Bulk density (BD)-free radical silicon molecule polymeric material capable of adapting to tire self repair

A technology of polymeric materials and free radicals, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of unsatisfactory requirements, high price, insufficient scope of application and insufficient protection methods, and achieve wide environmental adaptability and low temperature Tire inner temperature and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below, and the product formulation and its preparation process are very clear to those skilled in the art.

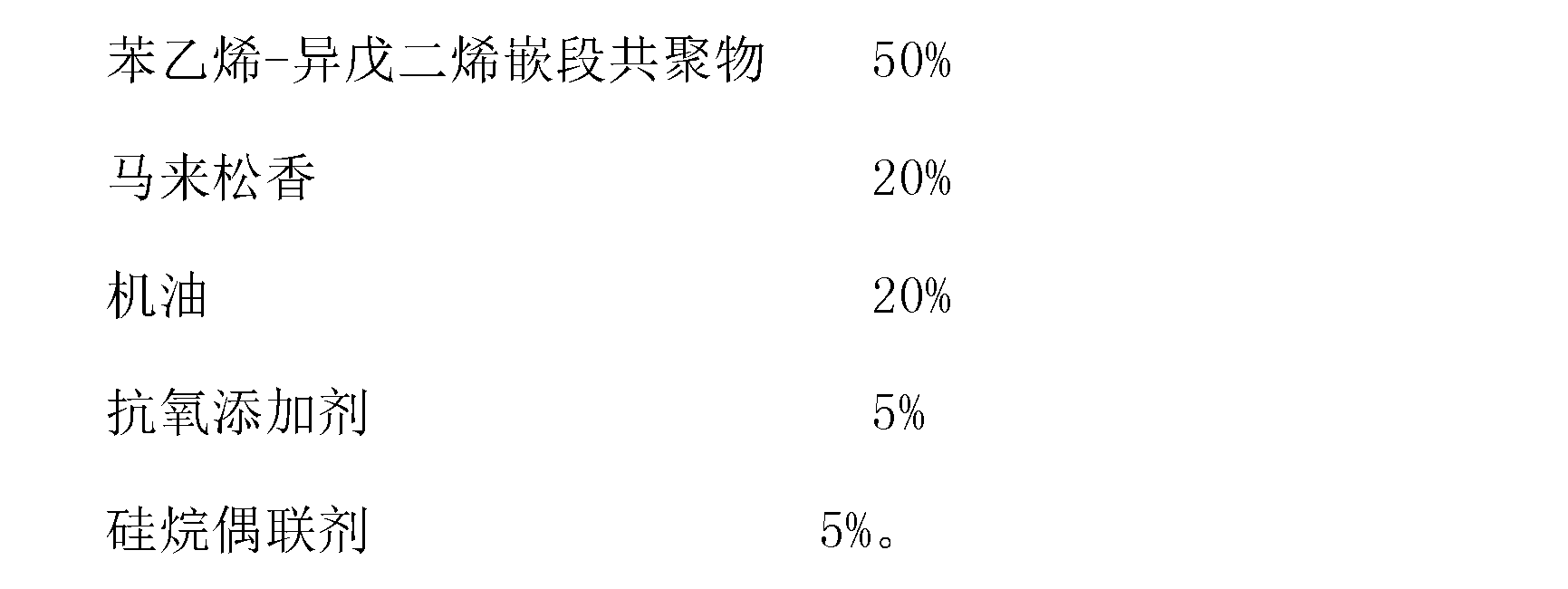

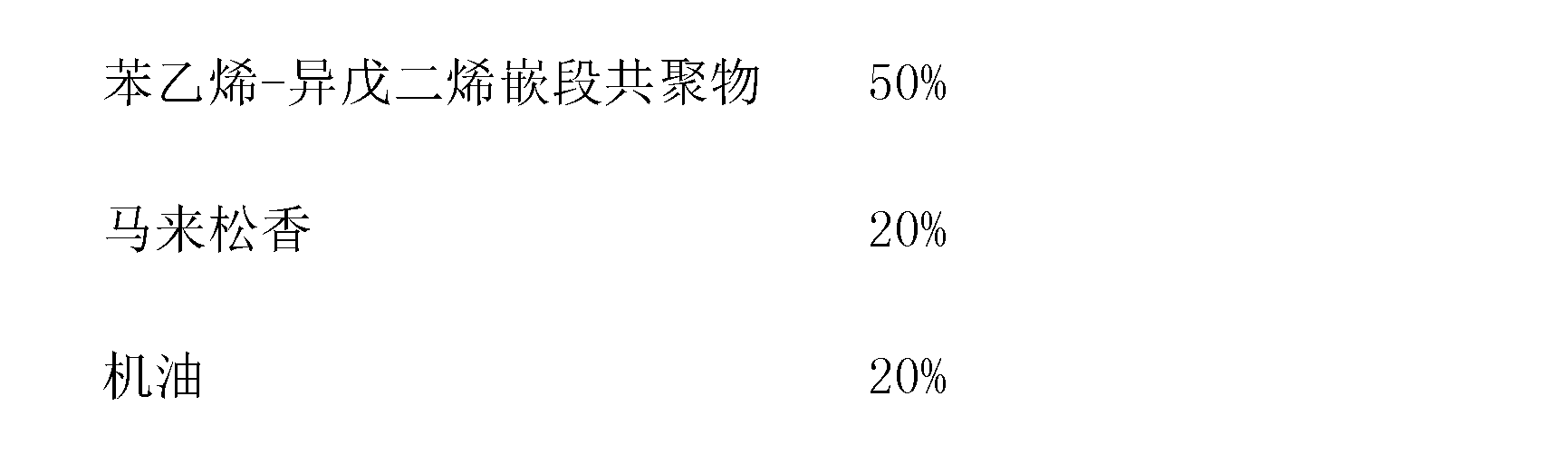

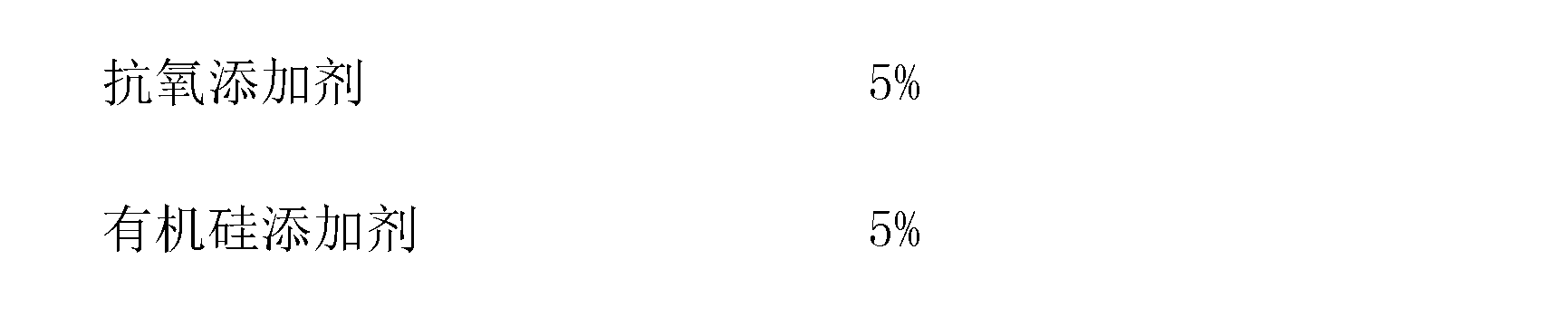

[0018] Free radical silicon molecular polymer materials include styrene-isoprene block copolymer, maleic rosin, engine oil, antioxidant additives and organic silicon additives. The weight ratio of the components is as follows:

[0019]

[0020] Styrene-isoprene block copolymers belong to thermoplastic elastomers and can be used as adhesives and sealing materials. Its chain structure, film-forming conditions and post-treatment methods can all affect its performance.

[0021] The silicone additive can be a silane coupling agent, whose general formula is Y(CH2)nSiX3, where n=0~3, X is a hydrolyzable group, which can often be chlorine, methoxy, ethoxy, methyl Oxyethoxy, acetoxy, etc., Y is an organic functional group, which can be vinyl, amino, epoxy, methacryloyloxy, mercapto or ureido, etc.

[0022] Preparation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com