A liquid colloid filling low-temperature well-cementing cement mortar system

A technology for cementing cement slurry and colloid, which is applied in the field of oil and gas well cementing, can solve the problems of difficulty in obtaining anti-channeling ability and early strength, high cost of fast-hardening cement, and difficulty in adjustment, and achieves good settlement stability and increased gas resistance. The effect of channeling performance and convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

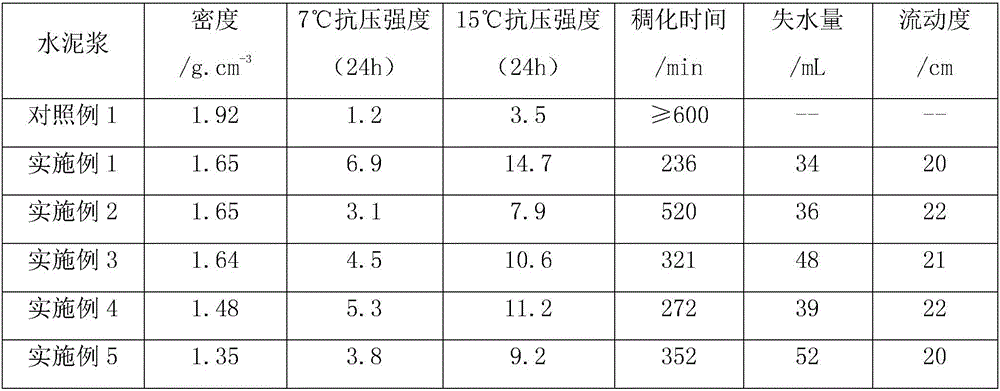

[0041] Cement slurry formula: 100 parts of Portland cement (label: P.O 52.5R) produced by Henan Mengdian Cement Factory, 80 parts of lynx brand superfine Portland cement (model: 1250) produced by Shandong Yingan Environmental Protection Material Technology Co., Ltd. 10 copies of hollow glass microspheres (model: Y8000) produced by Sinosteel Maanshan Mining Institute New Material Technology Co., Ltd., 10 copies of Sepsen brand micro-silicon provided by Shandong Boken International Trade Co., Ltd., Zhejiang Yuda Chemical Co., Ltd. 10 parts of silica sol (model: GS-35) produced by the company, 4 parts of early strength agent sodium sulfate, 1 part of polycarboxylate water reducer, 2 parts of water loss reducer, 1 part of tributyl phosphate defoamer , 120 parts of water.

[0042] Preparation method: dissolve early strength agent, water reducer, water reducing agent, defoamer and silica sol in water, and then prepare cement slurry with the obtained aqueous solution and cement accor...

Embodiment 2

[0047] Cement slurry formula: 100 parts of Shengwei G-grade cement produced by Shandong Shengwei Cement Factory, 80 parts of Lynx brand superfine Portland cement (model: 1250) produced by Shandong Yingan Environmental Protection Material Technology Co., Ltd., Ma'anshan, China Steel Group 10 parts of hollow glass microspheres (model: Y8000) produced by Mining Institute New Material Technology Co., Ltd., 10 parts of Sepsen brand micro-silicon provided by Shandong Boken International Trade Co., Ltd., silica sol produced by Zhejiang Yuda Chemical Co., Ltd. ( Model: GS-35) 10 parts, early strength agent sodium sulfate 4 parts, polycarboxylate water reducer 1 part, fluid loss reducer 2 parts, tributyl phosphate defoamer 1 part, water 120 parts.

[0048] Preparation method: dissolve early strength agent, water reducer, water reducing agent, defoamer and silica sol in water, and then prepare cement slurry with the obtained aqueous solution and cement according to API 10B-3-2004 oil wel...

Embodiment 3

[0051] Cement slurry formula: 180 parts of Portland cement (label: P.O 52.5R) produced by Henan Mengdian Cement Factory, 10 parts of hollow glass microspheres (model: Y8000) produced by Sinosteel Maanshan Mining Institute New Material Technology Co., Ltd. , 10 parts of Sepsen brand micro-silicon provided by Shandong Boken International Trade Co., Ltd., 10 parts of silica sol (model: GS-35) produced by Zhejiang Yuda Chemical Co., Ltd., 4 parts of early strength agent sodium sulfate, polycarboxylic acid 1 part of salt water reducer, 2 parts of fluid loss reducer, 1 part of tributyl phosphate defoamer, 120 parts of water.

[0052] Preparation method: dissolve early strength agent, water reducer, water reducing agent, defoamer and silica sol in water, and then prepare cement slurry with the obtained aqueous solution and cement according to API 10B-3-2004 oil well cement test method.

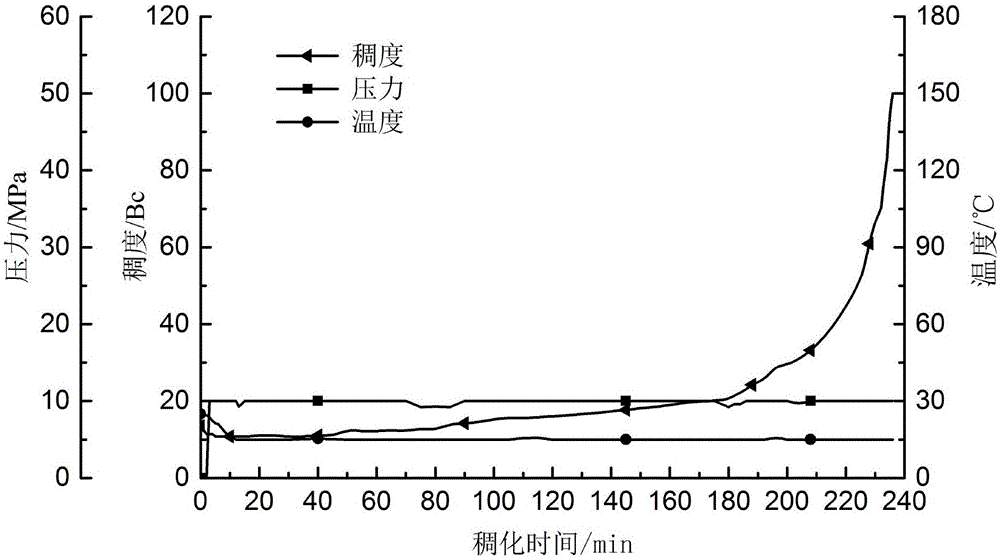

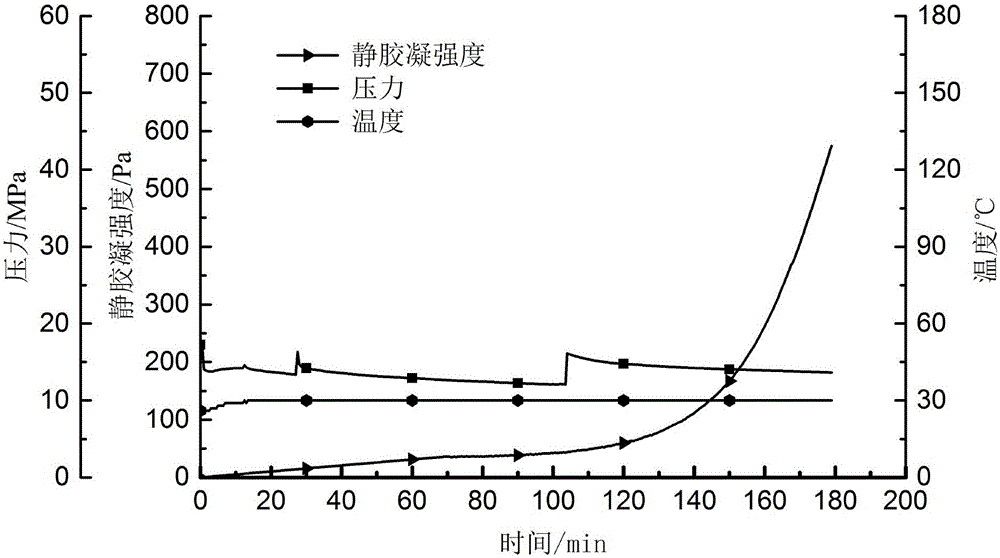

[0053] Refer to the standard SY / T 6544-2003 oil well cement slurry performance requirements to me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com