Endogenous toughened corrosion-resistant cement mortar system

A cement slurry and toughening technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of low compressive strength of cement cement, poor corrosion resistance and impact resistance, and large carbon fiber aspect ratio. problem, to achieve the effect of adjustable density and thickening time, low cost, and reduced water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Formula: 100 parts of high sulfate-resistant G grade oil well cement, 10 parts of microcrystalline calcium aluminate ferrite, 1 part of polyvinyl alcohol, 1 part of melamine formaldehyde resin, 2 parts of boric acid and 49 parts of water.

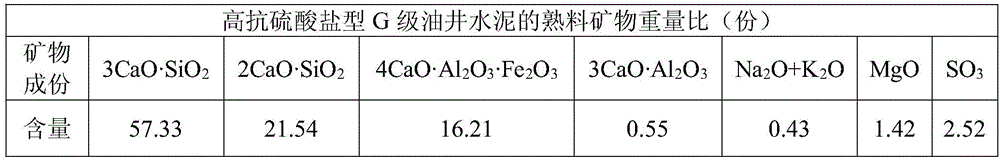

[0039] The clinker mineral composition of high sulfate-resistant G grade oil well cement is as follows:

[0040]

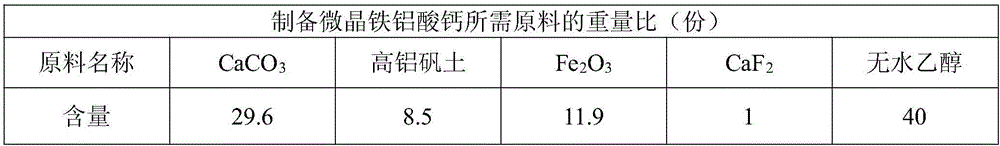

[0041] The proportions of raw materials required for the preparation of microcrystalline calcium aluminate ferrite and the preparation process are as follows:

[0042]

[0043] The raw materials required for the preparation of microcrystalline calcium aluminate ferrite were added into a ball mill jar, and the planetary ball mill was used to grind for 3.5 hours. The ground raw material is dried, and the dried raw material is compressed into tablets (the pressure is 45KN, the pressure increase rate is 0.1KN / s, the pressure is released after holding the pressure for 180s, and the pressure is ≤2.5KN when the pressure i...

Embodiment 2

[0045] Formula: 100 parts of high sulfate-resistant G grade oil well cement, 20 parts of microcrystalline calcium aluminate ferrite, 15 parts of microsilicon, 3 parts of polyacrylamide, 1 part of sodium hexametaphosphate, 0.5 parts of gypsum and 60 parts of water.

[0046] The composition and preparation of the high sulfate-resistant G grade oil well cement and microcrystalline calcium aluminoferrite are the same as those in Example 1.

Embodiment 3

[0048] Formula: 100 parts of high sulfate-resistant G grade oil well cement, 30 parts of microcrystalline calcium aluminate ferrite, 15 parts of micro silicon, 4 parts of carboxymethyl cellulose, 2 parts of sodium lignosulfonate, 2 parts of sodium borate and 64 parts of water share.

[0049] The composition and preparation of the high sulfate-resistant grade G oil well cement and microcrystalline calcium aluminoferrite are the same as in Example 1.

[0050] 2. Performance test of endogenous toughened and corrosion-resistant cement slurry system

[0051] Embodiment 1, Embodiment 2, and Embodiment 3 were respectively prepared according to the national standard GB / T 19139─2012 cement slurry, and measured the basic properties such as the density, fluidity and thickening time of the cement slurry, and the anti-corrosion properties before and after corrosion. compressive strength and flexural strength. The basic performance results of the endogenous toughened and corrosion-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com