Intermediate temperature retarder in oil well cement

A technology of oil well cement and temperature slowing, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of no gelation, etc., achieve short thickening transition time, good regularity and operability, and apply Wide temperature range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

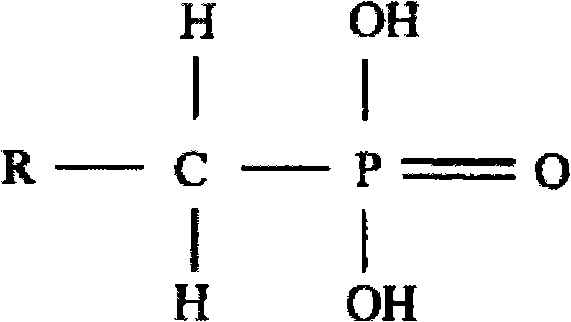

Method used

Image

Examples

Embodiment 1

[0018] Weigh various samples according to the following parts by weight:

[0019] Water: sodium hydroxyethylidene diphosphonate: citric acid: boric acid: alkylene phosphonic acid = 1: 0.02: 0.02: 0.05: 0.01

[0020] Add the above-mentioned materials in turn into the stirring cup, turn on the stirrer, the stirring speed is 4000r / min, and the stirring time is 5min to make a medium temperature retarder. Use R01 as the retarder code.

[0021] Mix the cement slurry performance of this retarder under the different test conditions of table 1

[0022]

Embodiment 2

[0024] Weigh various samples according to the following proportions:

[0025] Water: sodium hydroxyethylidene diphosphonate: glucoheptanoic acid: boric acid: alkylene phosphonic acid = 1: 0.01: 0.03: 0.08: 0.01

[0026] Add the above-mentioned materials in turn into the stirring cup, turn on the stirrer, the stirring speed is 4000r / min, and the stirring time is 5min to make a medium temperature retarder. Use R02 as the retarder code.

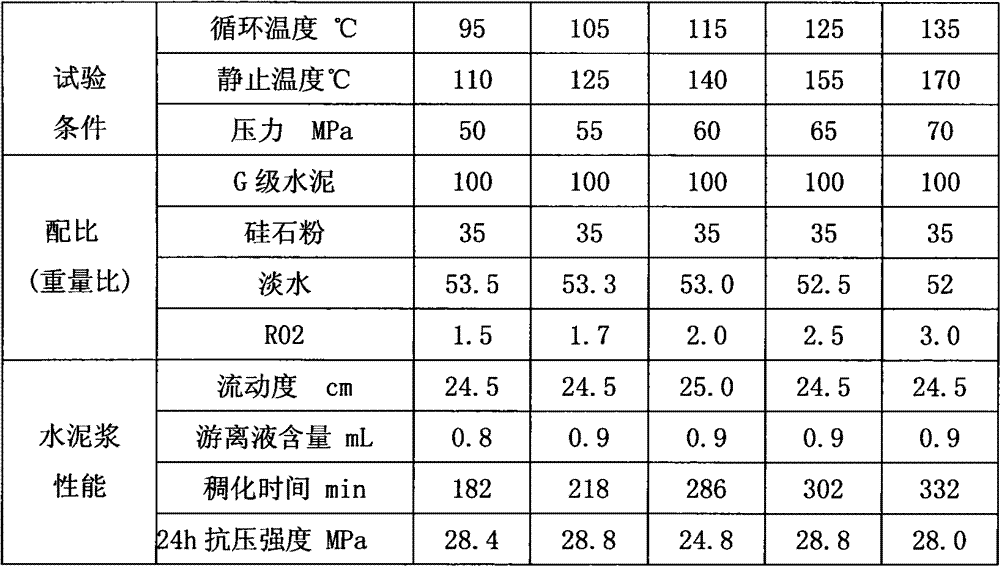

[0027] Mix the cement slurry performance of this retarder under the different test conditions of table 2

[0028]

Embodiment 3

[0030] Weigh various samples according to the following proportions:

[0031] Water: sodium hydroxyethylidene diphosphonate: gluconic acid: boric acid: alkylene phosphonic acid = 1: 0.05: 0.02: 0.10: 0.02

[0032] Add the above-mentioned materials in turn into the stirring cup, turn on the stirrer, the stirring speed is 4000r / min, and the stirring time is 5min to make a medium temperature retarder. Use R02 as the retarder code.

[0033] Mix the cement slurry performance of this retarder under the different test conditions of table 2

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com