Inorganic or organic nano composite material for protective suit and preparation method thereof

A nano-composite material and protective clothing technology, applied in the field of inorganic or organic nano-composite materials and their preparation, can solve the problems of poor cloth strength and flame retardancy, poor effect of harmful substances, etc., and achieve the effect of high flame retardant strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

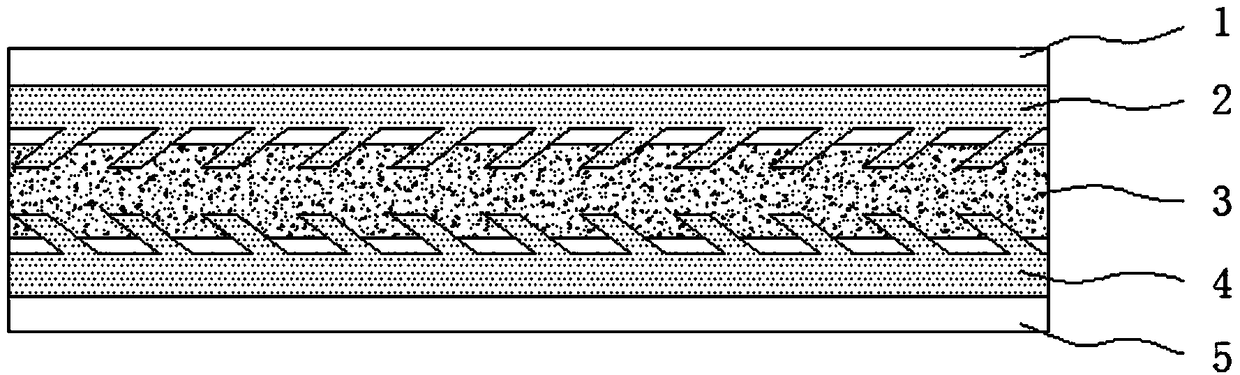

[0031] see figure 1 As shown, the present invention is an inorganic or organic nanocomposite material for protective clothing, which consists of the following five-layer structure from top to bottom: waterproof layer 110, nanocomposite material 120, fiber layer 130, hot melt adhesive film 140, contact layer 150 .

[0032] Further, the waterproof layer 110 adopts any one of polyurethane resin coating, PTFE or FEP; the thickness of the polyurethane resin coating, PTFE or FEP is in the range of 0.5mm.

[0033] Further, the nano-composite material 120 is a nano-scale adsorption complex, which includes in parts by weight:

[0034] Nanoscale Activated Carbon 75

[0035] Antimicrobial 5

[0036] Adhesive 3.

[0037] Further, the preparation method of the nanocomposite material 120 includes: adding an antibacterial agent and a binder to the nanoscale activated carbon, heating, mixing and kneading to make it uniform, and performing extrusion coating to form a film, cooling, compoun...

Embodiment 2

[0049] see figure 1 As shown, the present invention is an inorganic or organic nanocomposite material for protective clothing, which consists of the following five-layer structure from top to bottom: waterproof layer 110, nanocomposite material 120, fiber layer 130, hot melt adhesive film 140, contact layer 150 .

[0050] Further, the waterproof layer 110 adopts any one of polyurethane resin coating, PTFE or FEP; the thickness of the polyurethane resin coating, PTFE or FEP is in the range of 1.0mm.

[0051] Further, the nano-composite material 120 is a nano-scale adsorption complex, which includes in parts by weight:

[0052] Nanoscale Activated Carbon 80

[0053] Antimicrobial 10

[0054] Adhesive 5.

[0055] Further, the preparation method of the nanocomposite material 120 includes: adding an antibacterial agent and a binder to the nanoscale activated carbon, heating, mixing and kneading to make it uniform, and performing extrusion coating to form a film, cooling, compou...

Embodiment 3

[0067] see figure 1 As shown, the present invention is an inorganic or organic nanocomposite material for protective clothing, which consists of the following five-layer structure from top to bottom: waterproof layer 110, nanocomposite material 120, fiber layer 130, hot melt adhesive film 140, contact layer 150 .

[0068] Further, the waterproof layer 110 adopts any one of polyurethane resin coating, PTFE or FEP; the thickness of the polyurethane resin coating, PTFE or FEP is in the range of 1.5 mm.

[0069] Further, the nano-composite material 120 is a nano-scale adsorption complex, which includes in parts by weight:

[0070] Nanoscale Activated Carbon 95

[0071] Antimicrobial 15

[0072] Adhesive 7.

[0073] Further, the preparation method of the nanocomposite material 120 includes: adding an antibacterial agent and a binder to the nanoscale activated carbon, heating, mixing and kneading to make it uniform, and performing extrusion coating to form a film, cooling, compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com