Preparation method of retarder used for oil gas well cementing operation, retarder and application

A retarder, oil and gas well technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of short thickening time that cannot meet the safety construction requirements, large temperature difference between the top and bottom of the cement slurry column, and deep well cementing Problems such as engineering construction difficulties, to achieve the effect of low concentration required for triggering, avoiding induced decomposition, and high applicable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 1000ml four-necked round bottom flask, add 250g 2-acrylamido-2-methylpropanesulfonic acid and 500g deionized water and stir to dissolve, add NaOH solution to adjust the pH value of the system to 9, then add 83g itaconic acid, and The reactor was placed in a constant temperature water bath at 60°C, kept for 10 minutes, and azobisisobutylimidazoline hydrochloride initiator solution with a mass concentration of 20% was added dropwise, wherein the amount of the initiator was 2-acrylamido-2-methyl 0.1% of the total mass of propanesulfonic acid and itaconic acid was reacted at 90° C. for 2 hours to obtain sample 1 with an effective content of 37%.

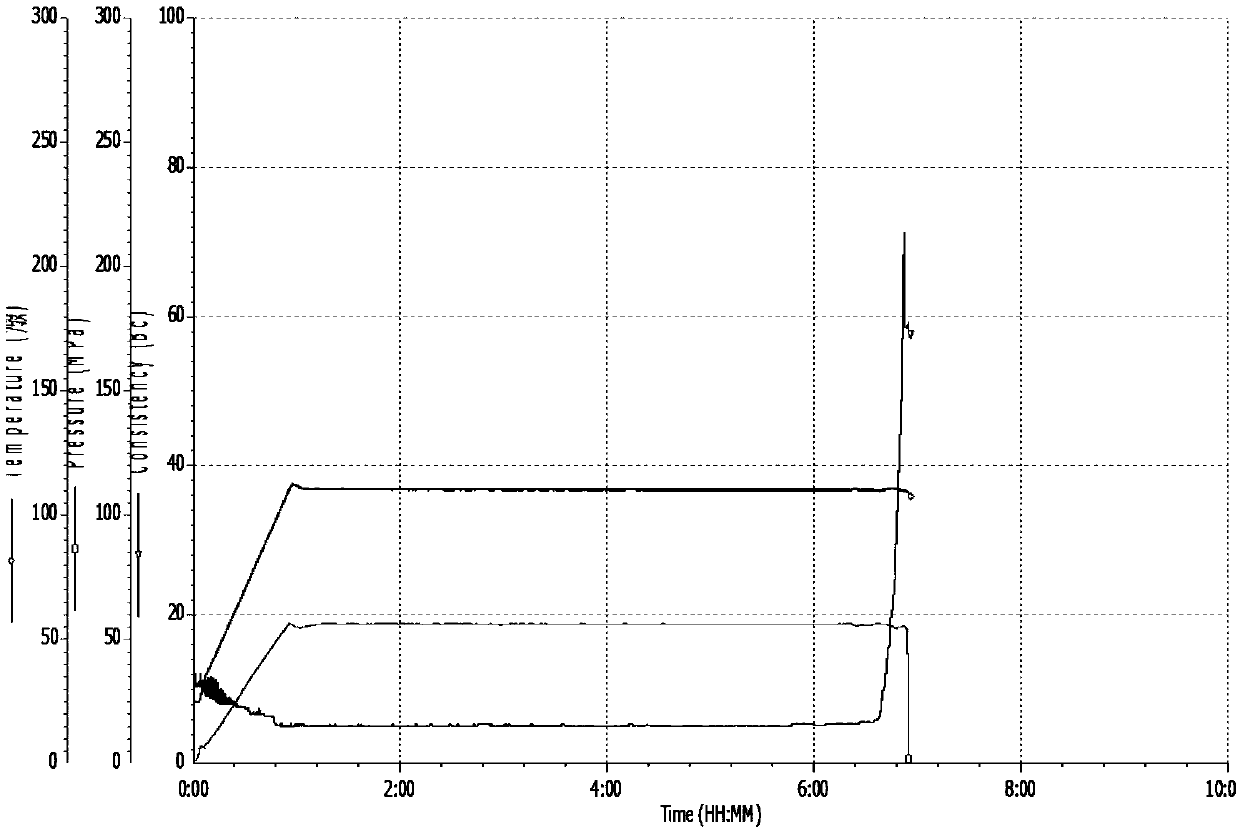

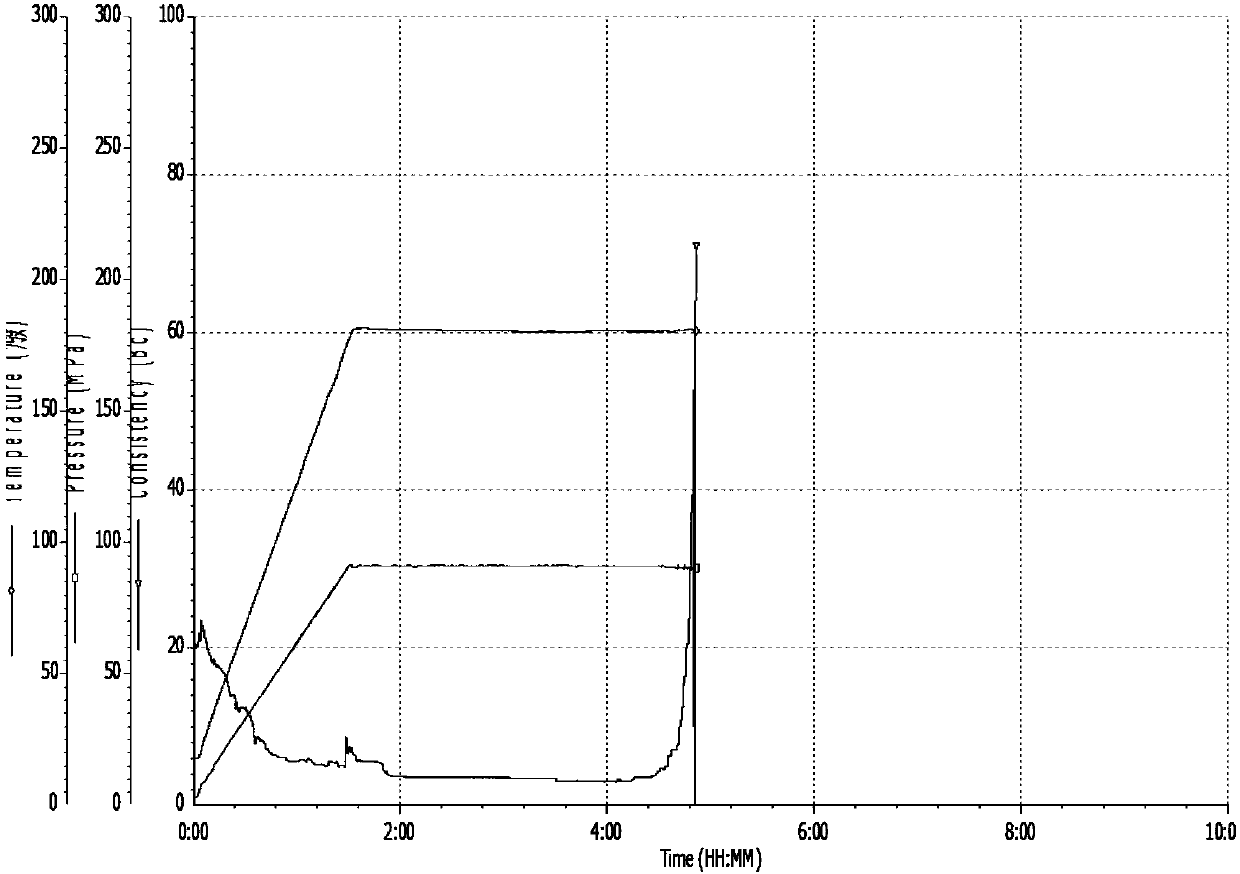

[0027] Prepare cement slurry according to GB / T 19139-2003 standard, and evaluate initial consistency, thickening time, and water loss. The cement slurry formula is: Jiahua G grade cement + 35% silica fume + sample 1 + fluid loss reducer (liquid) + water, the water-cement ratio is 0.44, and the amount of samples added in the f...

Embodiment 2

[0032] In a 500ml four-neck round bottom flask, add 125g of 2-acrylamido-2-methylpropanesulfonic acid and 250g of deionized water and stir to dissolve, use NaOH solution to adjust the pH value to 12, then add 46g of itaconic acid, and react Put the device in a constant temperature water bath at 40°C, keep it for 30 minutes, and add dropwise azobisisopropylimidazoline initiator solution with a mass concentration of 5%, wherein the amount of initiator is 2-acrylamido-2-methylpropanesulfonic acid React with 5% of the total mass of itaconic acid at 50°C for 5 hours to prepare an AMPS / IA copolymer retarder solution. The liquid product is precipitated with ethanol to obtain sample 2, which is a white solid product.

Embodiment 3

[0034] In a 500ml four-neck round bottom flask, add 125g of 2-acrylamido-2-methylpropanesulfonic acid and 250g of deionized water and stir to dissolve, use NaOH solution to adjust the pH value to 10, then add 46g of itaconic acid, and react Put the device in a constant temperature water bath at 50°C, keep it for 20 minutes, and add dropwise azobisisobutyramide hydrochloride initiator solution with a mass concentration of 10%, wherein the amount of initiator is 2-acrylamido-2-methylpropanesulfonate 1% of the total mass of acid and itaconic acid were reacted at 70° C. for 3 hours to obtain sample 3.

[0035] Prepare cement slurry according to GB / T 19139-2003 standard, and evaluate initial consistency, thickening time, and water loss. The cement slurry formula is: Jiahua G grade cement + 35% silica fume + sample 3 + fluid loss reducer (liquid) + water, the water-cement ratio is 0.44, and the amount of samples added in the formula is based on cement. The test performance is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com