Modified recycled concrete and preparation method thereof

A technology for recycling concrete and concrete, applied in the field of building materials, can solve the problems of accumulation of construction waste, poor mechanical properties, lack of resources, etc., and achieve the effect of improving performance, good performance, excellent mechanical performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

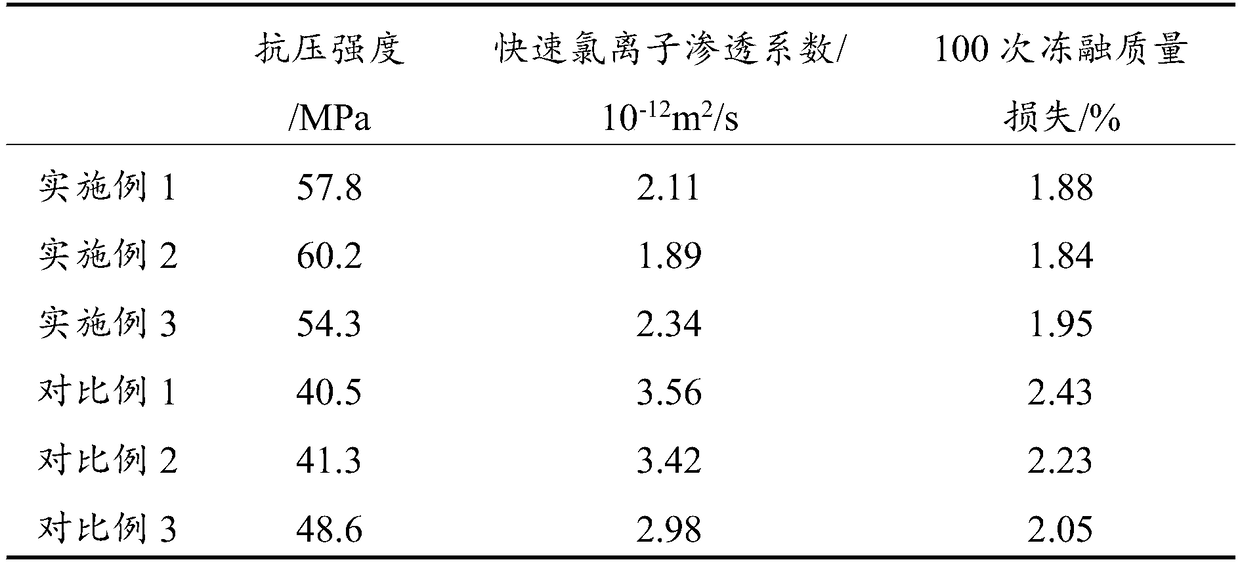

Examples

Embodiment 1

[0027] A modified recycled concrete, comprising the following raw materials in parts by weight: 100 parts of cement, 250 parts of recycled aggregate, 150 parts of sand, 40 parts of water, 6 parts of silica fume, 1.0 parts of nano silicon dioxide, 1.5 parts of water reducer, 1.0 parts of cellulose ether;

[0028] Among them, the recycled aggregate is prepared by the following method: the waste concrete is broken into 5-40mm aggregate, and then the broken aggregate is put into a tube mill without grinding body and stirred at a low speed for 5 minutes at a stirring speed of 15r / min After grinding and sieving the friable cement block in the aggregate, it can be obtained.

[0029] The cement is P.O 52.5 cement with a specific surface area greater than 280m 2 / kg; the specific surface area of nano-silica is 250m 2 / g, the specific surface area of silica fume is 30m 2 / g; the water reducer is a naphthalene-based water reducer; the sand is washed sand with a particle size of 0....

Embodiment 2

[0036] A modified recycled concrete, comprising the following raw materials in parts by weight: 100 parts of cement, 260 parts of recycled aggregate, 165 parts of sand, 45 parts of water, 10 parts of silica fume, 2.5 parts of nano silicon dioxide, 2.5 parts of water reducer, 1.5 parts of cellulose ether;

[0037] Among them, the recycled aggregate is prepared by the following method: crush the discarded concrete into aggregates of 5-40 mm, and then put the crushed aggregates into a tube mill without grinding body and stir for 5 minutes at a low speed, and the stirring speed is 10 r / min After grinding and sieving the friable cement block in the aggregate, it can be obtained.

[0038] The cement is P.O 52.5 cement with a specific surface area greater than 280m 2 / kg; the specific surface area of nano-silica is 300m 2 / g, the specific surface area of silica fume is 30m 2 / g; the water reducer is a polycarboxylate water reducer; the sand is a mixture of washed sand and quar...

Embodiment 3

[0045] A modified recycled concrete, comprising the following raw materials in parts by weight: 100 parts of cement, 235 parts of recycled aggregate, 145 parts of sand, 35 parts of water, 3 parts of silica fume, 0.5 parts of nano silicon dioxide, 0.5 parts of water reducer, 0.5 part of cellulose ether;

[0046]Among them, the recycled aggregate is prepared by the following method: crush the discarded concrete into aggregates of 5-40 mm, and then put the crushed aggregates into a tube mill without grinding body and stir for 5 minutes at a low speed, and the stirring speed is 20 r / min After grinding and sieving the friable cement block in the aggregate, it can be obtained.

[0047] The cement is P.O 52.5 cement with a specific surface area greater than 280m 2 / kg; the specific surface area of nano-silica is 250m 2 / g, the specific surface area of silica fume is 25m 2 / g; the water reducer is polycarboxylate water reducer; the sand is quartz sand with a particle size of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com