Elastic modified resin for oil well cement and preparation method and application thereof

A technology for modifying resin and oil well cement, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of complex application environment of oil well cement, inability to use resin for cementing, high temperature and high pressure, etc., and achieve thickening time Adjustable, low cost, lowering the effect of elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

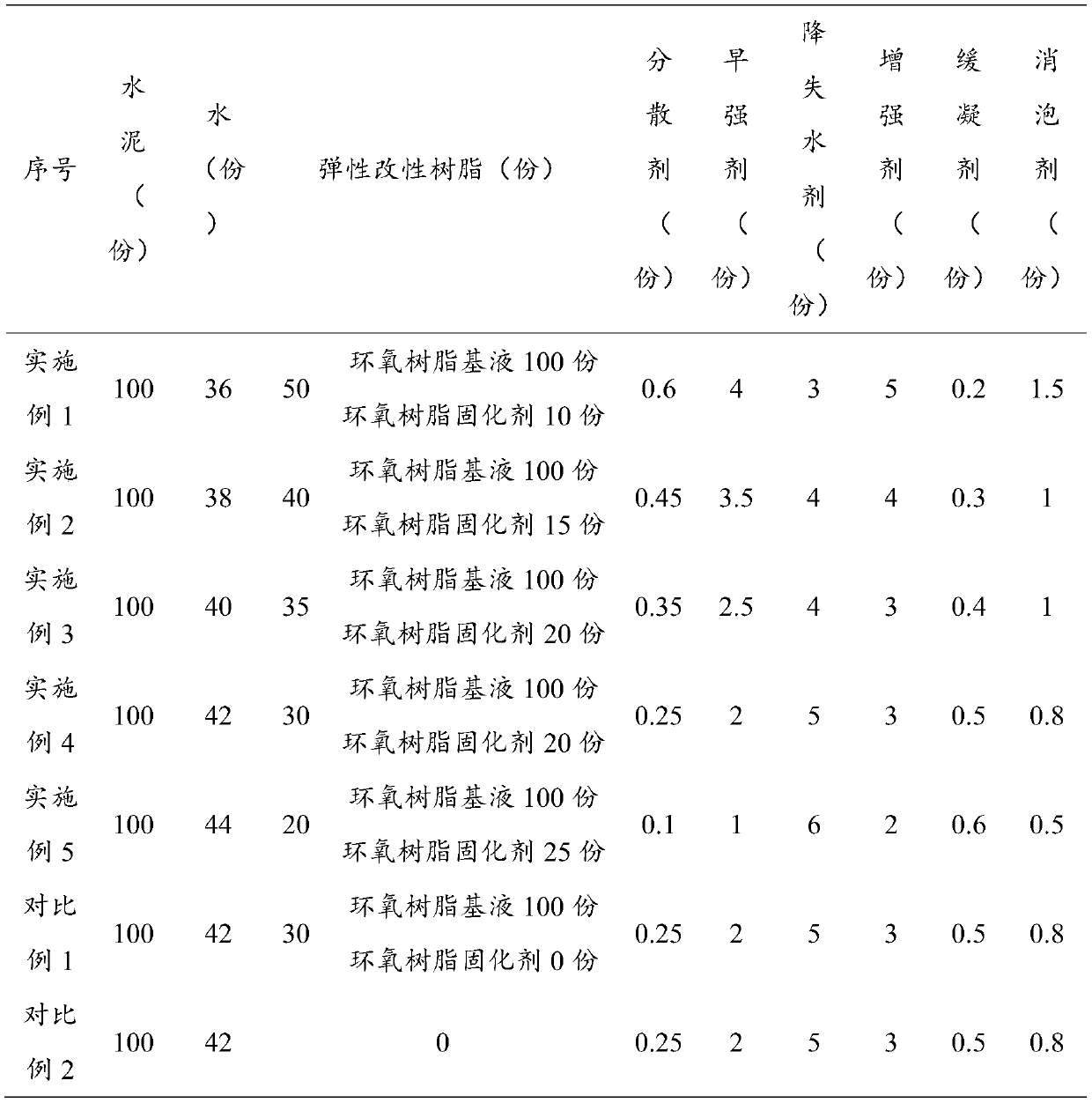

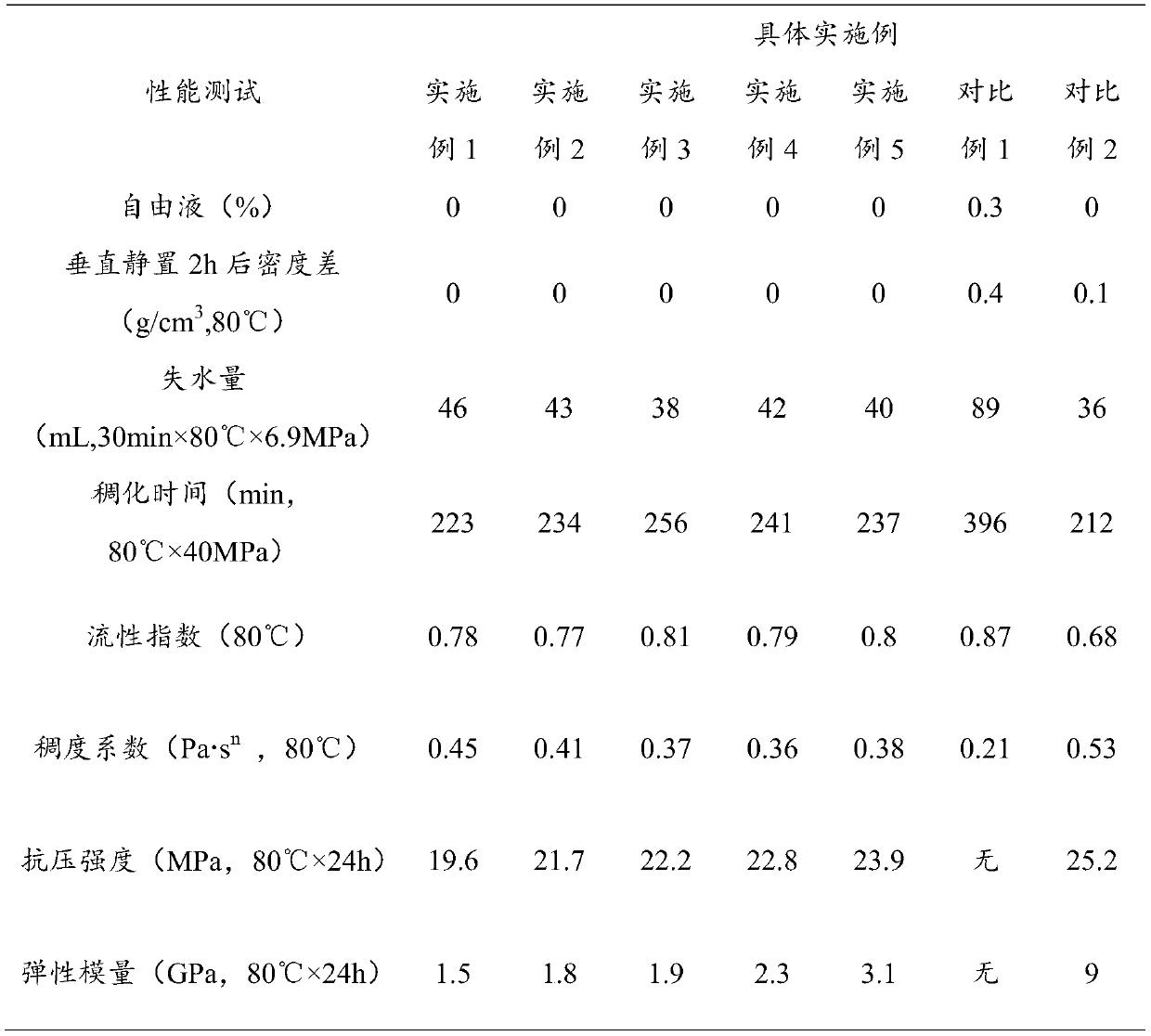

Embodiment 1

[0032] 1. Preparation of elastic modified resin for improving the elasticity of oil well cement

[0033] In terms of the weight of the epoxy resin base liquid, weigh 100 parts of the epoxy resin base liquid, weigh 10 parts of the epoxy resin curing agent, and then add the epoxy resin curing agent into the epoxy resin base liquid at a rate of 500±30r / Stir evenly at the rotating speed of min, and then obtain the elastic modified resin for improving the elasticity of oil well cement.

[0034] 2. Preparation of elastic cement slurry

[0035] Weigh 100 parts by weight of cement, 0.6 parts by weight of dispersant, 4 parts by weight of early strength agent, 3 parts by weight of water loss reducing agent, and 5 parts by weight of reinforcing agent, dry mix into dry powder, measure 36 parts by weight of fresh water, and weigh 50 parts by weight The elastic modified resin, 0.2 parts by weight retarder, and 1.5 parts by weight defoamer are dissolved in water. Then pour the aqueous sol...

Embodiment 2

[0037] 1. Preparation of elastic modified resin for improving the elasticity of oil well cement

[0038] In terms of the weight of the epoxy resin base liquid, weigh 100 parts of the epoxy resin base liquid, weigh 15 parts of the epoxy resin curing agent, and then add the epoxy resin curing agent into the epoxy resin base liquid at a rate of 500±30r / Stir evenly at the rotating speed of min, and then obtain the elastic modified resin for improving the elasticity of oil well cement.

[0039] 2. Preparation of elastic cement slurry

[0040] Weigh 100 parts by weight of cement, 0.45 parts by weight of dispersant, 3.5 parts by weight of early strength agent, 4 parts by weight of water loss reducing agent, and 4 parts by weight of reinforcing agent, dry mix into dry powder, measure 38 parts by weight of fresh water, and weigh 40 parts by weight The elastic modified resin, 0.3 parts by weight retarder, and 1 part by weight defoamer are dissolved in water. Then pour the aqueous sol...

Embodiment 3

[0042] 1. Preparation of elastic modified resin for improving the elasticity of oil well cement

[0043] In terms of the weight of the epoxy resin base liquid, weigh 100 parts of the epoxy resin base liquid, weigh 20 parts of the epoxy resin curing agent, and then add the epoxy resin curing agent into the epoxy resin base liquid at a rate of 500±30r / Stir evenly at the rotating speed of min, and then obtain the elastic modified resin for improving the elasticity of oil well cement.

[0044] 2. Preparation of elastic cement slurry

[0045]Weigh 100 parts by weight of cement, 0.35 parts by weight of dispersant, 2.5 parts by weight of early strength agent, 4 parts by weight of water loss reducing agent, and 3 parts by weight of reinforcing agent, dry mix into dry powder, measure 40 parts by weight of fresh water, and weigh 35 parts by weight The elastic modified resin, 0.4 parts by weight retarder, and 1 part by weight defoamer are dissolved in water. Then pour the aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com