High-temperature high-density cement slurry for oil field high-temperature high-pressure well cementation and preparation method thereof

A high-temperature, high-pressure, cement slurry technology, applied in the field of cement slurry, can solve problems such as construction difficulties, cement slurry rheology or settlement stability, poor stability, etc., to reduce operational risks, improve cementing quality, and good temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment the present invention is described in further detail:

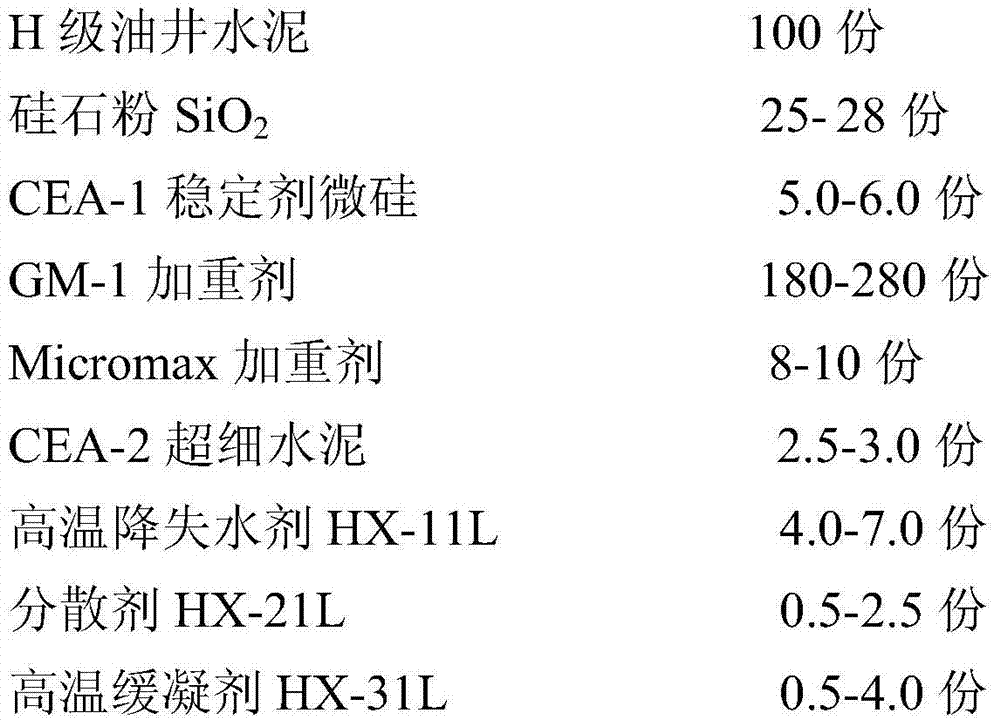

[0014] The high-temperature high-density cement slurry used for high-temperature and high-pressure well cementing in oil fields according to the present invention, the density of the cement slurry is 2.50-2.60g / cm 3 , in parts by weight, including the following ingredients and proportioning:

[0015]

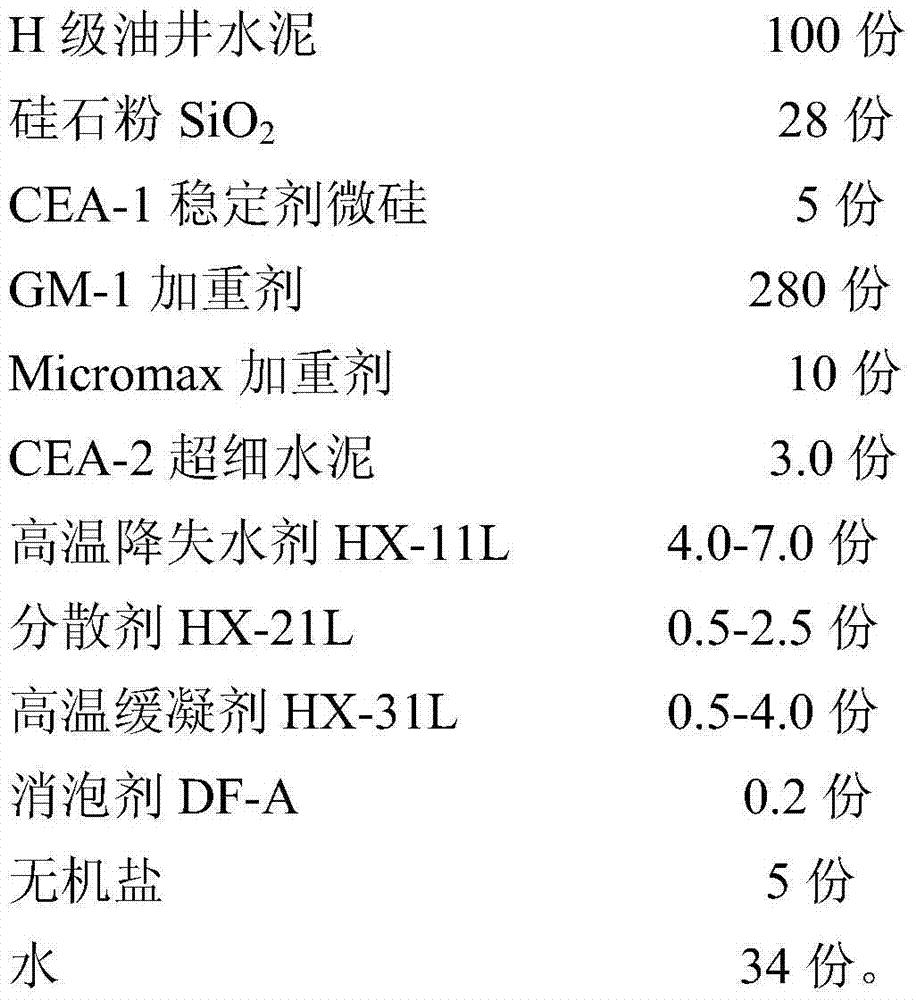

[0016] Preferably, the density of the cement slurry is 2.60g / cm 3 , in parts by weight, including the following ingredients and proportioning:

[0017]

[0018] The silica powder SiO 2 Silicon powder produced for Kuqa Huli Co., Ltd., fineness 0.095-0.075mm, that is, 160-200 mesh, sieve residue ≤ 4%, SiO 2 Purity >98%.

[0019] The inorganic salt is NaCl.

[0020] The above-mentioned preparation method of high-temperature and high-density cement slurry used for high-temperature and high-pressure well cementing in oil fields is divided into two steps of aggravati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com