Solid high-temperature retarding agent for oil-well cement and preparation method thereof

A technology of oil well cement and retarder, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as narrow applicable temperature range, non-setting of cement slurry, and large change in cement stone strength, and achieve thickening transition Short time, good compatibility, and good curve shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

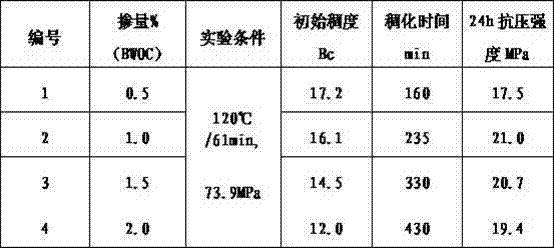

Examples

preparation example Construction

[0021] The preparation method of the oxidized starch comprises the following steps: prepare the starch emulsion with water with a concentration of 25%-30% by mass, keep stirring continuously, adjust the pH to 9-10 with alkali, and maintain the reaction at 45-55°C temperature, adding an oxidizing agent, and reacting for 2-3 hours. After the reaction, stand and separate layers, pour off the supernatant, and dry the lower emulsion to obtain oxidized starch.

[0022] The starch is one of potato starch, corn starch, tapioca starch or wheat starch.

[0023] The oxidizing agent is an aqueous hydrogen peroxide solution with a mass percentage concentration of 30%, and the addition amount is 5%-15% of the dry starch mass.

[0024] The alkali is a 2% sodium hydroxide solution in mass percent concentration.

[0025] In the preparation method of the above-mentioned solid high-temperature retarder for oil well cement, each raw material is weighed according to its percentage, and then added...

Embodiment 1

[0029] First prepare the oxidized starch. Prepare 30% potato starch milk, keep stirring, the stirring speed is 60r / min, adjust the pH to 9-10 with 2% NaOH solution, maintain the reaction temperature at 50°C, add starch (dry basis) in a mass percentage of 15% For hydrogen peroxide solution with a concentration of 30%, the formation of carboxyl groups during the oxidation process will cause a drop in pH value, and 2% NaOH solution should be added to control the pH value within a stable range (9-10), react for 2 hours, filter, and dry to obtain oxidized starch.

[0030] Take 325g of oxidized starch, 100g of hydroxyethylidene diphosphonic acid, 50g of zinc oxide, and 25g of sodium borate, and stir the four kinds of raw materials in a mixer for 30 minutes to obtain a solid high-temperature retarder sample 1.

Embodiment 2

[0032] First prepare the oxidized starch. Prepare 25% cornstarch milk, adjust the pH to 9-10, maintain the reaction temperature at 45°C, and add a 30% hydrogen peroxide solution with a mass percent concentration of 8% starch (dry basis).

[0033] Operate according to the method described in Example 1 to obtain oxidized starch.

[0034] Take 300g of oxidized starch, 115g of aminotrimethylene phosphonic acid, 60g of zinc oxide, and 25g of sodium borate, and stir the four kinds of raw materials in a mixer for 30 minutes to obtain solid high-temperature retarder sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com