High-temperature-resisting, anti-fluid-channeling and high-density well cementing slurry and its preparation method

A technology of cementing slurry and high temperature resistance, which is applied in the field of cementing slurry, and can solve the problem of not being able to effectively meet the technical requirements of preventing gas channeling, slow development of settlement stability and compressive strength, and not being able to meet the requirements of ultra-deep wells, etc. problems, to achieve excellent right-angle thickening, good flow properties, and slow compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 9

[0038] The preparation method of the present invention comprises the following steps:

[0039] Step 1. Prepare the raw material components according to the formula amount in the corresponding formula embodiment; prepare a mixing container with automatic stirring function;

[0040] Dry mix the oil well cement, weighting agent, silica powder, microsilica fume and suspension stabilizer in the formulated amount into a dry powder mixture, and mix well;

[0041] Dissolve the high-temperature water loss reducer, high-temperature retarder, dispersant, anti-air channeling agent and defoamer in the formulated amount in the formulated amount of water to form a mixed solution;

[0042] Step 2. Open the lid of the mixing container, put the mixed solution in the mixing container; start the mixing container, and make the mixing container rotate at a low speed for rotation and stirring. The rotation speed of the low speed rotation is 4000±200 rpm. Within 15 seconds, add the well-mixed dry po...

Embodiment 4

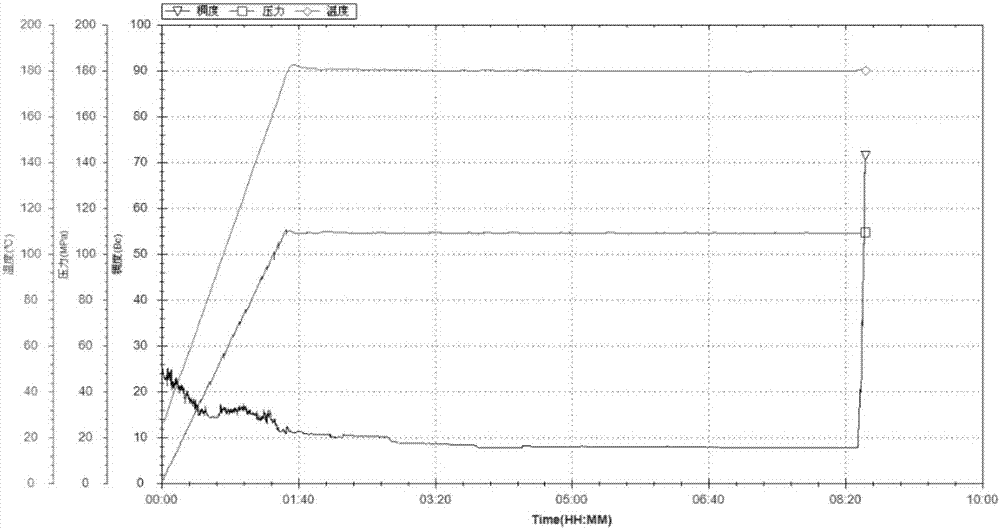

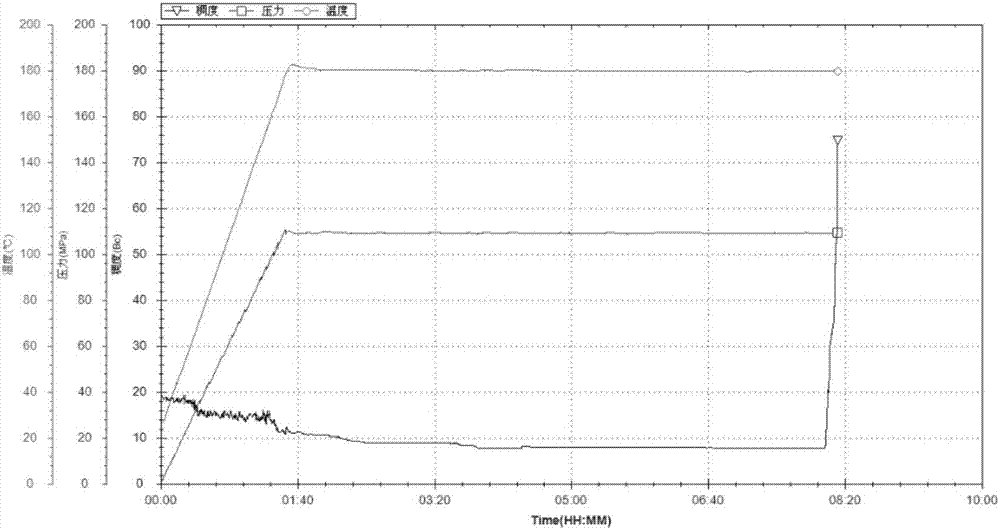

[0048] The experimental results of the cementing slurry that embodiment 4 and embodiment 9 make are shown in table 3 and figure 2 shown.

[0049] Table 3 Test performance table of cementing cement slurry with resistance to high temperature above 180°C, anti-gas channeling and high density prepared in Example 4 and Example 9

[0050] Test items

Experimental conditions

Test results

Density, g / cm 3

2.1

2.08~2.12

Initial consistency, Bc

OWC-9380

18

<30

40Bc~100Bc time, min

2

<10

Thickening time, min

180℃×110MPa

495

>300

Compressive strength, MPa

220℃×20.7MPa×72h

21

>20

Water loss, mL / 30min

180℃×6.9MPa

35

<100

Free solution, mL

90℃×2h

1

<5

Sedimentation stability, g / cm 3

2h

0.005

<0.02

[0051] The experimental results of the cementing slurry that embodiment 6 and embodiment 9 make are shown in table 4...

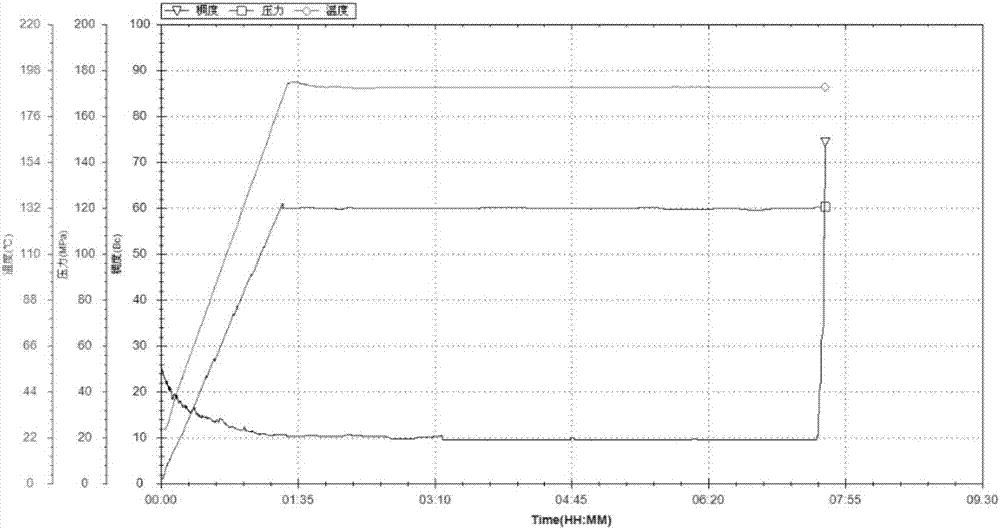

Embodiment 8

[0055] The experimental results of the cementing slurry that embodiment 8 and embodiment 9 make are shown in table 5 and Figure 4 shown.

[0056] Table 5 Test performance table of the high temperature resistance above 180°C, anti-gas channeling, high density cementing cement slurry prepared in Example 8 and Example 9

[0057] Test items

[0058] Through the above four test examples, it can be concluded that the high temperature resistance of the cement slurry of the present invention is above 180°C, the anti-gas channeling performance is strong, the density is high and the density adjustment range is 2.0-2.3g / cm 3 In addition, the cement slurry of the present invention has the characteristics of adjustable thickening time, good fluidity and small water loss. It can be seen that the cementing cement slurry of the present invention can fully meet the requirements of on-site cementing construction, has excellent "right-angle thickening" performance, SPN<3, and at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com