Well cementation cement paste with high water-cement ratio, low cost and low density and preparation method thereof

A cementing cement slurry, low-cost technology, applied in the direction of chemical instruments and methods, drilling composition, etc., to achieve high proportion, reduce micro-annulus, and adjustable thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

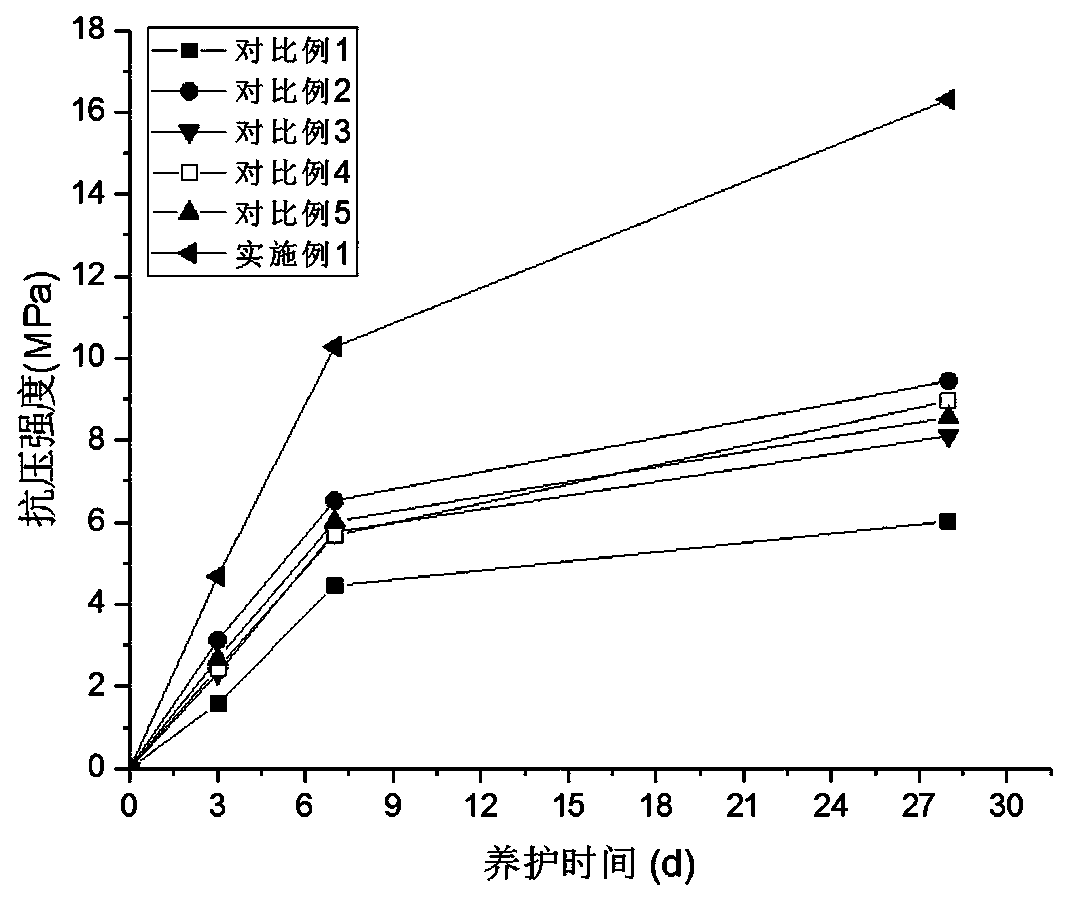

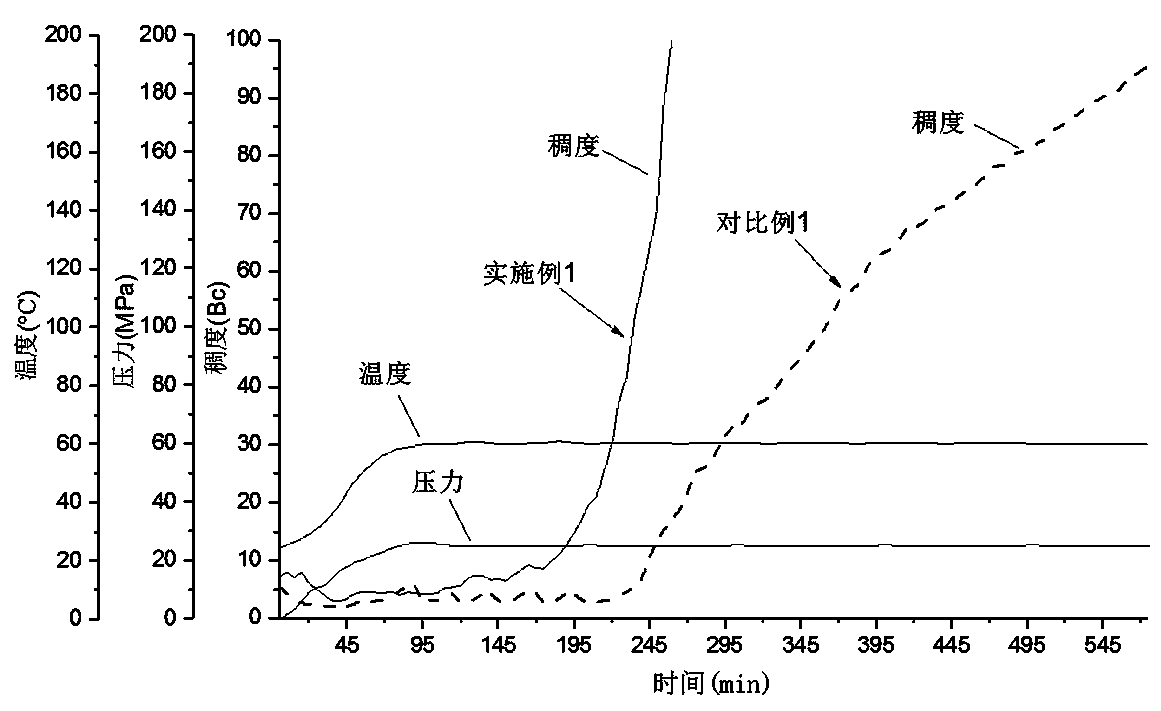

Embodiment 1

[0033] 1. A cement slurry with high water-cement ratio, low cost and low density, consisting of the following raw materials in parts by weight: 100 parts of G grade oil well cement, 25 parts of fly ash, 30 parts of microsilica fume, 2 parts of early strength agent, 2 parts of ternary activators, 3 parts of dehydration reducing agent, 0.2 part of defoamer, 223 parts of clear water, wherein, said ternary activator is a mixture of soda lime and magnesium sulfate with a mass ratio of 9:1, said Both soda lime and magnesium sulfate pass through a 100-mesh sieve;

[0034] The fly ash is Class F fly ash specified in GB / T 1596-2017;

[0035] The average particle size of the micro-silicon powder is 0.1-0.3 μm, and the specific surface area is 22-28m 2 / g;

[0036] The early strength agent is an inorganic salt early strength agent;

[0037] The fluid loss reducer is a water-soluble polymer fluid loss reducer;

[0038] The defoamer is a phosphate defoamer;

[0039] 2. the preparation...

Embodiment 2

[0044] 1. A cement slurry with high water-cement ratio, low cost and low density, consisting of the following raw materials in parts by weight: 40 parts of G grade oil well cement, 60 parts of fly ash, 30 parts of microsilica fume, 2 parts of early strength agent, 6 parts of ternary activators, 3 parts of water loss reducer, 0.2 part of dispersant, 0.2 part of defoamer, 195 parts of clear water, wherein the ternary activator is soda lime and magnesium sulfate with a mass ratio of 9:1 The mixture, the soda lime and magnesium sulfate all pass through 100 mesh sieves;

[0045] Described fly ash, microsilica fume, early strength agent, fluid loss reducer, defoamer are the same as embodiment 1;

[0046] The dispersant is sulfonated acetone formaldehyde condensation polymer;

[0047] 2. the preparation method of described high water-cement ratio low-cost low-density well cementing cement slurry, comprises the following steps:

[0048] (1) Combine oil well cement, fly ash, microsilic...

Embodiment 3

[0052] 1. A cement slurry with high water-cement ratio, low cost and low density, consisting of the following raw materials in parts by weight: 40 parts of G grade oil well cement, 60 parts of fly ash, 30 parts of microsilica fume, 2 parts of early strength agent, 8 parts of ternary activator, 3 parts of water loss reducer, 0.2 part of dispersant, 0.2 part of defoamer, 195 parts of clear water, wherein the ternary activator is soda lime and magnesium sulfate with a mass ratio of 9:1 The mixture, the soda lime and magnesium sulfate all pass through 100 mesh sieves;

[0053] Described fly ash, microsilica fume, early strength agent, water loss reducing agent, defoamer, dispersant are the same as embodiment 2;

[0054] 2. The method for preparing the cement slurry with high water-cement ratio, low cost and low density is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com