High temperature toughcementing carboxyl butadiene-styrene latex additive

A technology of carboxylated styrene-butadiene latex and admixture, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of seal failure, easy cracking, interlayer channeling, etc., and achieve prolonging service life and water loss Low, less water loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

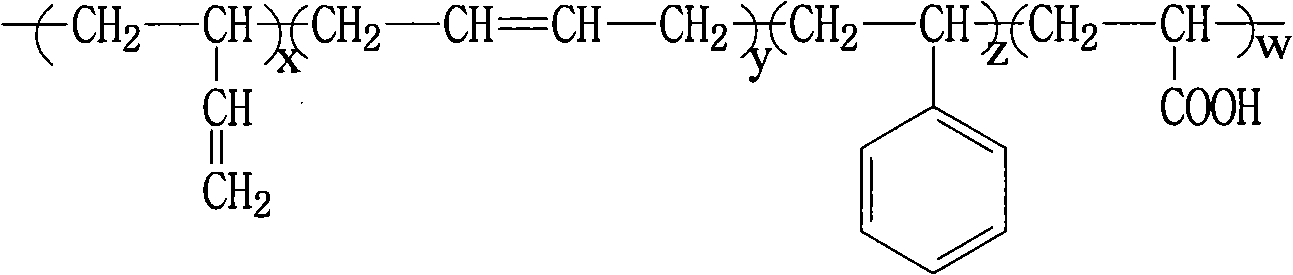

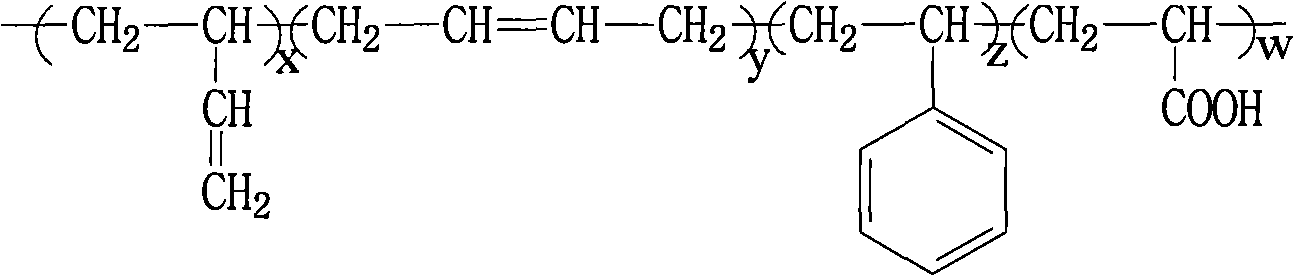

Method used

Image

Examples

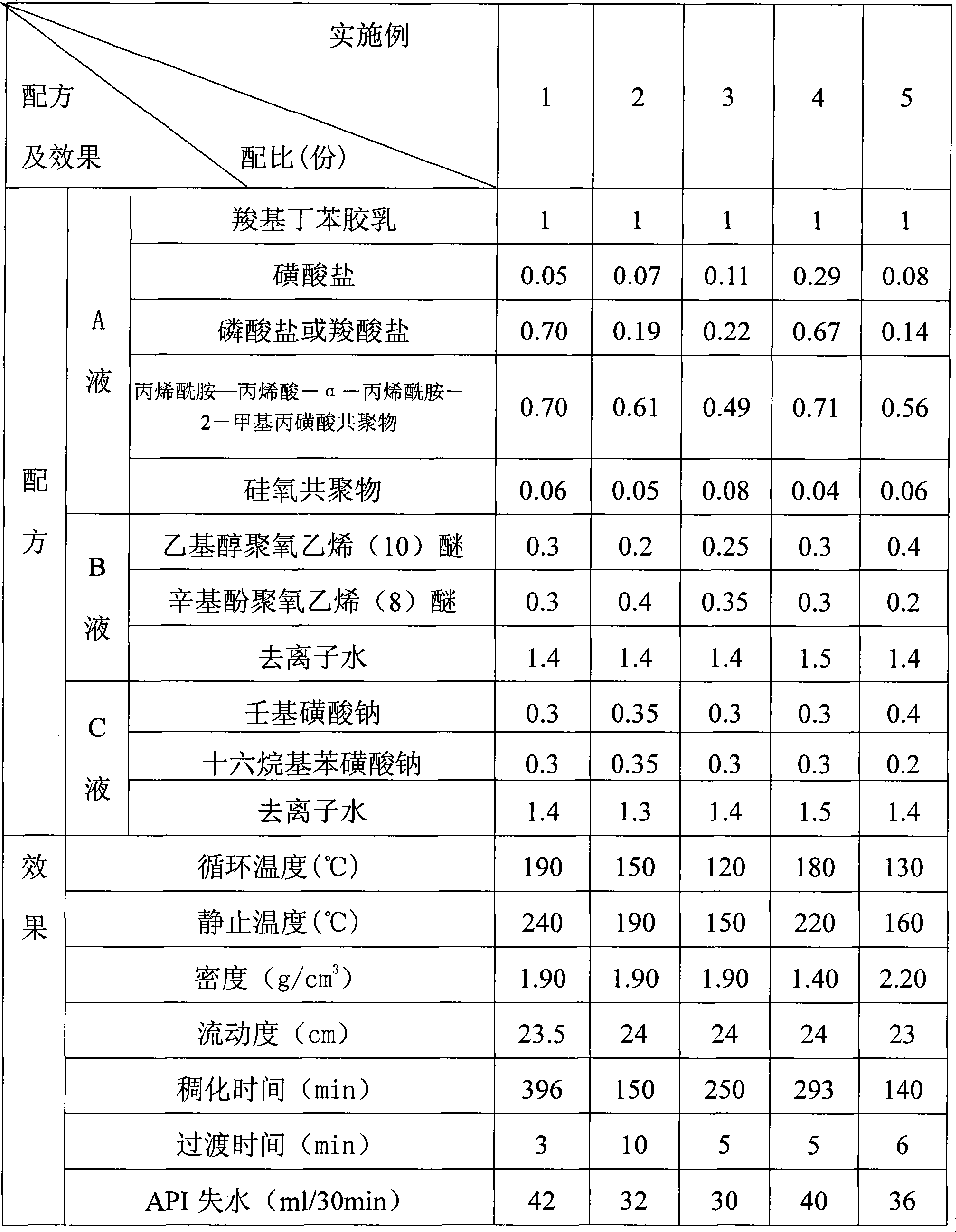

Embodiment 1

[0028] In a 500ml beaker, add 1 part by weight of carboxylated styrene-butadiene latex, 0.05 part by weight of formaldehyde, acetone, naphthalene and sulfamate condensation reaction to generate sulfonate, 0.70 part by weight of hydroxyethylidene diphosphoric acid, 0.70 part by weight of acrylamide-acrylic acid - α-acrylamide-2-methylpropanesulfonic acid copolymer and 0.06 parts by weight of siloxane copolymer were stirred for 30 seconds at a stirring speed of 4000 rpm to obtain liquid A. In a 250ml beaker, add 0.3 parts by weight of nonionic surfactant 1 ethyl alcohol polyoxyethylene (10) ether, 0.3 parts by weight of nonionic surfactant 2 octylphenol polyoxyethylene (8) ether and 1.4 parts by weight of deionized water, stirred at a stirring speed of 4000rpm for 20 seconds to obtain liquid B. In another 250ml beaker, add 0.3 parts by weight of anionic surfactant 1 sodium nonylsulfonate, 0.3 parts by weight of anionic surfactant 2 sodium hexadecylbenzenesulfonate and 1.4 parts ...

Embodiment 2

[0030]In a 500ml beaker, add 1 part by weight of carboxylated styrene-butadiene latex, 0.07 parts by weight of formaldehyde, acetone, naphthalene and sulfamate condensation reaction to generate sulfonate, 0.19 parts by weight of citric acid, 0.61 part by weight of acrylamide-acrylic acid-α- Acrylamide-2-methylpropanesulfonic acid copolymer and 0.05 parts by weight of siloxane copolymer were stirred for 30 seconds at a stirring speed of 4000 rpm to prepare liquid A. In a 250ml beaker, add 0.2 parts by weight of nonionic surfactant 1 ethyl alcohol polyoxyethylene (10) ether, 0.4 parts by weight of nonionic surfactant 2 octylphenol polyoxyethylene (8) ether and 1.4 parts by weight of deionized water, stirred at a stirring speed of 4000rpm for 20 seconds to obtain liquid B. In another 250ml beaker, add 0.35 parts by weight of anionic surfactant 1 sodium nonylsulfonate, 0.35 parts by weight of anionic surfactant 2 sodium hexadecylbenzenesulfonate and 1.3 parts by weight of deionize...

Embodiment 3

[0032] In a 500ml beaker, add 1 part by weight of carboxylated styrene-butadiene latex, 0.11 parts by weight of formaldehyde, acetone, naphthalene and sulfamate condensation reaction to generate sulfonate, 0.22 parts by weight of citric acid, 0.49 parts by weight of acrylamide-acrylic acid-α- Acrylamide-2-methylpropanesulfonic acid copolymer and 0.08 parts by weight of siloxane copolymer were stirred for 30 seconds at a stirring speed of 4000 rpm to prepare liquid A. In a 250ml beaker, add 0.25 parts by weight of nonionic surfactant 1 ethyl alcohol polyoxyethylene (10) ether, 0.35 parts by weight of nonionic surfactant 2 octylphenol polyoxyethylene (8) ether and 1.4 parts by weight of deionized water, stirred at a stirring speed of 4000rpm for 20 seconds to obtain liquid B. In another 250ml beaker, add 0.3 parts by weight of anionic surfactant 1 sodium nonylsulfonate, 0.3 parts by weight of anionic surfactant 2 sodium hexadecylbenzenesulfonate and 1.4 parts by weight of deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com