Calcined clay, preparation method thereof, and limestone calcined clay cement

A technology of calcining clay and limestone, which is applied in the direction of cement production, etc., and can solve problems such as unsustainable and large amount of residual sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] see figure 1 , the preparation method of the calcined clay of one embodiment, comprises the steps:

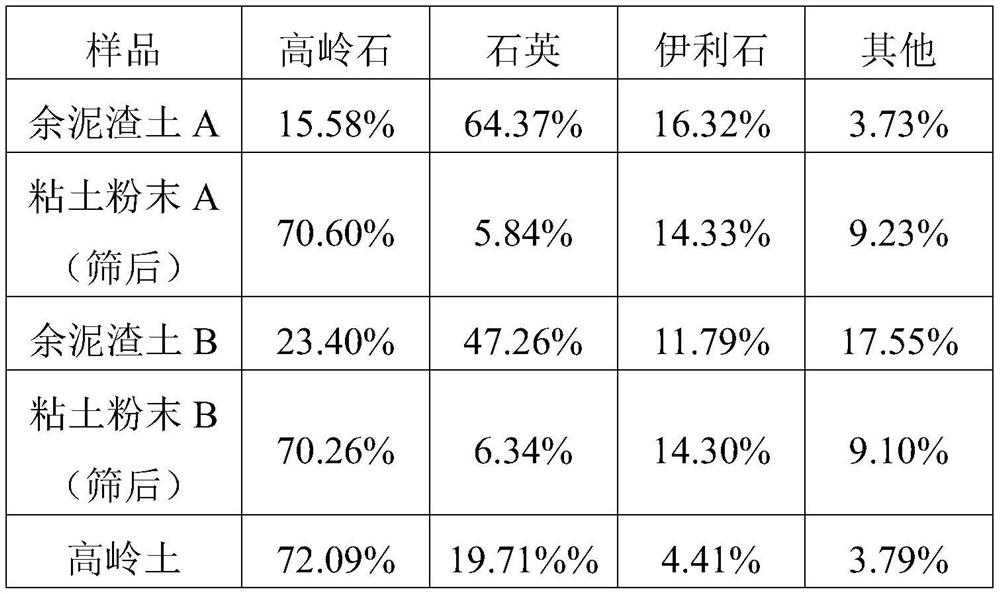

[0029] Step S110: Sieve the residual sludge to remove coarse particles with a particle size greater than 75 μm in the residual sludge to obtain clay powder.

[0030] Remaining mud and slag refers to construction waste such as soil, slag, and materials discarded in various construction projects. Traditional disposal methods of residual sludge include local dumping, local backfilling and construction of constructed wetlands. However, the amount of residual sludge generated every year is relatively large, which greatly exceeds the total capacity of the local dumping ground. According to statistics on the situation of residual sludge in Shenzhen City, the annual production amount reaches hundreds of millions of cubic meters. Due to the limited storage of local residual sludge, most of the residual sludge depends on off-site landfill. However, due to its high uncontrollable...

Embodiment 1

[0067] The preparation process of the calcined clay of the present embodiment is specifically as follows:

[0068] (1) Take 1500g of residual sludge and soil A in a clean beaker, then add 4000mL of pure water to soak for 24 hours, and then fully stir to obtain a sludge suspension.

[0069] (2) After the slag suspension obtained in step (1) is stirred completely, the soil sample solution is poured out in batches through a sieve with a mesh number of 0.075 mm, ensuring that there is no residual mud slag in the original beaker, and the sieve that does not pass The remaining granules are taken out and put into appropriate containers to obtain sieved liquid and unscreened granules.

[0070] (3) Continue to inject 1000mL of pure water into the unsifted granules for stirring, and then sieve through a sieve with a mesh number of 0.075mm to obtain the secondary sieving liquid and unsifted granules. Repeat step (3) three times.

[0071] (4) Pour all the sieving liquid obtained after m...

Embodiment 2

[0074] The preparation process of the calcined clay in this example is similar to the preparation process of the calcined clay in Example 1, the difference is that the sludge residue used in Example 2 is sludge residue B, and the prepared calcined clay is named as Calcined clay B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com