Reinforcing method of recycled coarse aggregate, obtained reinforced recycled coarse aggregate and concrete

A technology for recycling coarse aggregate and recycled concrete, applied in the field of building materials, can solve the problems of unstable performance, complicated operation and high cost, and achieve the effect of reducing porosity, simple operation and less process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

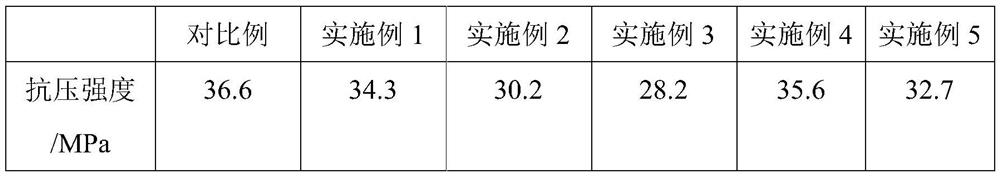

Examples

Embodiment 1

[0060] A method for strengthening recycled coarse aggregate and a method for preparing recycled concrete, comprising the following steps:

[0061] 1) grading, crushing and sieving the regenerated coarse aggregate to obtain 50 kg of regenerated coarse aggregate with a particle diameter of (5-40) mm;

[0062] 2) Rinse the regenerated coarse aggregate with running water for 5 minutes, and dry it naturally to obtain dry regenerated coarse aggregate;

[0063] 3) placing the dry regenerated coarse aggregate in a concrete mixer at 48r / min for mechanical grinding for 3h, taking out and sieving to obtain a physically strengthened regenerated coarse aggregate with a particle size of (5-36) mm;

[0064] 4) 2.5kg of 2000-purpose silica fume and 8kg of water are evenly stirred to obtain a silica fume slurry;

[0065] 5) Place 40kg of physically strengthened recycled coarse aggregate and silica fume slurry in a concrete mixer, and stir at 48r / min for 120s;

[0066] 6) Place 40kg of stones...

Embodiment 2

[0071] The regenerated coarse aggregate in this example is not chemically strengthened by silica fume slurry coating, and steps 4) and 5) in the above-mentioned example 1 are omitted. Coarse aggregate, 40kg of stones with a particle size of (5-25) mm and 65kg of sand with a particle size of (0.25-0.5) mm were placed in a concrete mixer at 48r / min for 60s, and 2.5kg of 2000 mesh silica fume and 8kg of water were mixed together. Add to the 30kg 42.5 grade ordinary Portland cement described in step 7) in the above embodiment 1, stir at 48r / min for 30s, and the rest are the same as in embodiment 1.

Embodiment 3

[0073] The regenerated coarse aggregate in this example does not undergo physical strengthening by mechanical grinding and chemical strengthening by coating with silica fume slurry, and steps 3), 4) and 5) in the above-mentioned Example 1 are omitted. In the above-mentioned Example 1 Step 1) is to classify, crush and sieve the regenerated coarse aggregate to obtain 40kg of regenerated coarse aggregate with a particle size of (5-36) mm. For the gravel of (5-25) mm and the sand of (0.25-0.5) mm with a particle diameter of 65kg, place in the concrete mixer and stir 60s at 48r / min, add 2.5kg of 2000 purpose silica fume and 8kg of water to the steps in the above-mentioned embodiment 1 7) In the described 30kg 42.5 grade ordinary Portland cement, stir together at 48r / min for 30s, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com