Foam cement slurry system and composition

A cement slurry and foam technology, applied in the field of chemical nitrogen-filled foam cement cementing, can solve the problems of uneven pore structure of foamed cement stone, poor foam stability, poor biodegradability, etc., and achieves adjustable density and thickening time. The effect of good foaming and foam stabilization and fast dissolving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

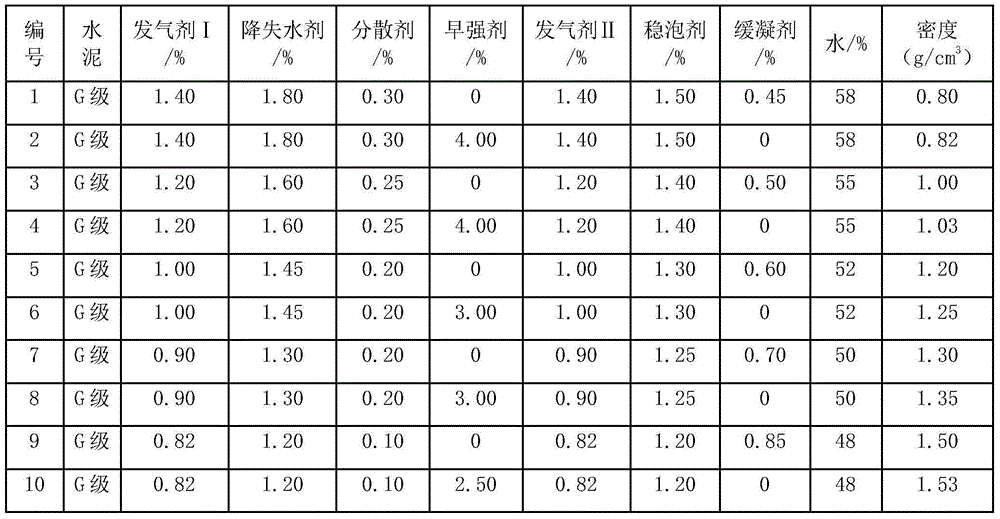

[0018] Embodiment 1: foam cement slurry density test

[0019] High sulfur-resistant G grade oil well cement was used to prepare foam cement slurry according to the standard API10B-4-2004. The basic composition of slurry dry ash is: high sulfur-resistant G oil well cement, air-generating agent I, fluid loss reducer (solid), dispersant, early strength agent; the basic composition of slurry mixing liquid is: air-generating agent II, foam stabilizer , fluid loss reducer (liquid), retarder and water; in this experiment, the solid dry ash component and the liquid component of the slurry were first weighed and mixed, and then according to the standard API10B-4-2004 During the preparation of cement slurry, during the stirring process, the air-generating agent Ⅰ in the solid dry ash component and the air-generating agent Ⅱ in the liquid component contact in the cement slurry to produce nitrogen gas, which realizes the purpose of filling the cement slurry with nitrogen gas. Under the f...

Embodiment 2

[0022] Embodiment 2: Simulation of foam cement slurry density change test under certain temperature / pressure conditions

[0023] Using high sulfur-resistant G-grade oil well cement, prepare foamed cement slurry according to standard API10B-4-2004, test the density of the cement slurry at room temperature 20 ° C / standard atmospheric pressure, and then pour the cement slurry into a diameter of 8 cm and a height of 10 cm In the circular pressure-resistant steel mold, the inside of the circular pressure-resistant steel mold is coated with polytetrafluoroethylene, the lower part is sealed with a threaded cover, and there is a small hole (0.5cm in diameter) in the middle of the upper sealed threaded cover for pressure transmission. Then put the circular pressure-resistant steel mold filled with foam cement slurry into the high-temperature and high-pressure curing kettle, use water as the heat transfer and pressure transfer medium to heat and pressurize the curing, take out the ceme...

Embodiment 3

[0026] Embodiment 3: the performance of foam cement slurry

[0027] High sulfur-resistant grade G oil well cement was used to prepare foamed cement slurry according to the standard API10B-4-2004 and the performance of foamed cement slurry was measured. The test results are shown in Table 3.

[0028] Table 3 Performance parameters of foam cement slurry

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com