Compound admixture for anti-crack limestone powder and preparation method of compound admixture

A composite admixture and limestone powder technology, which is applied in the field of anti-cracking limestone powder composite admixture and its preparation, can solve the problems of affecting the working performance and mechanical properties of concrete, the reduction of concrete crack resistance, and the reduction of crack resistance. It is beneficial to the development of early strength, enhances the ability to resist plastic shrinkage cracking, and weakens the effect of tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The weight percent of each component of an anti-cracking limestone powder composite admixture is: Blaine's specific surface area is 350m 2 / kg limestone powder 70%; 0.045mm square hole sieve is 10% Class I fly ash 28.85%; single filament diameter 27-32μm, aspect ratio 40, density 0.91g / cm 3, modulus of elasticity 40GPa, elongation at break 30% of polypropylene fiber 1%, triethanolamine 0.15%. Mix the weighed limestone powder, fly ash, polypropylene fiber and triethanolamine uniformly in a mixer to obtain the crack-resistant limestone powder composite admixture III.

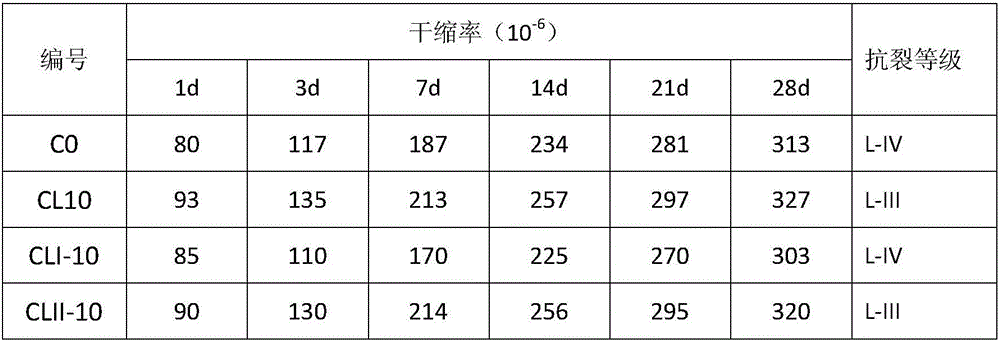

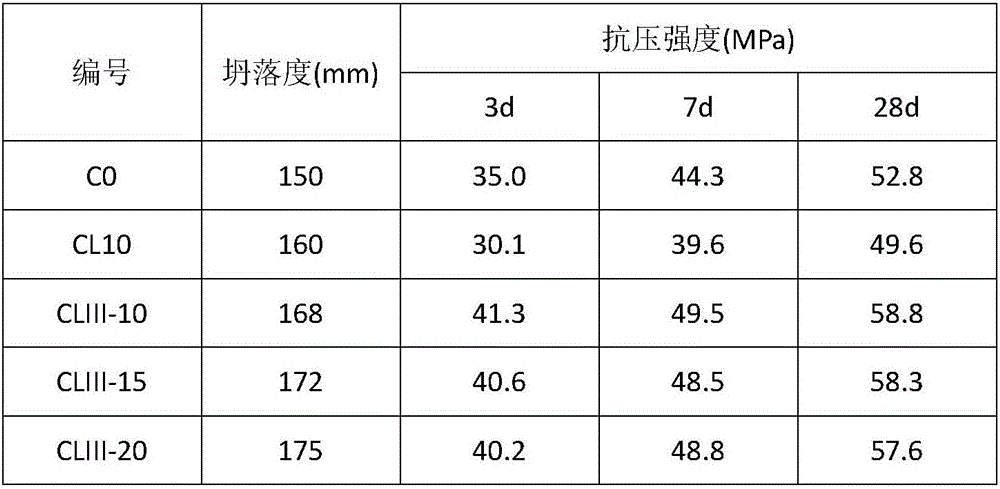

[0046] The anti-cracking limestone powder composite admixture III is used to prepare concrete, the mix ratio is shown in Table 4, and the properties of the concrete are shown in Table 5 and Table 6.

[0047] The raw materials for preparing concrete are as follows: 42.5 ordinary Portland cement is used for cement, river sand with a fineness modulus of 2.6 is used for fine aggregate, 5-25mm continuously grad...

Embodiment 2

[0071] The weight percent of each component of an anti-cracking limestone powder composite admixture is: Blaine's specific surface area is 350m 2 / kg of limestone powder 65%; 0.045mm square hole sieve 17% grade II fly ash 33.3%; single filament diameter 27-32μm, aspect ratio 40, density 0.91g / cm 3 , modulus of elasticity 40GPa, elongation at break 30% of polypropylene fiber 1.5%, triethanolamine 0.2%. Mix the weighed limestone powder, fly ash, polypropylene fiber and triethanolamine uniformly in a mixer to obtain the crack-resistant limestone powder composite admixture VI.

[0072] Use anti-cracking limestone powder composite admixture VI to prepare concrete, the mix ratio is shown in Table 10, and the properties of the concrete are shown in Table 11 and Table 12.

[0073] The raw materials for preparing concrete are as follows: 42.5 ordinary Portland cement is used for cement, river sand with a fineness modulus of 2.6 is used for fine aggregate, 5-25mm continuously graded cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com