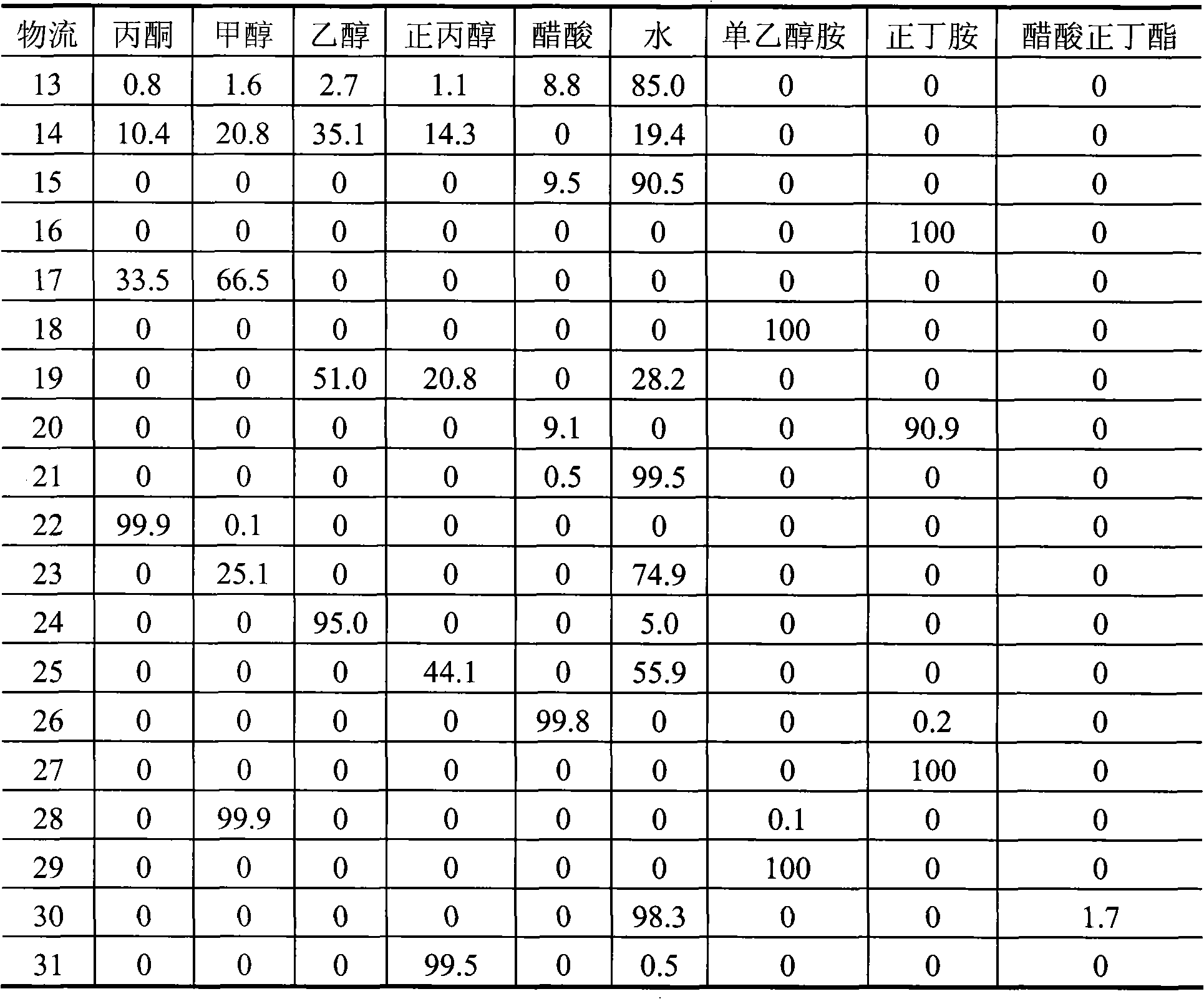

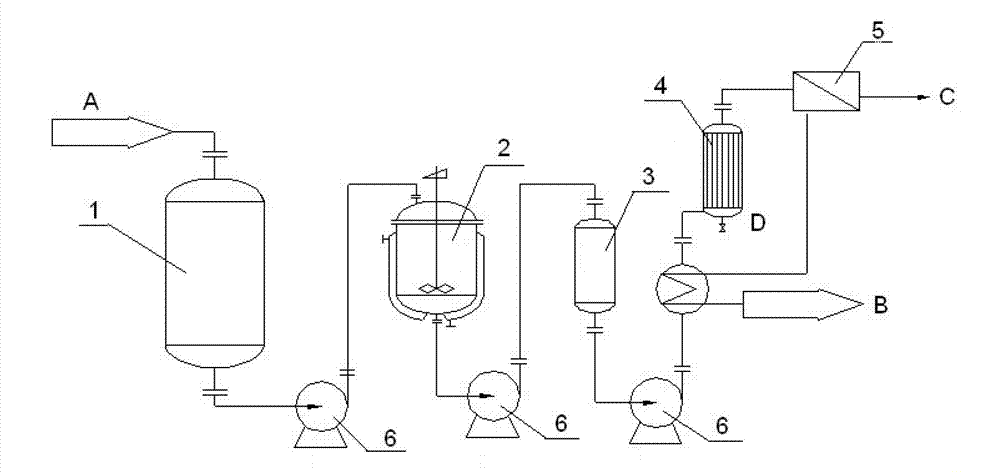

Separating method of aqueous phase byproduct from Fischer-Tropsch synthesis

ActiveCN101555193AHydroxy compound separation/purificationCarbonyl compound separation/purificationAcetic acidBoiling point

The invention relates to a separating method of an aqueous phase byproduct from Fischer-Tropsch synthesis and mainly aims at solving the problem that the direct discharge of the aqueous phase byproduct of Fischer-Tropsch synthesis at present is not economical and pollutes the environment. The method adopts the following steps: the aqueous phase byproduct enters the middle part of a common rectifying tower 1, a distillate stream I with the boiling range of 50-120 DEG C is extracted at a lateral line, a light component with a boiling range of less than 40 DEG C is obtained at the top of the tower, and a heavy component with the boiling range of more than 120 DEG C is obtained at a kettle of the tower; and the lateral line distillate is rectified and separated by an isolating tower 2, a co-boiling rectifying tower 3, an acetic acid extraction tower 4 and an extractant recovering tower 5 so as to obtain methanol-acetone solution, ethanol, n-propanol and a basic organic raw material of acetic acid, and such a technical scheme better solves the problem and can be used in the industrial production for treating the aqueous phase byproduct from the Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

High efficiency low-foaming blue leather degreaser

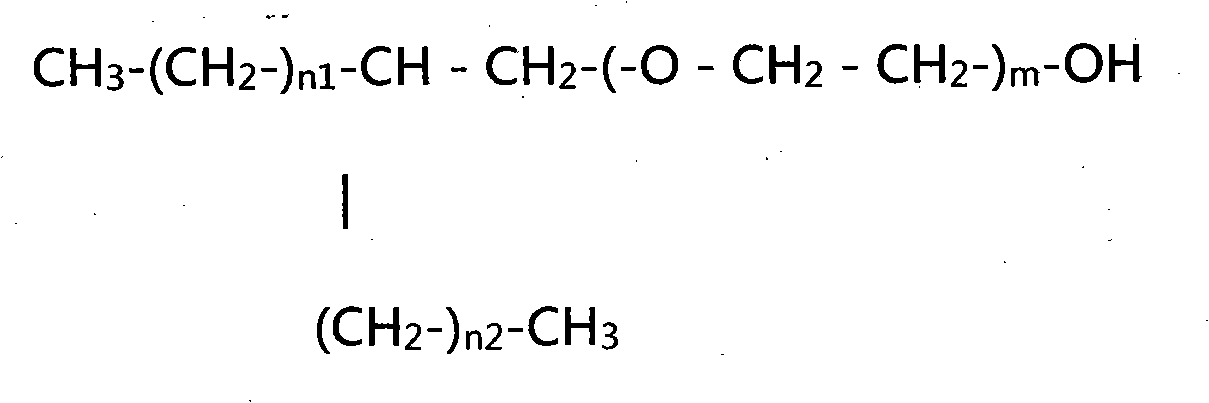

InactiveCN101831362ASuitable for a wide temperature rangeFacilitates cleaning removalNon-ionic surface-active compoundsDetergent compounding agentsWater basedKerosene

The invention relates to a degreaser used for degreasing blue leather. The degreaser is a washing composite mainly using surfactant as base material and is clear and transparent microemulsion. The formula of the degreaser comprises the following components by weight percent: 20-60% of surfactant (one or two of non-ionic surfactants such as fatty alcohol polyoxyethylene ether, fatty alcohol polyoxypropylene ether and alkanolamide, 10-40% of solvent (one or two of toluene, xylene, turpentine, C8-C12 of solvent oil, trichloroethylene, tetrachloroethylene and solvent kerosene), 0-5% of cosolvent ( one or two of ethanol, n-propanol, isopropanol and ethylene glycol monobutyl ether, 0-10% of acidic lipase, 0-2% of defoaming agent and 40-60% of water. The application temperature of the microemulsion degreaser is wide, and can be stored for long time without layering and have stable state; and the degreaser has the advantages of solvent degreasing and emulsion degreasing, the fat dissolving and cleaning functions of organic solvents and the cleaning characteristics of water-based surfactants. Therefore, the natural fat in blue leather can be reduced to less than 1%.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Ceramic product having alcoholic drink alcoholization function and preparation method thereof

InactiveCN102690102AGood colorSpicy and violent tasteAlcoholic beverage preparationClaywaresIsobutanolSilicic acid

The invention relates to an alcoholic drink storage utensil and a preparation method thereof. The alcoholic drink storage utensil is a ceramic product having an alcoholic drink alcoholization function and is composed of purple sand, an alcoholic drink purifying solvent, an energy activator and an environment-imitating solvent, wherein the purple sand accounts for 70-80% of the raw materials, the alcoholic drink purifying solvent accounts for 5-20% of the raw materials s, the energy activator accounts for 5-20% of the raw materials s, and the environment-imitating solvent accounts for 2-6% of the raw materials. The alcoholic drink purifying solvent contains major elements of potassium, sodium, calcium, magnesium and phosphorus and further contains zinc, iron, selenium, copper, strontium, iodine, fluorine and metasilicic acid; the energy activator can be tourmalinite or negative ion powder or a mixture of the tourmalinite and the negative ion powder; the environment-imitating solvent is diatomite. The function of the ceramic products is that parameters such as acetaldehyde, methanol, n-propanol, sec-butyl alcohol, isobutanol, n-butanol and isoamyl alcohol, and the like can be reduced to a different degree; parameters such as ethyl acetate, ethyl butyrate, ethyl lactate and ethyl caproate, and the like can be raised to different degrees. According to the invention, the alcoholic drink has good shade, virgin whiteness, no thickness, no pungent smell and no other off-flavors.

Owner:冯政

Stable non-dihydrate azithromycin oral suspensions

This invention relates to a powder for oral suspension, and an oral suspension made therefrom, which comprises a n-propanol solvate of non-dihydrate azithromycin and an azithromycin conversion stabilizing excipient, wherein said excipient reduces the conversion of the form of azithromycin, when placed in suspension, to another form of azithromycin.This invention also relates to an oral suspension which comprises a n-propanol solvate of non-dihydrate azithromycin and an aqueous vehicle.

Owner:PFIZER INC +1

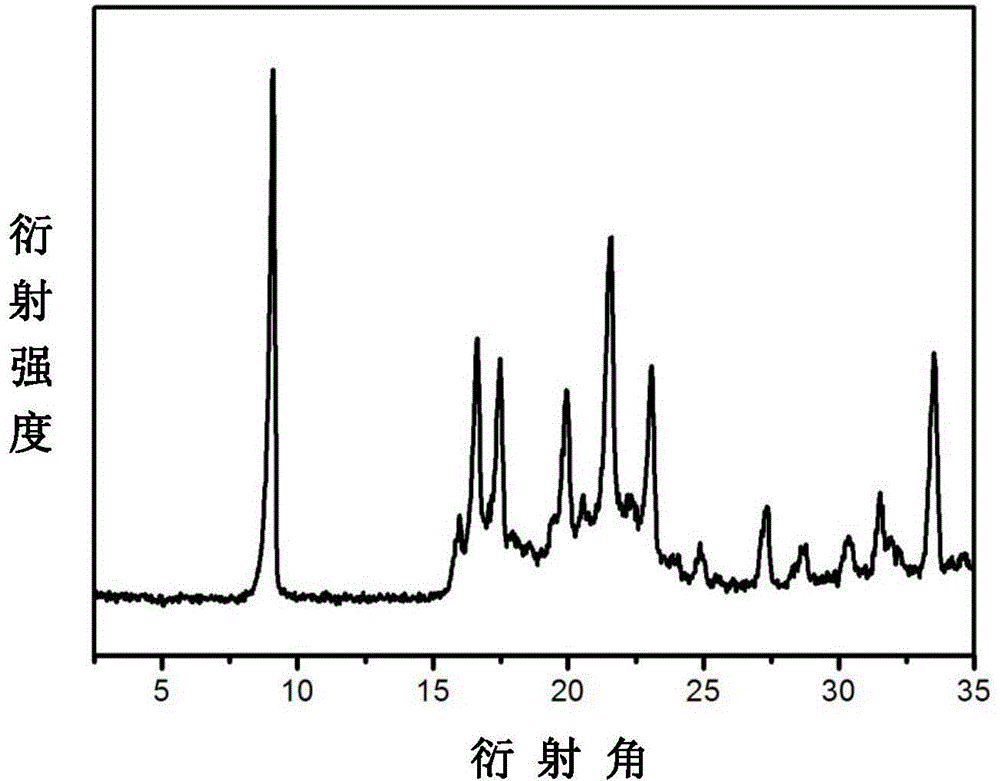

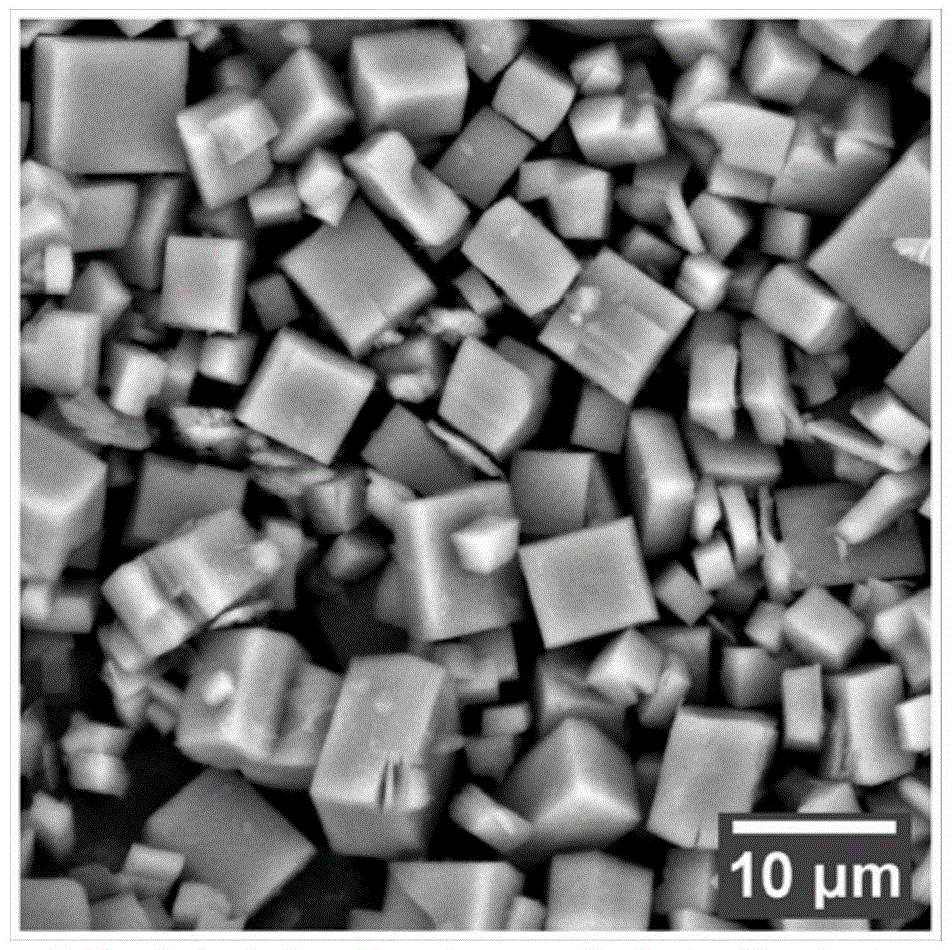

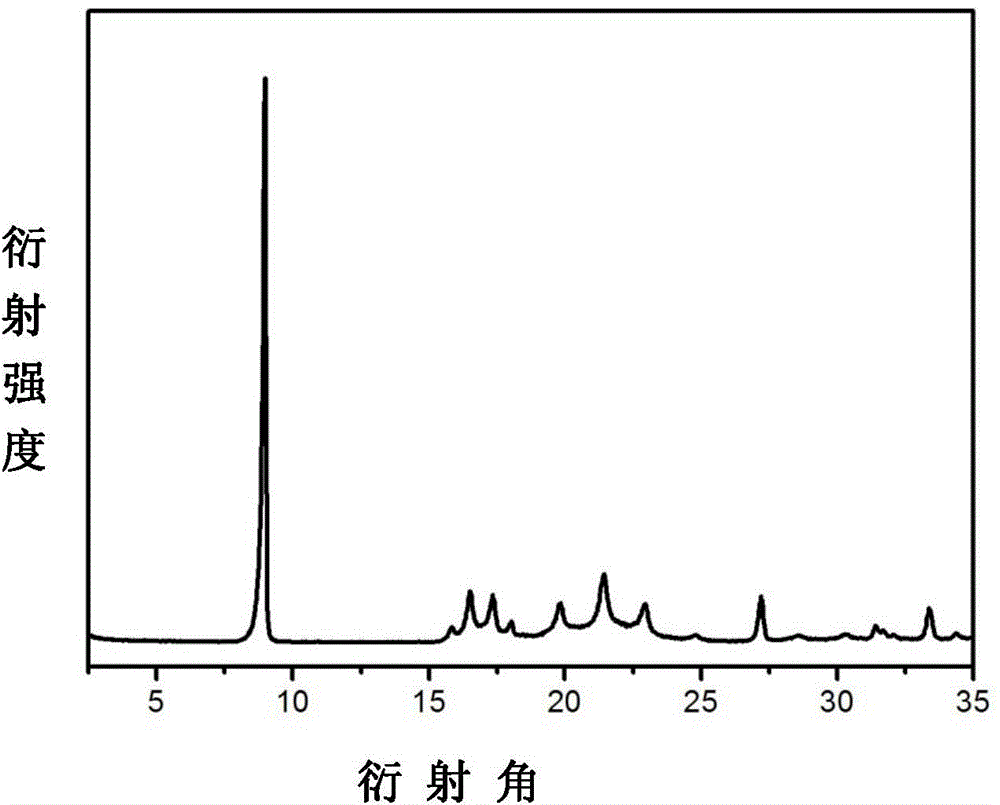

Support type ultrathin two-dimensional layered MOF film and preparation method thereof

ActiveCN105709610AImprove gas separation performanceGood repeatabilitySemi-permeable membranesRepeatabilityN-Propanol

The invention relates to a support type ultrathin two-dimensional layered MOF film and a preparation method thereof. The preparation method comprises the steps of: (1) mixing a two-dimensional layered MOF material, anhydrous methanol and n-propanol in a mass ratio of 1:2000-5000:0-3000, then performing ball milling treatment at a speed of 30-200rpm for 30-200min; (2) standing the mixture obtained in step (1) for 4h-30d; and (3) under the condition of 20-200DEG C, dripping an upper solution obtained in step (2) to a porous base membrane carrier surface and conducting drying to obtain the product. The preparation method of the support type ultrathin two-dimensional layered MOF film provided by the invention can prepare a highly oriented support film without extra seed preparation and coating process and has high repeatability. The obtained support type ultrathin two-dimensional layered MOF film has excellent gas separation performance and wide application fields.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

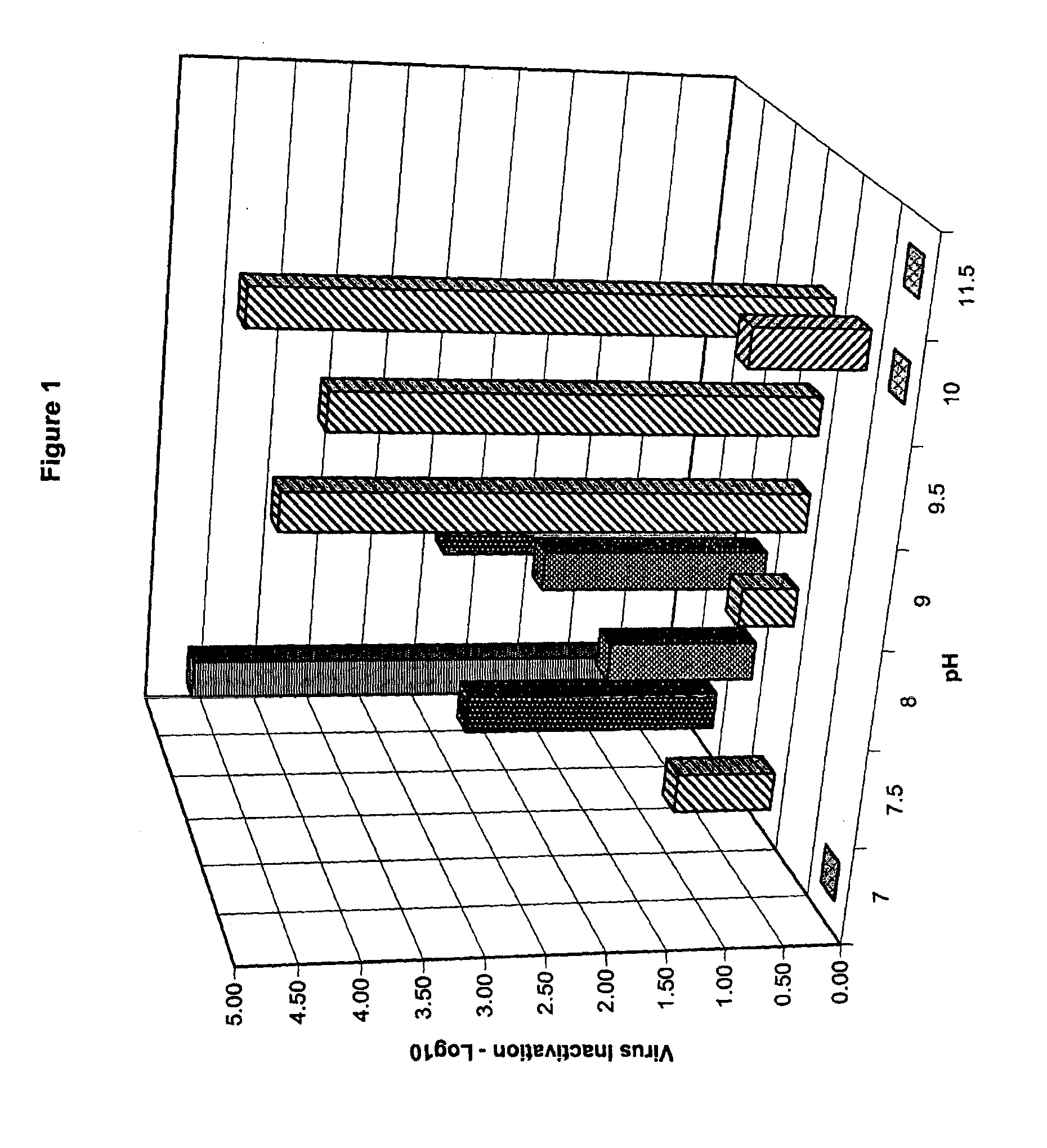

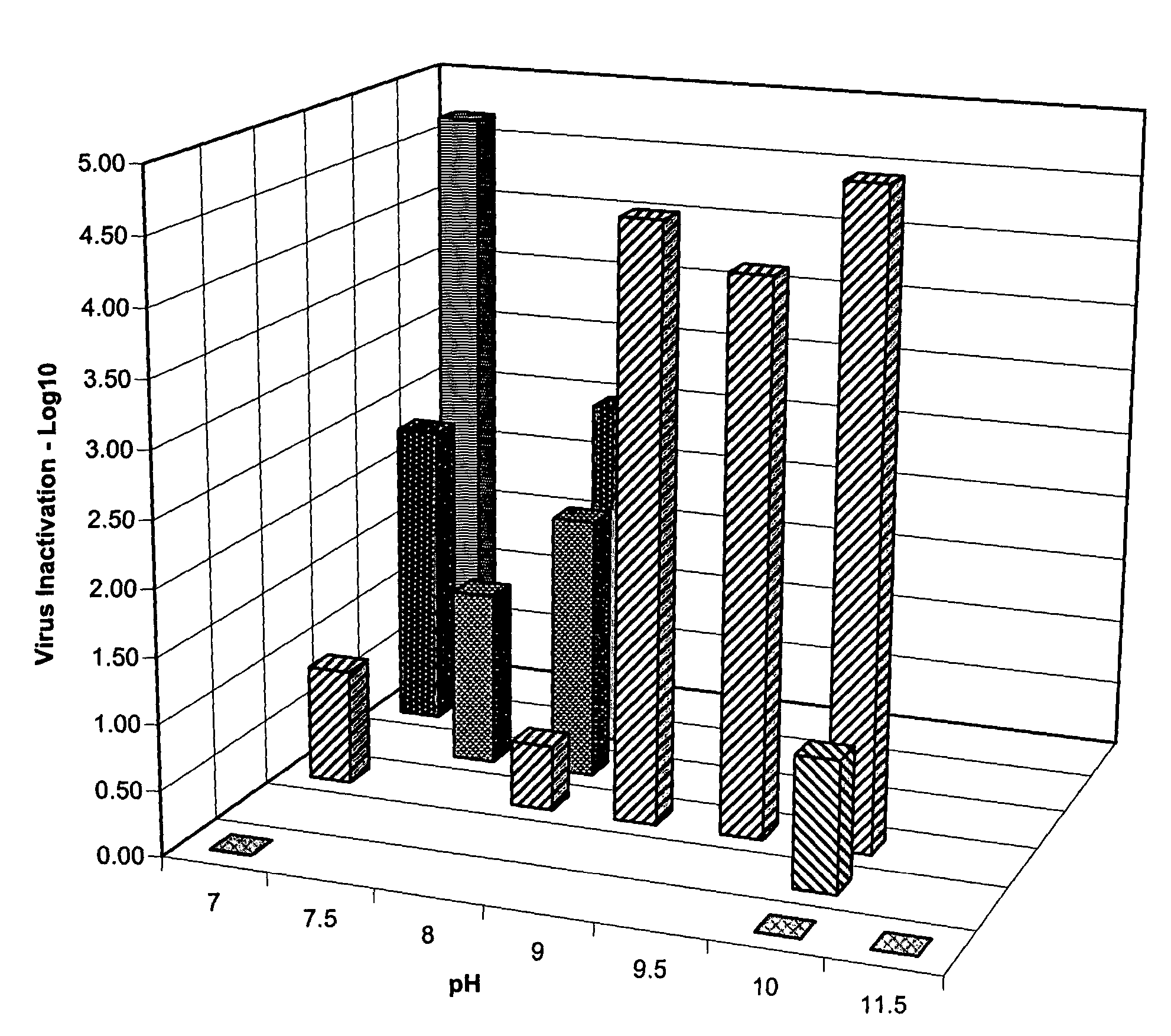

Compositions and methods for disinfecting hard surfaces

Owner:RECKITT BENCKISER (UK) LTD

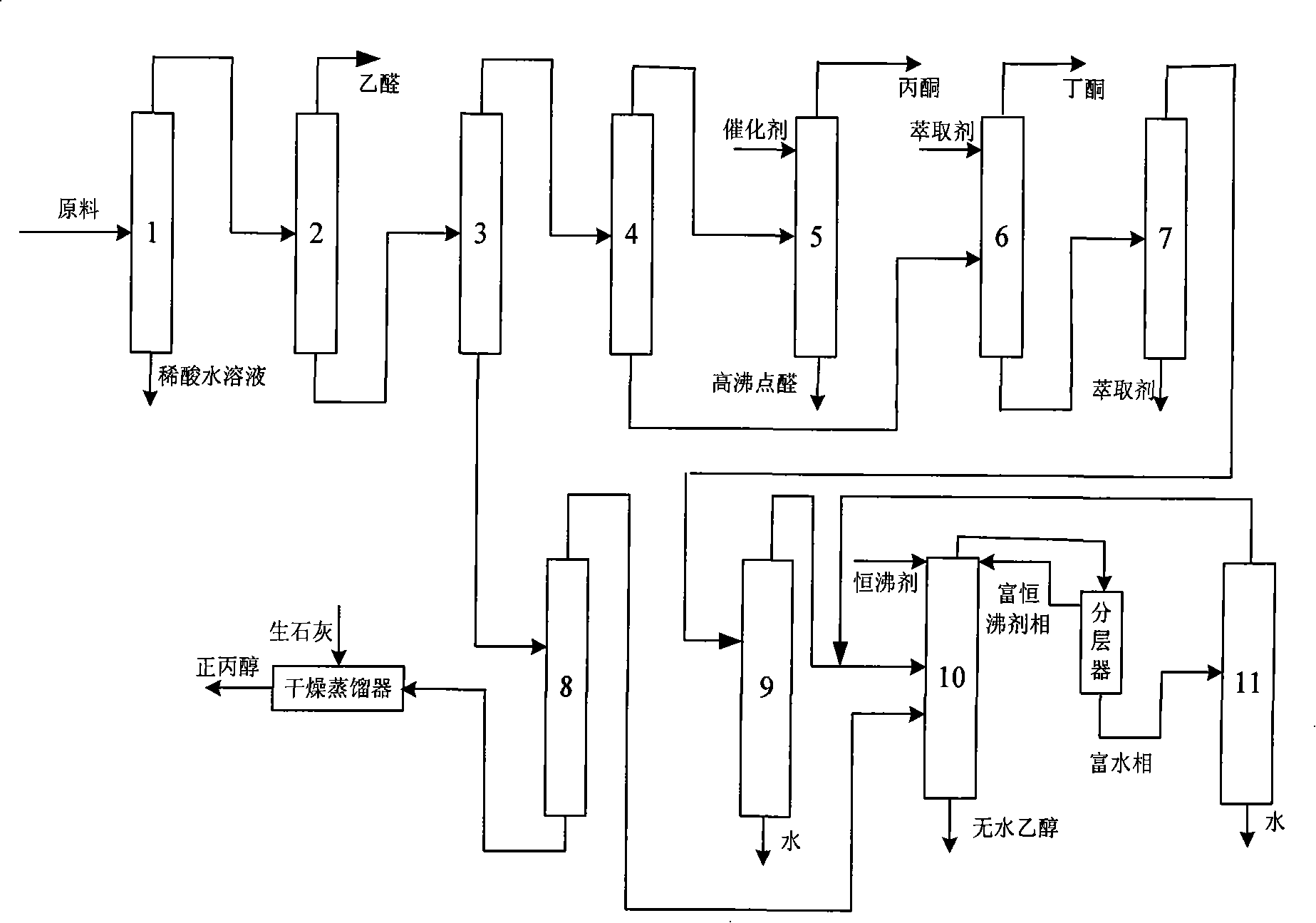

Method for separating aqueous phase byproduct from Fischer-Tropsch synthesis reaction

ActiveCN101555194AHydroxy compound separation/purificationCarbonyl compound separation/purificationAcetic acidBoiling point

The invention relates to a method for separating an aqueous phase byproduct from Fischer-Tropsch synthesis reaction and mainly aims at solving the problem that the direct discharge of the aqueous phase byproduct from Fischer-Tropsch synthesis reaction at present is not economical and pollutes the environment. The method adopts the following steps: the aqueous phase byproduct enters the middle partof a common rectifying tower 1, a distillate stream I with the boiling range of 50-120 DEG C is extracted at a lateral line, a light component with the boiling range of less than 40 DEG C is obtainedat the top of the tower, and a heavy component with the boiling range of more than 120 DEG C is obtained at a kettle of the tower; and the distillate stream I is rectified and separated by an aceticacid cutting tower 2, an ethanol cutting tower 3, an acetic acid extraction tower 4, an extracting and rectifying tower 5, an ethanol removing tower 6, an extractant recovering tower 7, a solvent recovering tower and a co-boiling rectifying tower 9 so as to obtain acetone, methano, ethanol, n-propanol and a basic organic raw material of acetic acid, and such a technical scheme better solves the problem and can be used in the industrial production for treating the aqueous phase byproduct from the Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

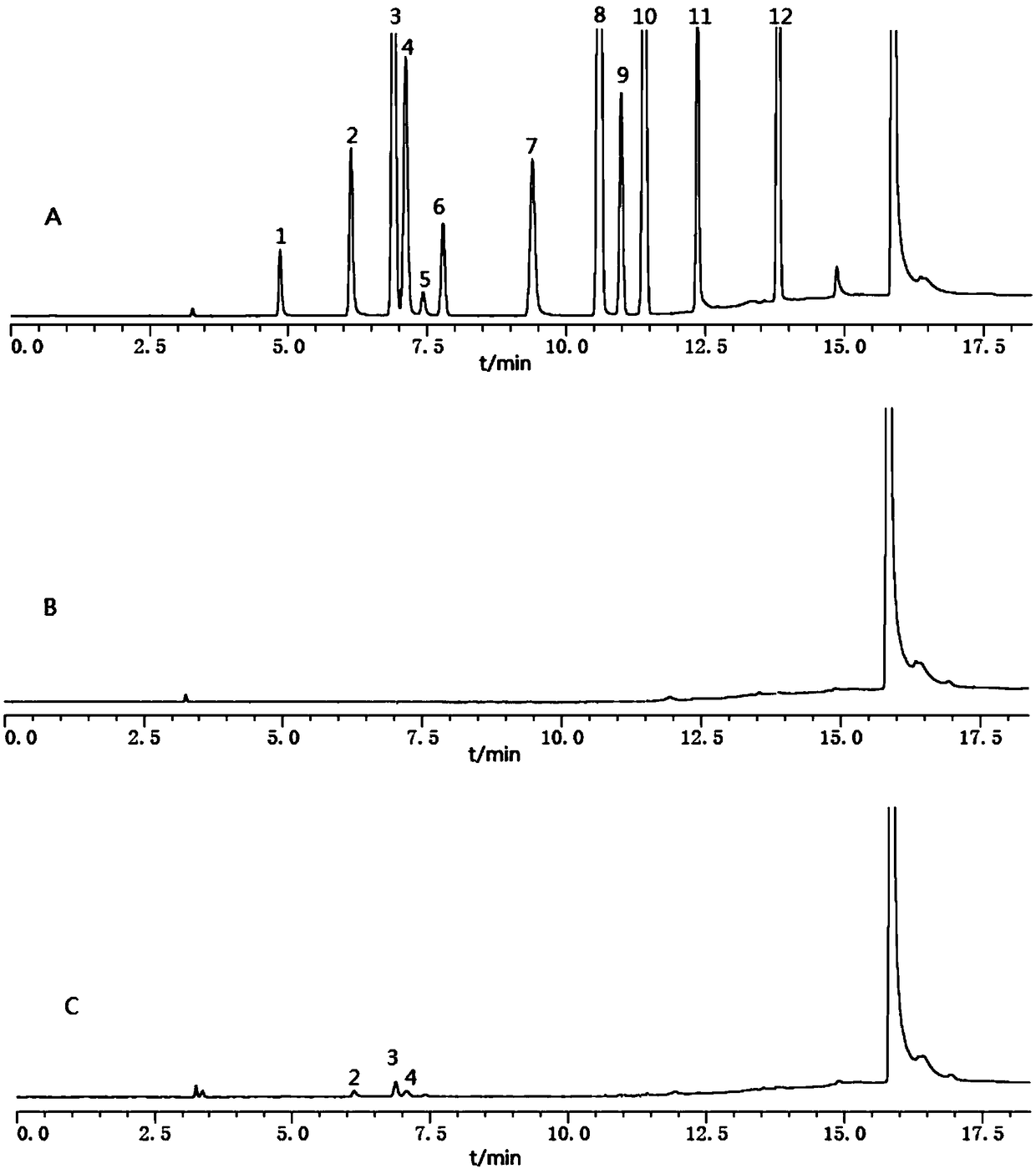

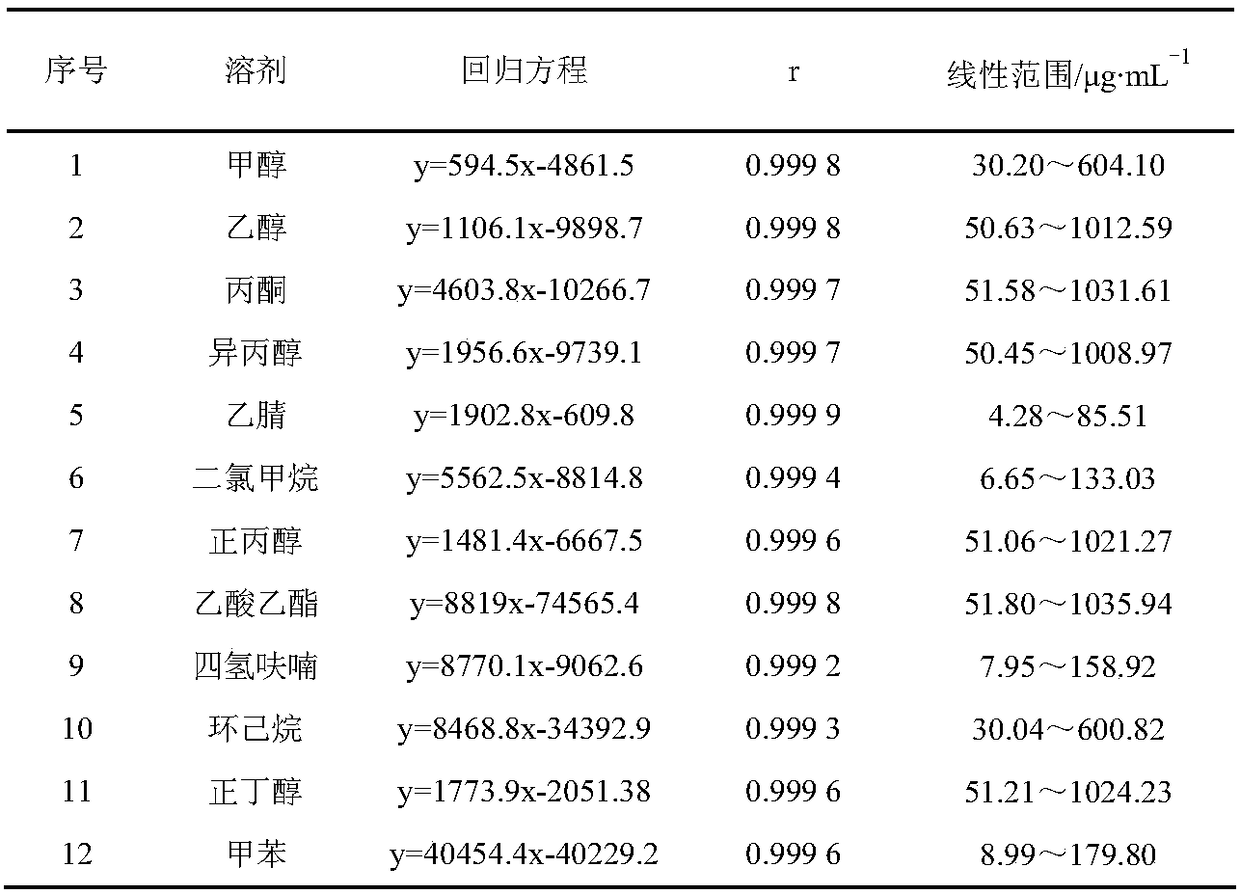

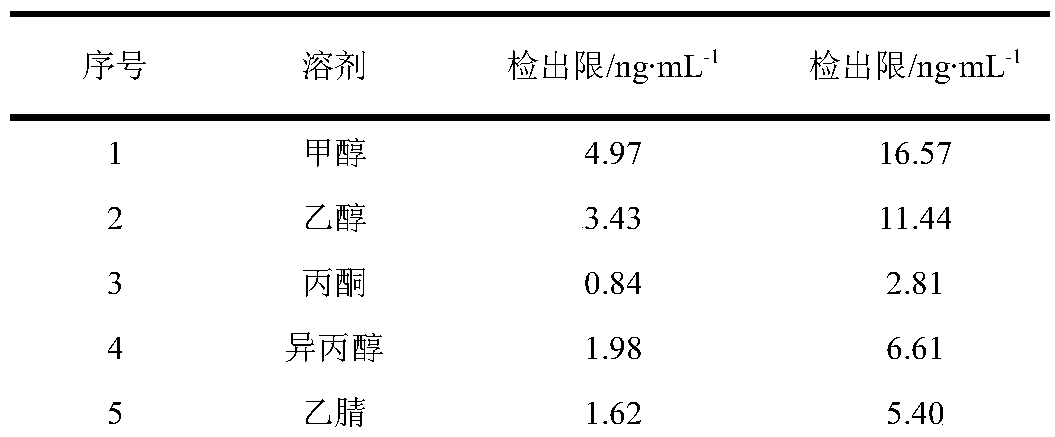

Headspace gas chromatography method for determining residual quantity of organic solvent in glycine bulk drug

InactiveCN108614058AEffective quality controlEasy to operateComponent separationNitrogen gasCapillary column

The invention discloses a headspace gas chromatography method for determining the residual quantity of an organic solvent in a glycine bulk drug. The method is implemented under conditions that a DB-624 capillary column and a hydrogen flame ionization detector are used, sample inlet temperature is 150 DEG C, the detector temperature is 250 DEG C, high purity nitrogen is taken as carrier gas with flow rate being 2.2 mL / min, the split ratio is 10:1, headspace heating temperature is 80 DEG C, and equilibrium time is 35 min; besides, glycine is easily soluble in water and the 12 solvents are soluble in water to a certain degree, so that an aqueous solvent is adopted. The method can be used for simultaneously determining the residual quantity of the 12 organic solvents including methanol, ethanol, acetone, isopropanol, acetonitrile, dichloromethane, n-propanol, ethyl acetate, tetrahydrofuran, cyclohexane, n-butanol and toluene in the glycine bulk drug, has the characteristics of being easyto operate, quick, sensitive and accurate in result, and provides reference for effectively controlling the quality of the glycine raw material and ensuring medication safety.

Owner:广西壮族自治区食品药品检验所

Method for preparing and purifying propyl acetate

InactiveCN1733685AOrganic compound preparationCarboxylic acid esters preparationAcetic acidPropyl acetate

The invention relates to a method for preparing and purifying propyl acetate, which comprises charging quantitative acetic acid, n-propanol (or isopropanol) and acidic homogeneous catalyst continuously into a pre-reactor, loading into esterification tower, obtaining crude ester on the top of the tower, loading the crude ester into a liquid-liquid rotating disc extraction tower, extracting and purifying with aqueous solution extracting agent of salts, recycling the extract phase and loading into rectifying tower for continuous distillation, thus obtaining n-propyl acetate or isopropyl acetate whose content is above 99.5% on the bottom of the tower.

Owner:SHANGHAI WUJING CHEM

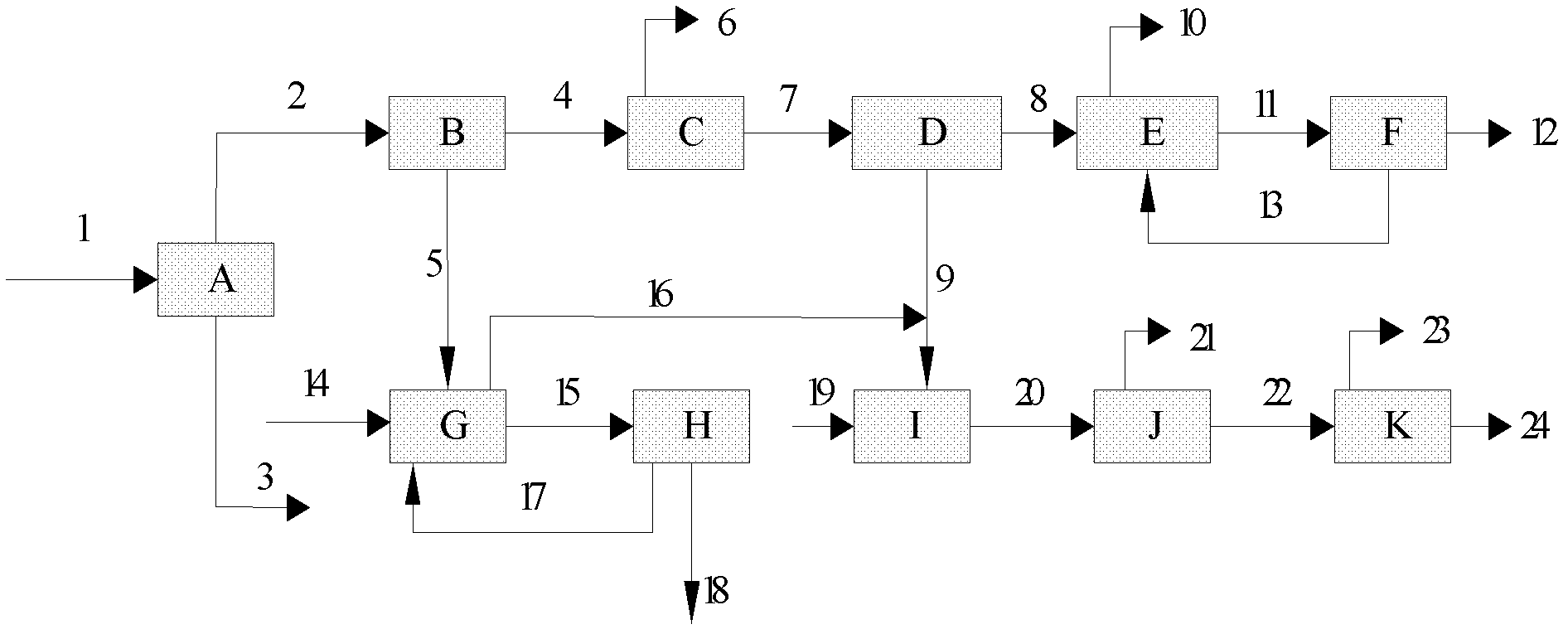

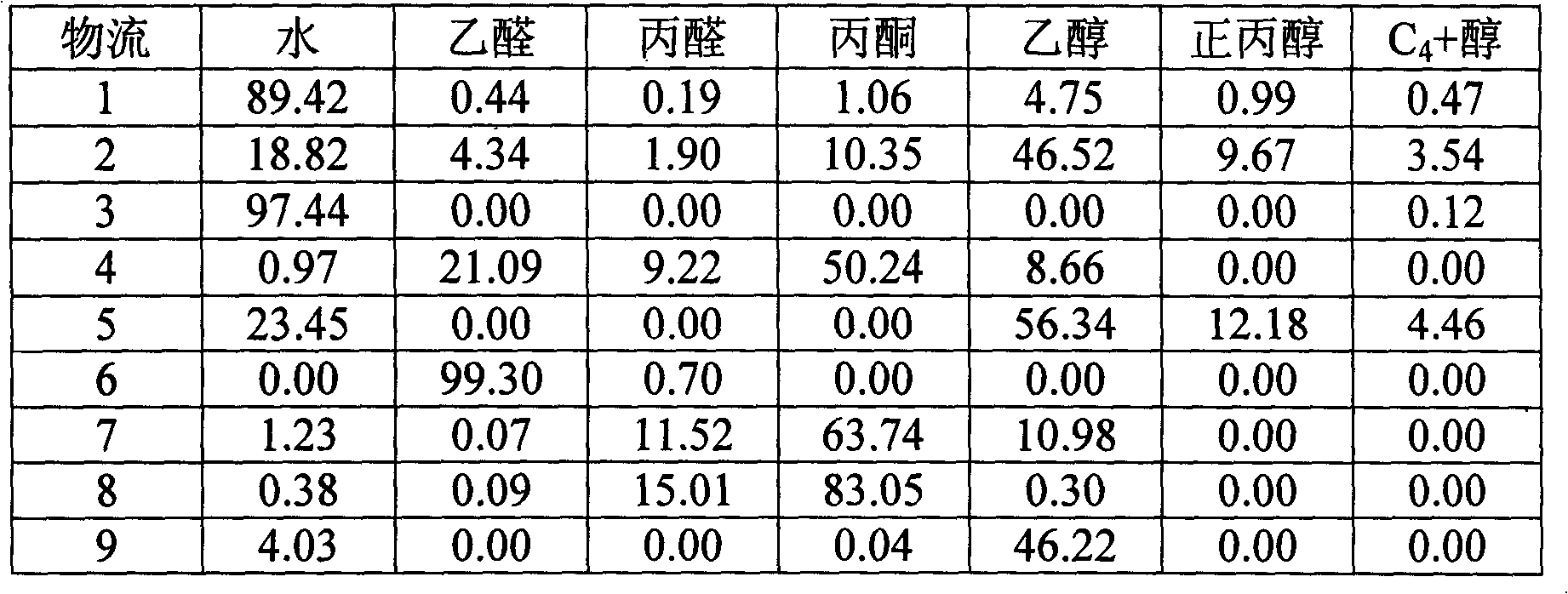

Method for separating and recovering non-acidic oxygenated organic substances in Fischer-Tropsch synthesis reaction water

ActiveCN103044217AHigh recovery rateReduce pollutionOrganic compound preparationHydroxy compound preparationOrganic acidAlcohol

The invention relates to a method for treating non-acidic oxygenated organic substances in Fischer-Tropsch synthesis reaction water, which mainly solves the problem of separation and recovery of non-acidic oxygenated organic substances in Fischer-Tropsch synthesis reaction water. The method comprises the following steps: Fischer-Tropsch synthesis reaction water is subjected to (a) organic acid rectification separation, (b) ketol cutting rectification separation, (c) acetaldehyde refinement, (d) propanal acetone rectification separation, (e) acetone refinement, (f) propanal refinement, (g) anhydrous fusel separation, (h) alcohol-water separation, (i) aldehyde and ketone hydrogenation reduction, (j) ethanol refinement and (k) n-propanol refinement to finally obtain basic organic raw materials, including acetaldehyde, propanal, acetone, ethanol, n-propanol, mixed alcohols and the like. Compared with the prior art, the invention has the advantages of simple technical scheme, high recovery rate and the like, well solves the problem of separation of organic oxygenated compounds in the Fischer-Tropsch synthesis reaction water, and can be widely used in industrial production of non-acidic oxygenated organic substances from Fischer-Tropsch synthesis reaction water.

Owner:YANKUANG ENERGY R&D CO LTD

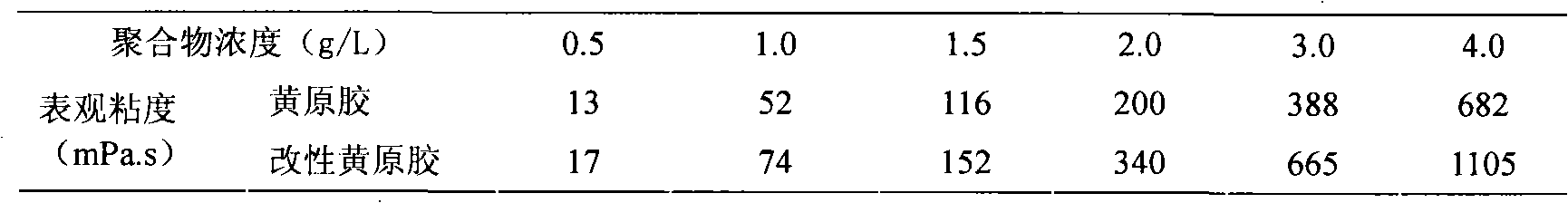

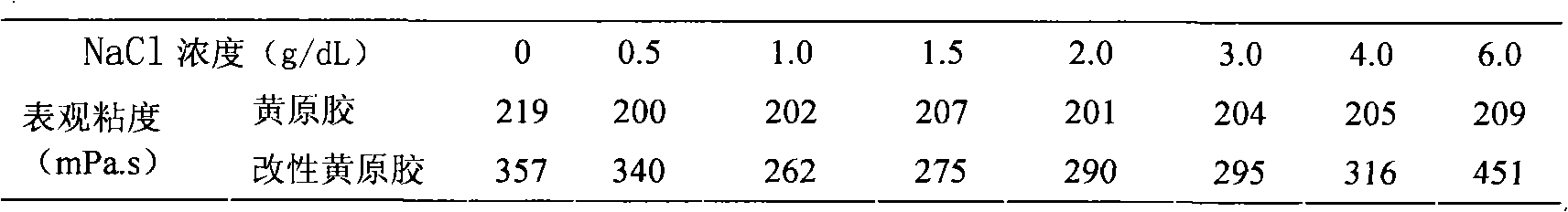

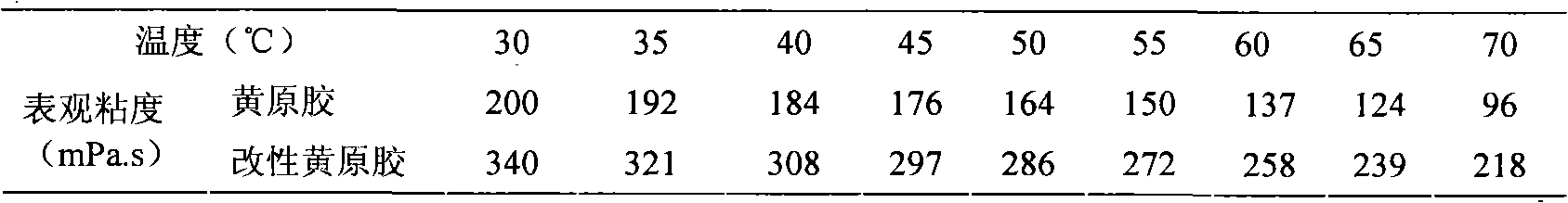

Preparation method of associated modified xanthan gum

InactiveCN102134283AStrong viscosity increasing abilityMolecular association abilityDrilling compositionBottleSolvent

The invention discloses a preparation method of an associated modified xanthan gum, which is characterized by adding 20 parts of xanthan gum with a medium or low molecular weight, 10-900 parts of solvents, and 0.01-15 parts of catalysts, on a weight basis, into a three-mouth reaction bottle equipped with a reflux condensation device, stirring and swelling the mixture at room temperature for 24 hours; then increasing the temperature to 30-95 DEG C, slowly adding 0.1-20 parts of phenyl ring-containing chlorinated hydrocarbon modifiers, and reacting for 4-72 hours; precipitating and washing the products by acetone, n-propanol or isopropanol to remove unreacted modifiers and catalysts, and filtering; drying in a vacuum oven at 30-70 DEG C for 4-8 hour so as to obtain the associated modifiedxanthan gum. Compared with unmodified xanthan gums, the associated modified xanthan gum has better tackifying performance, heat resistance, salt resistance, and aging resistance, and has a lower using amount. The associated modified xanthan gum with a medium or low molecular weight can be used as an oil displacement agent for tertiary oil recovery in medium and low-permeability oil reservoir, andcan also be used as a thickening agent in drilling fluid; the associated modified xanthan gum can be crosslinked with an inorganic or organic agent to obtain a weak gel used as an oil displacement agent, a profile control and oil displacement agent, a profile control agent, or a plugging agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

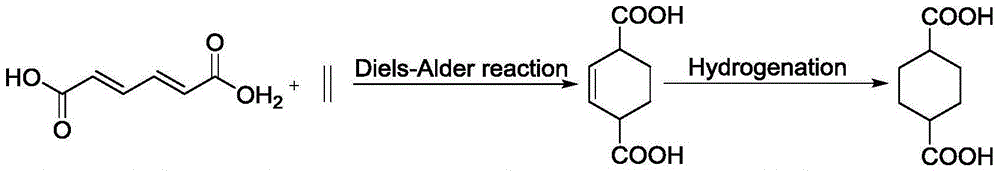

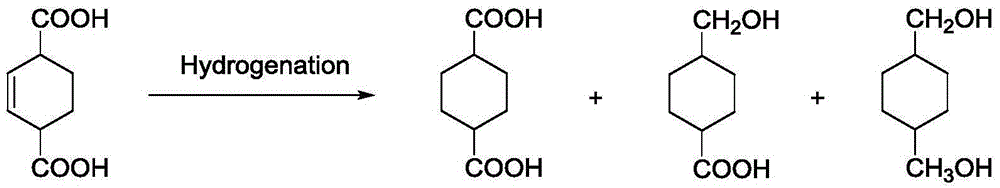

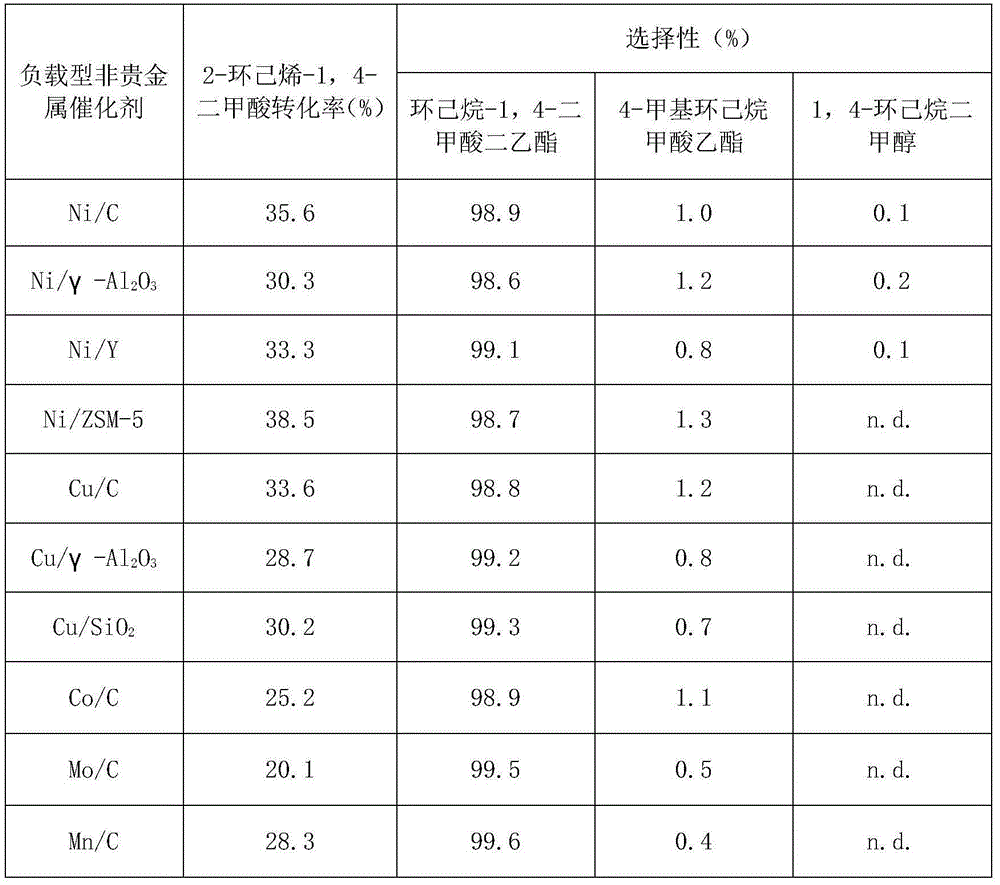

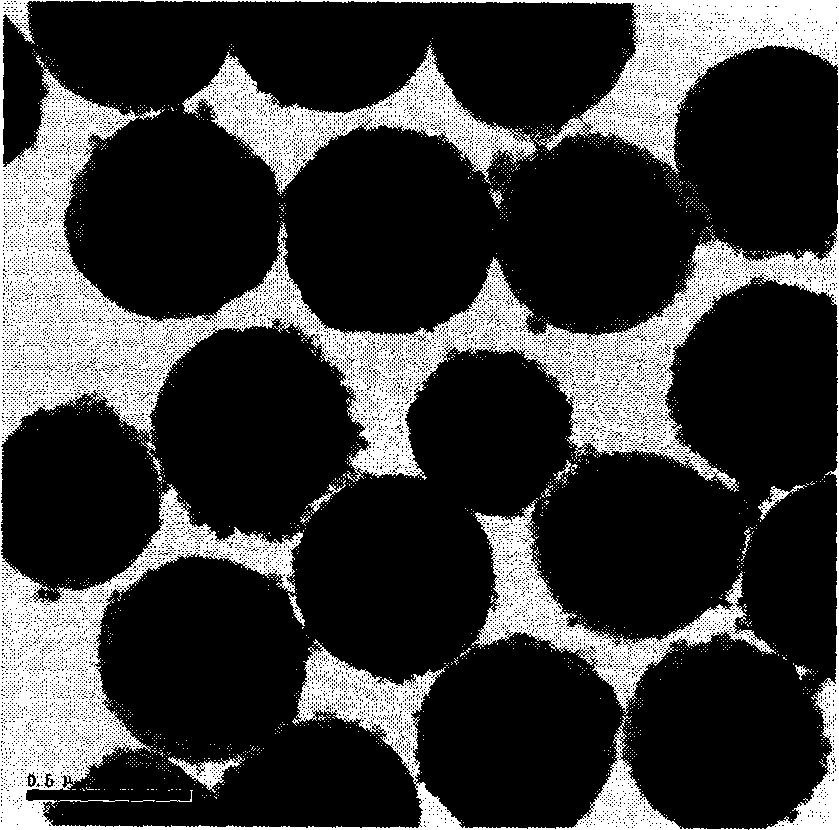

Preparation method for 1,4-cyclohexane dicarboxylic acid (CHDA) and diester thereof

InactiveCN106467459AReduce dependenceOrganic compound preparationCarboxylic acid esters preparationCyclohexeneN-Butanol

The invention discloses a preparation method for 1,4-cyclohexane diformic acid (CHDA) and diester thereof. In particular, 2-cyclohexene-1,4-dicarboxylic acid is subjected to catalytic hydrogenation to prepare the CHDA or CHDA diester under the effect of a supported metal catalyst with hydrogen under certain pressure fed, a solvent being polar or non-polar, wherein the polar solvent may be water, methanol, ethanol, n-propanol, isopropanol, n-butanol, glycol dimethyl ether and diethylene glycol dimethyl ether, and the non-polar solvent may be one or more than two selected from n-hexane, n-heptane, n-octane, cyclohexane, benzene and toluene. A metal active component of the supported metal catalyst is non-noble metal and / or noble metal. A carrier of the supported metal catalyst may be one or more than two selected from a carbon carrier, a nano metal oxide, a nano non-metal oxide and a molecular sieve. When the conversion rate of the 2-cyclohexene-1,4-diformic acid is more than 98%, the selectivity of the CHDA or CHDA diester can reach 96%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation of coating type cerium oxide / silicon oxide compound abrasive

The invention belongs to the field of preparation of ultrafine compound powder, and relates to a novel method for preparing a coated type cerium oxide / silicon oxide compounded abrasive. The method comprises the following steps: firstly, using cerium nitrate hexahydrate, acetylacetone, citric acid, n-propanol and anhydrous ethanol as raw materials to prepare a cerium colloidal sol; secondly, steeping silicon oxide powder into the cerium colloidal sol, and keeping stand the mixture after dispersing the mixture through ultrasound and mechanical agitation; and thirdly, using a centrifugal method to separate the silicon oxide of which the surface is coated with the cerium colloidal sol, drying and grinding the silicon oxide in an air drying box, and then calcining the silicon oxide to obtain the coated type cerium oxide / silicon oxide compounded abrasive. The method can further prepare the coated type cerium oxide / silicon oxide compounded abrasive with different particle sizes and coating quantities by preparing the cerium colloidal sols with different cerium ion concentrations and selecting the silicon oxide powder with different particle sizes as an inner core. The method has the advantages of good coating effect, comparatively simple process, and good experimental repeatability. Besides, the method can be applied to preparing coated structure compounded abrasive of which the surface is coated with nanometer cerium oxide particles by using other powder as the inner core.

Owner:溧阳常大技术转移中心有限公司

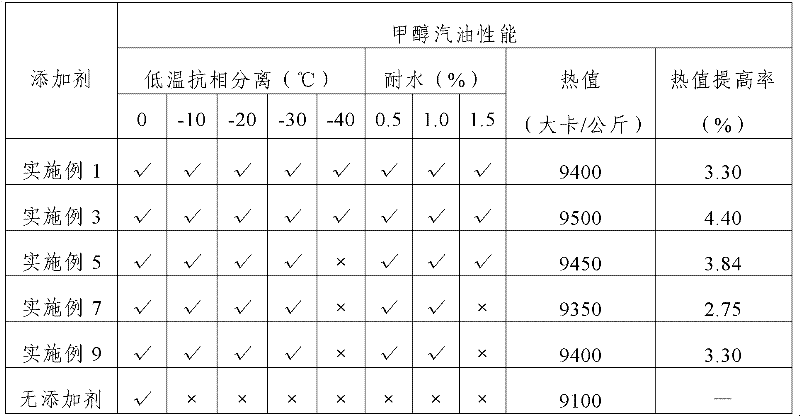

Additive for improving resisting phase separation performance and heat value of methanol gasoline

InactiveCN102344837AImprove oilinessReduce fuel consumptionLiquid carbonaceous fuelsAmyl acetateN-Butyl Alcohol

The invention discloses an additive for improving resisting phase separation performance and a heat value of methanol gasoline. The additive consists of the following raw materials in percentage by weight: 35-45 percent of aliphatic alcohol, 10-20 percent of aliphatic ether, 15-30 percent of aliphatic ester, 5-15 percent of aliphatic acid, 1-5 percent of aliphatic amine and 0.1-3 percent of emulsifier OP, wherein the aliphatic alcohol is one or more of isopropyl alcohol, n-propanol, n-amyl alcohol, isoamyl alcohol and n-butyl alcohol; the aliphatic ether is one or more of ethylene glycol methyl ether, ethylene glycol ethyl ether and ethylene glycol butyl ether; the aliphatic ester is one or more of butyl acetate, n-amyl acetate and isoamyl acetate; the aliphatic acid is oleic acid and / or naphthenic acid; the aliphatic amine is dimethylamine and / or diethylamine; and the emulsifier OP is emulsifier OP-15 and / or emulsifier OP-20. The methanol gasoline in which the additive is added has superior low-temperature resisting phase separation and water resisting phase separation performances and an obviously improved heat value.

Owner:西安祺祥能源科技发展有限公司

Preparation method of Roxadustat

ActiveCN108017583AEasy to prepareRaw materials are easy to getOrganic chemistryEthylenediamineAcetic anhydride

The invention discloses a preparation method of Roxadustat, compound 1 and bis(dimethylamino)methane are heated in a mixed solvent of acetic acid and trifluoroacetic acid for reaction to form compound2; acetic anhydride is added to the obtained reaction solution of the compound 2 for completing reaction by heating to form compound 3; the compound 3 is dissolved in ethyl acetate and heated, then is catalyzed by Pd / C, and reduced by hydrogen to obtain compound 4; the compound 4 and glycine are dissolved in a solvent, and heated under the action of an organic base for reaction to obtain compound5; wherein the solvent is one or more of dioxane, ethylene glycol monomethyl ether, toluene, acetonitrile and n-propanol, the organic base is one or more of triethylamine, 1,8-diazabicyclo undecane-7-ene, N,N-diisopropylethylamine, N-methylmorpholine, pyridine, and ethylenediamine; the preparation method has the advantages of shorter reaction time, low reaction temperature, low equipment condition requirements and high crude product purity, is suitable for large-scale industrial production, and has a good industrialization prospect.

Owner:XUZHOU WANBANG JINQIAO PHARMA +1

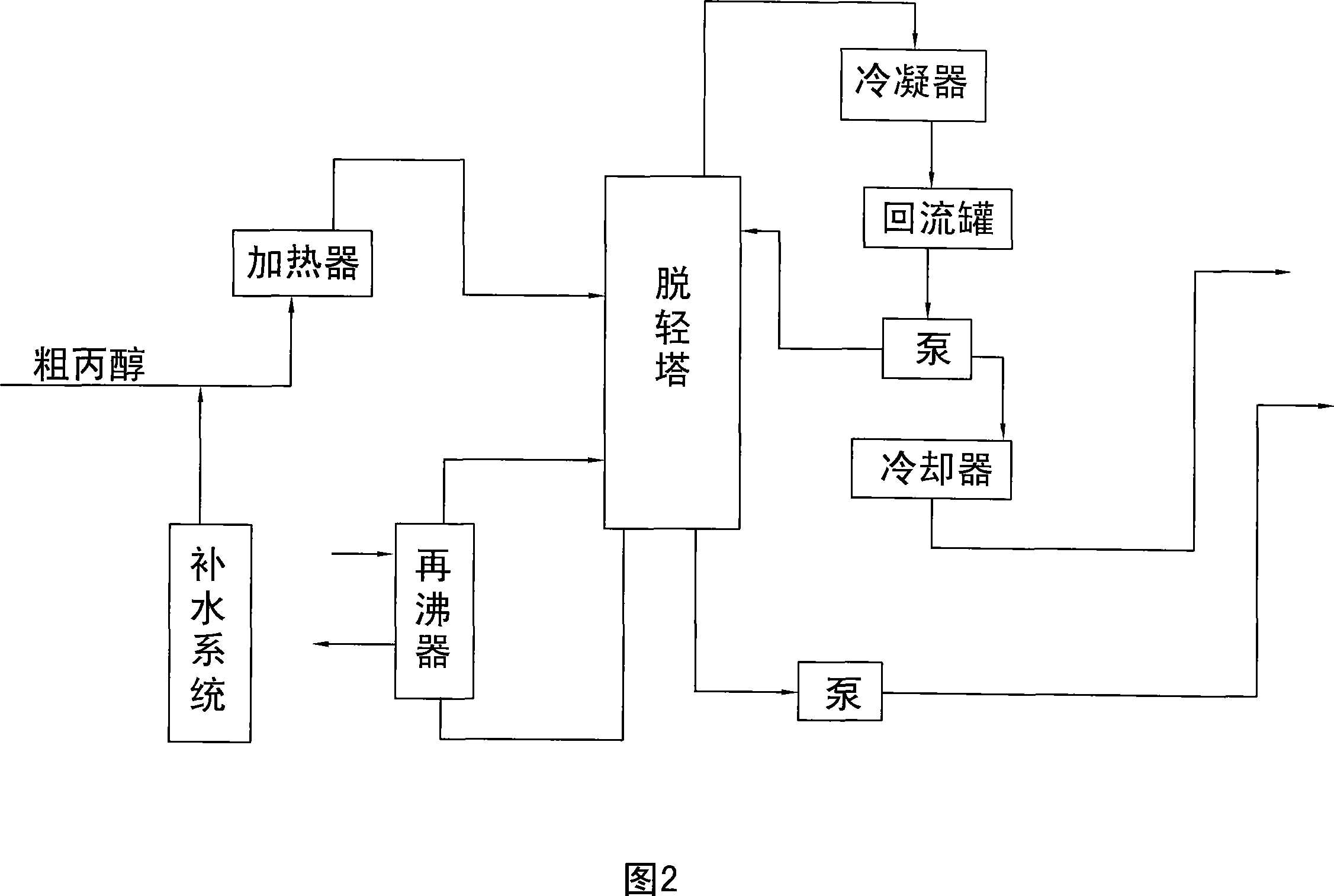

N-propanol refining technology

ActiveCN102887815AEliminate reprocessing costsIncreased propanol contentHydroxy compound separation/purificationPropanolDistillation

The invention discloses an n-propanol refining technology which comprises the following steps of: in a reaction kettle, adjusting the pH value of the n-propanol coarse liquid to 8-10 by adding alkaline liquid into the coarse propanol from an n-propanol reaction process; injecting the adjusted coarse propanol liquid from the reaction kettle into a distillation tower by a pump; controlling the temperature of the tower kettle of the distillation tower to 95-130 DEG C, and controlling the temperature at the tower top to 90-130 DEG C; enabling the steam containing water and propanol obtained from the top of the distillation tower to enter a pervaporation membrane separation unit for dehydration; and further cooling the n-propanol steam obtained from the membrane separation unit by circulating water to obtain the product, and collecting the product.

Owner:JIANGSU NINE HEAVEN HIGH TECH

Microorganisms and methods for the co-production of isopropanol and 1,4-butanediol

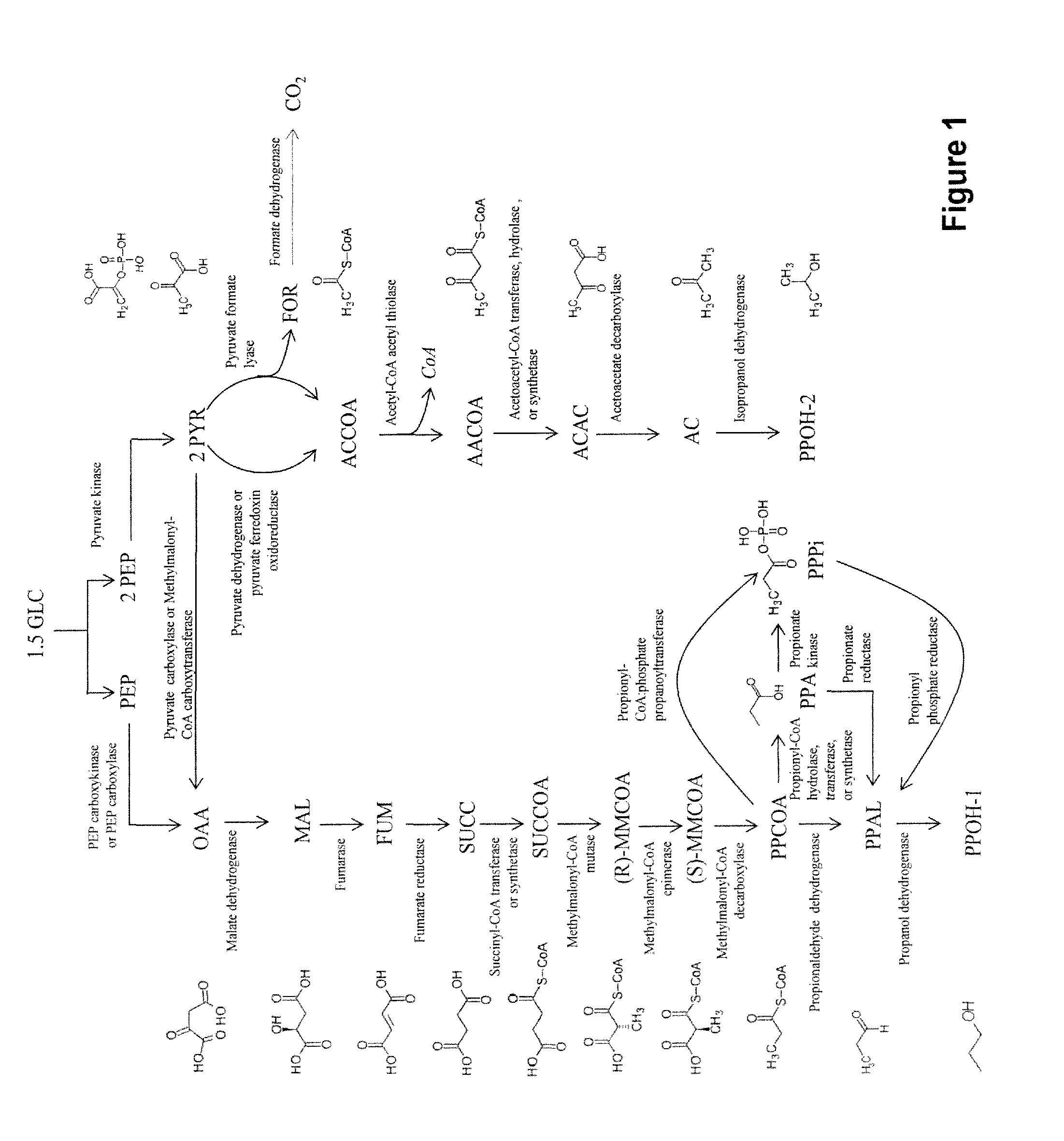

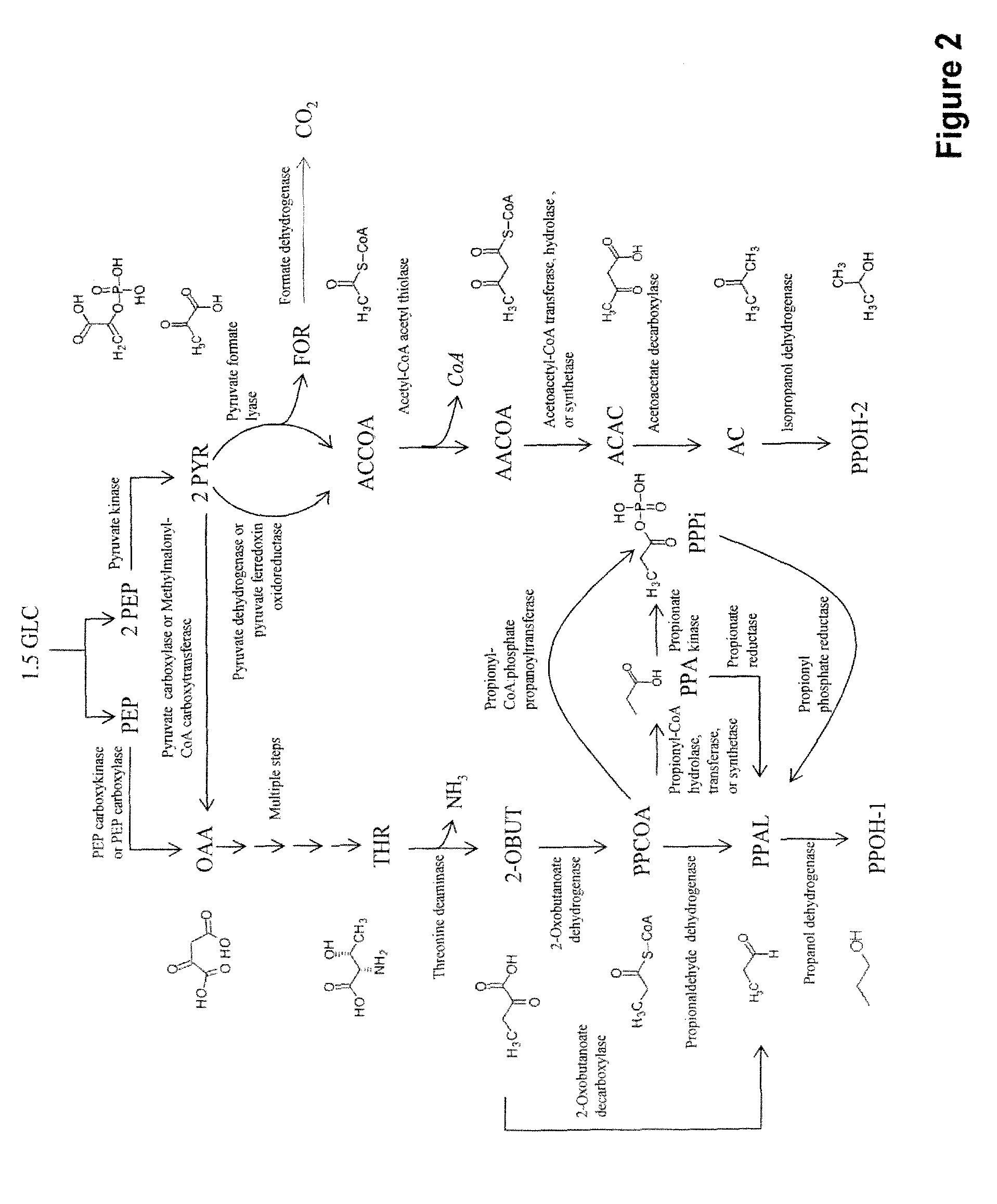

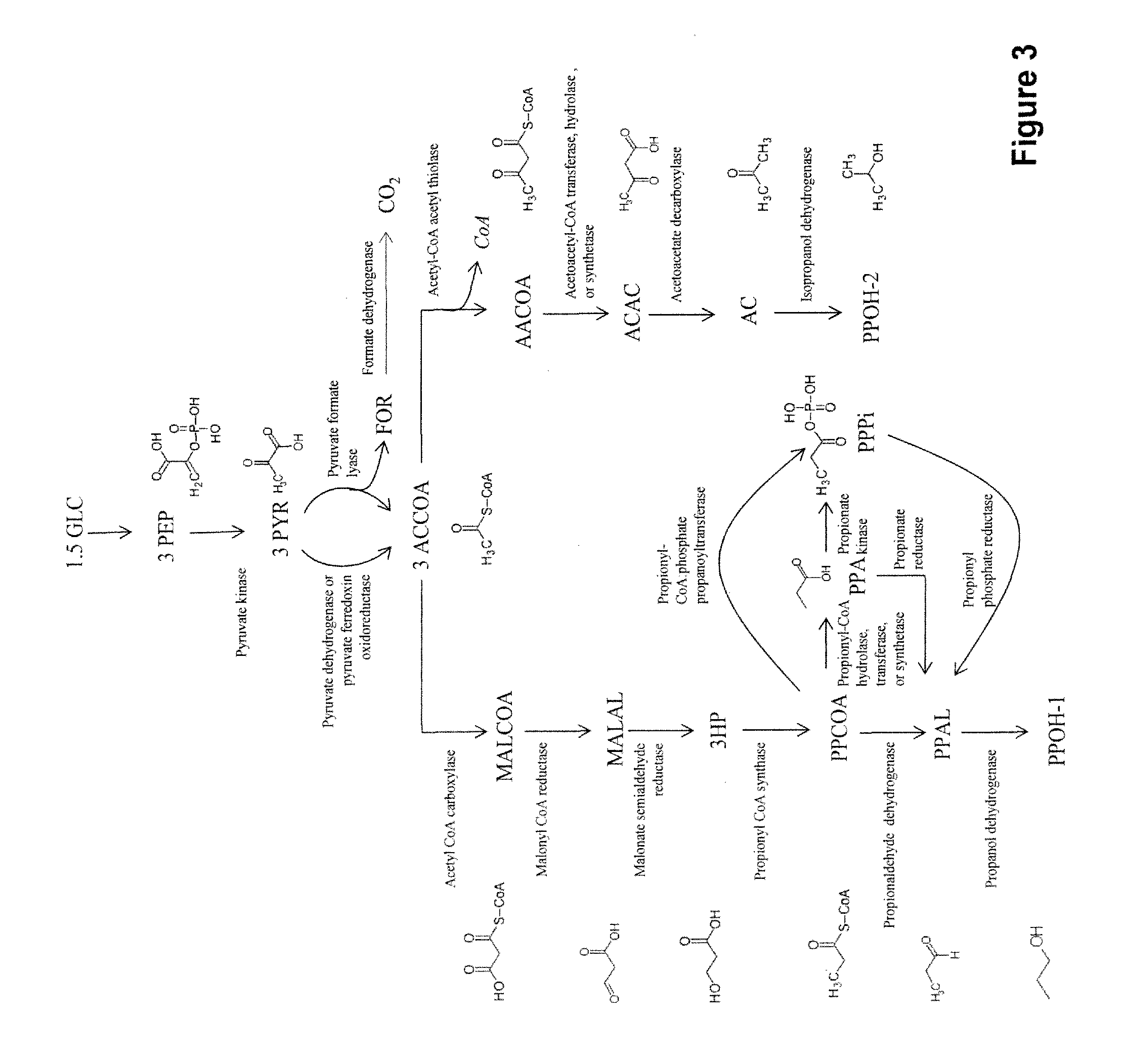

The invention provides a non-naturally occurring microbial organism having n-propanol and isopropanol pathways, 1,4-butanediol (14-BDO) and isopropanol pathways, 1,3-butanediol (13-BDO) and isopropanol pathways or methylacrylic acid (MAA) and isopropanolpathways. The microbial organism contains at least one exogenous nucleic acid encoding an enzyme in each of the respective n-propanol, 14-BDO, 13-BDO or MAA and isopropanol pathways. The invention additionally provides a method for co-producing n-propanol and isopropanol, 14-BDO and isopropanol, 13-BDO and isopropanol or MAA and isopropanol. The method can include culturing an n-propanol and an isopropanol co-producing microbial organism, where the microbial organism expresses at least one exogenous nucleic acid encoding an n-propanol, an isopropanol, a 14-BDO, a 13-BDO and / or a MAA pathway enzyme in a sufficient amount to produce each of the respective products, under conditions and for a sufficient period of time to produce each of the respective products.

Owner:GENOMATICA INC

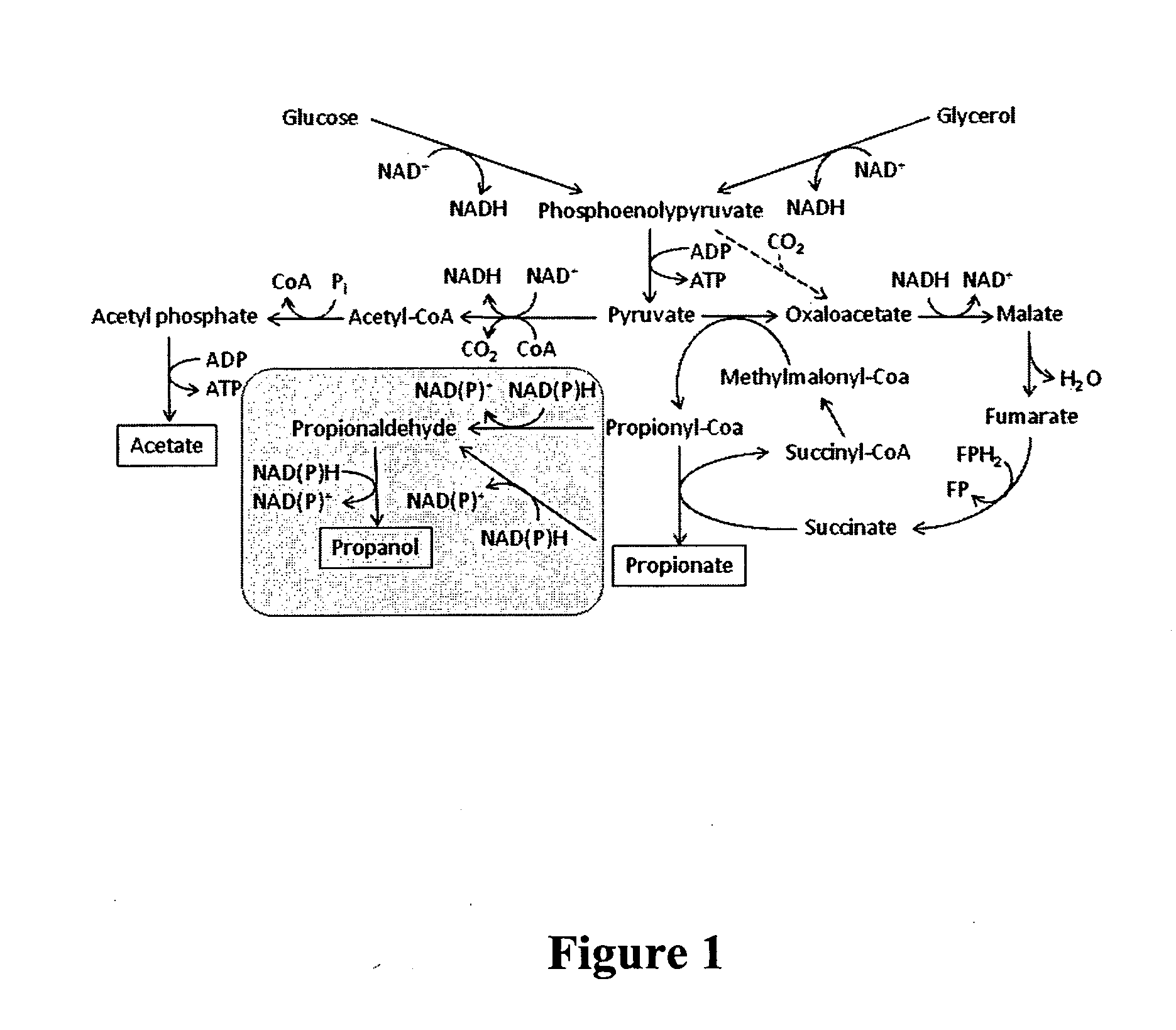

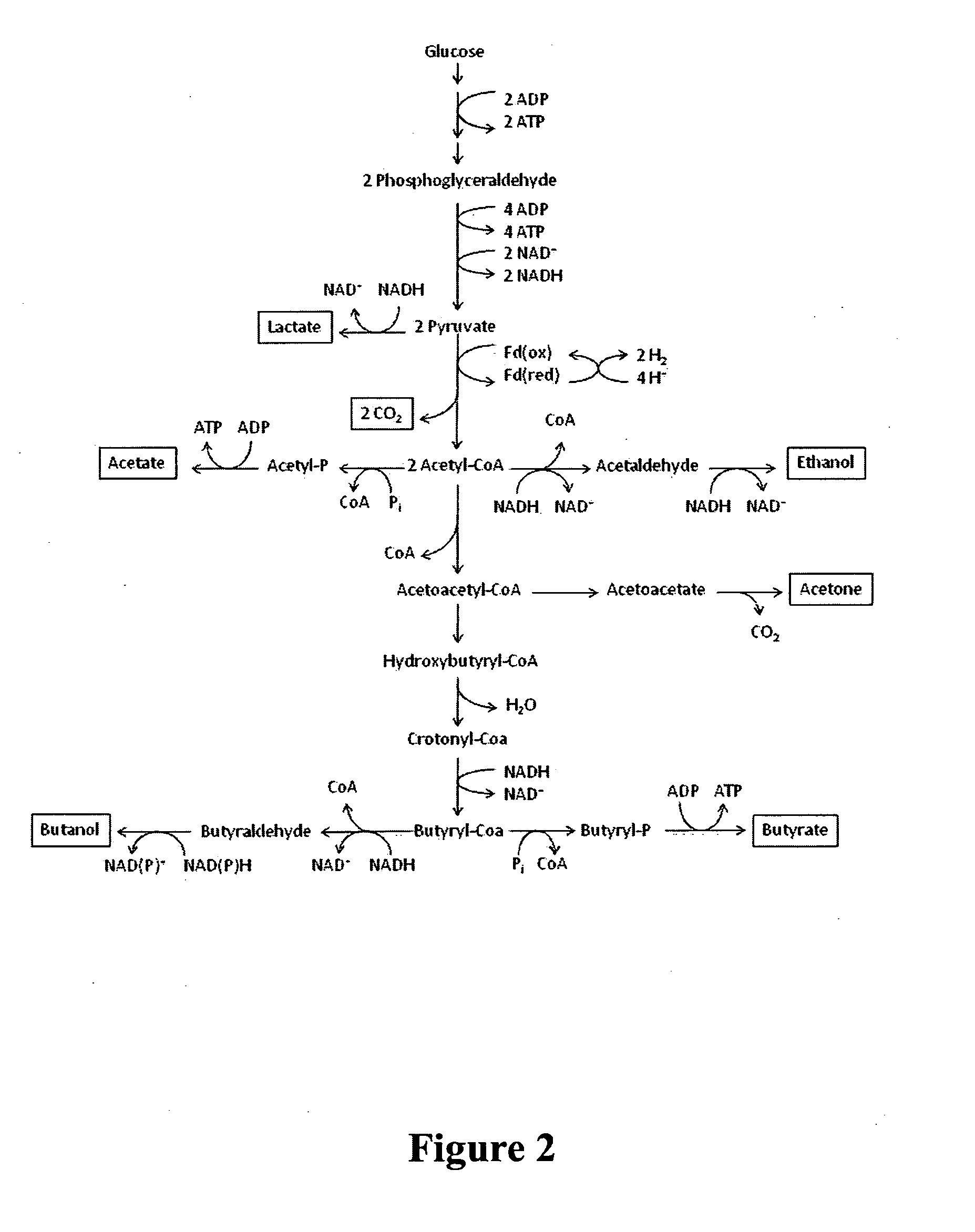

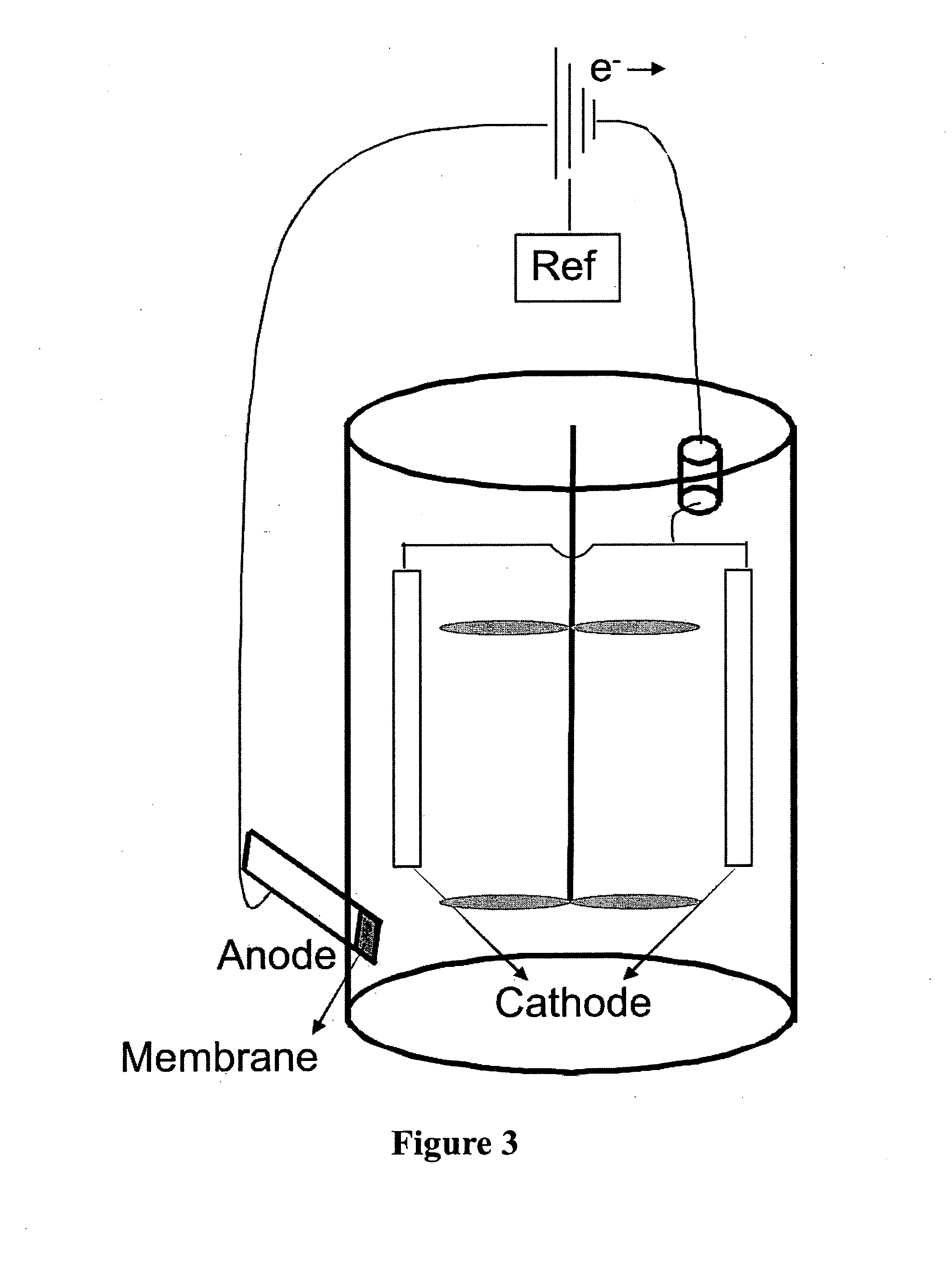

Engineered microorganisms and integrated process for producing n-propanol, propylene and polypropylene

The invention provides fermentative methods for producing n-propanol. The methods of the invention involve providing a suitable carbon source, a microorganism expressing the dicarboxylic acid pathway, reducing equivalents, and at least one gene coding for an enzyme that catalyzes the conversion of propionate / propionyl-CoA into n-propanol. The methods further involve contacting the carbon source and reducing equivalents with the microorganism under conditions favorable for the production of n-propanol. Also provided are methods for producing propylene and polypropylene from the n-propanol and microorganisms suitable for use in the methods of the invention.

Owner:BRASKEM SA +1

Neutral multifunctional paint remover and manufacturing method thereof

The present invention relates to a neutral multifunctional paint remover and its preparation method. The composition comprises dichloromethane, absolute methanol, glycol monoethyl ether, n-propanol, liquid paraffin, methyl cellulose, Tx-10 and water, and its preparation method includes the following steps: placing the dichloromethane into a steel container, adding liquid paraffin according to the defined proportion, fully stirring, standing still for 8-12 min, adding absolute methanol, uniformly dissolving, then adding glycol monoethyl ether, n-propanol, methyl cellulose, Tx-10 and water, placing them into a colloid mill and grinding them to obtain colloidal material whose pH is 6.5-7.5 and packaging in container.

Owner:MOER ENVIRONMENTAL PROTECTION MATERIAL CHANGSHA

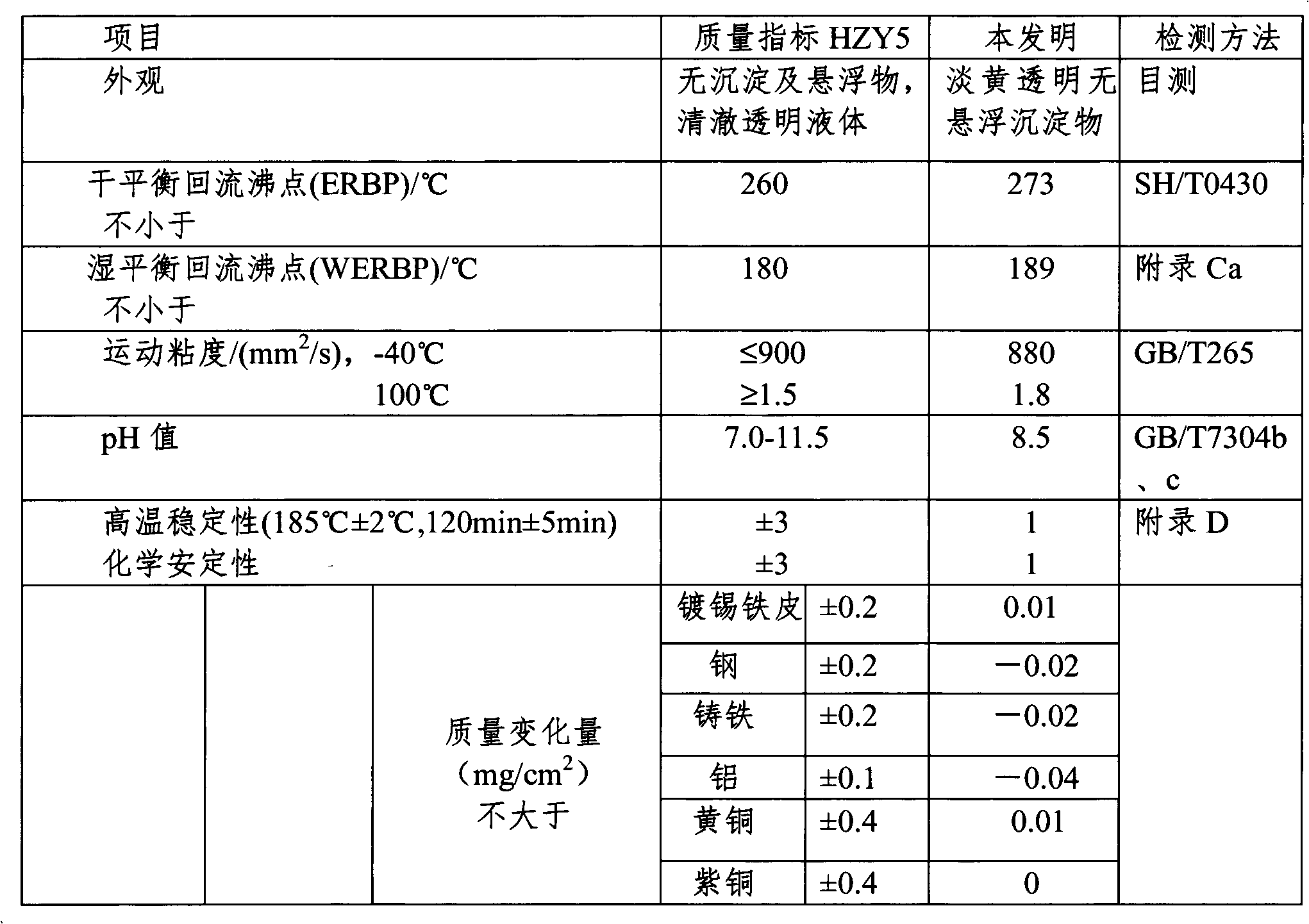

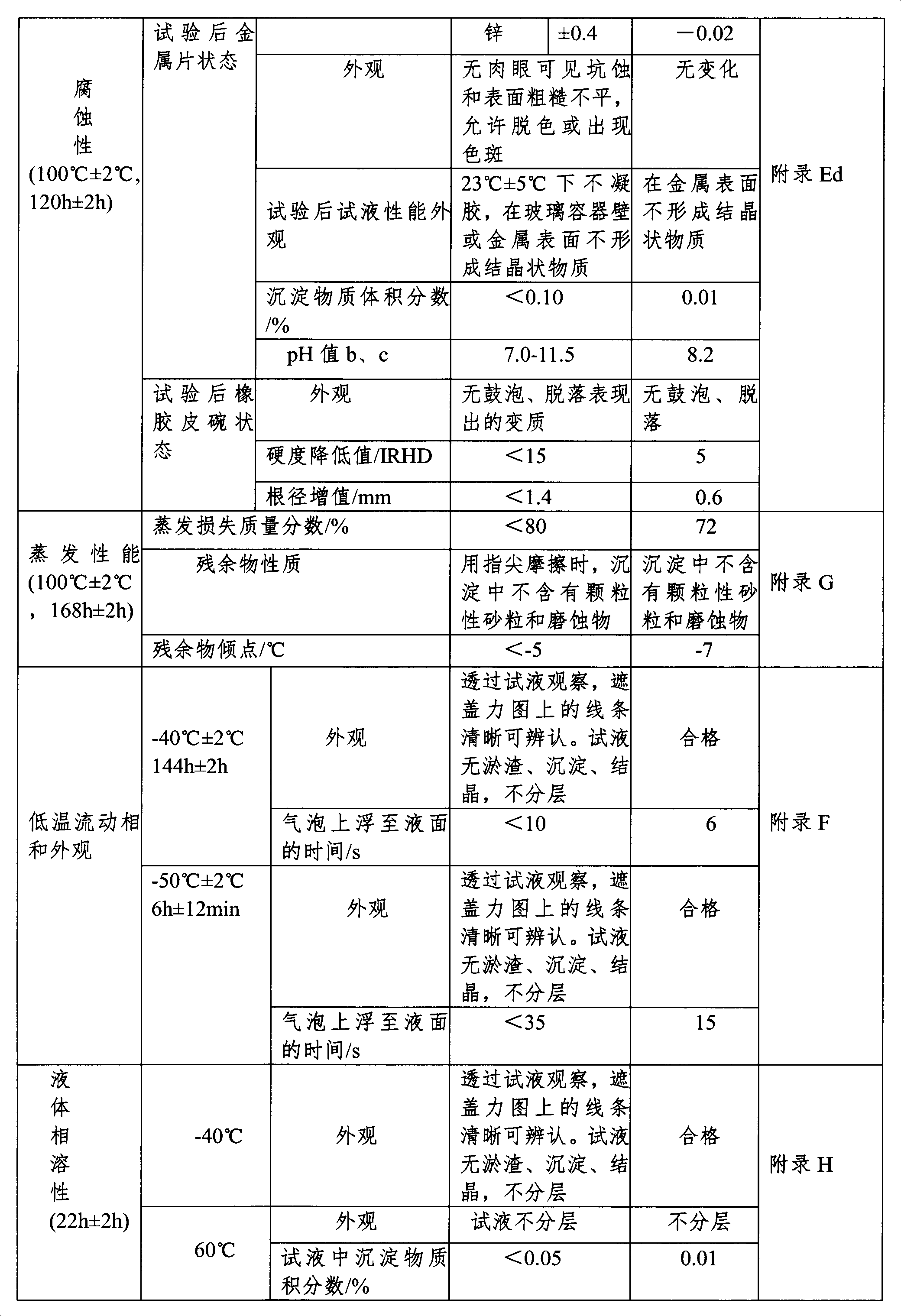

Preparation method of high-grade borate type automobile brake fluid

InactiveCN102796600AHigh boiling pointHigh value-added utilizationGroup 3/13 element organic compoundsEther preparation from oxiranesDistillationGlycerol

The invention relates to a preparation method of a high-grade borate type automobile brake fluid, which comprises a synthesis of polyxinolum and borate as well as blending of the brake fluid. The method is characterized in that n-propanol and epoxypropane are taken as raw materials, a polymerization is generated under the effect of a basic catalyst, and the high polyxinolum with 4-6polymerization degree can be obtained after decolouring, adsorbing, filtering and performing reduced pressure distillation. The method takes high polyxinolum, boric acid and 1,3-propylene glycol as raw materials to synthesize six-membered ring borate with low-viscosity by a two stages esterification method, and the dry equilibrium reflux boiling point and the hydrolytic stability of the brake fluid. The semi-polar boric acid diglyceride is synthesized, and can be used as a basic additive solution to increase the wet equilibrium reflux boiling point of the brake fluid, and can be used with glycerol to prevent the swelling of the rubber. According to the invention, the six-membered ring borate and the boric acid diglyceride are taken as basic liquids, low polyxinolum is taken as a diluent, a proper amount of additive is added, and the high-grade borate type automobile brake fluid can be blended.

Owner:XIANGTAN UNIV

Method for removing byproduct propyl propionate during preparation process of n-propanol by hydrogenation of propionaldehyde

ActiveCN101225018AHigh purityReduce contentOrganic compound preparationHydroxy compound preparationPropionatePropanol

Owner:淄博诺奥化工有限公司

Azeotropic compositions comprising fluorinated olefins for cleaning applications

The present invention relates to azeotropic or azeotrope-like compositions comprising a fluorinated olefin having the formula E- or Z-C3F7CH═CHC3F7, and at least one alcohol, halocarbon, hydrofluorocarbon, fluoroether, or alkanes and combinations thereof. In one embodiment, the one compound selected from the group consisting of alcohols, halocarbons, fluoroalkyl ethers, hydrofluorocarbons, alkanes is either methanol, ethanol, iso-propanol, n-propanol, trans-1,2-dichloroethylene, cis-1,2-dichloroethylene, n-propyl bromide, C4F9OCH3, C4F9OC2H5, HFC-43-10mee, HFC-365mfc, heptane, or combinations thereof. In another embodiment, these compositions are useful in cleaning applications as a degreasing agent or defluxing agent for removing oils and / or other residues from a surface.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com