Oil well cement high temperature retarder

A technology of oil well cement and retarder, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem that the thickening time is not easy to control, the retarder's retarding effect is unstable, and the application temperature range of the retarder is narrow. and other problems, to achieve the effects of good cementing quality, good regularity and operability, and easy thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

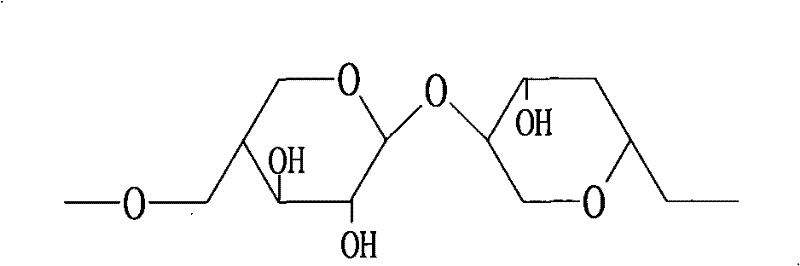

Image

Examples

Embodiment 1~4

[0024] Add 1 part by weight of seawater in a 500ml beaker, then add gluconic acid, potassium sodium tartrate, carboxymethyl hydroxyethyl cellulose and styrene sulfonate, the addition of parts by weight of each component, as shown in Table 1, stir Stir for 60 seconds at a speed of 4000rpm to obtain a high-temperature retarder for oil well cement. The retarder is prepared at a rate of 1.90g / cm 3 The properties of cement paste are shown in Table 1.

[0025] Table 1 Oil well cement high temperature retarder components and their preparation 1.90g / cm 3 Grout properties

[0026]

[0027]

[0028] Note: BWOC is the percentage of cement mass.

Embodiment 5~8

[0030] Add 1 part by weight of fresh water in a 500ml beaker, then add citric acid, sodium glucoheptanate, hydroxyethyl cellulose and fatty acid methyl ester sulfonate, the addition of parts by weight of each component, as shown in Table 2, at stirring speed Stir for 60 seconds at 4000rpm to prepare a high-temperature retarder for oil well cement. The retarder is prepared at a rate of 1.40g / cm 3 The properties of cement paste are shown in Table 2.

[0031] Table 2 Oil well cement high temperature retarder components and their preparation 1.40g / cm 3 Grout properties

[0032]

[0033]

Embodiment 9~12

[0035] Add 1 weight of fresh water in a 500ml beaker, then add glucoheptanoic acid, potassium citrate, carboxymethyl hydroxyethyl cellulose and methacryl sulfonate, the addition weight parts of each component, as shown in table 3, Stir for 60 seconds at a stirring speed of 4000rpm to obtain a high-temperature retarder for oil well cement. The retarder is prepared at a rate of 2.30g / cm 3 The properties of cement paste are shown in Table 3.

[0036] Table 3 Oil well cement high temperature retarder components and their preparation 2.30g / cm 3 Grout properties

[0037]

[0038]

[0039] It can be seen from the composition and effects shown in Table 1, Table 2 and Table 3 that the cement slurry prepared by the high-temperature retarder has a wider application temperature than the previous high-temperature cementing cement slurry, and the bottom of the cementing well The circulating temperature can reach 200°C, and the static temperature can reach 250°C, which can meet the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com