Toughened cement paste used for gas storage wells

A technology of gas storage and cement slurry, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of cement stone elastic modulus, poor toughness, easy to be damaged, etc., and achieve good Chemical stability and compatibility, improved channeling ability, and improved penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

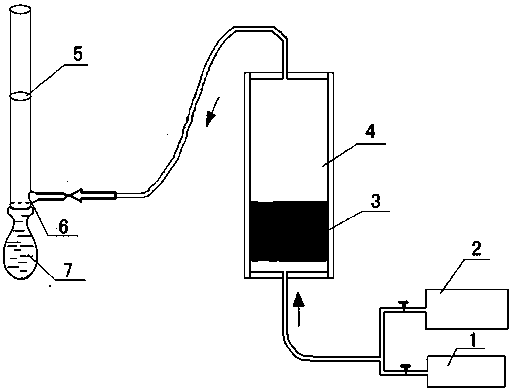

Image

Examples

Embodiment 1

[0028] (1), component raw materials

[0029] Fusion-bonded epoxy resin powder: produced by CNOOC Changzhou Environmental Protection Paint Co., Ltd., model CTN-7500.

[0030] Oil well cement: high sulfate resistance (HSR) G grade oil well cement, produced by Dalian Cement Group Co., Ltd.;

[0031] Quartz sand: 200 mesh, Hongrun Quartz Silica Powder Co., Ltd.;

[0032] Fluid loss reducer: patent name: a fluid loss reducer with a temperature resistance of 200°C, the publication number is 102229797A;

[0033] Retarder: patent name: a strong inhibitory medium-high temperature oil well cement retarder and its preparation method, publication number 106008844A;

[0034] Dispersant: SXY, produced by Chengdu Chuanfeng Chemical Engineering Co., Ltd.;

[0035] Defoamer: tributyl phosphate, produced by Qingdao Huihe Chemical;

[0036] (2), component content

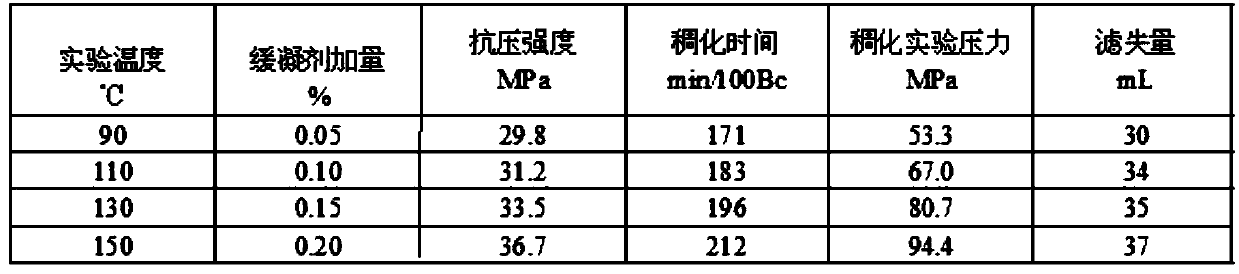

[0037] 3 parts of fusion-bonded epoxy resin powder, 25 parts of quartz sand, 100 parts of oil well cement, 1.5 parts of fluid l...

Embodiment 2

[0058] Component content: 5 parts of fusion-bonded epoxy resin powder, 25 parts of quartz sand, 100 parts of oil well cement, 1.5 parts of fluid loss reducer, 0.1 part of retarder, 0.2 part of dispersant, 0.2 part of defoamer, 51 parts of water .

[0059] performance testing

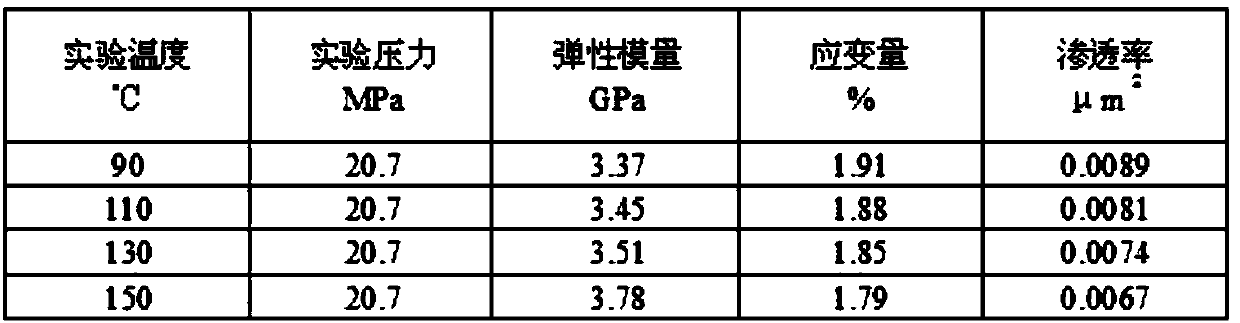

[0060] ① By changing the amount of epoxy resin powder added, it has little effect on the conventional properties of the cement slurry. The conventional properties are basically the same as the values in Example 1, and the mechanical properties have changed. The mechanical properties of the cement stone are shown in Table 3 below:

[0061] Table 3 Mechanical properties of cement stone at different temperatures

[0062]

[0063] The test results show that the elastic modulus of epoxy resin tough cement stone in the experimental temperature range is below 4GPa, which meets the technical index of elastic modulus of less than 6GPa proposed in the "Technical Requirements for Tough Cement Slurry for Gas S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com