Oil well cement leak-proof toughening agent

A technology of oil well cement and toughening agent, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of cement stone inherent brittleness, cement slurry leakage, etc., and achieve the improvement of cement stone toughness, cement toughness improvement, preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

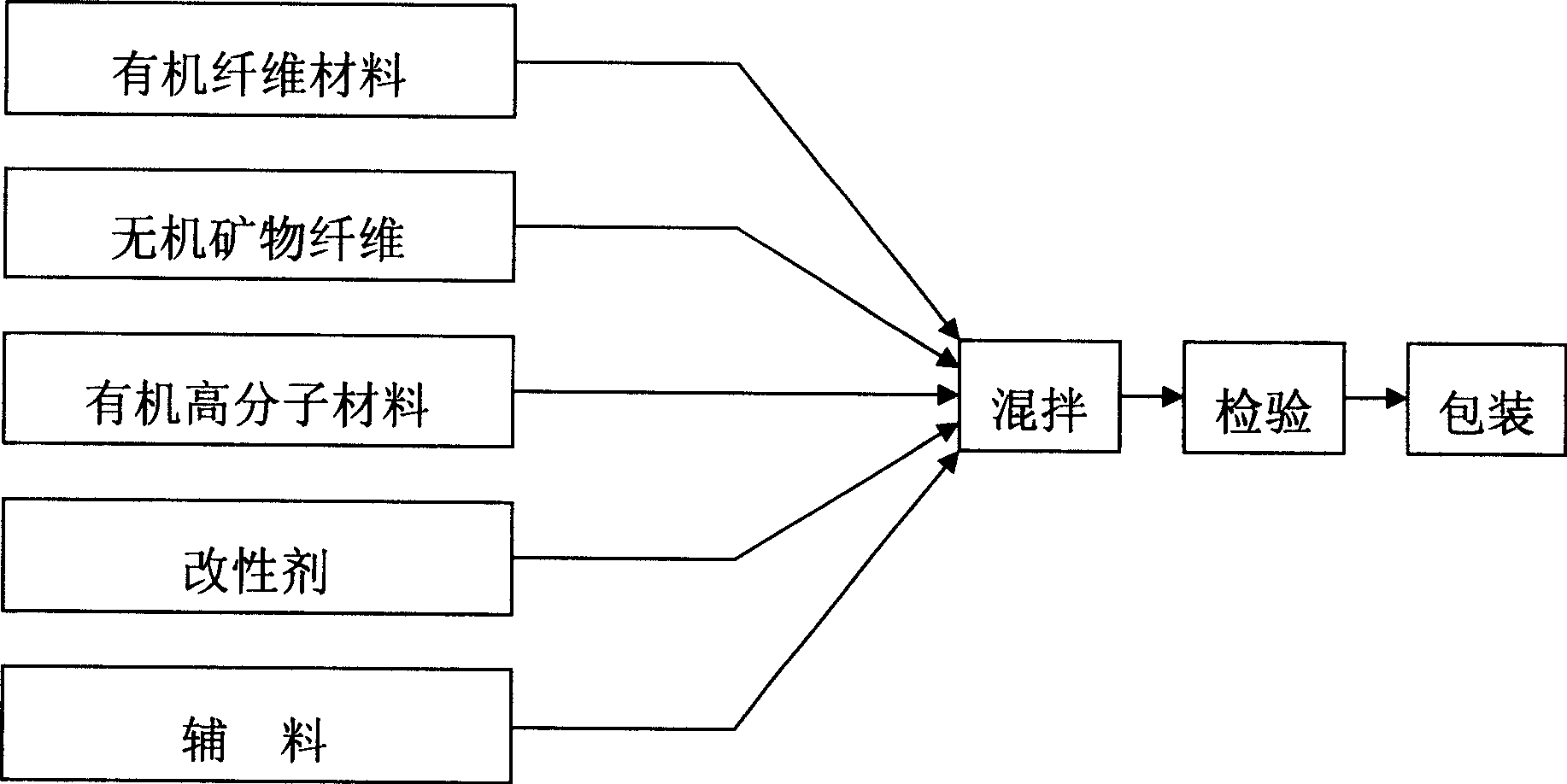

Method used

Image

Examples

Embodiment 1

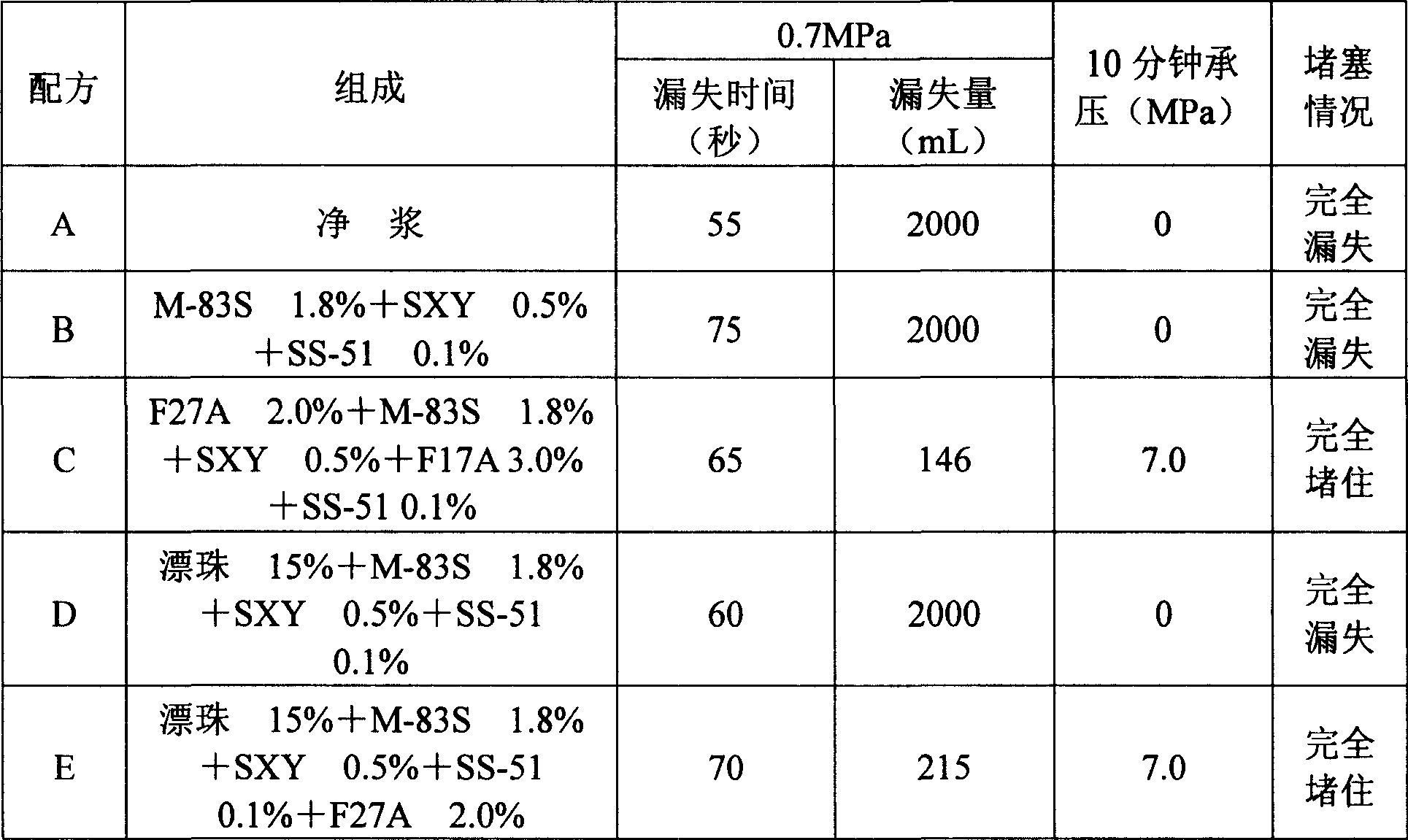

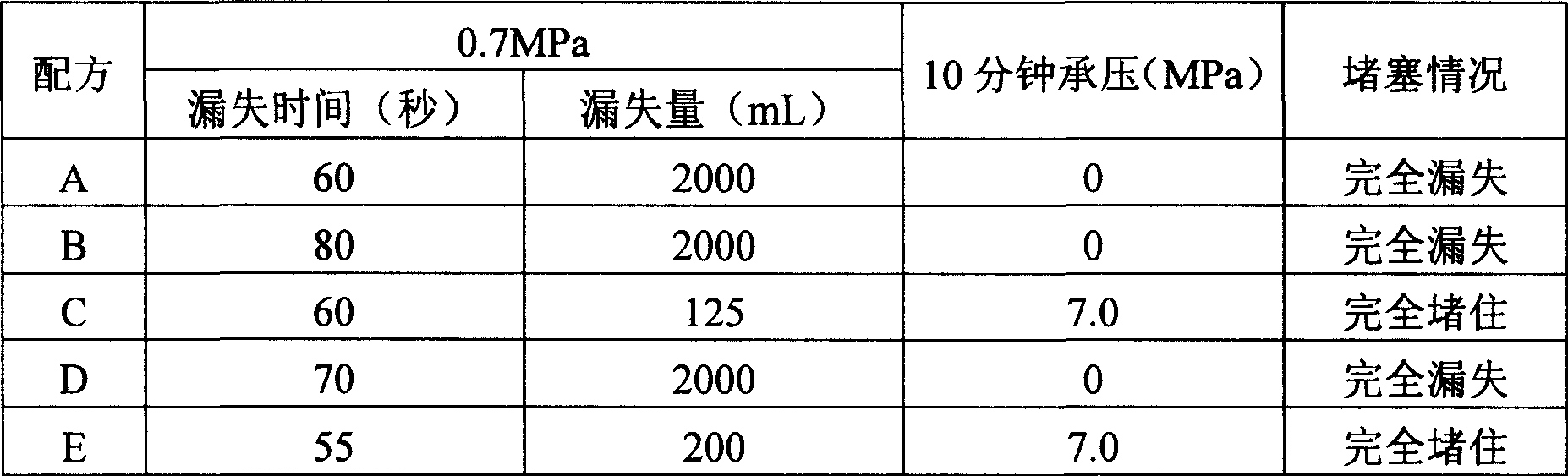

[0024] The raw materials are weighed according to the following weight ratio, and the product of the present invention is obtained after uniform mixing. The test results are shown in Table 1.

[0025] Modified polypropylene profiled fiber 25kg, its diameter is 20μm, elastic modulus is 15GPa, length-diameter ratio is 500;

[0026] 50kg of special inorganic fiber, made of basalt by 1550℃ melt drawing, the diameter of the made is 10μm, the elastic modulus is 20GPa, and the aspect ratio is 350;

[0027] Polyoxyethylene ether 7kg, its average molecular weight is 3 million;

[0028] 10kg of modifier, including 2kg of polyoxyethylene lauryl ether and 8kg of SXY drag reducer produced by Chengdu Chuanfeng Chemical Engineering Co., Ltd.;

[0029] Amphibole 8kg, length to diameter ratio of 150, of which SiO 2 The content is 55%, Al 3 O 2 The content is 35%.

Embodiment 2

[0031] The raw materials are weighed according to the following weight ratio, and the product of the present invention is obtained after uniform mixing. The test results are shown in Table 1.

[0032] 10kg of polyester special-shaped fiber, its diameter is 30μm, elastic modulus is 5GPa, length-diameter ratio is 200; special inorganic fiber 70kg, made of sepiolite melted and drawn at 1300℃, the diameter is 5μm, elastic The modulus is 15 GPa and the aspect ratio is 600;

[0033] 10kg of modified polyvinyl alcohol, with an average molecular weight of 1 million;

[0034] Modifier 5kg, including 4kg polyoxyethylene lauryl ether and 1kg SXY drag reducer produced by Chengdu Chuanfeng Chemical Engineering Co., Ltd.;

[0035] Wollastonite 5kg, aspect ratio of 80, SiO 2 The content of 50%, Al 3 O 2 The content is 30%.

Embodiment 3

[0037] The raw materials are weighed according to the following weight ratio, and the product of the present invention is obtained after uniform mixing. The test results are shown in Table 1.

[0038]30kg of modified polypropylene profiled fiber, with a diameter of 20μm, an elastic modulus of 15GPa, and a length-to-diameter ratio of 800;

[0039] Special inorganic fiber 50kg, made of sepiolite melted and drawn at 1750℃, with a diameter of 10μm, an elastic modulus of 20GPa, and a length-to-diameter ratio of 500;

[0040] Polyoxyethylene ether 2kg, its average molecular weight is 3 million;

[0041] 15kg of modifier, including 3kg of polyoxyethylene lauryl ether and 12kg of SXY drag reducer produced by Chengdu Chuanfeng Chemical Engineering Co., Ltd.;

[0042] Amphibole 3kg, length-to-diameter ratio is 150, of which SiO 2 The content is 55%, Al 3 O 2 The content is 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com