Gradient composite cubic boron nitride material and preparation technology and application thereof

A cubic boron nitride, gradient technology, used in other manufacturing equipment/tools, turbines, engine components, etc., can solve problems such as unsatisfactory overall performance, reduce residual tensile stress, improve toughness and wear resistance, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

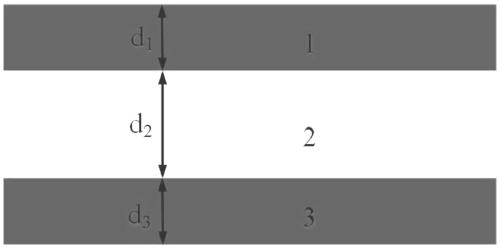

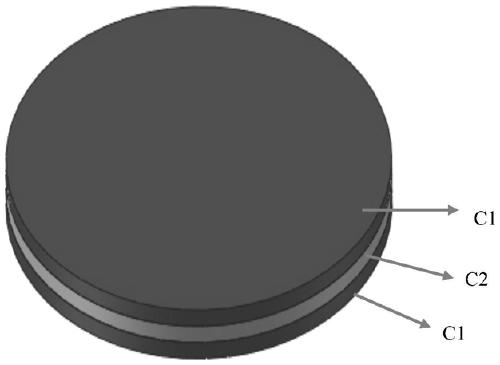

[0034] The gradient cubic boron nitride tool material of the present invention has a 3-layer symmetrical gradient structure (such as figure 2 shown) as an example, the present invention provides some embodiments, the volume percentage of each component raw material is: CBN 70-80vol.%, TiC10vol.%, Al 5-10vol.% and Co 5-10vol.%. The layer thickness ratio is selected as 0.2-0.6, and the composition gradient between layers is 2vol.%-10vol.%. For example, the gradient of cubic boron nitride is 4vol.%-10vol.%, and the gradient of aluminum and cobalt is 2vol.%- 5vol.%. The powder is loaded into the molybdenum cup by layering and filling, and the cubic boron nitride tool material is synthesized by high temperature and high pressure. The specific preparation methods include:

[0035] Put TiC, Al and Co into ball mill jars respectively, with cemented carbide balls as grinding balls and absolute ethanol as medium, the mass ratio of grinding balls to powder is 20:1, and the ball millin...

Embodiment 1

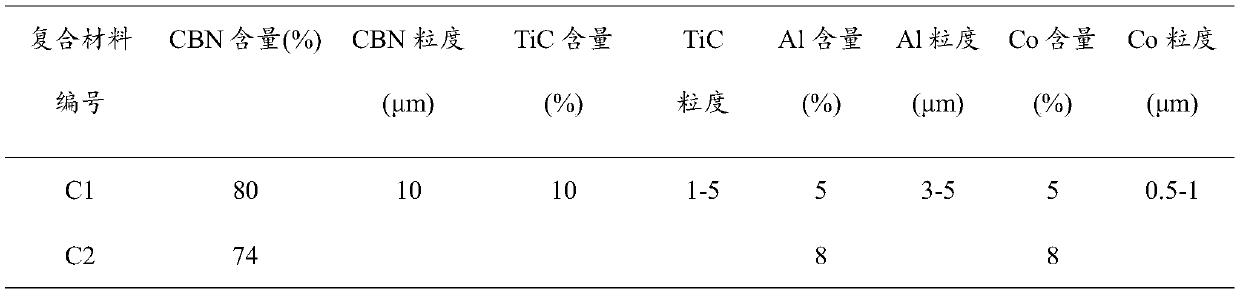

[0037] Prepare a gradient cubic boron nitride cutter with a layer thickness ratio of 0.3, a number of layers of 3, an interlayer CBN composition gradient of 6vol.%, and an Al and Co composition gradient of 3vol.%. The ingredients are shown in Table 1, given The volume percentage (vol.%) of the components of the C1 (surface layer) and C2 (middle layer) two groups of mixed powders is shown.

[0038] Table 1

[0039]

[0040] Put TiC, Al and Co into ball mill jars respectively, with cemented carbide balls as grinding balls and absolute ethanol as medium, the mass ratio of grinding balls to powder is 20:1, and the ball milling time is 48h; The suspension is dried in a vacuum drying oven at 110°C, passed through a 200-mesh sieve after drying, and packaged for later use; mix all the powders according to the volume ratio, pass the quality control layer thickness, and put the weighed powder into the molybdenum cup layer by layer According to the order of C1 / C2 / C1, each layer of po...

Embodiment 2

[0042] Prepare a gradient cubic boron nitride tool with a layer thickness ratio of 0.3, a number of layers of 3, an interlayer CBN composition gradient of 4vol.%, and an Al and Co composition gradient of 2vol.%. The ingredients are shown in Table 2, given The volume percentage (vol.%) of the three groups of mixed powders of C1 (surface layer) and C3 (middle layer) are shown

[0043] Table 2

[0044]

[0045] Put TiC, Al and Co into ball mill jars respectively, with cemented carbide balls as grinding balls and absolute ethanol as medium, the mass ratio of grinding balls to powder is 20:1, and the ball milling time is 48h; The suspension is dried in a vacuum drying oven at 110°C, passed through a 200-mesh sieve after drying, and packaged for later use; mix all the powders according to the volume ratio, pass the quality control layer thickness, and put the weighed powder into the molybdenum cup layer by layer According to the order of C1 / C3 / C1, each layer of powder needs to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com