Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Offset tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

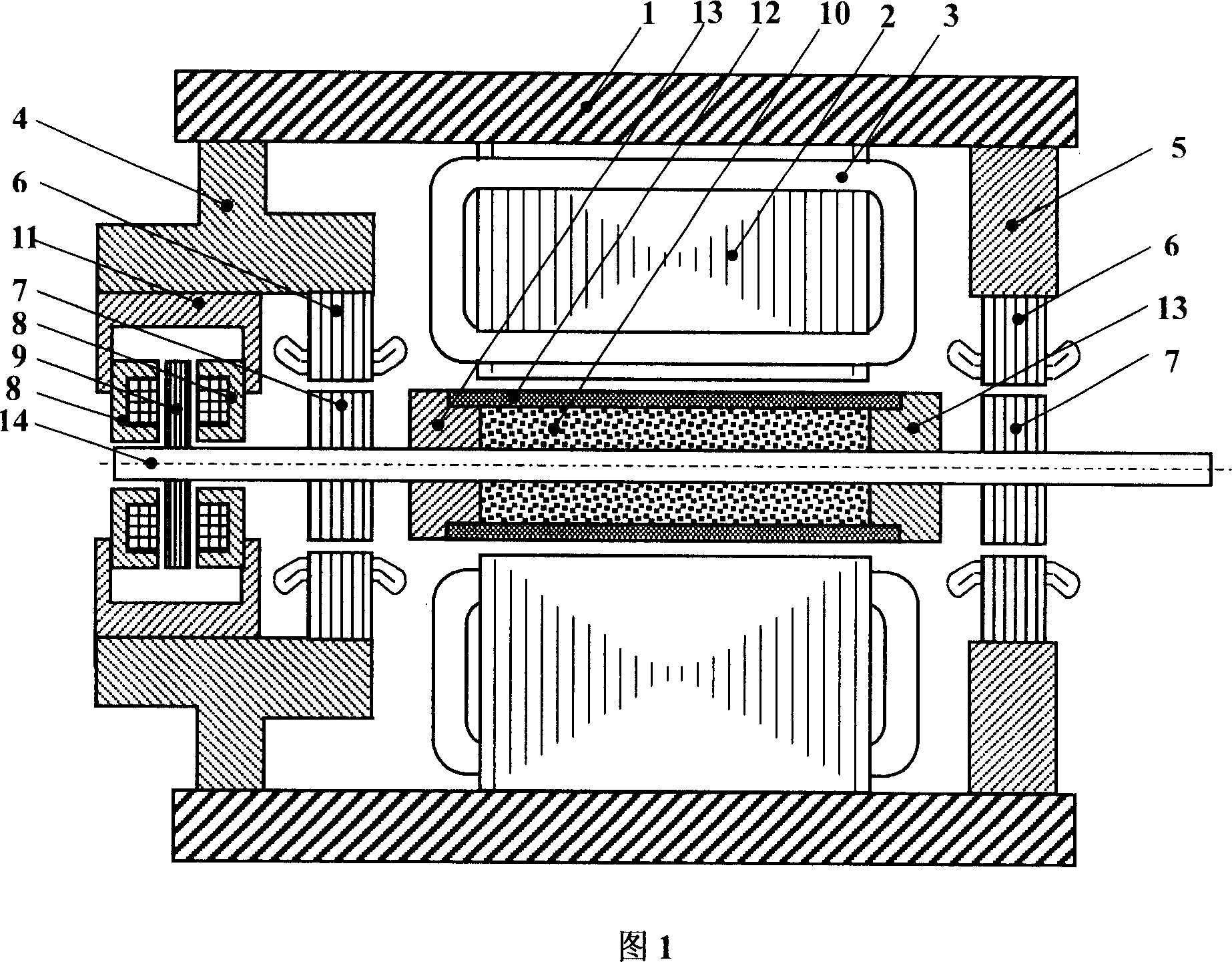

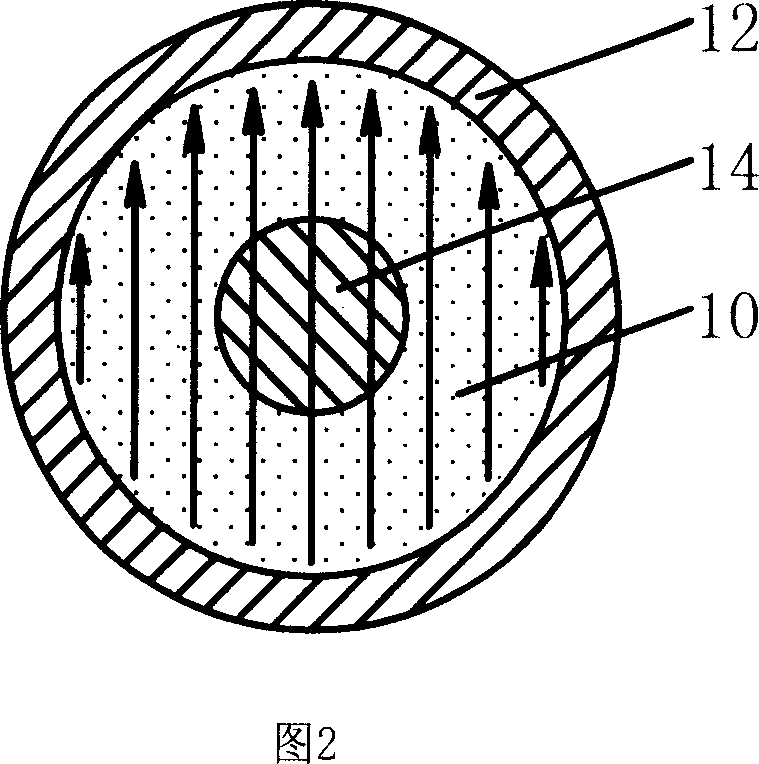

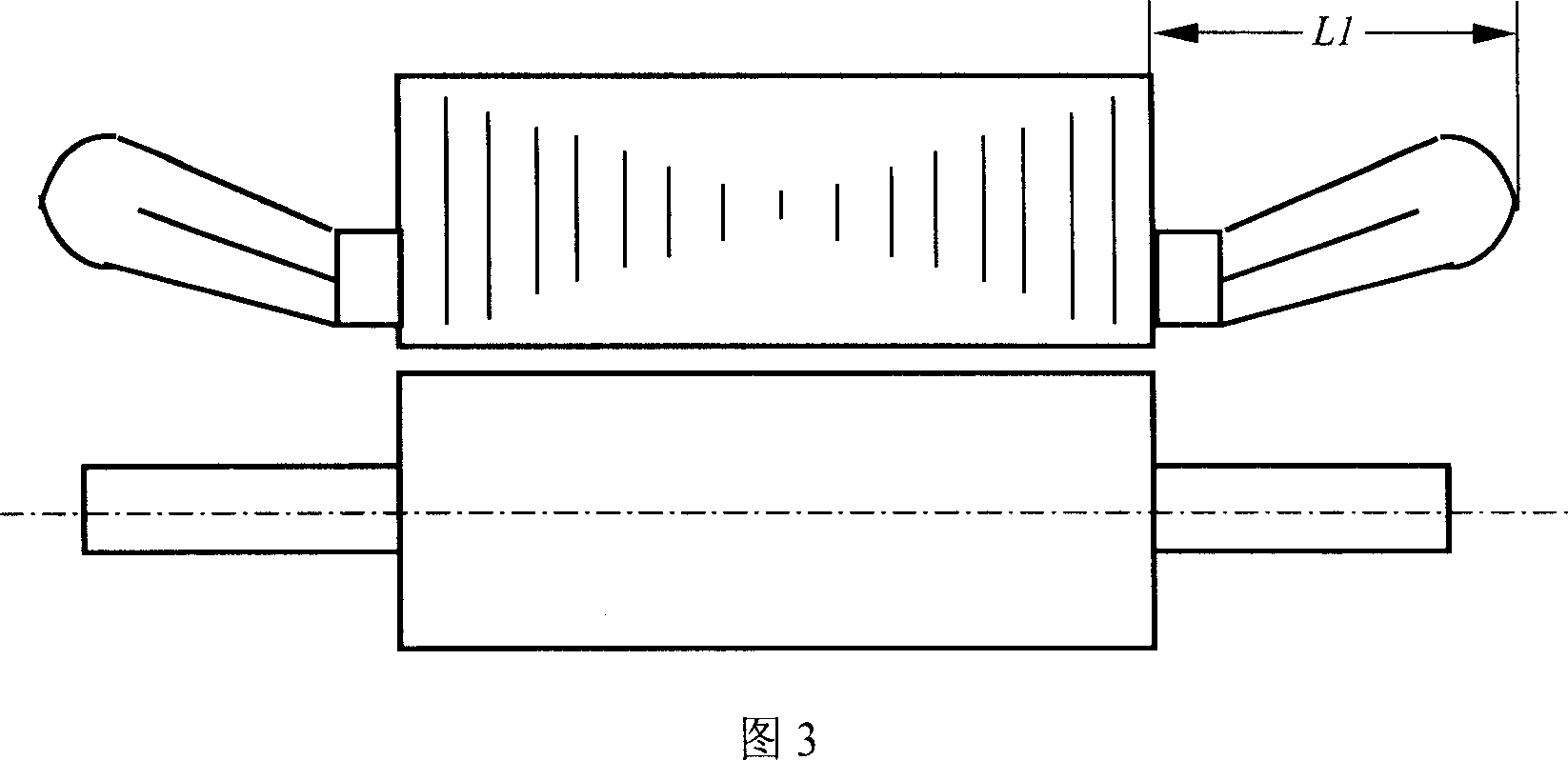

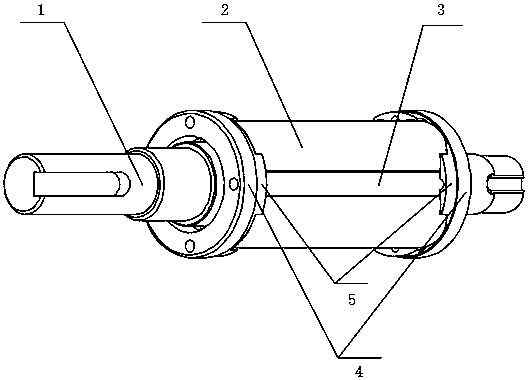

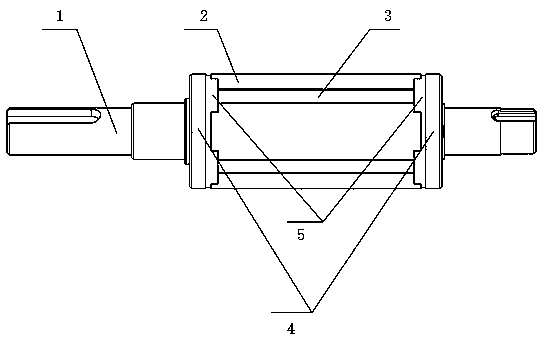

Integrated permanent magnet rotor magnetic suspension high speed motor

InactiveCN1945940ASolve the quality balance problemSimple manufacturing processSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorCoupling

An integral permanent magnet rotor magnetic suspension high speed motor includes a shell, right and left covers, a stator core, a stator winding, a magnet rotor, a shaft, an axial magnetic suspension bearing and right and left radial magnetic suspension bearings, in which, the magnet rotor is set on the shaft of the motor, the stator core is mounted on the internal wall and surrounding the rotor, the stator winding is inserted in the core tank, the right and left covers are fixed at either end of the shell at both sides of the stator core, a right radial magnetic suspension bearing is set between the shaft and the right cover, the left radial suspension bearing and the axial bearing are mounted between the shaft and the left cover and the axial bearing is set at the end of the shaft, the other end of the shaft is connected with the drive device by a coupling and the magnet rotor is an integer structure.

Owner:SHENYANG POLYTECHNIC UNIV

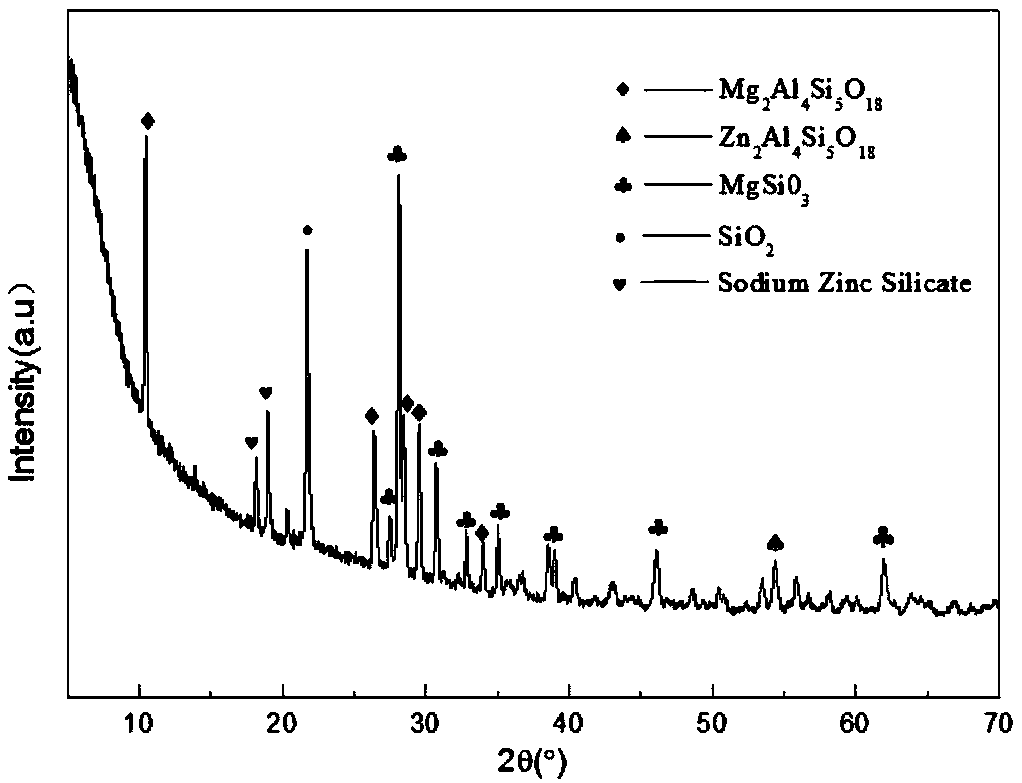

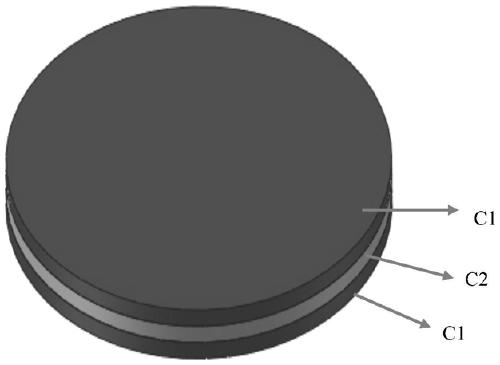

High-strength domestic ceramic prestressed coating material and preparation method and ceramic product thereof

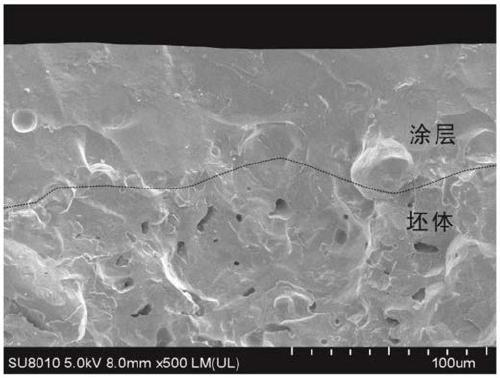

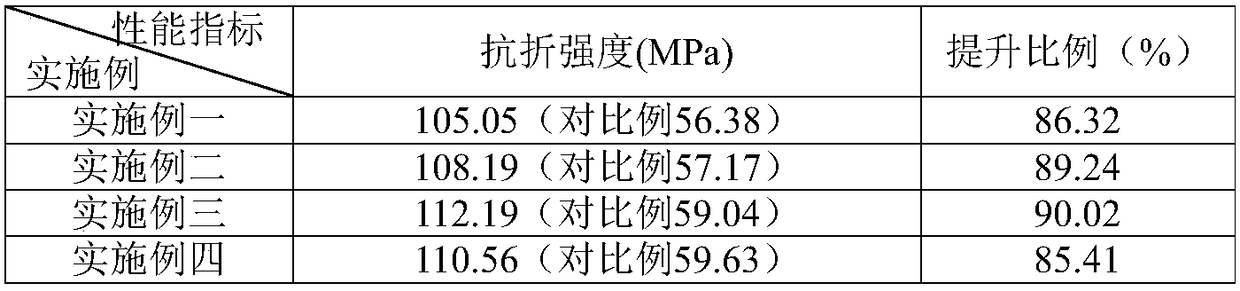

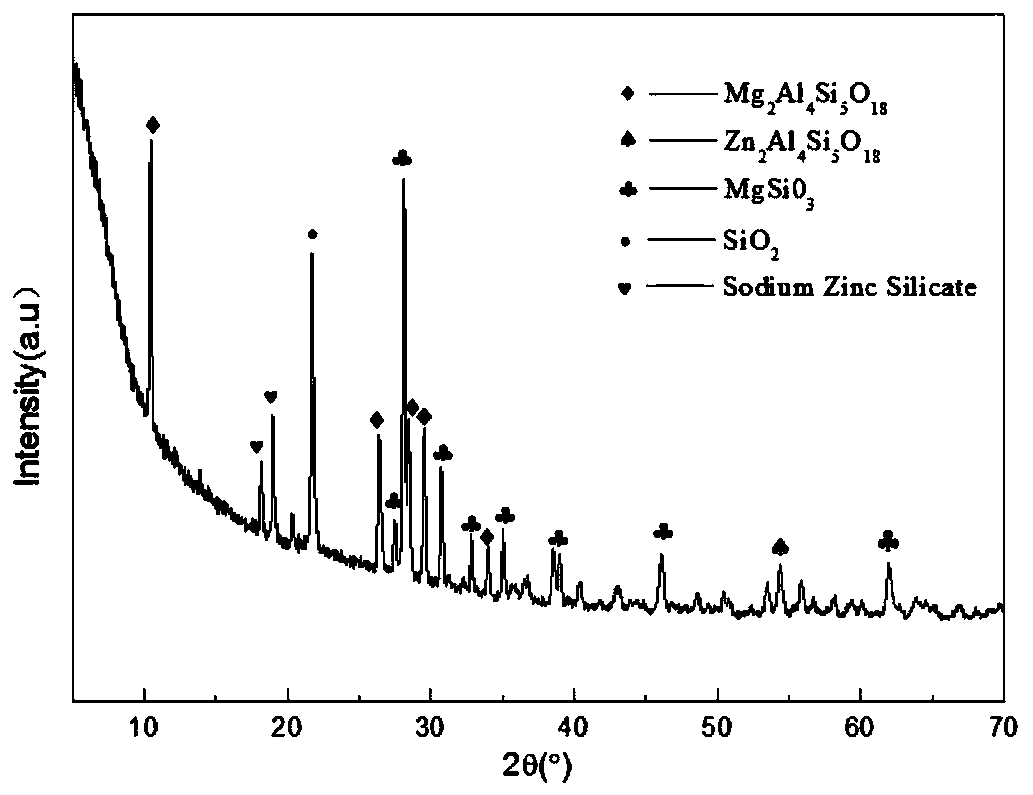

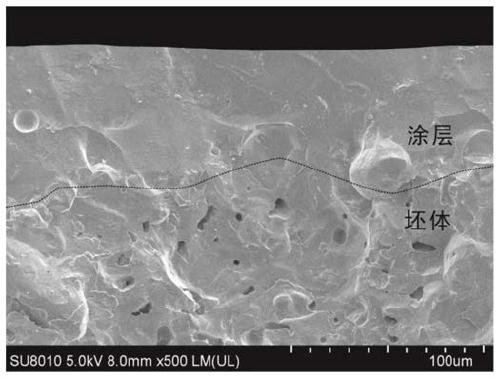

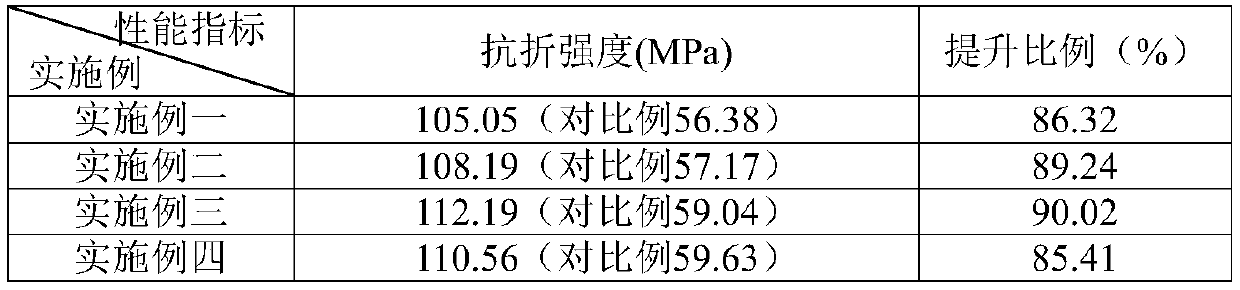

The invention discloses a high-strength domestic ceramic prestressed coating material. The high-strength domestic ceramic prestressed coating material consists of a base material and an adhesive solution under the condition that the ratio of the base material to the adhesive solution equals to 1 g: 4-8 mL; the base material comprises the following raw material components: 10-20 wt% of Al2O3, 45-70wt% of SiO2, 12-28 wt% of MgO and 2-10 wt% of ZnO; and the adhesive solution is a solution of one or more of CMC, PVA, PVB or water glass, and the concentration of the adhesive solution is 5-10 wt%.The invention further discloses a preparation method and a ceramic product of the high-strength domestic ceramic prestressed coating material. A surface coating mode is adopted, by adjusting and optimizing the ratio of the coating raw materials, pressure stress is introduced on the surface of a ceramic blank by coated layer coating treatment, and therefore, the integral strength of ceramics is improved remarkably. Raw materials are toxic-free and pollution-free, the process is simple and practicable, and industrialized application and popularization are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

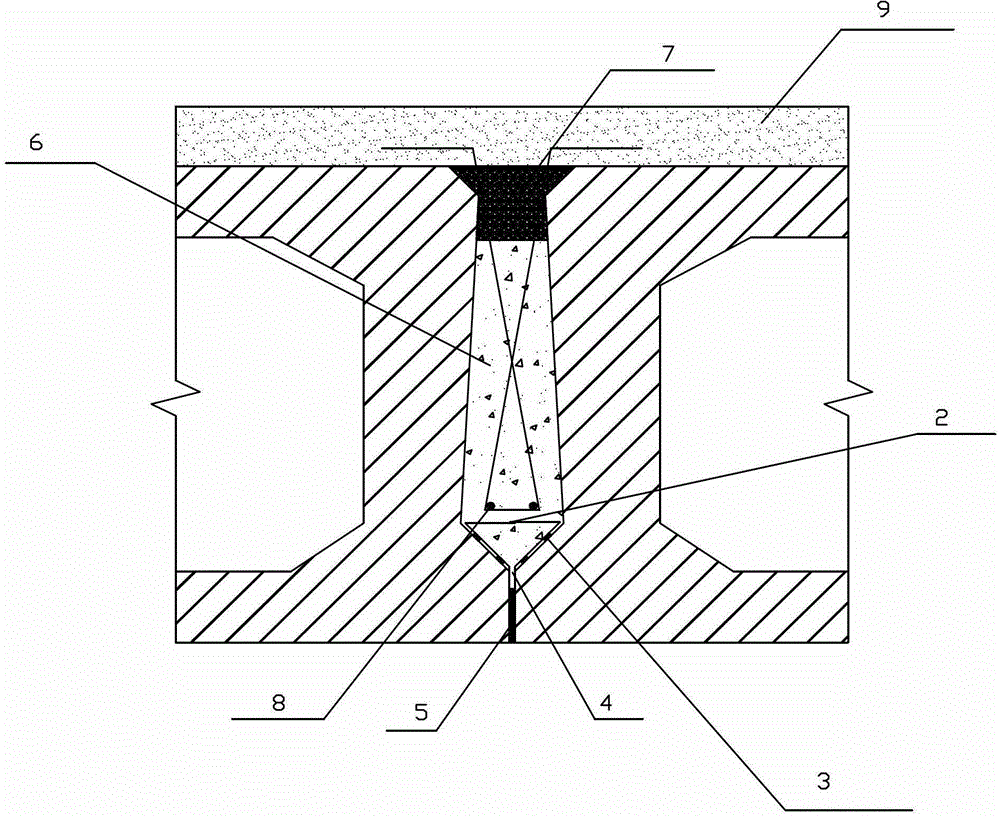

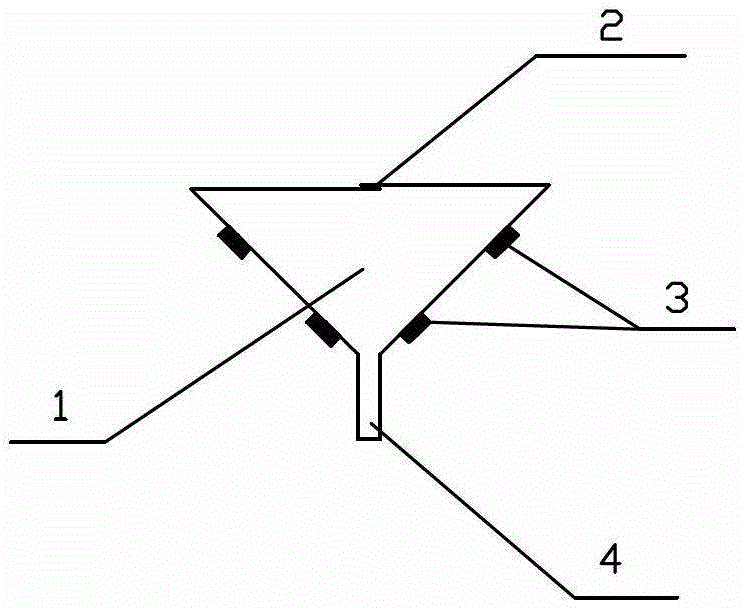

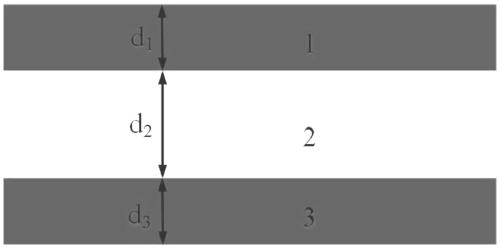

Method for filling hinge joint of fabricated prestressed hollow beam slab

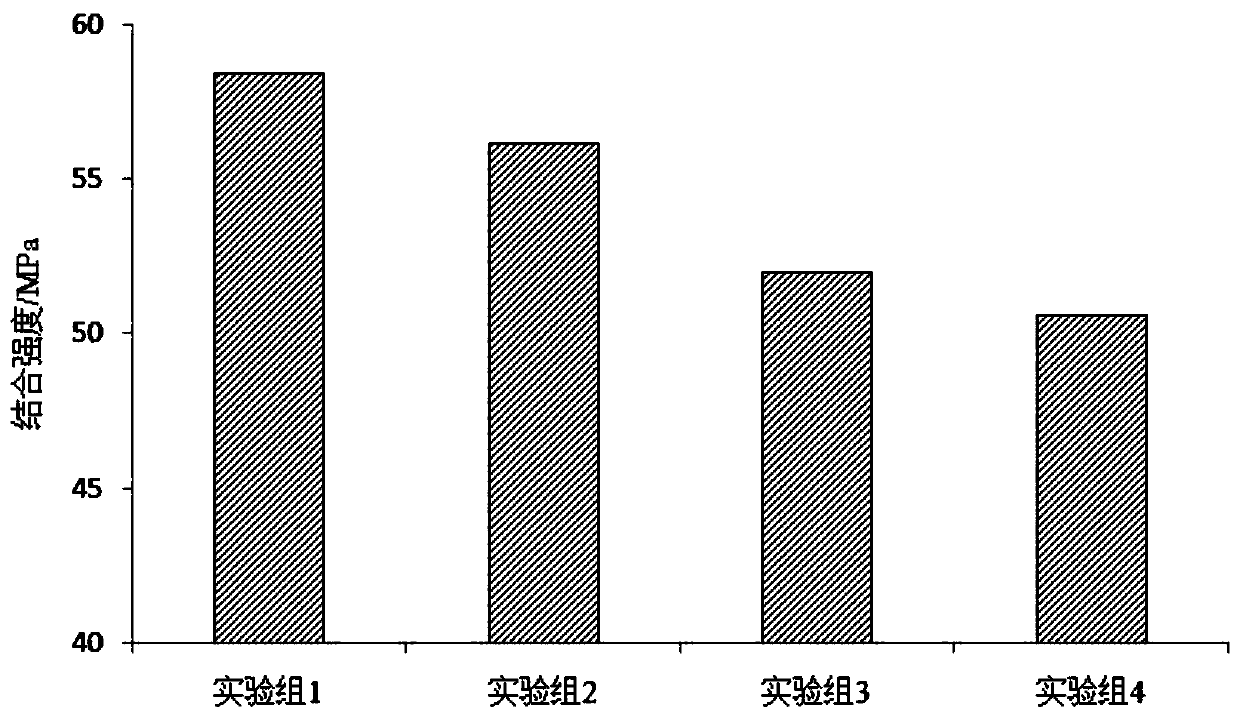

InactiveCN103147395AImprove crack resistanceReduce porosityBridge structural detailsHollow coreHinge joint

The invention provides a method for filling a hinge joint of a fabricated prestressed hollow beam slab, and belongs to the technical field of bridge engineering. The method comprises the steps as follows: inserting a screw type blocking strip into a bottom gap of the hinge joint, wherein the top surface of the screw type blocking strip comprises two split parts, one part is lapped on the other part, the length of the lapping position is 3-5 cm, and rubber strips are arranged on wing plates on the two sides of the screw type blocking strip; filling the middle of the hinge joint with micro-expansion concrete; when the concrete of the hinge joint reaches enough age period, filling the top of the hinge joint with bituminous grout; and when the bituminous grout reaches the design performance, pouring a pavement layer on the top surface of the hollow beam slab. When the micro-expansion concrete is poured, the top surface of the screw type blocking strip is open, so that the space of a vertical column is communicated with that of the hinge joint and the screw type blocking strip is stabilized by the rubber strips on the wing plates and the self weight of the concrete of the hinge joint; and the middle of the hinge joint is filled with the micro-expansion concrete, so that the space of the hinge joint is closed for a long time and the problem of water seepage due to premature failure of the hinge joint is solved.

Owner:山东畅通路桥科技股份有限公司 +3

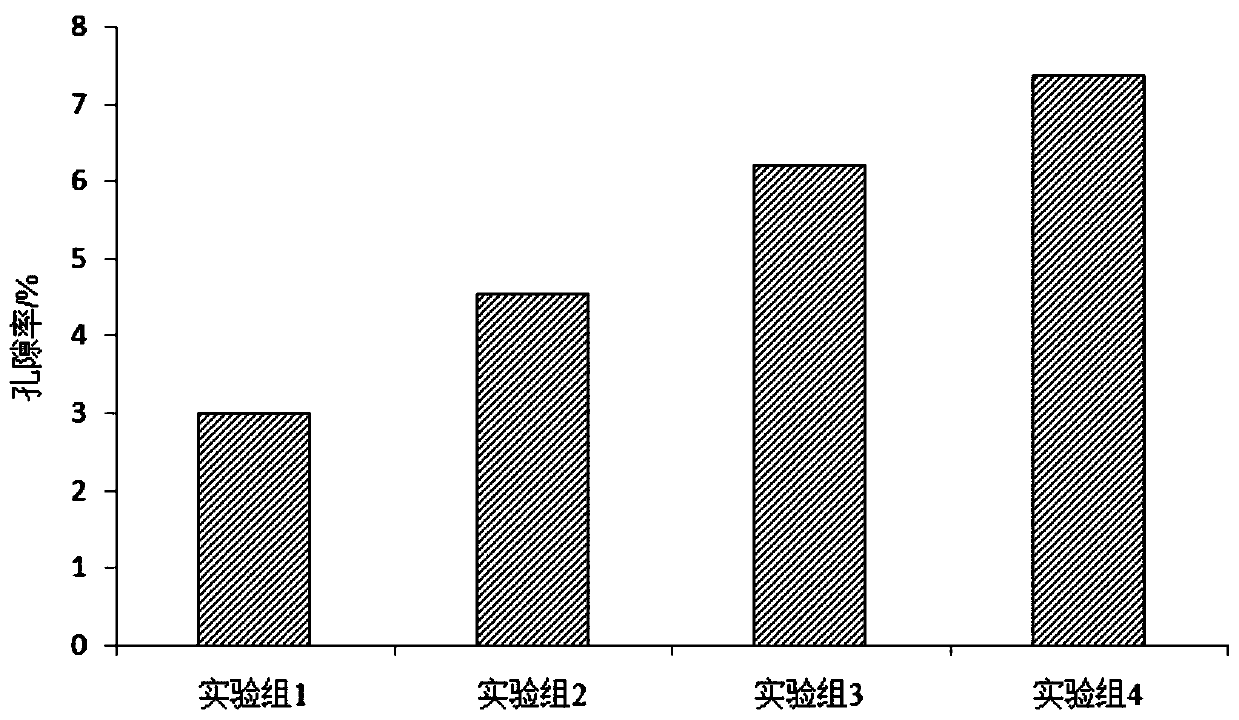

Preparation method of reinforced ceramic three-dimensional constraint coating

The invention provides a preparation method of a reinforced ceramic three-dimensional constraint coating. The method comprises the following steps that 1, sand blasting equipment is adopted to performsand blasting coarsening treatment on the surface of a ceramic matrix; 2, fly dust on the surface of the ceramic matrix subjected to the sand blasting treatment in the step 1 is cleared, the surfaceof the ceramic matrix is cleaned with ultrasonic waves, and then drying is conducted; 3, spraying raw materials are crushed into powder, and weighing and taking 250 g are conducted for spraying; and 4, spraying treatment is conducted on the surface of the ceramic matrix, and the spraying treatment comprises plasma spraying and supersonic flame spraying. The coating prepared through the method andceramic have high bonding strength, when the ceramic is impacted, the coating breaks along with the ceramic, energy is absorbed, so that crack propagation is prevented, in addition, a fracture of thecoating can change the ceramic crack trend, a crack propagation area is increased, and the toughness is improved.

Owner:中航装甲科技有限公司

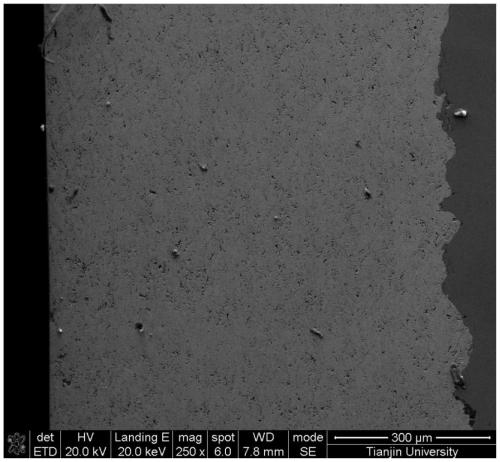

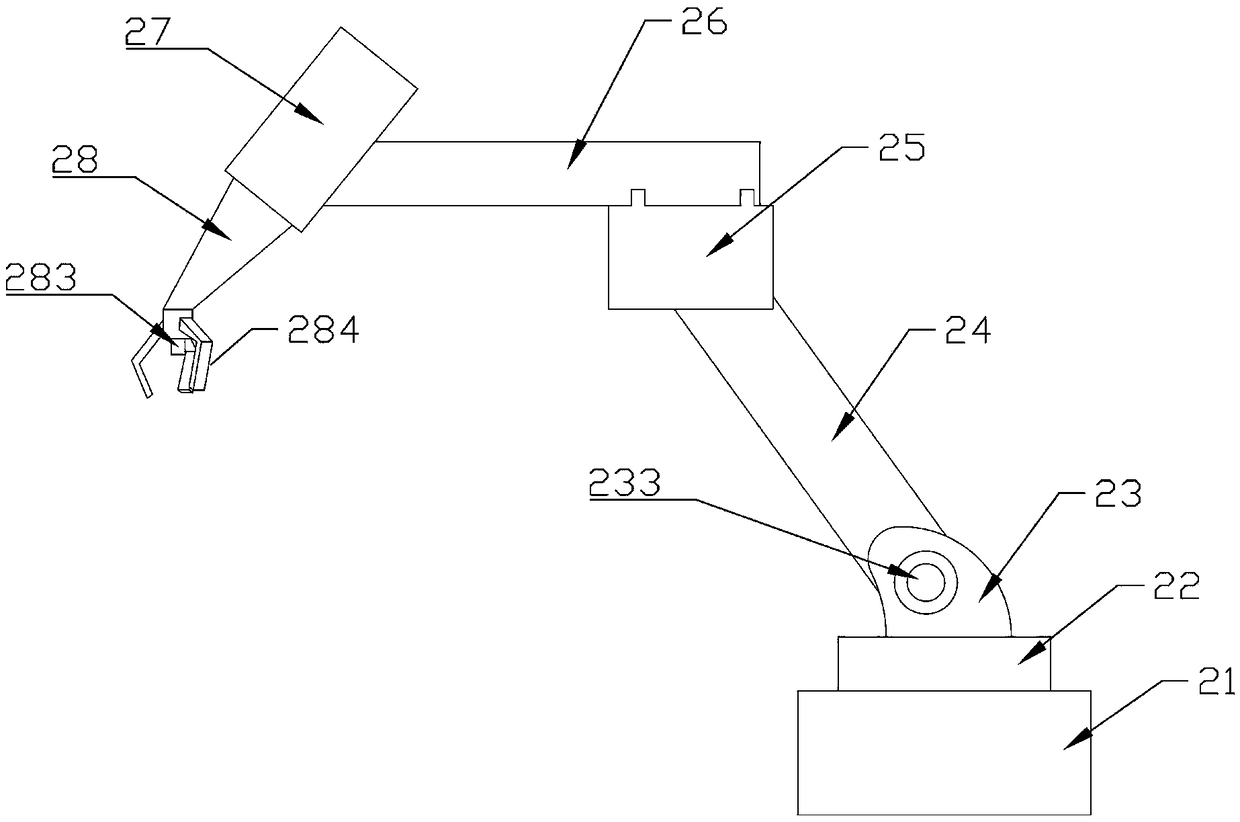

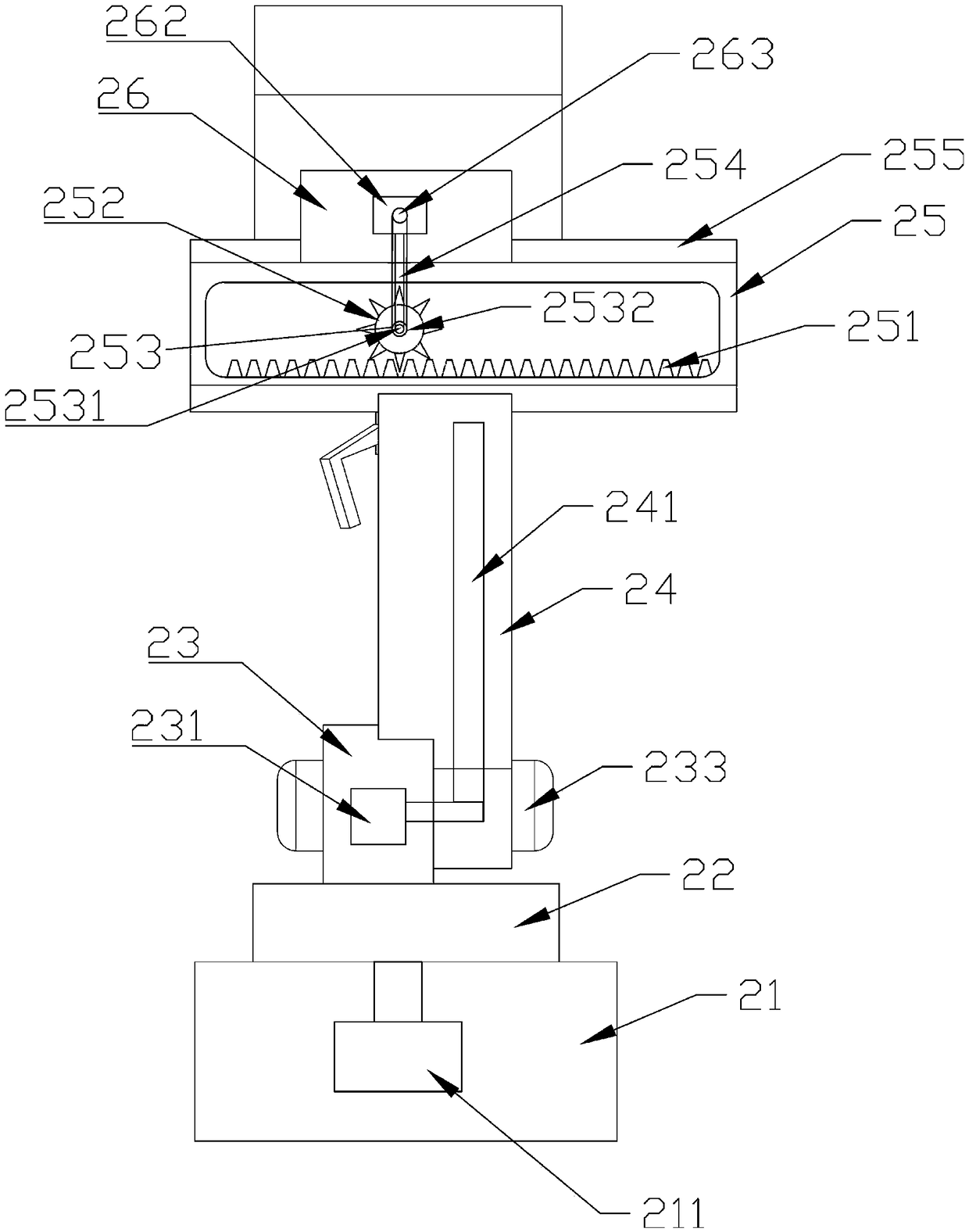

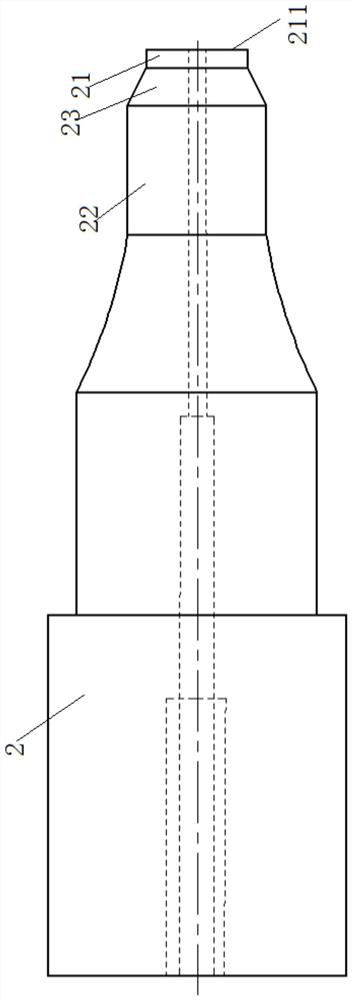

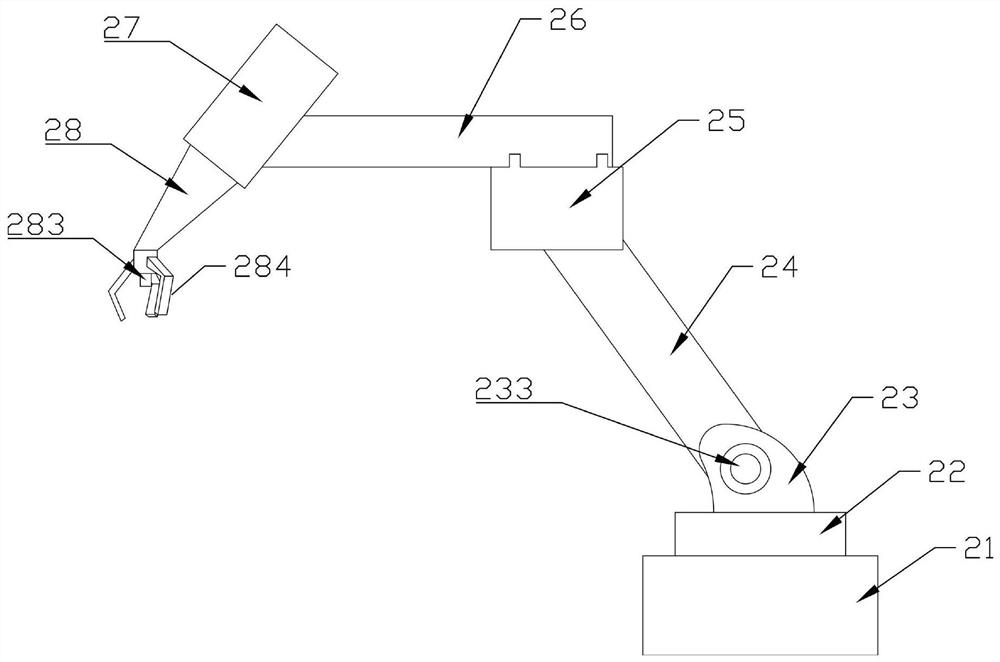

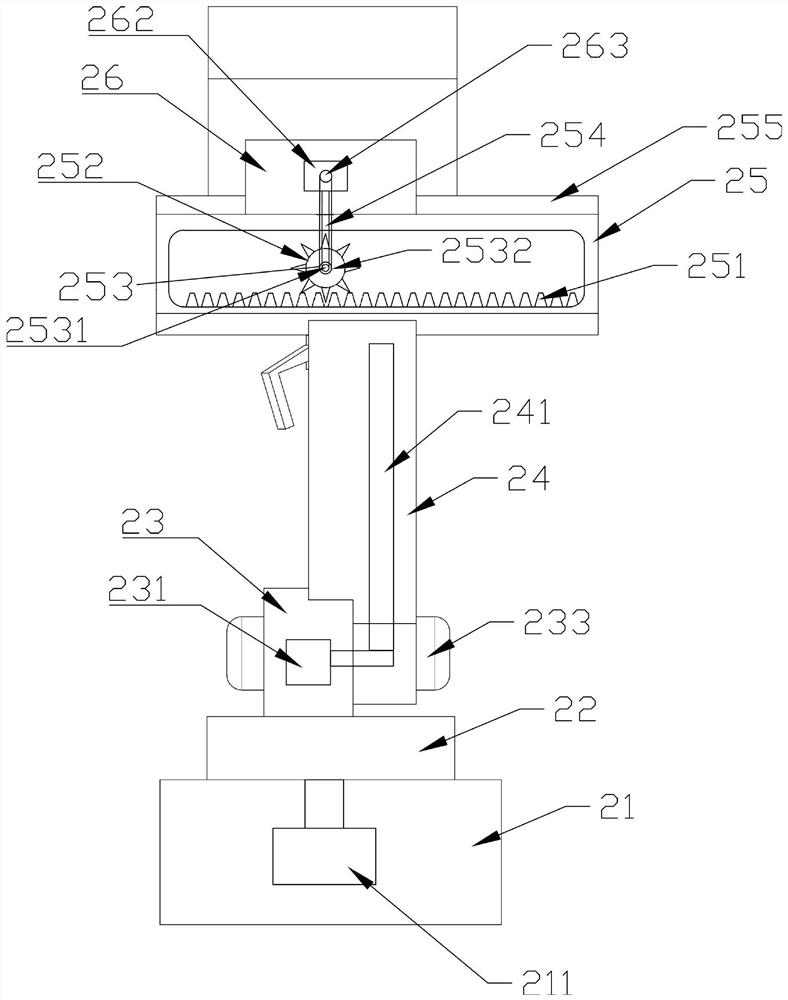

Automatic deposition device and method applied to outer surface of environment-friendly container nozzle

ActiveCN109483014AImprove corrosion resistanceGuaranteed CorrosionArc welding apparatusWelding/cutting media/materialsInstabilityAlloy

The invention discloses an automatic deposition device and method applied to the outer surface of an environment-friendly container nozzle. The automatic deposition device comprises a welding box, a mechanical arm, a welding rod box and a rotating device; and through a controller, the mechanical arm can achieve rotating, pitching and telescopic operation to automatically clamp a welding rod, and is matched with a rotating shaft to conduct omnidirectional deposition on the outer surface of the nozzle. The welding box is ventilated through a three-way valve, thus the whole welding box is in theprotective atmosphere of inert gas, waste of the inert gas in the traditional welding deposition process can be reduced, and the phenomena of deposition metal oxidation and air holes caused by instability of inert airflow in the welding process can also be avoided; and through the automatic device, the outer surface of an environment-friendly container is evenly and fully covered with a nickel-based alloy 690, and a residual pressure stress layer is formed on the outer surface of the nozzle to improve the hardness and corrosion resistance of the outer surface of the environment-friendly container nozzle.

Owner:上海蜂云航空科技有限公司

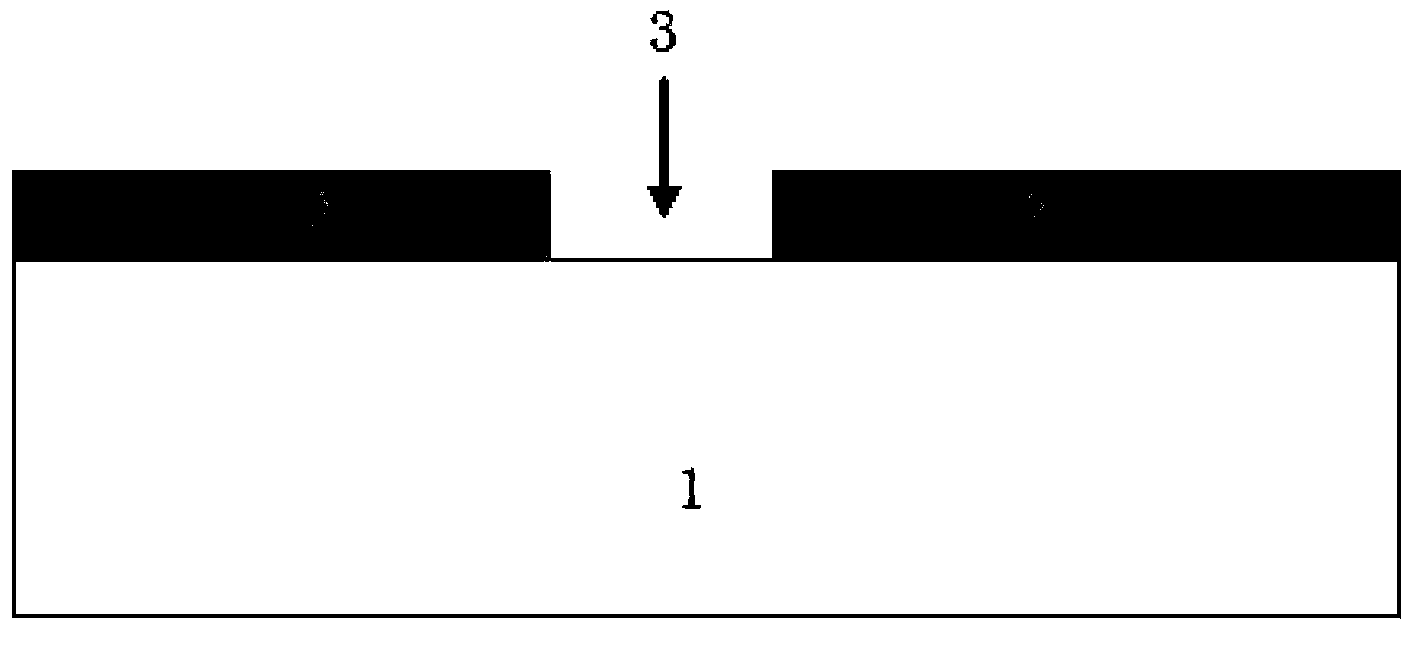

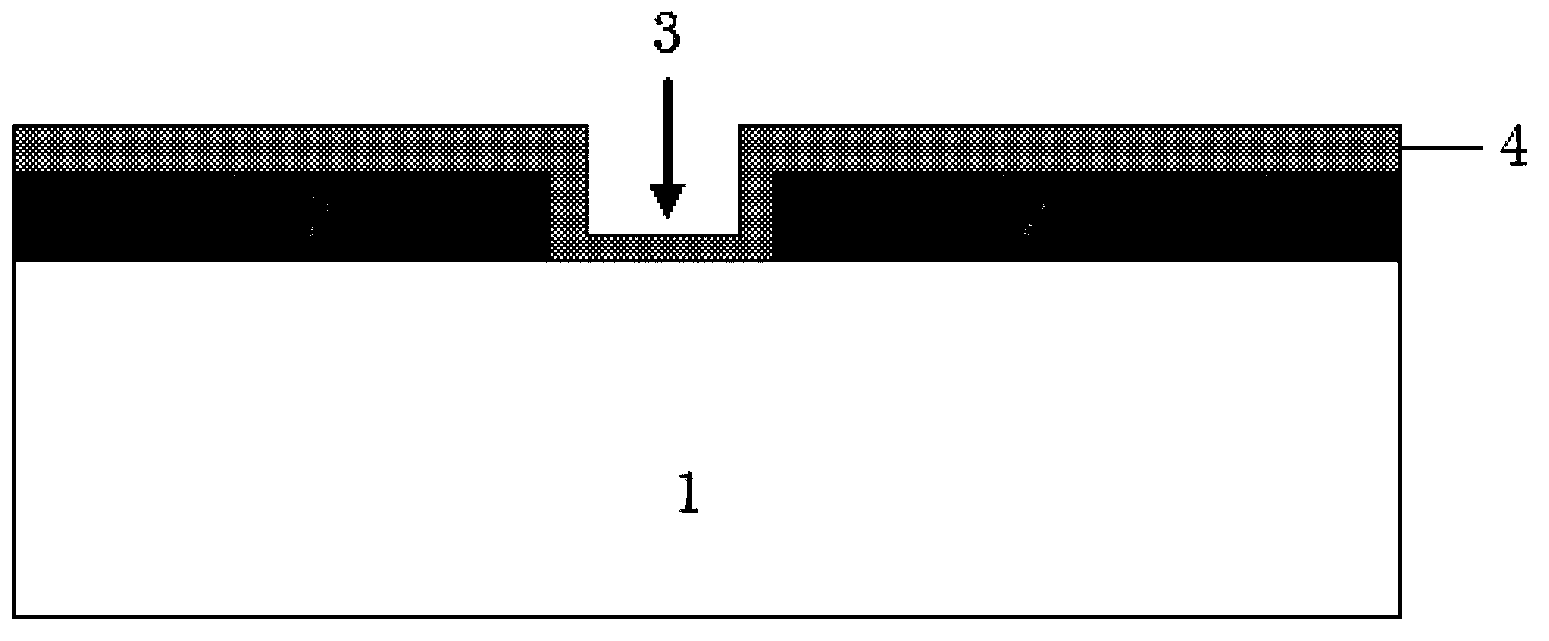

Method for improving silicon chip warping degree

ActiveCN103633012AImprove warpageOffset tensile stressSemiconductor/solid-state device manufacturingSilicon chipRapid thermal annealing

The invention discloses a method for improving silicon chip warping degree. The method comprises the following steps: step one: a pre-metal dielectric layer is formed on a silicon substrate, and a contact hole penetrating through the pre-metal dielectric layer is formed in the pre-metal dielectric layer; step two: a layer of metal connecting layer is deposited on the pre-metal dielectric layer and the contact hole; step three: rapid heat annealing processing is performed on the metal connecting layer; step four: plasma etching is performed, and a metal natural oxide layer naturally formed on the surface of the metal connecting layer is removed; and step five: a titanium nitride blocking layer is deposited on the upper surface of the metal connecting layer. Warping degree of silicon chips can be effectively improved by the method so that difficulty in silicon chip production flow is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

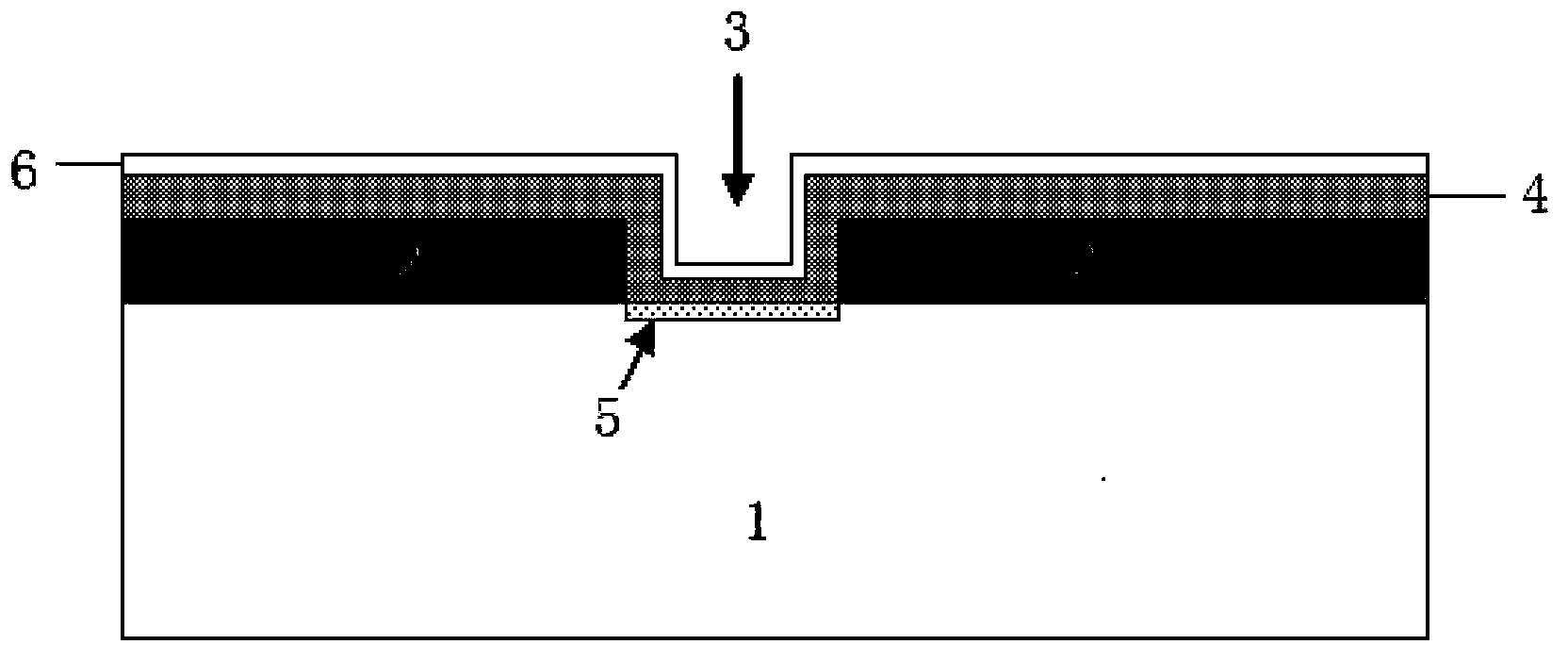

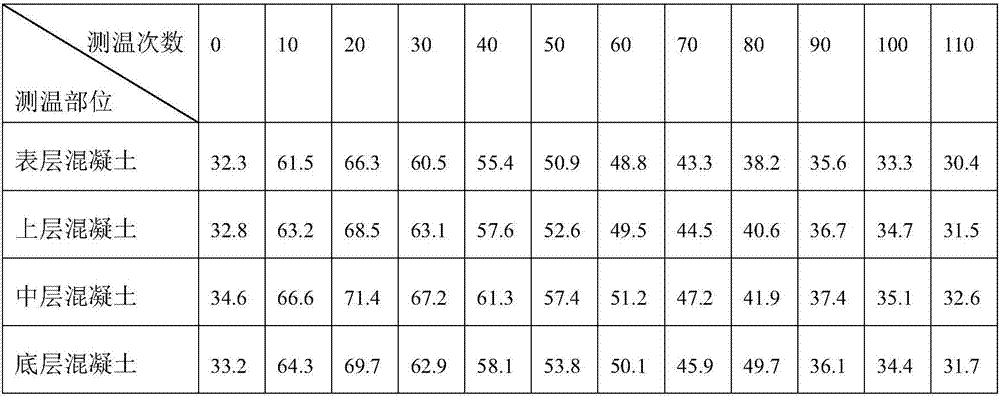

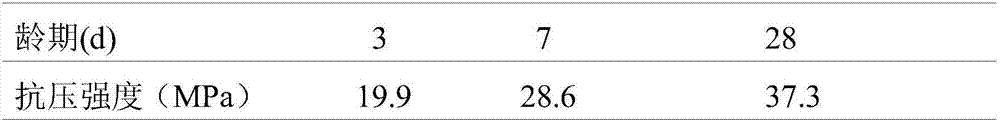

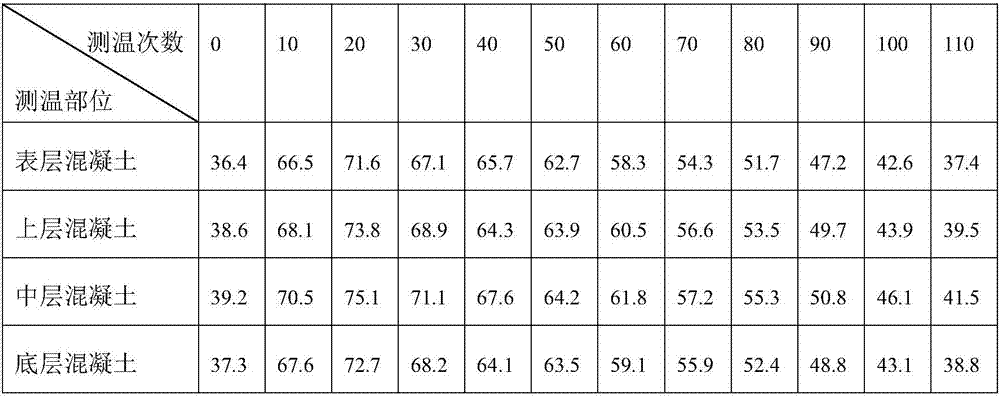

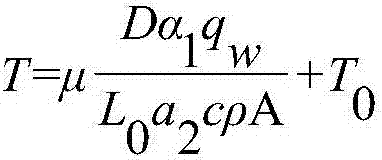

Concrete and cracking-resistant pouring method by adopting concrete

InactiveCN107311551AReduce heat of hydrationHigh compressive strengthBuilding material handlingTemperature differenceThermal expansion

The invention discloses concrete, which comprises the following components: 270-290kg of cement, 178-205kg of water, 528-560kg of fine aggregate, 1200-1350kg of coarse aggregate, 3.5-5.6kg of pumping aid, 27-32kg of swelling agent and 101-116kg of coal ash. The invention also discloses a cracking-resistant pouring method by adopting the concrete disclosed by the invention. The cracking-resistant pouring method comprises the following steps: S1: adding ice blocks into the concrete for stirring, wherein the addition of the ice blocks is 35-51kg / m<3>; S2: continuously pumping evenly stirred concrete into a die cavity, and evenly vibrating until the whole die cavity is vibrated. The concrete disclosed by the invention can be suitable for large-volume concrete pouring, heat of hydration is lowered, and the heat retaining property of the concrete is improved. If the cracking-resistant pouring method disclosed by the invention is adopted, the temperature of the concrete can be evenly distributed, the heat retaining property of the concrete is good, the cooling speed of the concrete is low, the temperature difference of each layer of the concrete is reduced, the heat expansion and cold contraction of each layer of the concrete tends to be synchronous, and the interior of the concrete can be prevented from cracking due to the temperature difference.

Owner:渝建实业集团股份有限公司

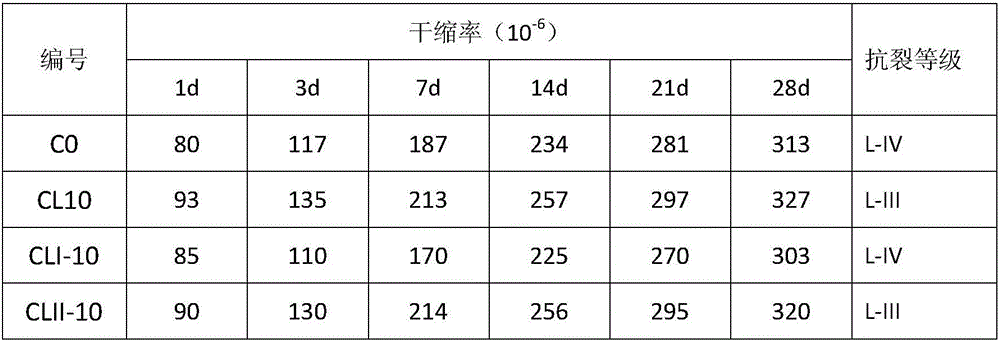

Compound admixture for anti-crack limestone powder and preparation method of compound admixture

The invention provides a compound admixture for anti-crack limestone powder and a preparation method of the compound admixture. The compound admixture comprises, by mass, 60-70 parts of limestone powder, 28-40 parts of coal ash, 1-2 parts of polypropylene fibers and 0.1-0.2 part of triethanolamine. By the compound admixture for the anti-crack limestone powder, concrete contraction can be reduced and concrete anti-crack performance can be improved while working performance and mechanical performance of concrete are guaranteed, so that durability of limestone powder concrete is improved, and application of the limestone powder to the concrete is widened.

Owner:CENT SOUTH UNIV

Surface deformation-enhanced non-tempered axle shaft manufacturing method

InactiveCN109517967AImprove mechanical propertiesSmall mechanical propertiesFurnace typesIncreasing energy efficiencyHigh energyRoom temperature

The invention discloses a surface deformation-enhanced non-tempered axle shaft manufacturing method which comprises the steps of raw material preparing, forging and cooling controlling, local induction normalizing, machining, surface induction quenching and tempering and surface deformation strengthening treatment. 38MnVS non-tempered steel is adopted as raw materials of an axle shaft; a forging and cooling controlling technology is used for forging forming of the non-tempered steel, and uniform microstructures are obtained by local induction normalizing after forging; the axle shaft is then machined through machining; surface induction quenching and tempering are carried out on the surface of the axle shaft; and surface deformation strengthening treatment is carried out, in other words, an impact head with the ultrasonic frequency and high energy density at the room temperature is used for conducting surface impact strengthening, the pressing amount of the impact head on the surface of a workpiece is controlled, a deformation strengthening layer is formed on the surface, the surface deformation layer depth is controlled to be 20 microns to 100 microns, and finally the non-temperedaxle shaft with good tissue uniformity and good fatigue and wear resistance is obtained.

Owner:NANJING INST OF TECH

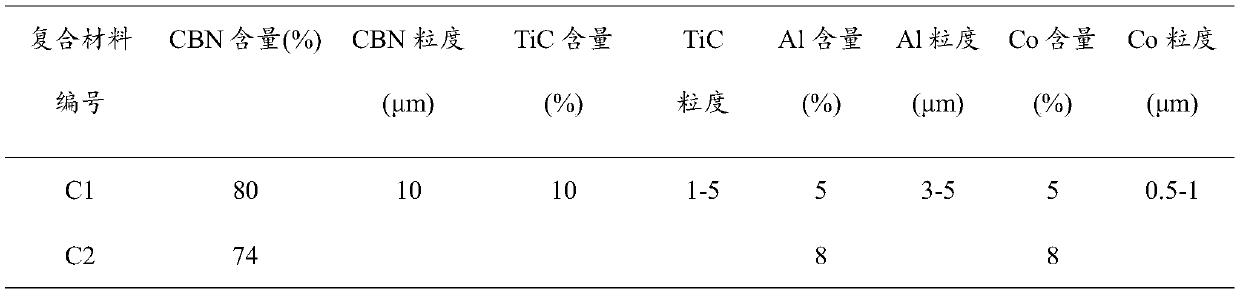

Gradient composite cubic boron nitride material and preparation technology and application thereof

ActiveCN110465669AImprove toughnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsBoron nitrideTitanium carbide

The invention provides a gradient composite cubic boron nitride material and a preparation technology and application thereof. The material is manufactured by sintering cubic boron nitride, titanium carbide, aluminum and cobalt as raw materials, and material is of three layers of symmetric gradient structures symmetric about the middle layer, wherein the material is prepared from, by volume, 70-80% of cubic boron nitride, 10% of titanium carbide, 5-10% of aluminum and 5-10% of cobalt, wherein the cubic boron nitride is adopted as a matrix, the titanium carbide is adopted as a ceramic binding agent, and aluminum and cobalt are adopted as metal binding agents. The raw material component contents of symmetric layers symmetric about the middle layer are the same, and the thickness is symmetrically distributed. The material has the high tenacity and corrosion resistance, a tool better adapts to high-speed cutting and wear-resisting part machining, and the wider application prospect is achieved.

Owner:四川英诺航空科技有限公司

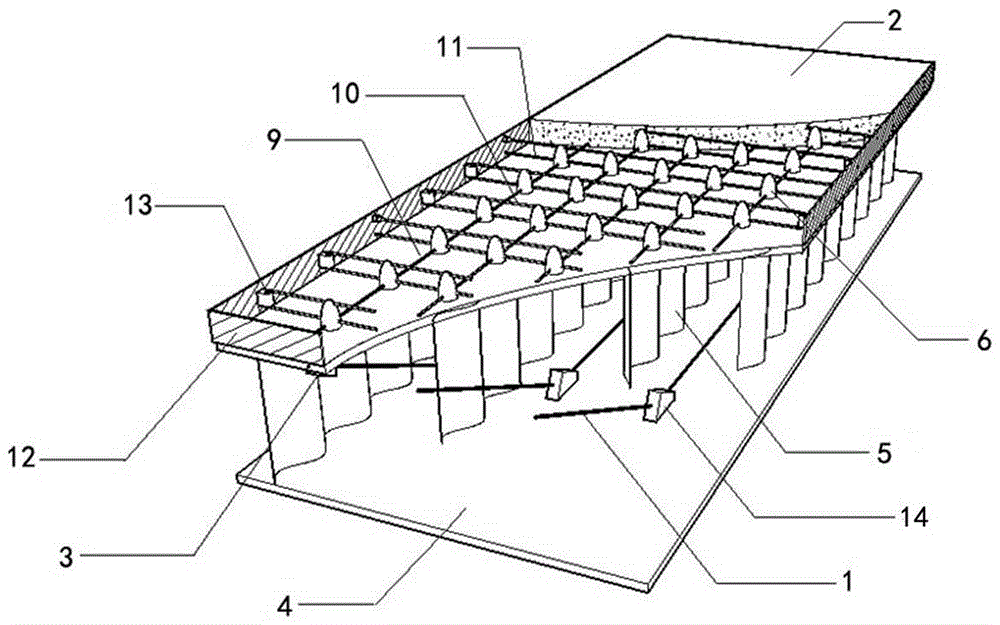

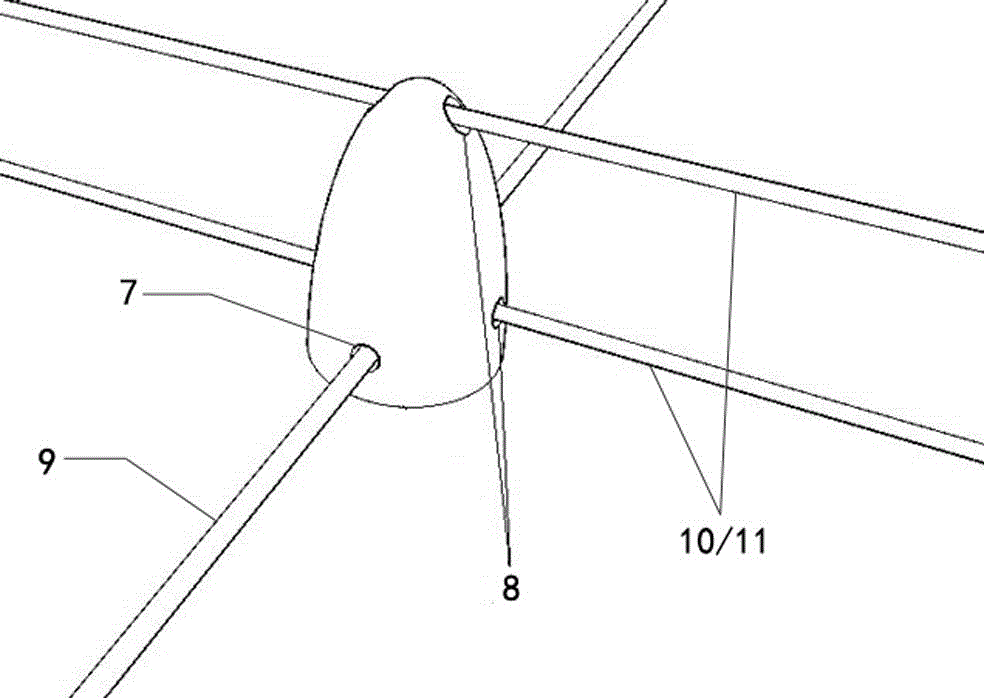

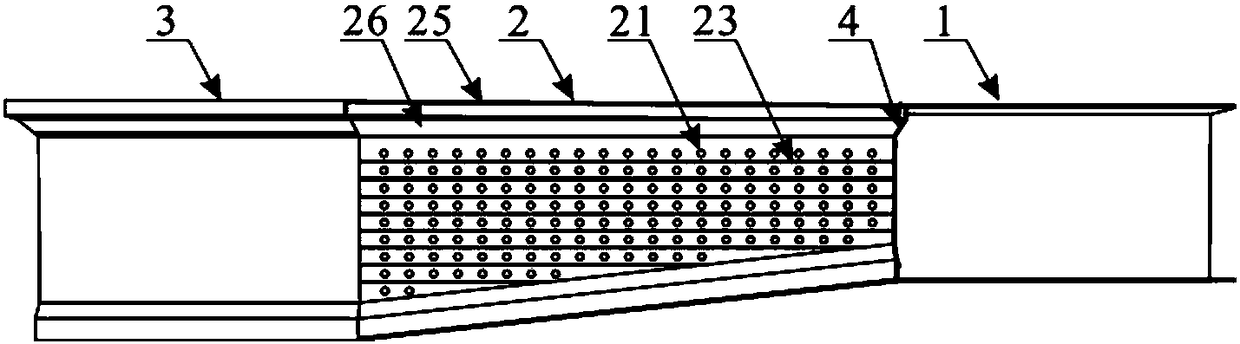

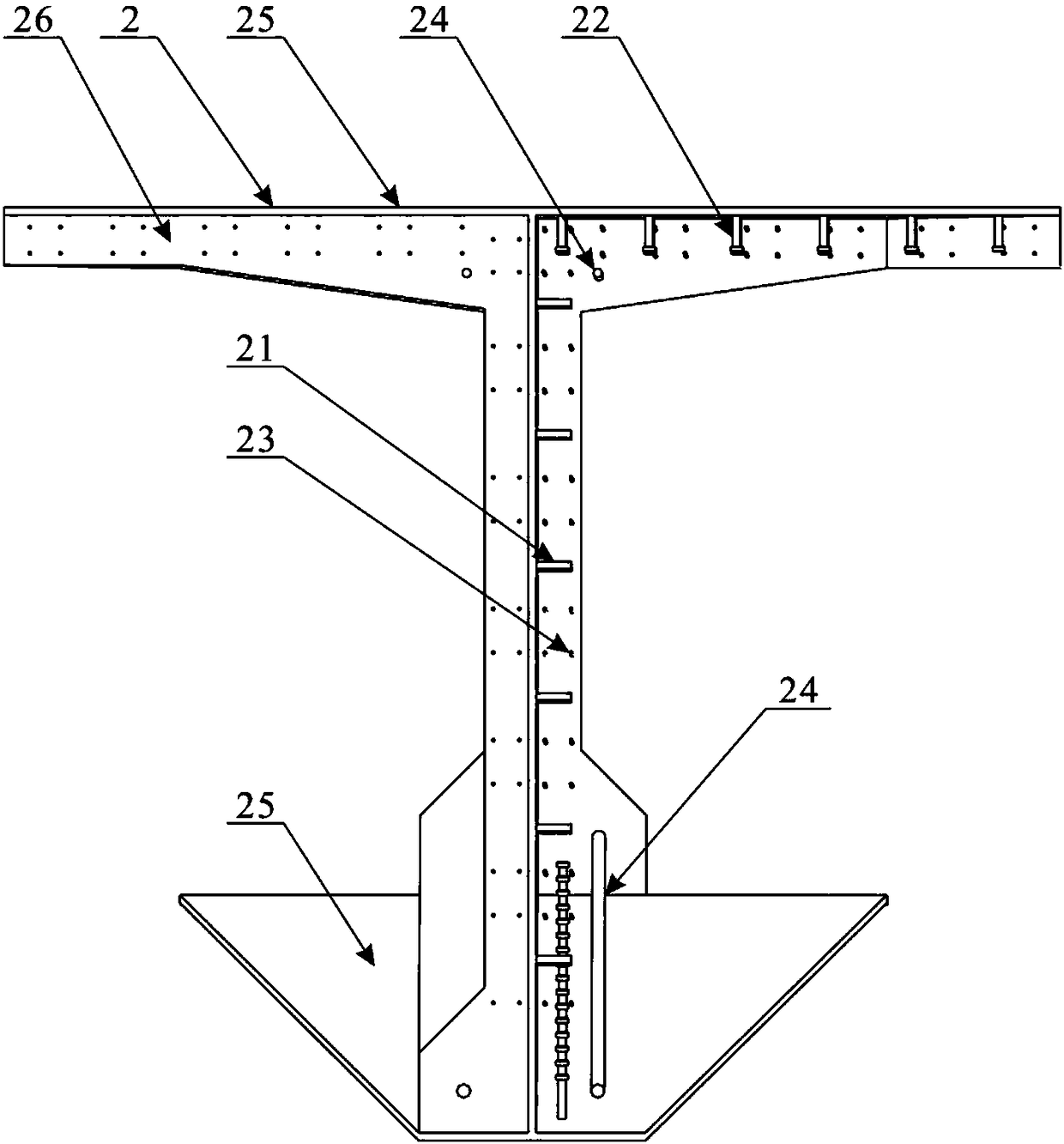

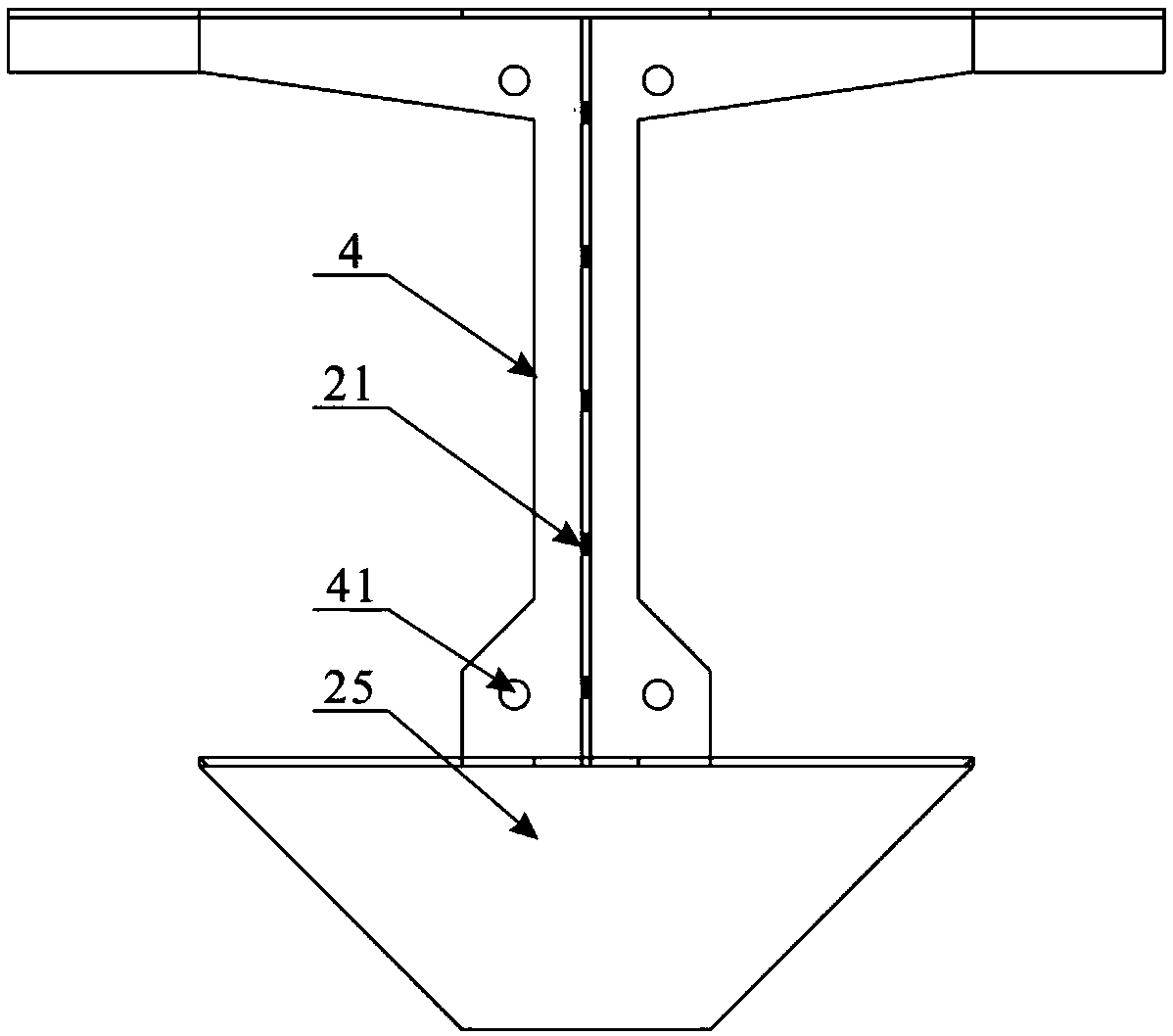

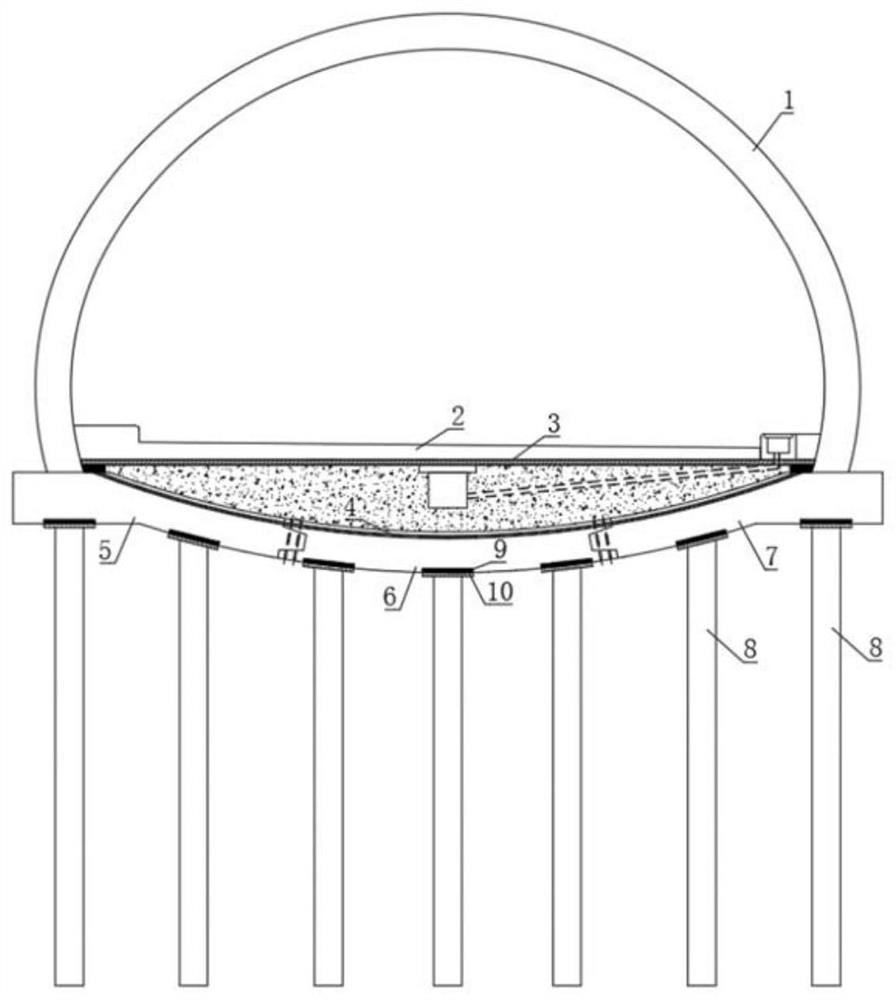

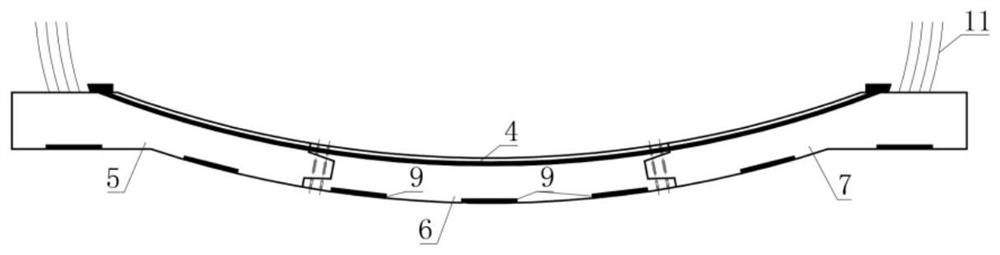

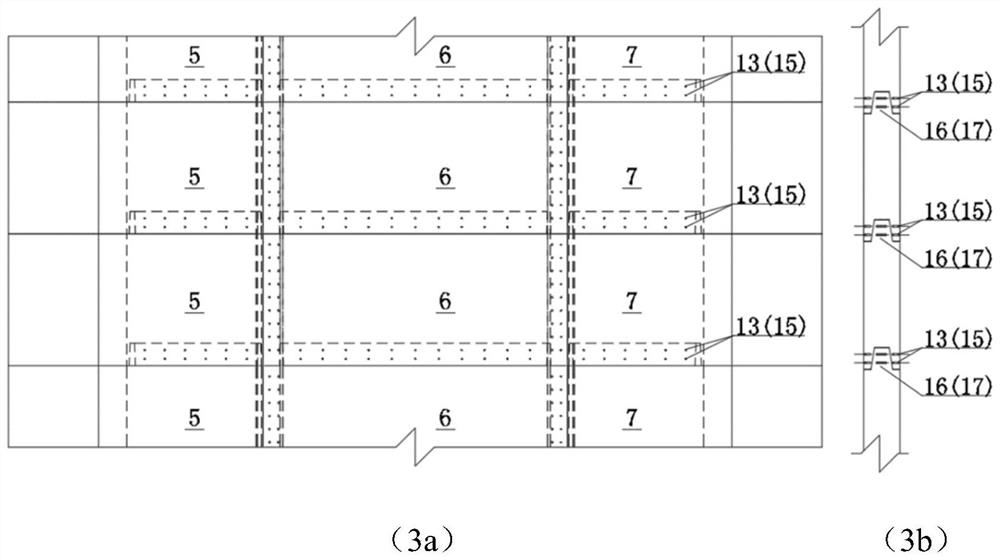

Corrugated web prestress FRP-concrete combined box beam and construction method thereof

InactiveCN105780637ALightweight and high strengthReduce down deflectionBridge materialsPre stressPrestressed concrete

The invention belongs to the field of new material new structures and combination structures in civil engineering and particularly relates to a corrugated web prestress FRP-concrete combined box beam and a construction method thereof. The combined box beam comprises an FRP box beam body, and every two adjacent corrugated webs between a top plate and a bottom plate form a box beam box chamber; and each box beam box chamber is internally provided with an external prestress bar, the two ends of each external prestress bar are connected to the two longitudinal ends of the top plate correspondingly, tension can enable the FRP box beam body to generate a pre-camber in the height direction, and concrete is poured at the top of the box beam body. Each external prestress bar is tensioned in the corresponding box beam box chamber, so that a beam body generates a certain pre-camber in the height direction; thus, the lower flexibility of the FRP-concrete combined box beam under the vehicle load is decreased, the method that the use quantity of FRP or concrete materials is increased to meet structural rigidity in the past is changed, the self weight of the structure is decreased, and the manufacturing cost is reduced; and the problems of shrinkage creep of a traditional prestressed concrete structure and prestress bar loosening and the like are solved.

Owner:SHANXI UNIV

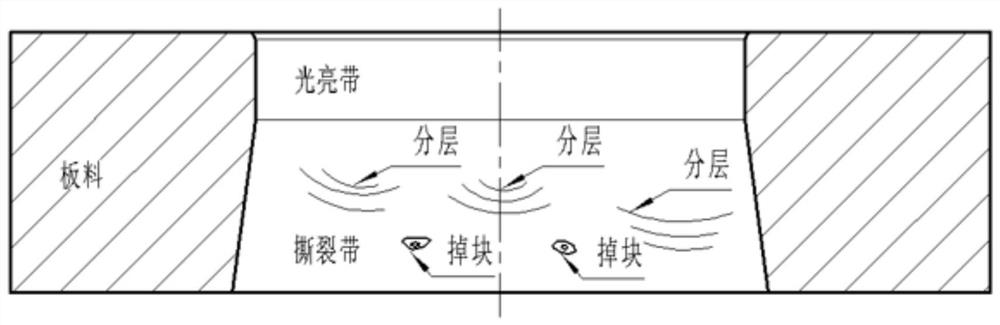

Stamping die and prestress punching process thereof

ActiveCN111922190AAvoid formingAvoid it happening againPerforating toolsPunchingStructural engineering

The invention relates to a stamping die and a prestress punching process thereof. The stamping die is used for punching a steel plate and comprises a female die, a male die matched with the female dieand a second-stage step positioned above a first-stage step and used for punching the steel plate, wherein a stepped punch is fixed to the male die and is provided with the first-stage step positioned at the lowest end and used for extruding the surface of the steel plate, and the height h of the first-stage step is 1 / 4-1 / 3 of the thickness t of the steel plate. By means of the stamping die and the prestress punching process thereof, layering can be decreased, and further block falling is decreased.

Owner:DONGFENG COMML VEHICLE CO LTD

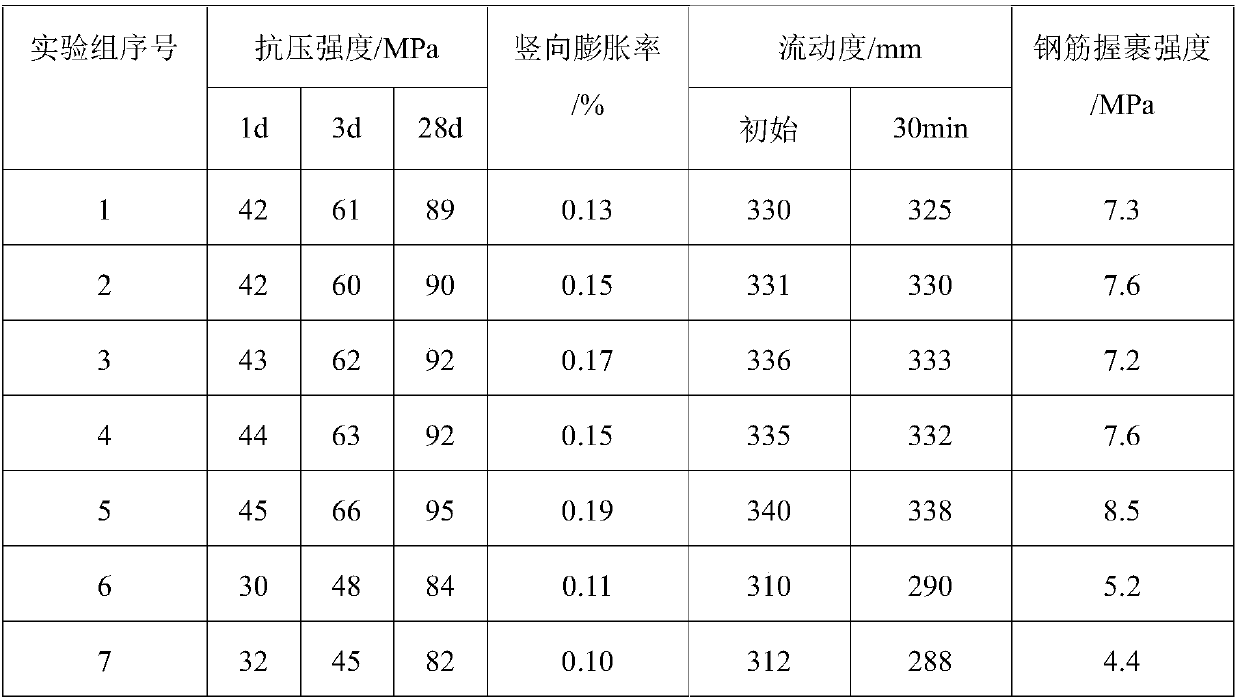

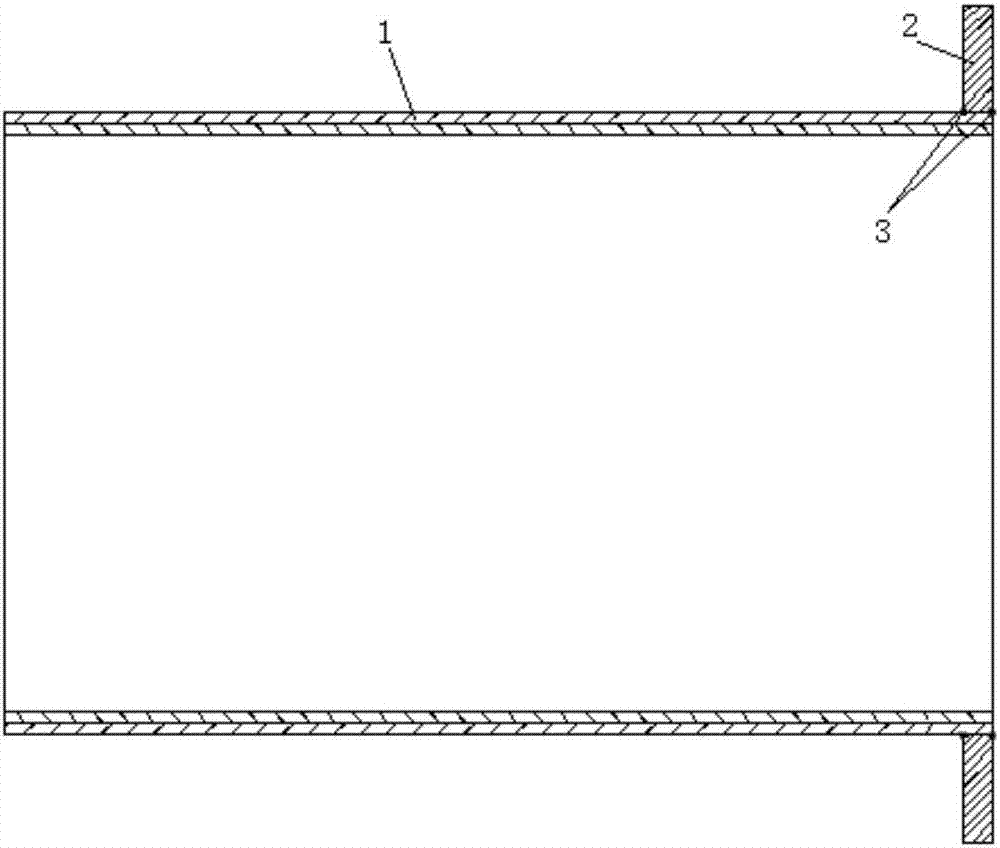

Grouting material for sound barrier backboard

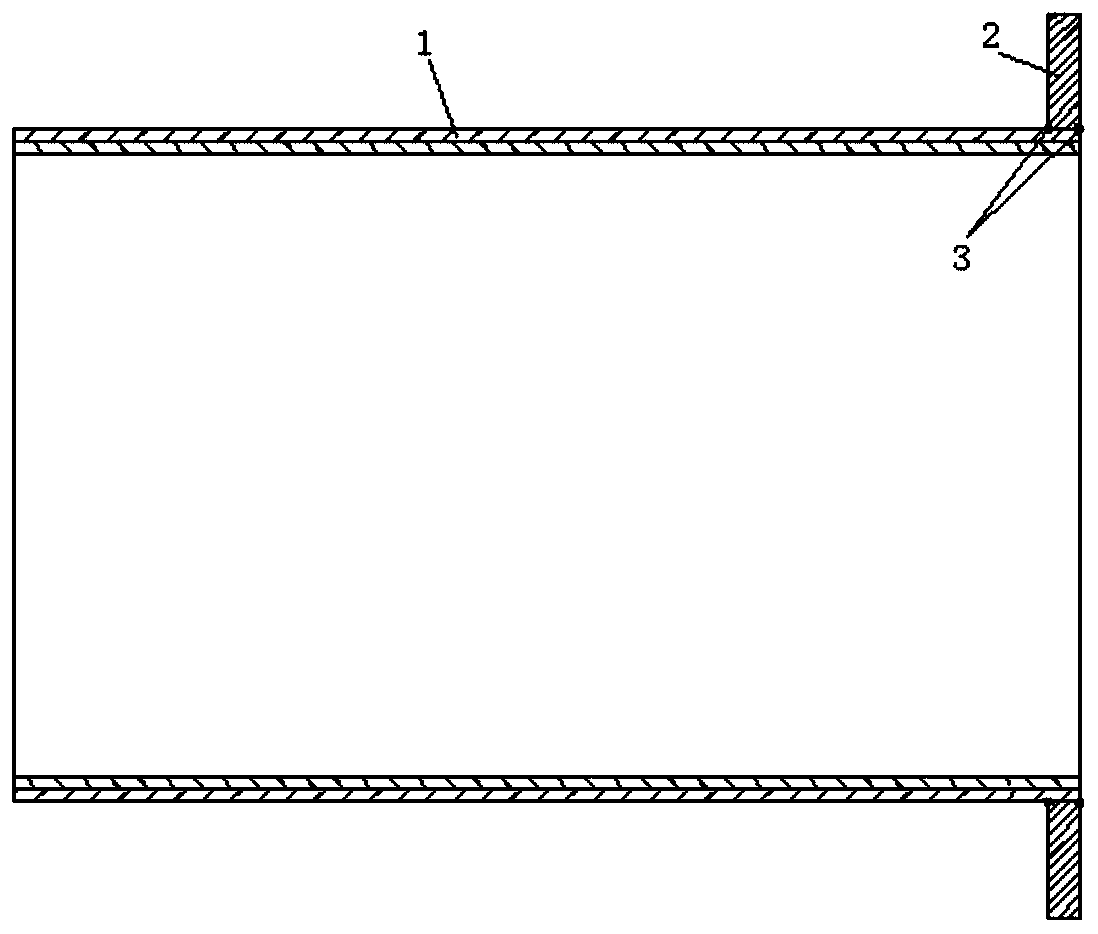

InactiveCN107602006AHas fast hardeningGood adhesionNoise reduction constructionPre stressingHeat stability

The invention relates to the technical field of building materials and provides a grouting material for a sound barrier backboard. The grouting material comprises the following raw materials (by weight): 15-25 parts of Portland cement, 30-40 parts of fly ash, 50-70 parts of building rubbish, 10-15 parts of water and 0.61-1.08 parts of additives. The grouting material has advantages of wide sourcesof raw materials, high utilization rate of solid wastes, low cost, rapid hardening, early strength, slight expansion, strong bonding force, good heat stability and the like, and can be used as a binder for bonding or reinforcement of engineering equipment. The sound barrier backboard is provided with multiple reinforcing holes. after the backboard is maintained to design strength, the backboard is tensioned with pre-stress steel bars or steel strands, and then the grouting material is injected to glue the pre-stress steel bars or steel strands with the sound barrier backboard as a whole. Thus, the sound barrier backboard is safe and stable and durable.

Owner:SICHUAN SHUANGTIE TECH CO LTD

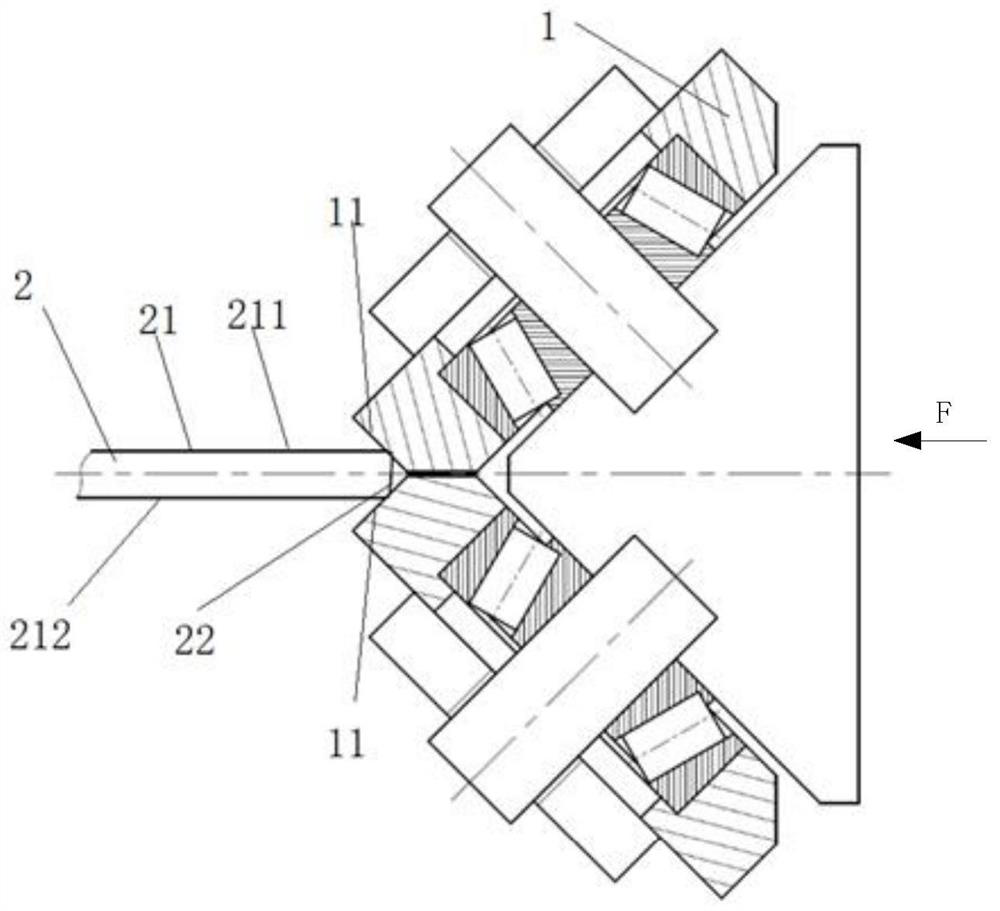

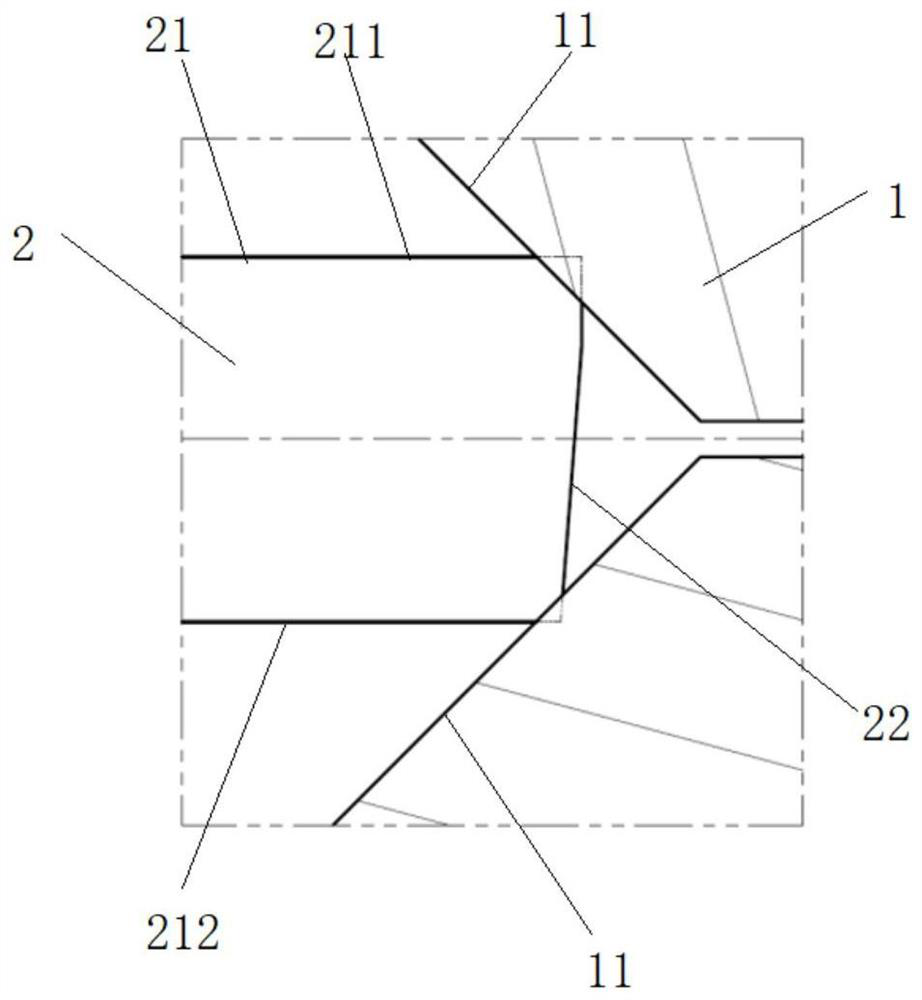

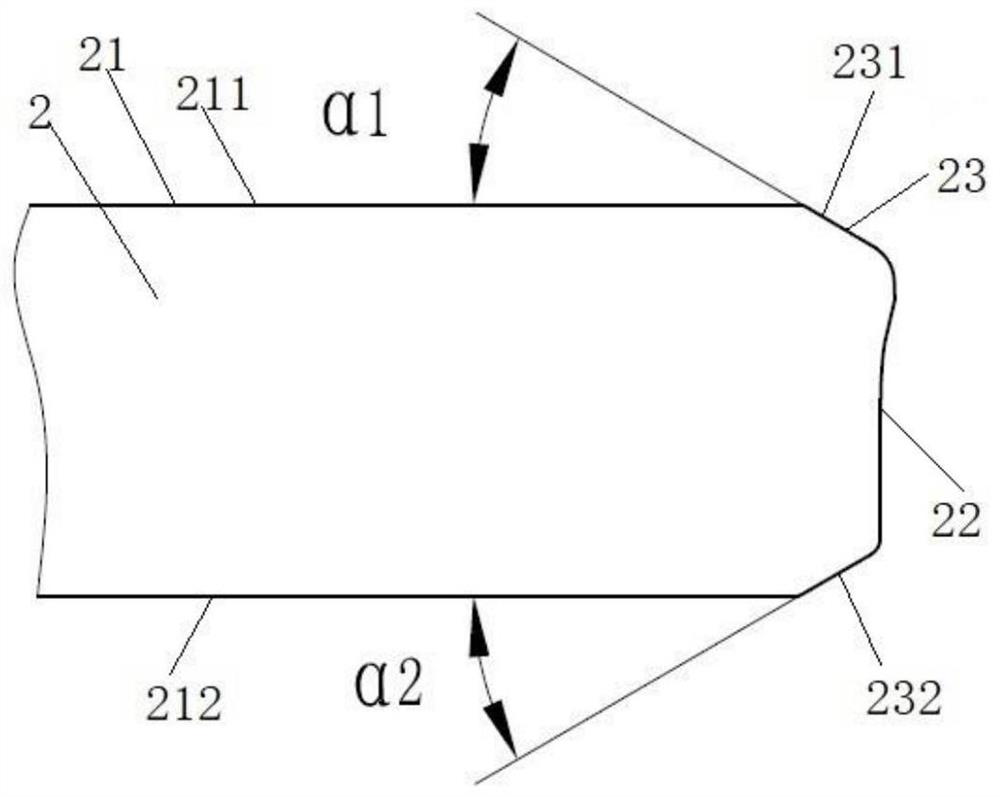

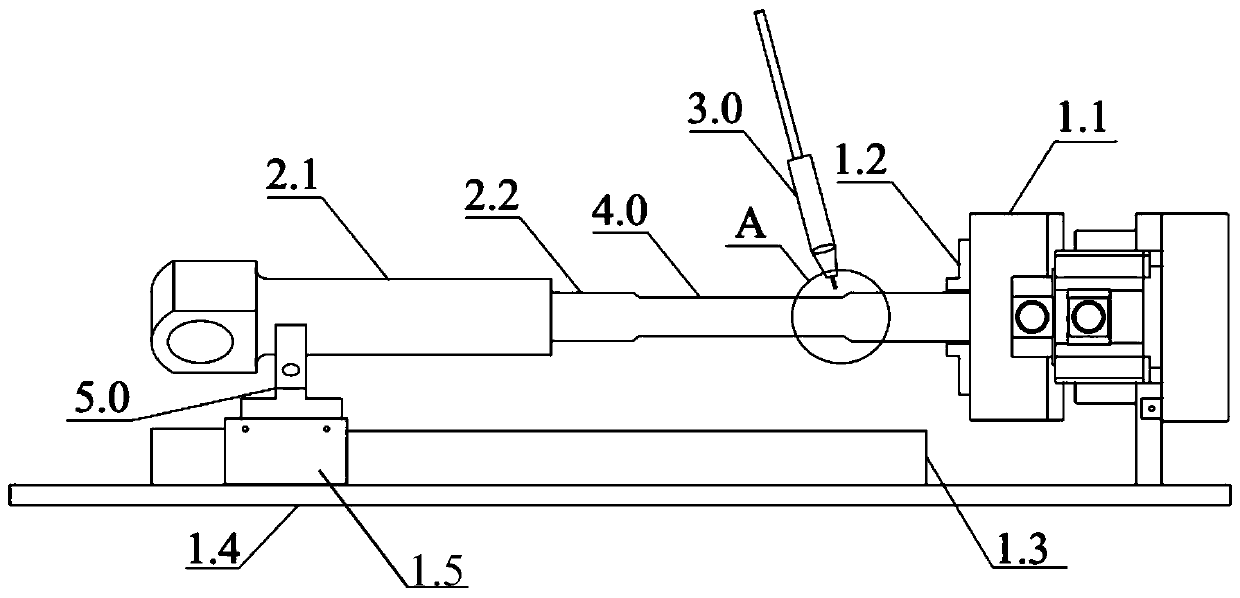

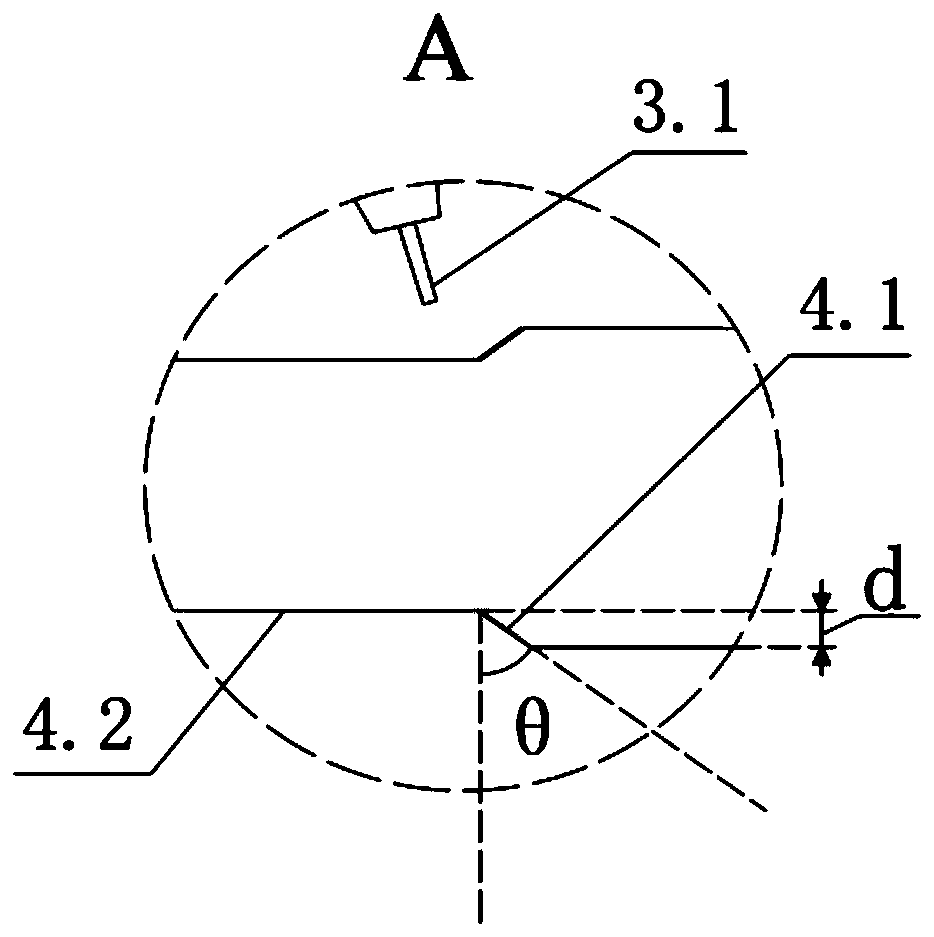

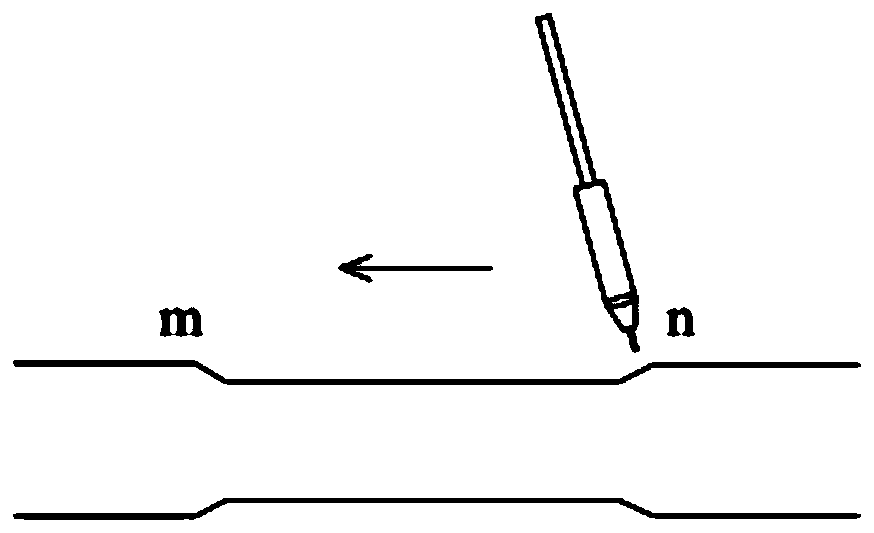

Metal plate shearing edge rolling strengthening method and plate-shaped part manufactured through same

The invention relates to a metal plate shearing edge rolling strengthening method and a plate-shaped part manufactured through the same. The method comprises the steps that a rolling wheel is installed on rolling equipment, the rolling wheel is driven to move to make contact with a shearing edge of a metal plate, and the rolling wheel is enabled to keep thrust F in the moving direction of the rolling wheel; and the metal plate is driven to move close to the rolling wheel in the direction perpendicular to the thrust F, meanwhile, the rolling wheel rolls the edge of the shearing edge to form a chamfer, and the included angle between the rolling face of the rolling wheel and the plate face of the metal plate ranges from 30 degrees to 45 degrees. According to the metal plate shearing edge rolling strengthening method and the plate-shaped part manufactured through the same, burrs on the edge of the shearing edge can be removed, the shearing edge can be thinned in the thickness direction, residual pressure stress is formed on the whole shearing edge, and therefore the fatigue strength of the shearing edge of the plate-shaped part is greatly improved.

Owner:DONGFENG COMML VEHICLE CO LTD

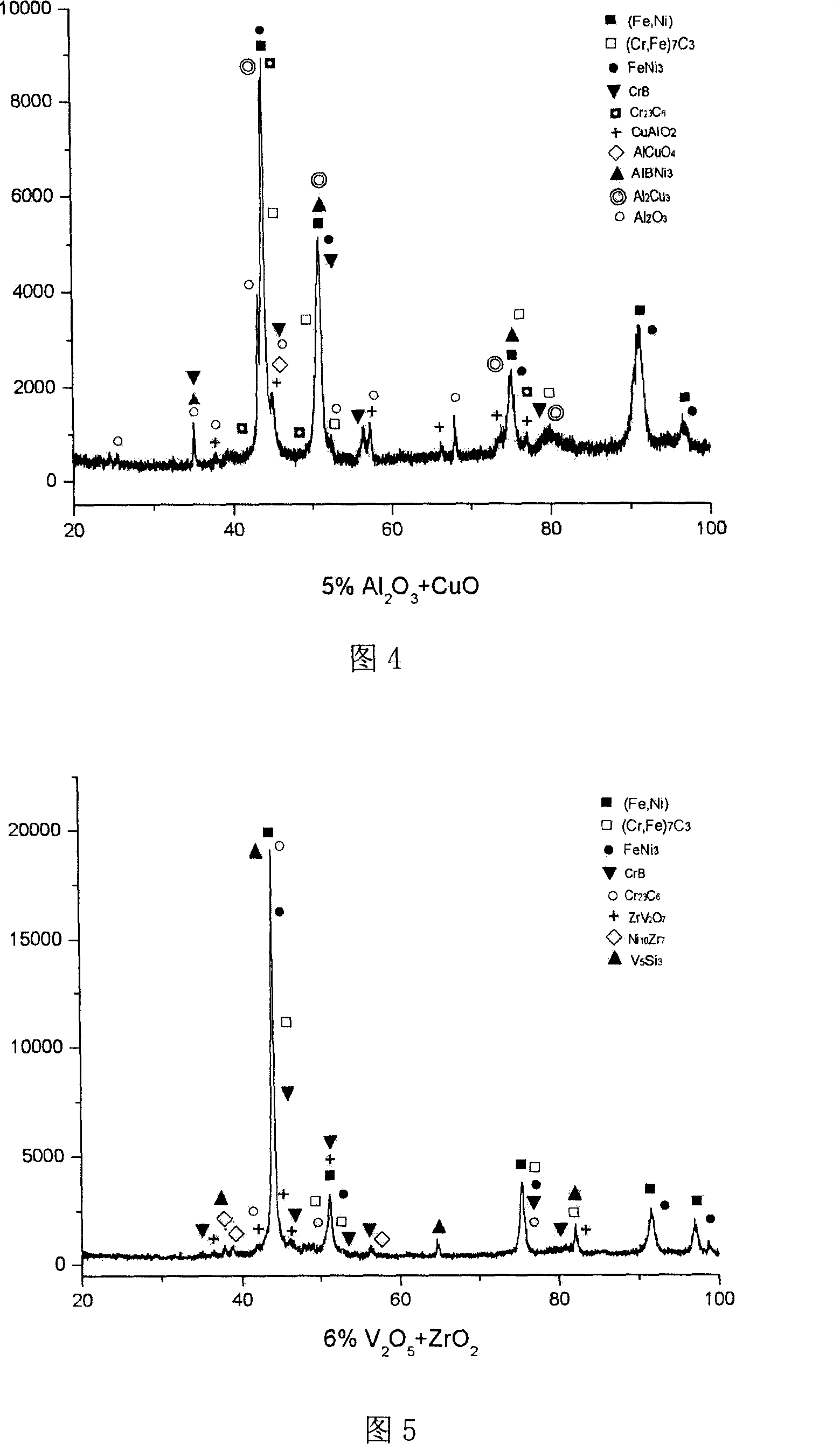

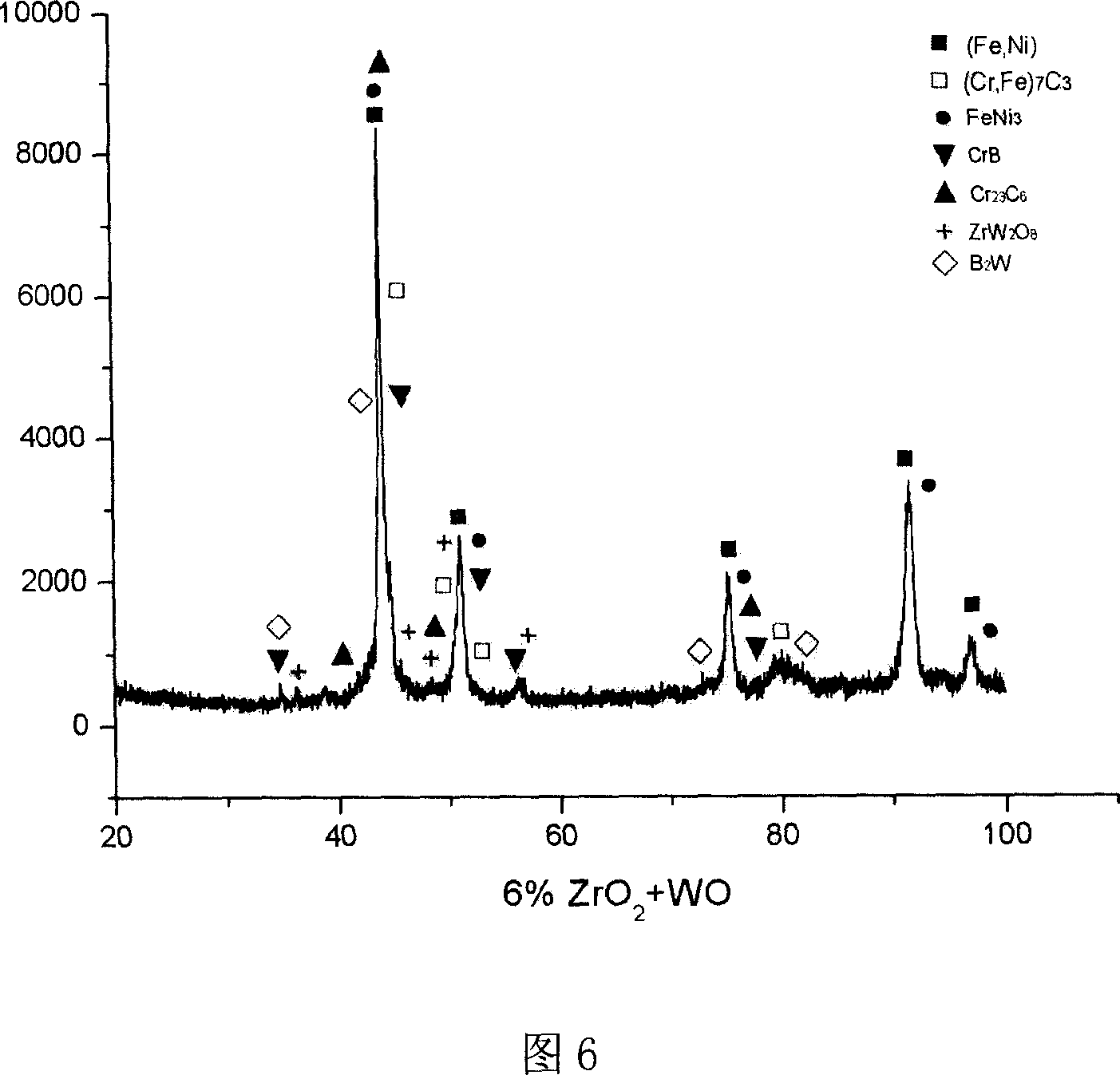

Laser deposited nickel-base alloy powder

InactiveCN1935419ACounteract volume shrinkageOffset tensile stressHeat inorganic powder coatingAlloyMetal

The present invention relates to a laser deposited nickel base alloy powder, belonging to the field of metal surface treatment material technology. It is characterized by that in its interior some raw material components capable of in-situ forming negative thermals expansion coefficient substance can be doped. The described raw material components capable of in-situ forming negative thermal expansion coefficient substance are Al2O3, Cu, ZrO2 and V2O5 or ZrO2 and WO3. The added quantity of Al2O3 and Cu is 1-5% of nickel base alloy weight, the mole ratio of Al2O3 and Cu is 1:2, the added quantity of ZrO2 and V2O5 is 1-10% of nickel base alloy weight, the mole ratio of ZrO2 and V2O5 is 1:1, and the added quantity of ZrO2 and WO3 is 1-10% of nickel base alloy weight, the mole ratio of ZrO2 and WO3 is 1:2. In the course of quick solidification of laser deposition the above-mentioned all components can in-situ produce the compounds of CuAlO2, ZrV2O7 or ZrW2O8 with negative thermal expansion coefficient.

Owner:ZHENGZHOU UNIV

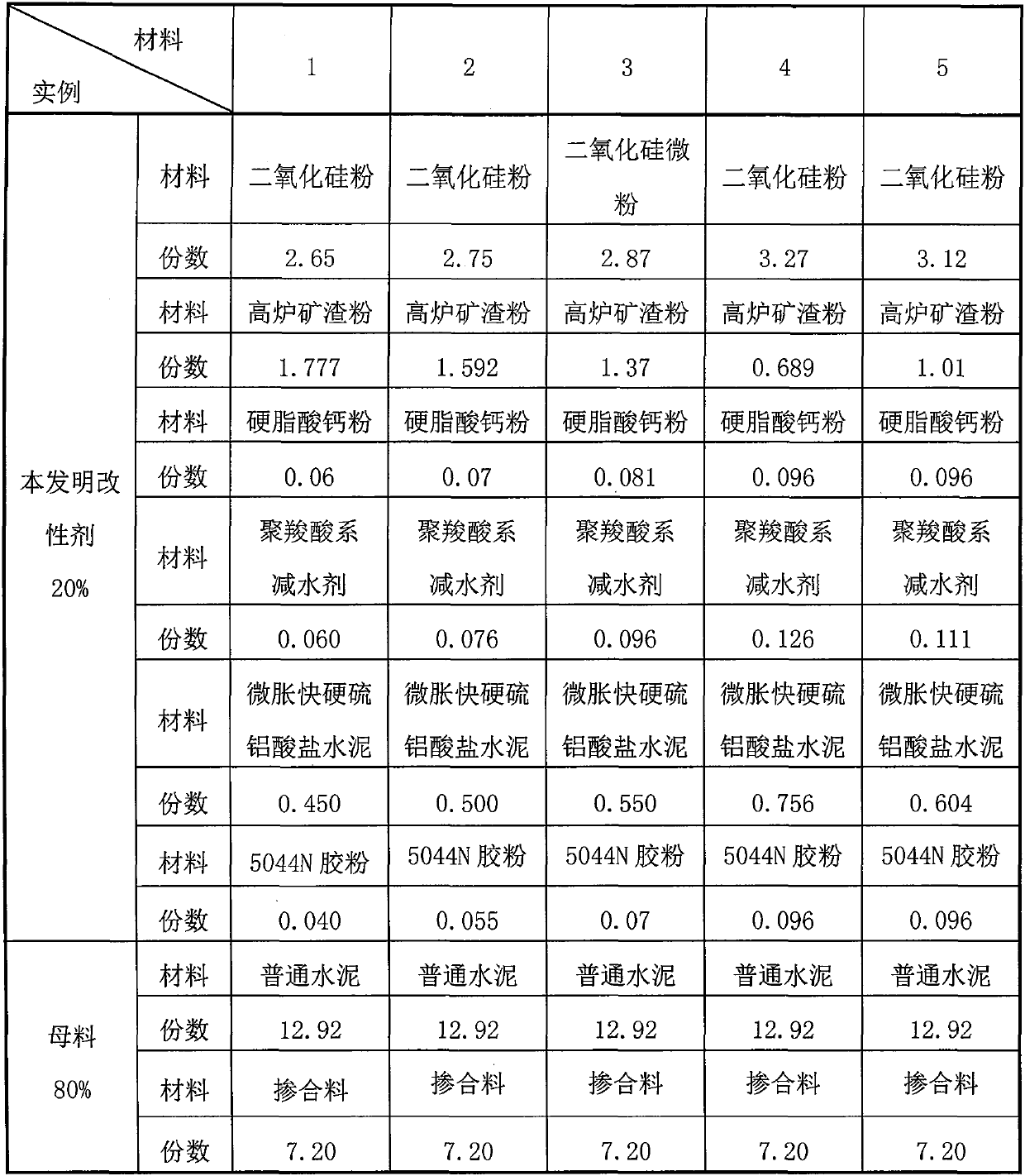

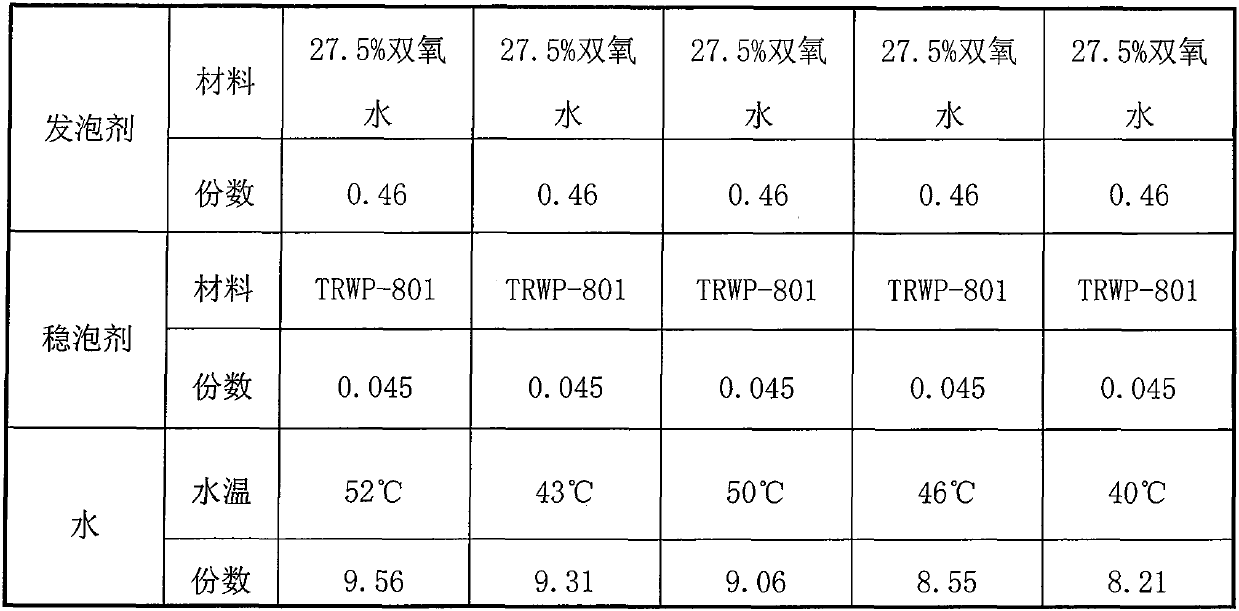

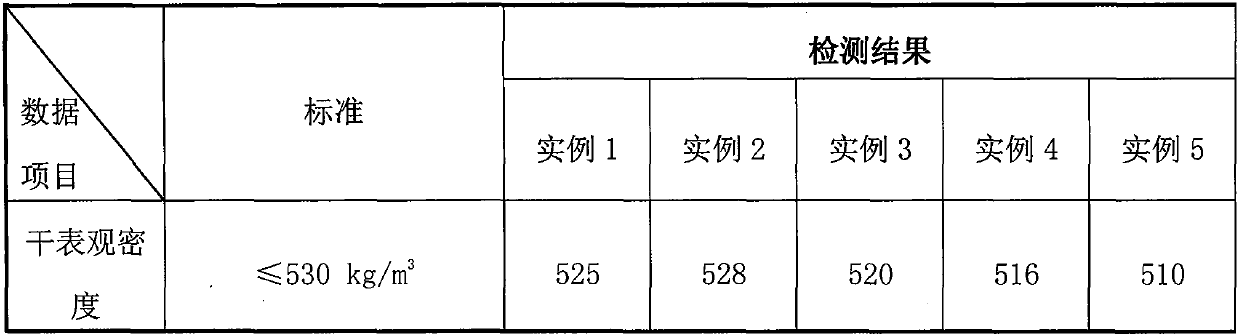

Multifunctional inorganic composite foam concrete modifier and preparation method thereof

InactiveCN110950568AImprove crack resistanceShort initial setting timeFoam concreteCompressive resistance

The invention discloses a multifunctional inorganic composite foam concrete modifier and a preparation method thereof. The multifunctional inorganic composite foam concrete modifier is prepared from inorganic functional material nano silicon powder, mineral powder, expansive quick-hardening cement, rubber powder, a water reducing agent powder and a water repellent powder. The preparation method comprises the following steps: sequentially adding all the materials into a stirrer in parts by weight, mechanically stirring while adding the raw materials, and uniformly mixing, thereby obtaining themultifunctional inorganic composite foam concrete modifier; and then mixing and foaming according to the ratio of 0.80 part of a master batch to 0.20 part of the multifunctional inorganic composite foam concrete modifier to prepare a high-performance foam concrete product. The compressive strength of the foam concrete added with the modifier reaches 1.45 times of the industrial standard, and the foam concrete has the advantages of light weight, hydrophobicity, no cracking, flame retardance, heat preservation and insulation, sound insulation, the same service life as a building main body structure and the like, and is simple to prepare and convenient to operate and produce.

Owner:涂迎青

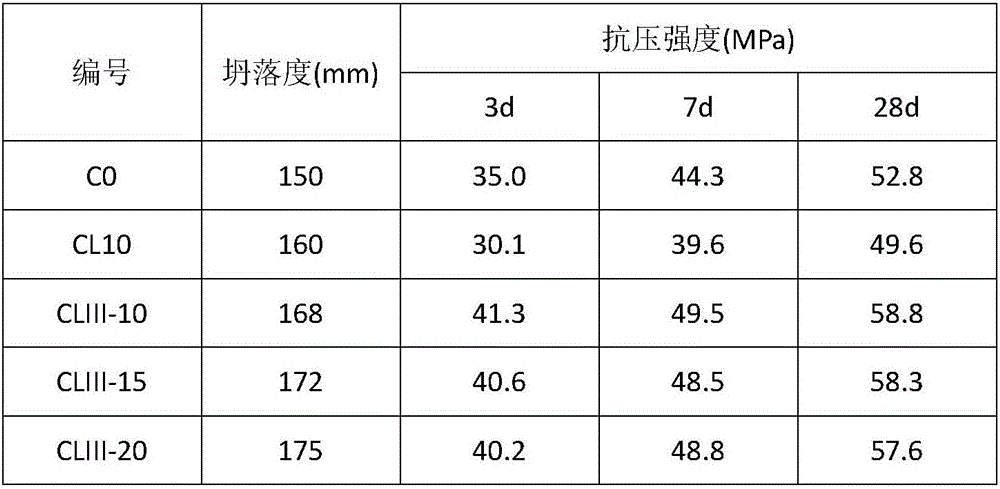

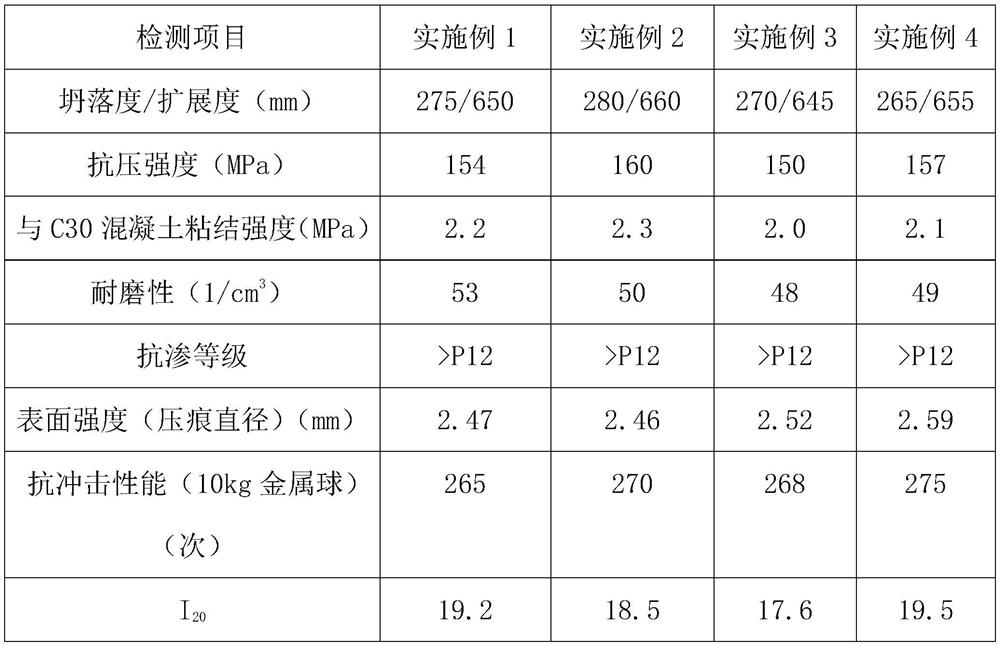

Steel-concrete with ultrahigh performance joint section and manufacturing method thereof

PendingCN108374318AImprove toughness and strengthHigh compressive strengthBridge erection/assemblyConcrete beamsBuilding construction

Owner:SOUTHWEST JIAOTONG UNIV

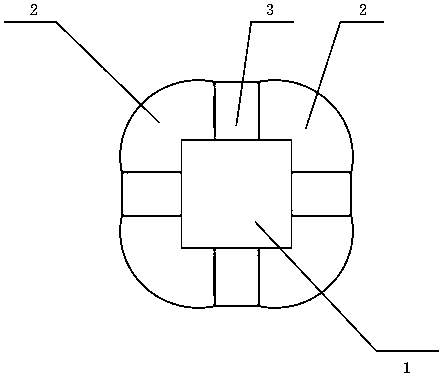

Novel rotor applied to high-speed permanent magnet motor

InactiveCN109861422AReduce the equivalent air gap lengthReduced rotor eddy current lossMagnetic circuit rotating partsMechanical energy handlingPhysicsSystem structure

The present invention discloses a novel rotor applied to a high-speed permanent magnet motor. Part of a circular rotating shafts are changed to a polygonal rotating shaft, the apex of the polygon is inlaid into a main permanent magnet to perform circumferential fixation of the permanent magnet so as to increase the adsorption power between the permanent magnet and the rotating shaft, enhance the radial fixing of the permanent magnet to resist the centrifugal force in a high rotation speed, improve the air-gap field waveform and reduce the loss. A non-magnetic copper ring is modified to an approximate cup-shaped structure to achieve axial and radial fixing of the permanent magnet while achieving non-magnetic and dynamic balance functions. A common rotor sheath fixing device is omitted to simplify the system structure. The omission of the sheath reduces the equivalent gas length to obtain a larger electromagnetic torque in the same motor dimension parameters so as to increase the power density of the motor. The problem of the fixing of the rotor permanent magnet is solved, the utilization efficiency of the permanent magnet is improved and the operation reliability of the motor is improved to facilitate lightweight of the high-speed permanent magnet motor and facilitate improvement of the operation speed of the motor and improvement of the performances of the motor.

Owner:SHANGHAI UNIV

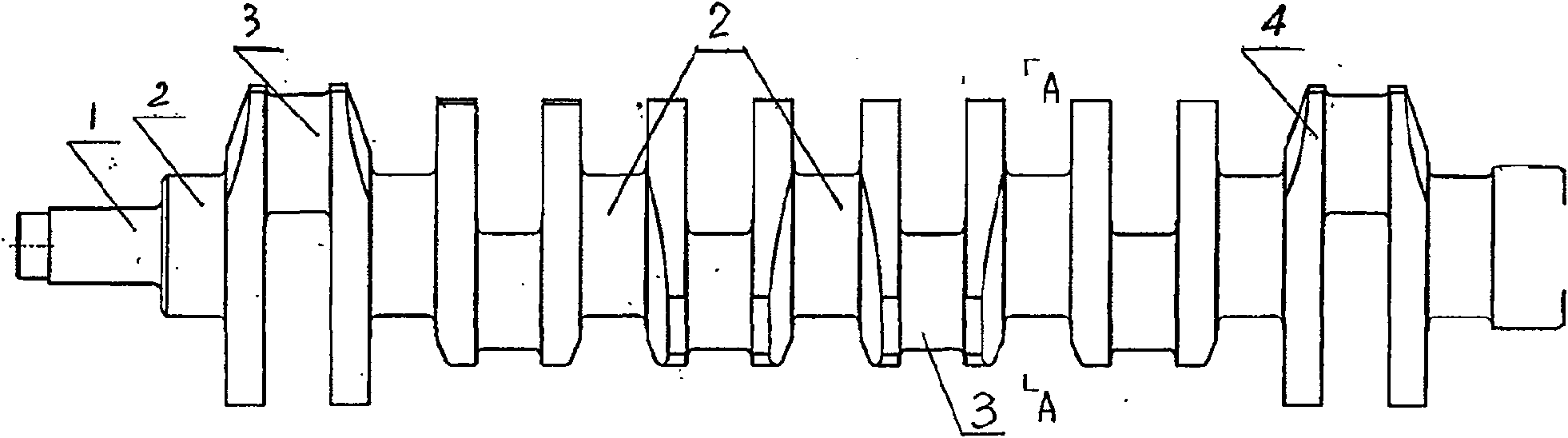

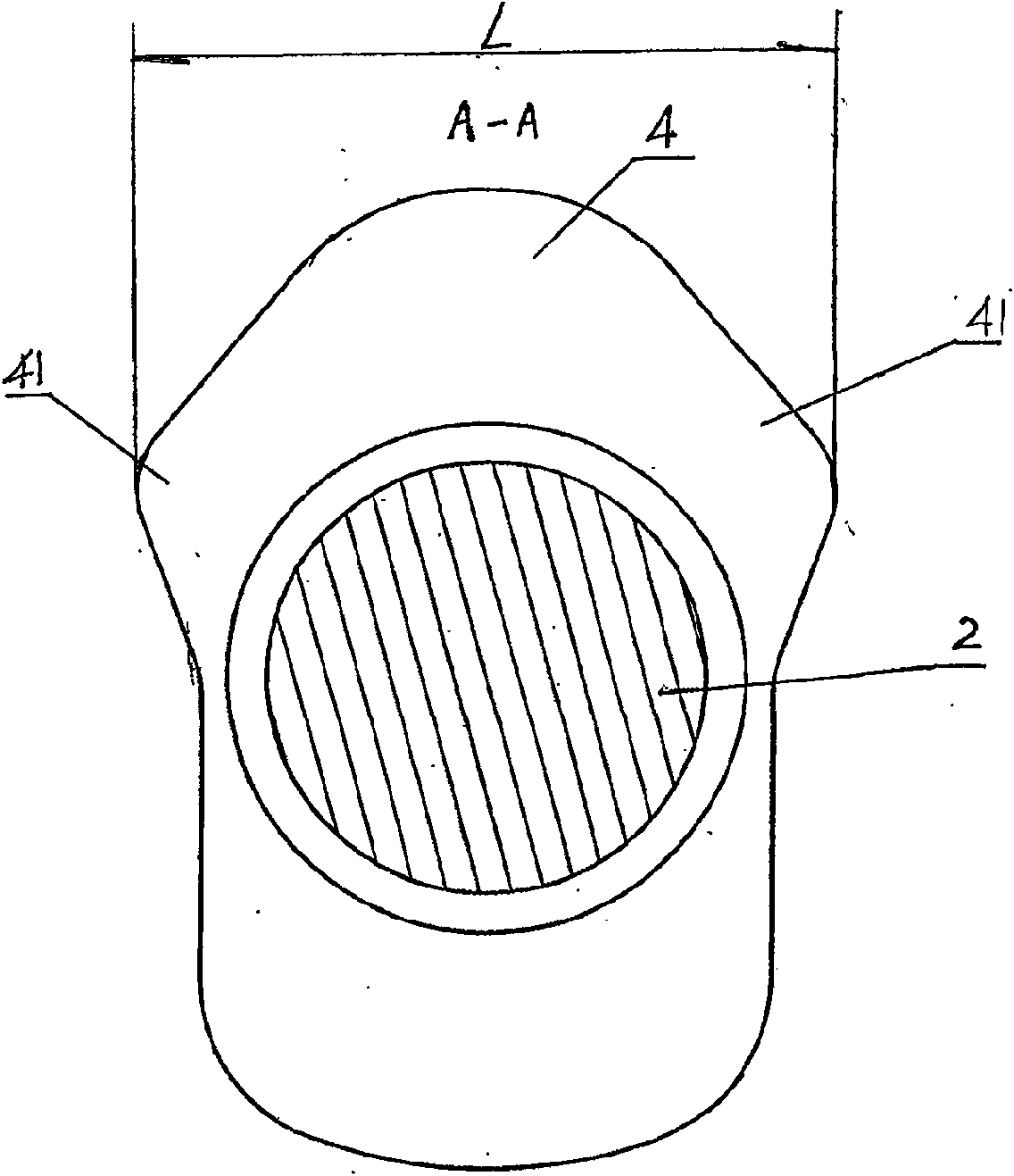

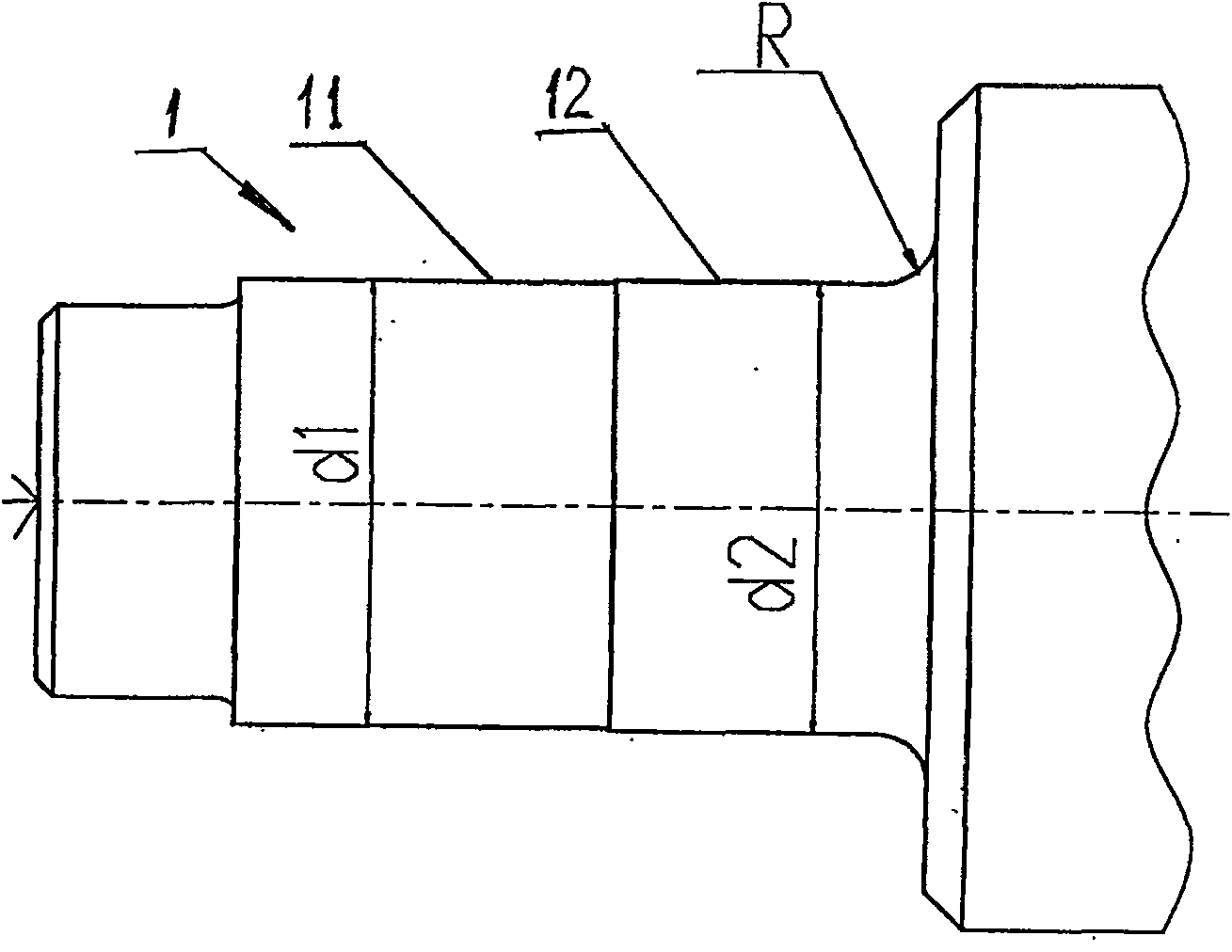

Engine ductile iron crankshaft

The present invention provides an engine crankshaft made of ductile iron for replacing a same type forged steel crankshaft. Compared with the same type forged steel crankshaft, the diameter of the front end shaft journal of the free end of the engine crankshaft made of ductile iron of the present invention is increased by 7-12%, the diameter of the inner end shaft journal is increased by 408%; the radius of the transition round angle at the connection place between the free end and the main shaft journal; the crank arms of the crankshaft made of ductile iron are symmetrically double lug shape extending to the outside from the left and the right, the maximum width of the double lug shape place is increased by 20-40% more than the maximum of corresponding part of same type forged steel crankshaft. The surface of the crankshaft made of ductile iron of the invention is processed with nitriding treatment by glow plasma; the increased transition round angle place, the main shaft journal and the connection rod journal are processed with rolling treatment. The life of the crankshaft made of ductile iron of the invention is equal to or higher than the life of the same type forged steel crankshaft.

Owner:TIANRUN IND TECH CO LTD

Self-leveling floor material and preparation method thereof

The invention discloses a self-leveling floor material which comprises the following components in parts by weight: 260-300 parts of cement, 70-100 parts of silica fume, 40-60 parts of fly ash, 30-50parts of stone powder, 430-490 parts of quartz sand, 7-12 parts of a toughening agent, 10-15 parts of a water reducing agent, 2-6 parts of a shrinkage reducing agent, 10-20 parts of a viscosity reducer and 40-70 parts of water. The invention also discloses a preparation method of the self-leveling floor material. The self-leveling floor material disclosed by the invention has excellent mechanicalproperties, durability, wear resistance, impermeability and impact resistance, and is excellent in apparent effect; the material can be suitable for a self-leveling construction process, and the construction process is simple; and raw materials are wide in source and low in manufacturing cost, and remarkable economic benefits and wide application prospects are achieved.

Owner:HUAXIN CEMENT +1

Welding process for prepressing stress bimetal centrifugal casting composite pipe end flange

ActiveCN107175421AReduce residual tensile stress after weldingIncrease compressive stressWelding apparatusWelding residual stressEngineering

The invention discloses a welding process for a prepressing stress bimetal centrifugal casting composite pipe end flange. The welding process comprises the following steps that a groove is formed in the welding face of the flange, and the flange is preheated evenly before welding and is heated to a certain temperature; then the flange is installed at the end of a bimetal centrifugal casting composite pipe, and the flange is fixed to the bimetal centrifugal casting composite pipe in a spot welding mode; and then the flange and the bimetal composite pipe are connected through circular welding. The flange welded by the welding process can form certain pressure stress on the composite pipe, thus the problem of interlaminar separation of the composite pipe due to welding residual stress after welding of the bimetal composite pipe end flange can be avoided effectively, and the reliability of a connector of the double-layer bimetal centrifugal casting composite pipe end flange is improved greatly.

Owner:WUHAN UNIV OF TECH

A Welding Process for the End Flange of a Prestressed Bimetallic Centrifugal Casting Composite Pipe

ActiveCN107175421BReduce residual tensile stress after weldingIncrease compressive stressWelding apparatusWelding residual stressPre stress

The invention discloses a welding process for a prepressing stress bimetal centrifugal casting composite pipe end flange. The welding process comprises the following steps that a groove is formed in the welding face of the flange, and the flange is preheated evenly before welding and is heated to a certain temperature; then the flange is installed at the end of a bimetal centrifugal casting composite pipe, and the flange is fixed to the bimetal centrifugal casting composite pipe in a spot welding mode; and then the flange and the bimetal composite pipe are connected through circular welding. The flange welded by the welding process can form certain pressure stress on the composite pipe, thus the problem of interlaminar separation of the composite pipe due to welding residual stress after welding of the bimetal composite pipe end flange can be avoided effectively, and the reliability of a connector of the double-layer bimetal centrifugal casting composite pipe end flange is improved greatly.

Owner:WUHAN UNIV OF TECH

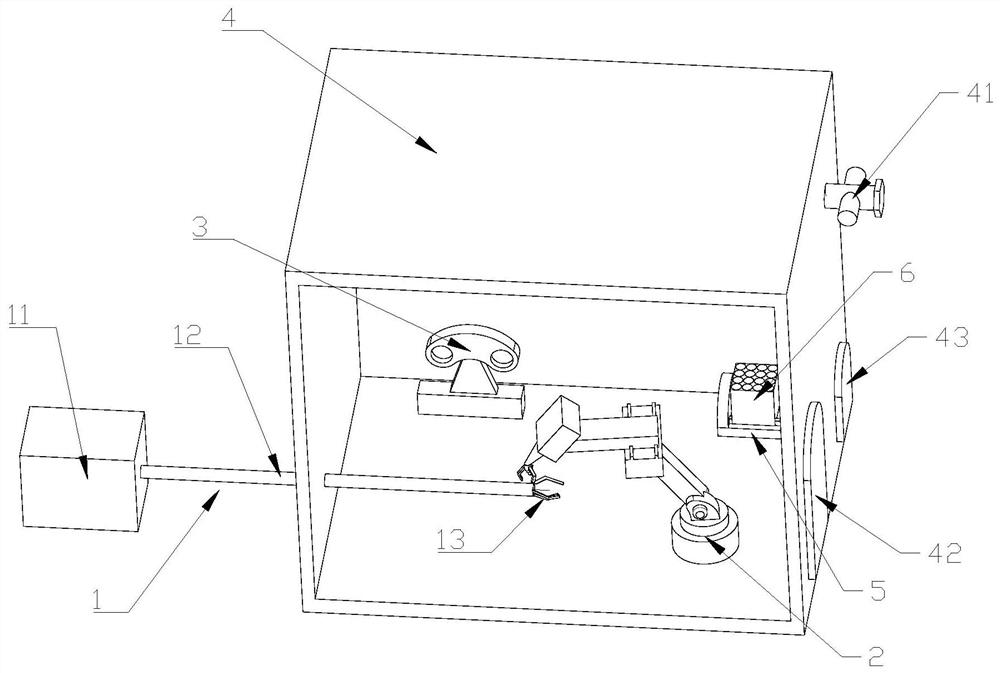

An automatic cladding equipment and method applied to the outer surface of the nozzle of an environmental protection container

ActiveCN109483014BImprove corrosion resistanceGuaranteed CorrosionArc welding apparatusWelding/cutting media/materialsRotational axisRobotic arm

The invention discloses an automatic deposition device and method applied to the outer surface of an environment-friendly container nozzle. The automatic deposition device comprises a welding box, a mechanical arm, a welding rod box and a rotating device; and through a controller, the mechanical arm can achieve rotating, pitching and telescopic operation to automatically clamp a welding rod, and is matched with a rotating shaft to conduct omnidirectional deposition on the outer surface of the nozzle. The welding box is ventilated through a three-way valve, thus the whole welding box is in theprotective atmosphere of inert gas, waste of the inert gas in the traditional welding deposition process can be reduced, and the phenomena of deposition metal oxidation and air holes caused by instability of inert airflow in the welding process can also be avoided; and through the automatic device, the outer surface of an environment-friendly container is evenly and fully covered with a nickel-based alloy 690, and a residual pressure stress layer is formed on the outer surface of the nozzle to improve the hardness and corrosion resistance of the outer surface of the environment-friendly container nozzle.

Owner:上海蜂云航空科技有限公司

A method for repairing and remanufacturing the surface of a locomotive buffer bar

ActiveCN109079421BGuaranteed stabilityReduce welding heat inputWelding apparatusSand blastingEngineering

A method for repairing and remanufacturing the surface of a buffer rod of a locomotive, the steps of which are as follows: S1, screening out repairable buffer rods to be repaired; S2, inspecting the wear amount of the buffer rod to be repaired, respectively in the shaft sections of the buffer rods with different radii, Determine the area to be repaired according to the size of the wear amount, and process the groove to be repaired in the area to be repaired; S3, perform sandblasting, cleaning and preheating treatment on the buffer bar to be repaired in sequence; S4, fix one end of the buffer bar to be repaired on the variable On the positioner, continuous annular welding is performed on the groove to be repaired by the CMT automatic welding system to complete the repair of the buffer bar to be repaired; S5, post-weld slow cooling treatment is performed on the repair buffer bar obtained in step S4; S6, the repair area of the repair buffer bar is Machined to original drawing size and then sandblasted as a whole. The method of the invention has low cost, high efficiency and high repairing quality, and the quality standard of new parts can be reached after repairing and remanufacturing through the method of the invention.

Owner:SOUTHWEST JIAOTONG UNIV

Inverted arch prefabricated assembly structure suitable for loess highway tunnel and construction method

PendingCN114320345AReduce settlementIncrease contact areaRoadwaysUnderground chambersPre stressArchitectural engineering

The invention relates to an inverted arch prefabricated assembly structure suitable for a loess highway tunnel and a construction method.The inverted arch prefabricated assembly structure comprises prefabricated inverted arch units, prestressed tendons are arranged at the tops of the prefabricated inverted arch units in a penetrating mode, and embedded steel plates used for being connected with grouting steel pipe piles are arranged at the bottoms of the prefabricated inverted arch units; each prefabricated inverted arch unit comprises a plurality of prefabricated blocks which are spliced and connected, and the outer ends of the two prefabricated blocks on the outermost side extend to form arch foot parts; the construction method comprises the steps of excavating the loess tunnel, carrying out splicing construction on the inverted arch prefabricated splicing structure, installing the prestressed tendons, tensioning and fixing the prestressed tendons, pouring the inverted arch filling layer and laying the plastic concrete buffer layer. Compared with the prior art, the method has the advantages that differential settlement of the arch springing relative to the middle of the inverted arch can be effectively reduced, and the like.

Owner:甘肃二车高等级公路项目管理有限公司 +2

A high-strength daily-use ceramic prestressed coating material and its preparation method and ceramic product

The invention discloses a high-strength domestic ceramic prestressed coating material. The high-strength domestic ceramic prestressed coating material consists of a base material and an adhesive solution under the condition that the ratio of the base material to the adhesive solution equals to 1 g: 4-8 mL; the base material comprises the following raw material components: 10-20 wt% of Al2O3, 45-70wt% of SiO2, 12-28 wt% of MgO and 2-10 wt% of ZnO; and the adhesive solution is a solution of one or more of CMC, PVA, PVB or water glass, and the concentration of the adhesive solution is 5-10 wt%.The invention further discloses a preparation method and a ceramic product of the high-strength domestic ceramic prestressed coating material. A surface coating mode is adopted, by adjusting and optimizing the ratio of the coating raw materials, pressure stress is introduced on the surface of a ceramic blank by coated layer coating treatment, and therefore, the integral strength of ceramics is improved remarkably. Raw materials are toxic-free and pollution-free, the process is simple and practicable, and industrialized application and popularization are facilitated.

Owner:JINGDEZHEN CERAMIC UNIV

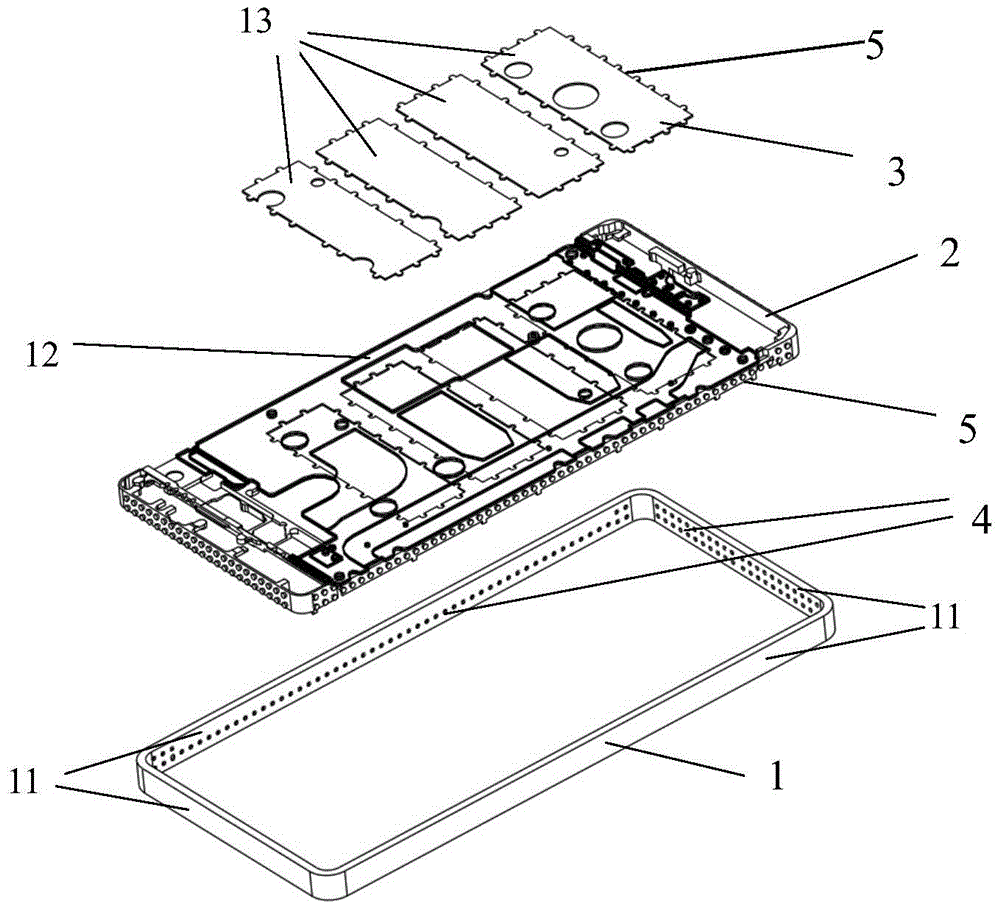

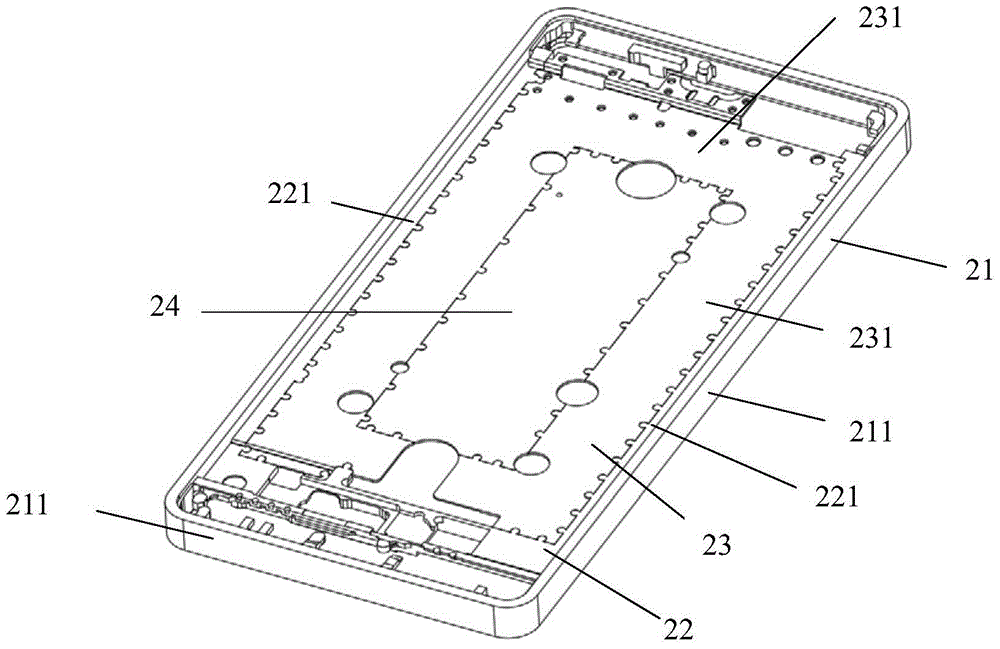

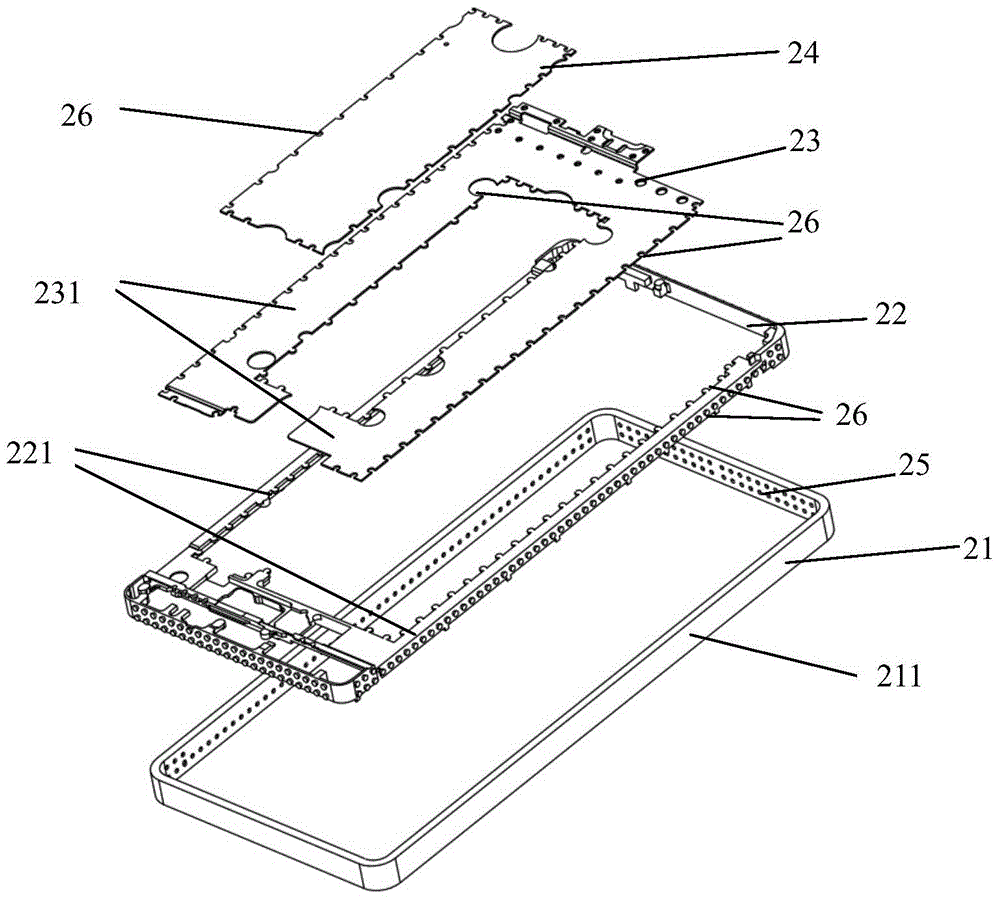

Appearance structural part applied to intelligent terminal products and manufacturing method thereof

InactiveCN104842603BReduce cooling shrinkageReduce deformation stressLamination ancillary operationsLaminationPressure castingFailure risk

Owner:深圳市华欣永业科技有限公司 +1

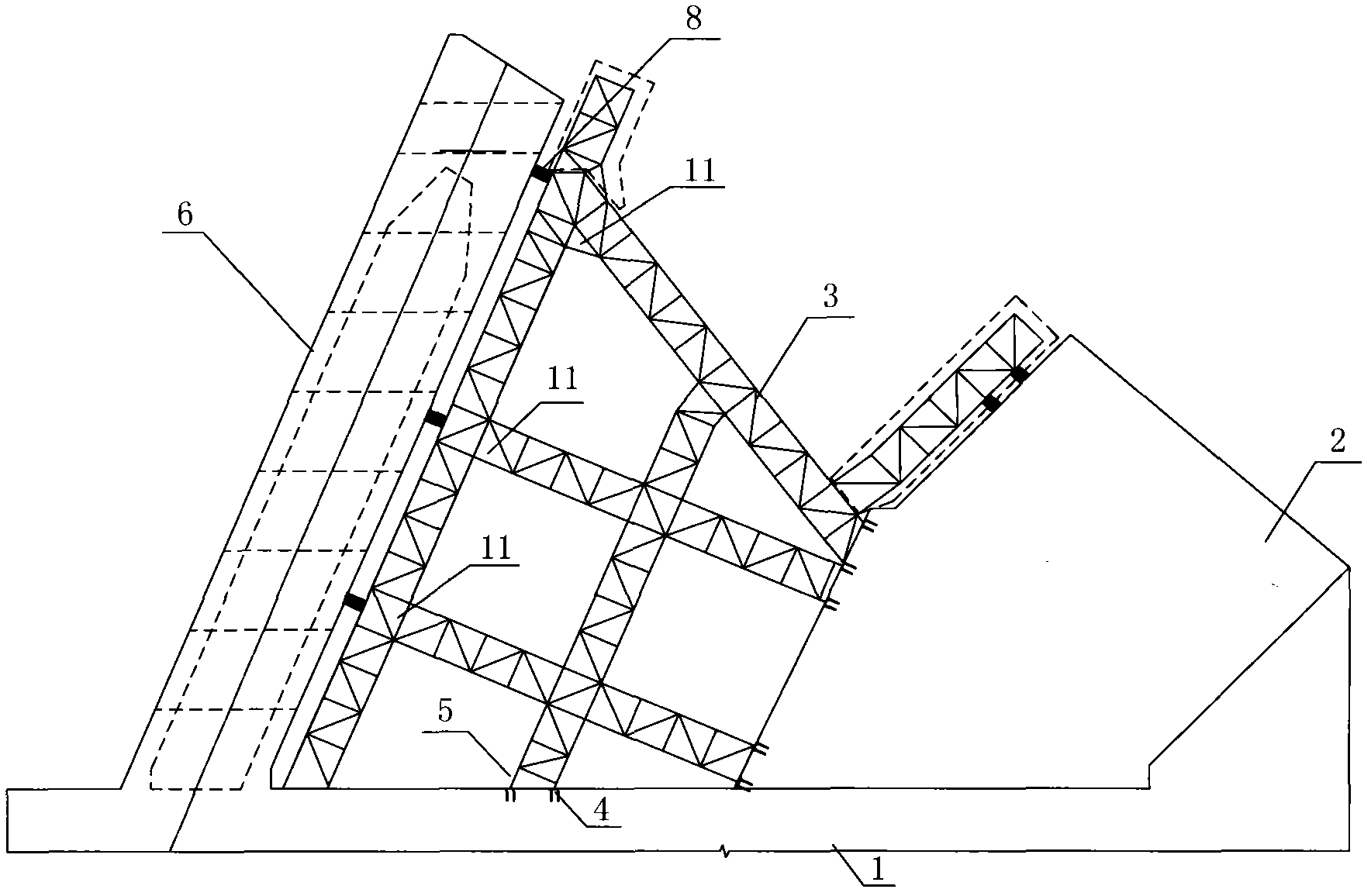

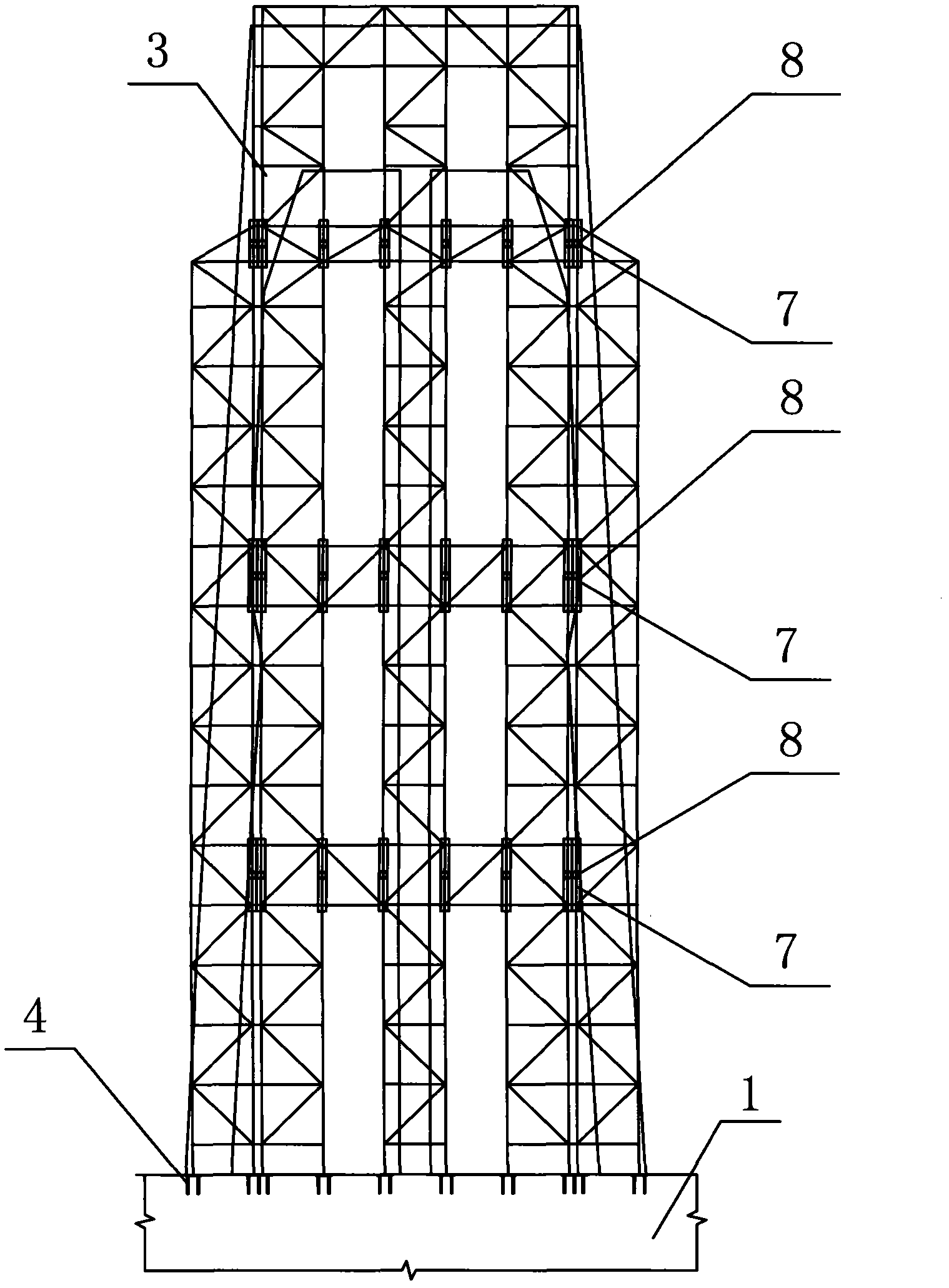

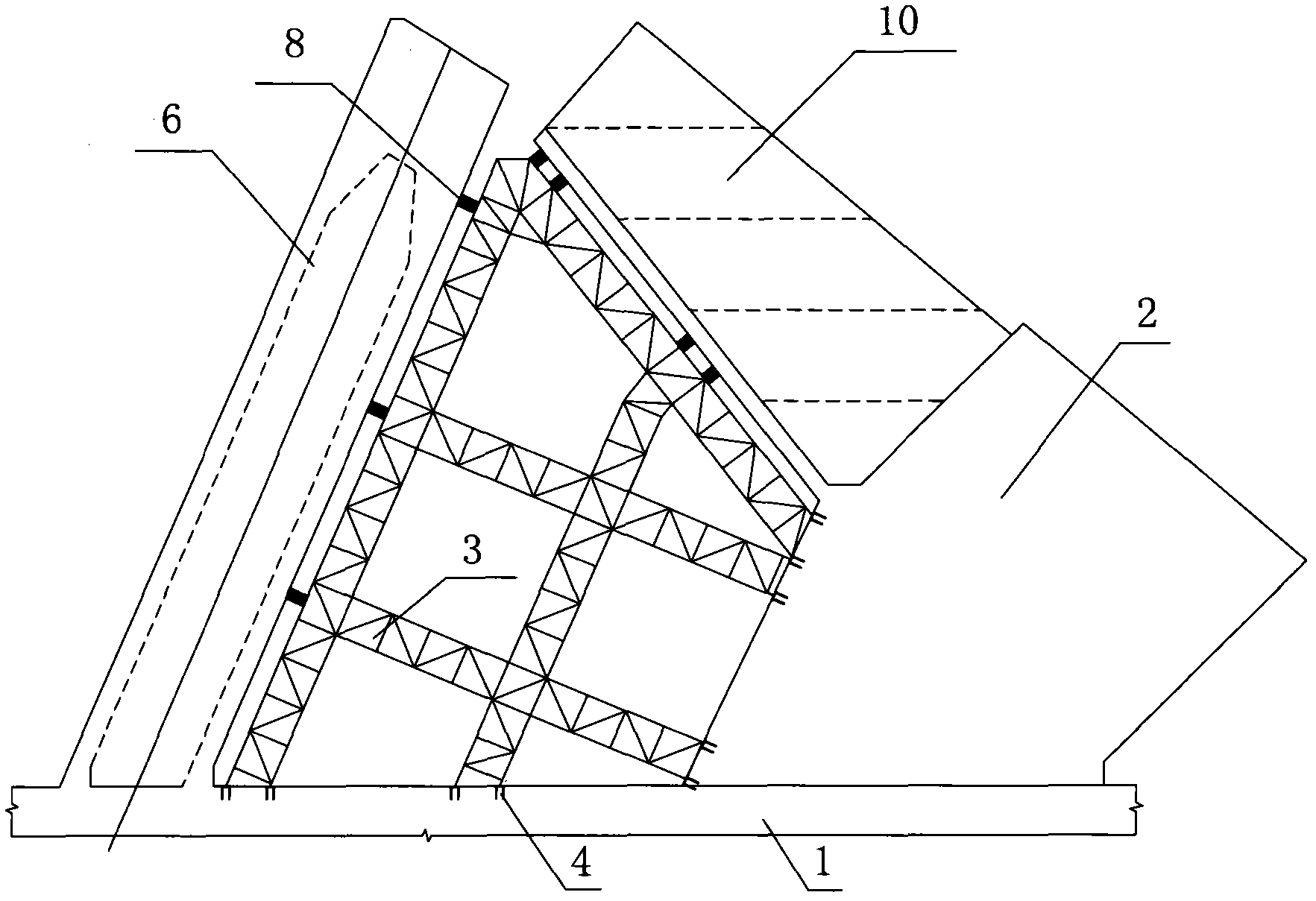

Control method for actively overcoming dead weight and line shape of vice cable saddle buttress concrete

ActiveCN102425115BControl construction qualityClear forceBridge structural detailsBridge erection/assemblyFalseworkButtress

Owner:中铁大桥局第七工程有限公司

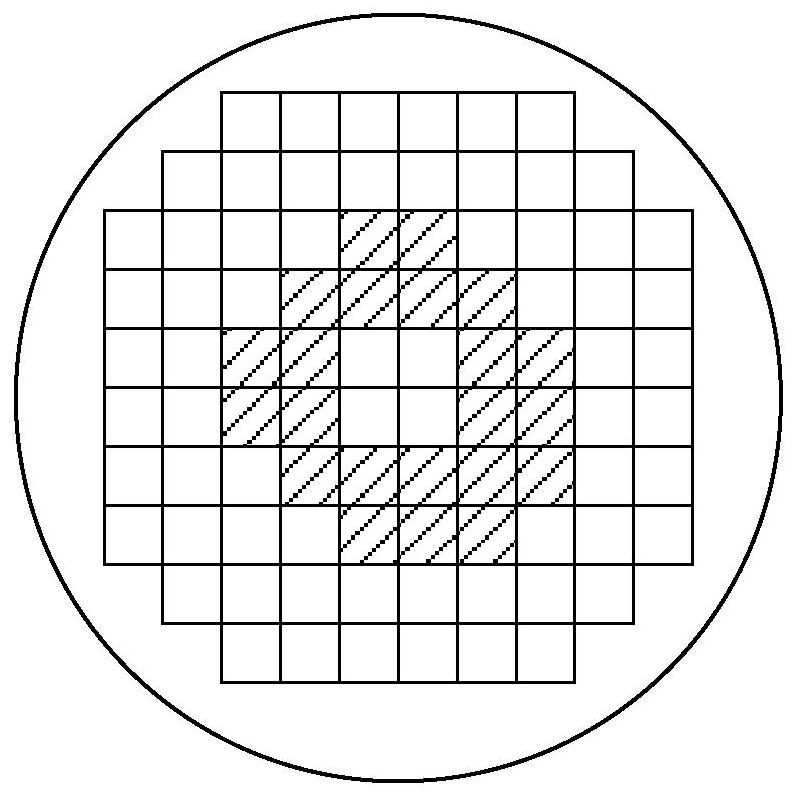

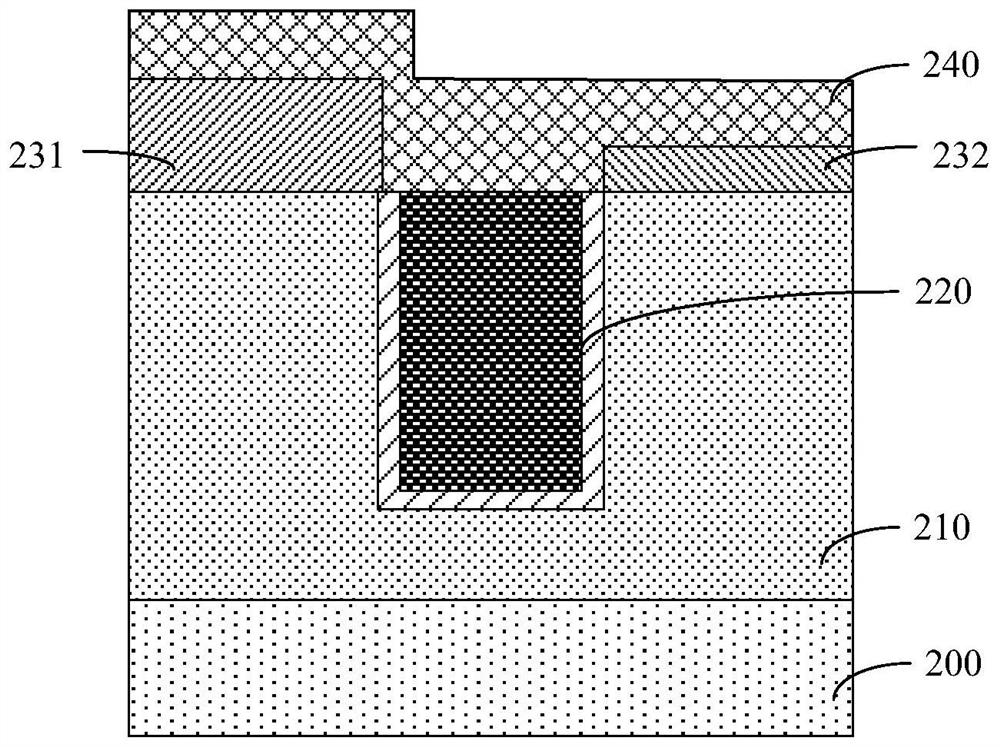

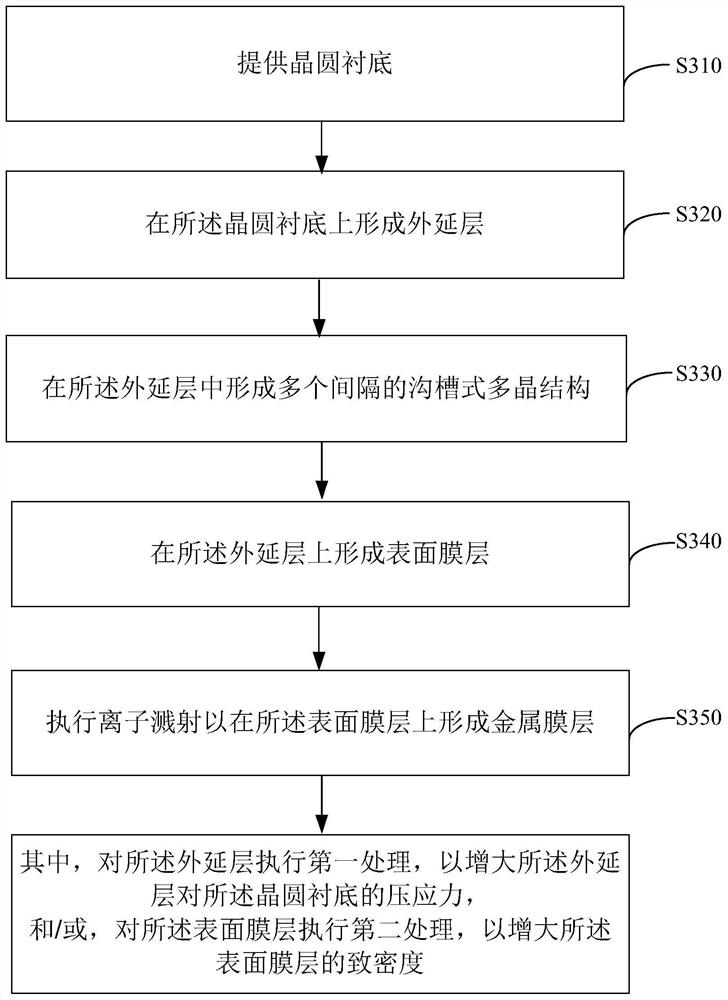

Manufacturing method of trench metal oxide semiconductor barrier Schottky diode device

PendingCN113903662AIncrease compressive stressHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingWaferPhysical chemistry

The invention discloses a manufacturing method of a trench metal oxide semiconductor barrier Schottky diode device. The method comprises the following steps: providing a wafer substrate; forming an epitaxial layer on the wafer substrate; forming a plurality of groove type polycrystalline structures at intervals in the epitaxial layer; forming a surface film layer on the epitaxial layer; performing ion sputtering to form a metal film layer on the surface film layer, wherein first processing is performed on the epitaxial layer so as to increase the pressure stress of the epitaxial layer on the wafer substrate, and / or second processing is performed on the surface film layer so as to increase the density of the surface film layer. According to the method provided by the invention, by increasing the pressure stress of the epitaxial layer on the wafer substrate and / or increasing the density of the surface film layer, the tensile stress generated by forming the metal film layer through subsequent sputtering is counteracted and / or the stress strain resistance of the wafer is enhanced, the buckling deformation of the wafer is avoided, and the flatness of the wafer is improved.

Owner:CSMC TECH FAB2 CO LTD

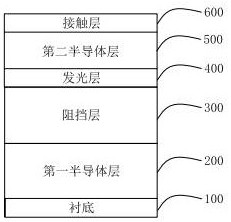

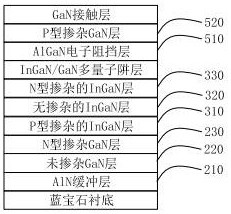

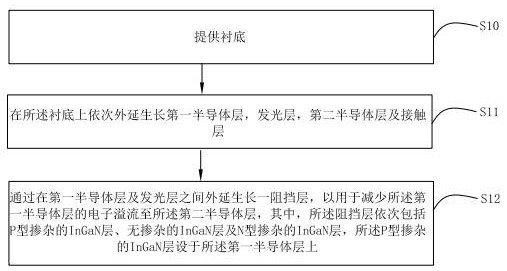

A kind of light-emitting diode and its preparation method

ActiveCN114284409BImprove luminous efficiencySolve the technical problems of luminous efficiencySemiconductor devicesElectron holeQuantum well

The invention discloses a light-emitting diode and a preparation method thereof, and relates to the technical field of light-emitting diodes. The light-emitting diode comprises: a substrate; a first semiconductor layer, a light-emitting layer, a second semiconductor layer and a contact layer sequentially arranged on the substrate; The barrier layer arranged between the first semiconductor layer and the light-emitting layer is used to reduce the overflow of electrons from the first semiconductor layer to the second semiconductor layer. The barrier layer sequentially includes a P-type doped InGaN layer, an undoped InGaN layer layer and an N-type doped InGaN layer, and a P-type doped InGaN layer is arranged on the first semiconductor layer. The invention can solve the technical problem in the prior art that the electron-hole wave function overlap rate in the quantum well is low, which affects the luminous efficiency of the light-emitting diode.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com