Preparation method of reinforced ceramic three-dimensional constraint coating

A three-dimensional, coating technology, applied in coating, metal material coating process, melt spraying and other directions, can solve problems such as insufficient rigidity constraints, ceramic micro-cracks, broken, etc., to increase the crack expansion area and prevent crack expansion. , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] B 4 Surface C is sandblasted, the blasting pressure is 0.5MPa, the sand grain is brown corundum, and the grain size is 60 mesh. The blasting distance is 25cm, the blasting angle is 60°, and the blasting time is 5s. After sandblasting, the surface of the ceramics is cleaned with compressed air and the surface is cleaned with ultrasonic, and then dried with a hair dryer. Weigh 250g of Ti powder, place it in a blast drying oven at 120°C for 2h, take it out, and wait for spraying. The plasma spraying process parameters are: spraying current is 500A, spraying voltage is 70V, spraying distance is 100mm.

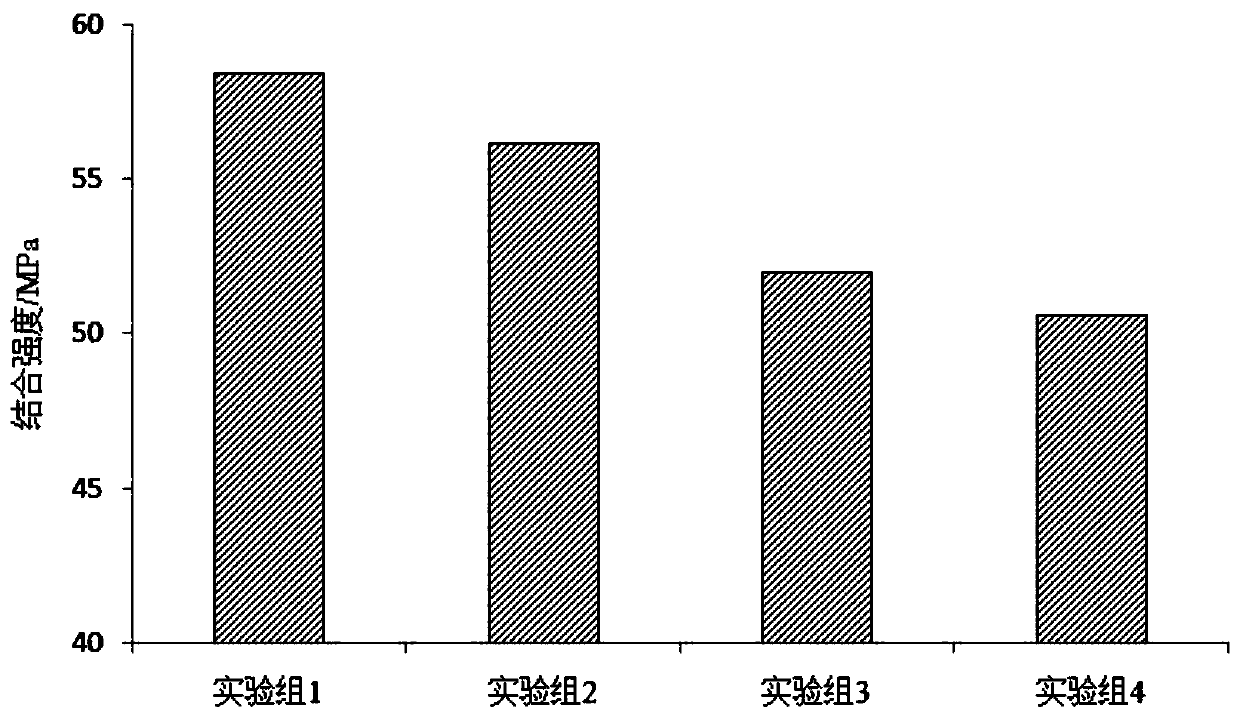

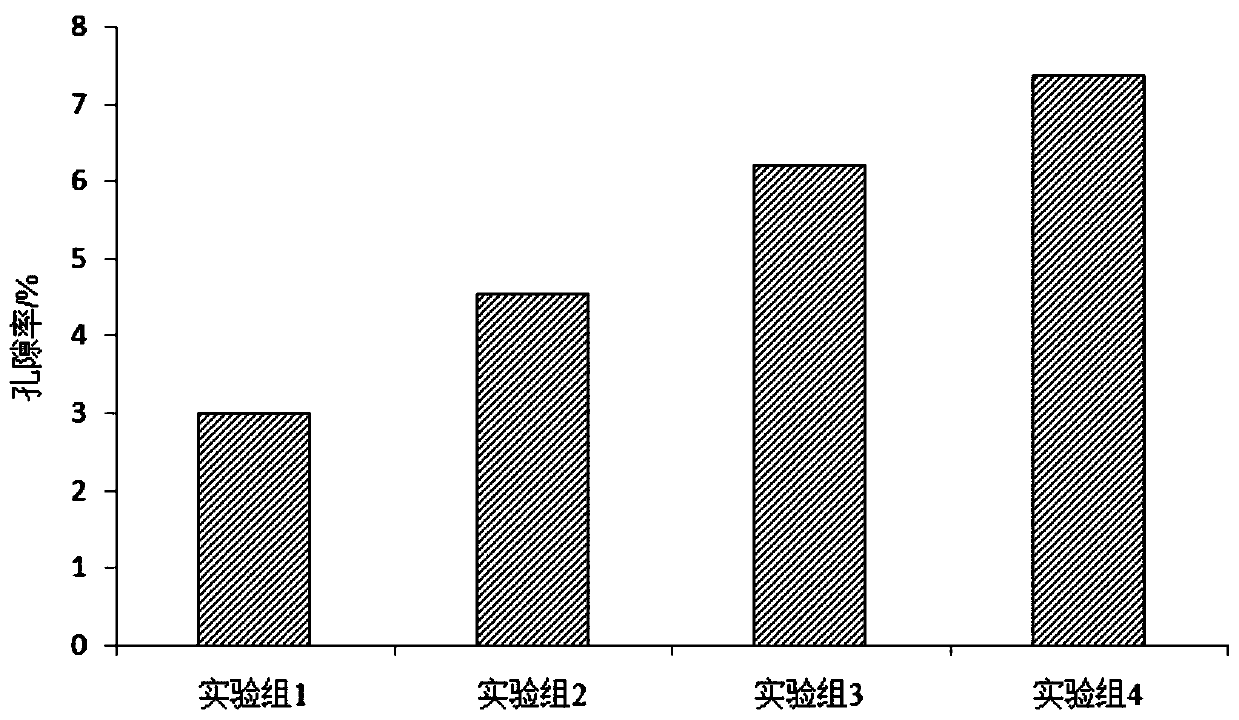

[0045] The preparation method of this embodiment is used to study the influence of the powder particle size of the spraying raw materials on the bonding strength and porosity of the coating, and Ti powder is divided into 4 groups according to the particle size, as shown in Table 1.

[0046] Table 1 Ti powder particle size

[0047] Group Particle size / μm Experimental group ...

Embodiment 2

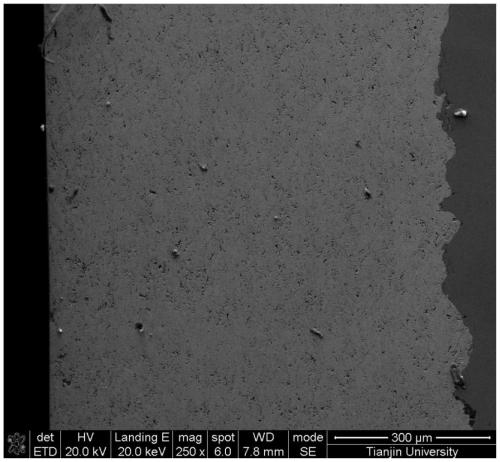

[0050] Al 2 O 3 The surface is sandblasted, the blasting pressure is 0.6MPa, the sand grain is brown corundum, and the grain size is 70 mesh. The blasting distance is 20cm, the blasting angle is 90°, and the blasting time is 8s. After sandblasting, the surface of the ceramics is cleaned with compressed air and the surface is cleaned with ultrasonic, and then dried with a hair dryer. Weigh 250g of AT40 powder, put it in a blast drying oven at 120°C for 2h, take it out, and wait for spraying. The plasma spraying process parameters are: spraying current is 500A, spraying voltage is 65V, spraying distance is 100mm. Such as image 3 As shown, the scanning electron microscope image of the sprayed product at 300μm.

Embodiment 3

[0052] The SiC surface is sandblasted, the blasting pressure is 0.5MPa, the sand grain is brown corundum, and the grain size is 80 mesh. The blasting distance is 30cm, the blasting angle is 45°, and the blasting time is 10s. After sandblasting, the surface of the ceramics is cleaned with compressed air and the surface is cleaned with ultrasonic, and then dried with a hair dryer. Weigh 250g of WC-Co powder, put it in a blast drying oven at 120°C for 2h, take it out, and wait for spraying. The process parameters of supersonic flame spraying are: gas (C 2 H 2 ) The flow rate is 25L / min, the oxygen flow rate is 200L / min, and the spraying distance is 270mm. Such as Figure 4 As shown, the scanning electron microscope image of the sprayed product under 100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com