High-strength domestic ceramic prestressed coating material and preparation method and ceramic product thereof

A technology for coating materials and ceramic products, which is applied in the field of ceramic products, can solve problems such as difficult popularization and application, and achieve the effects of simple and easy process, easy industrial application and promotion, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

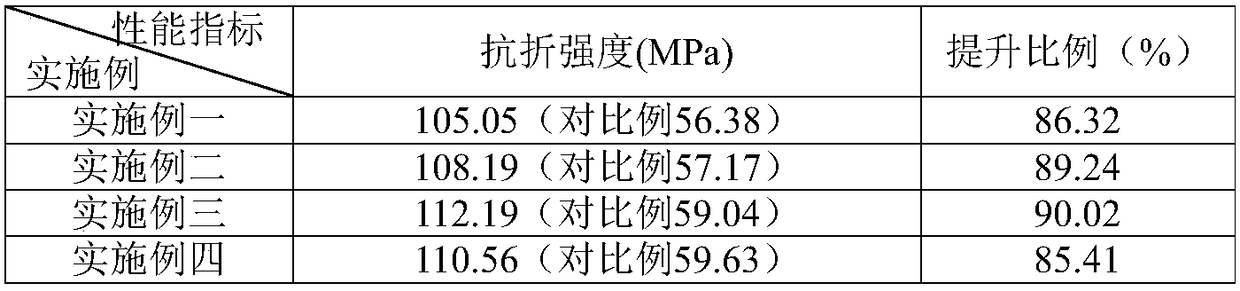

Embodiment 1

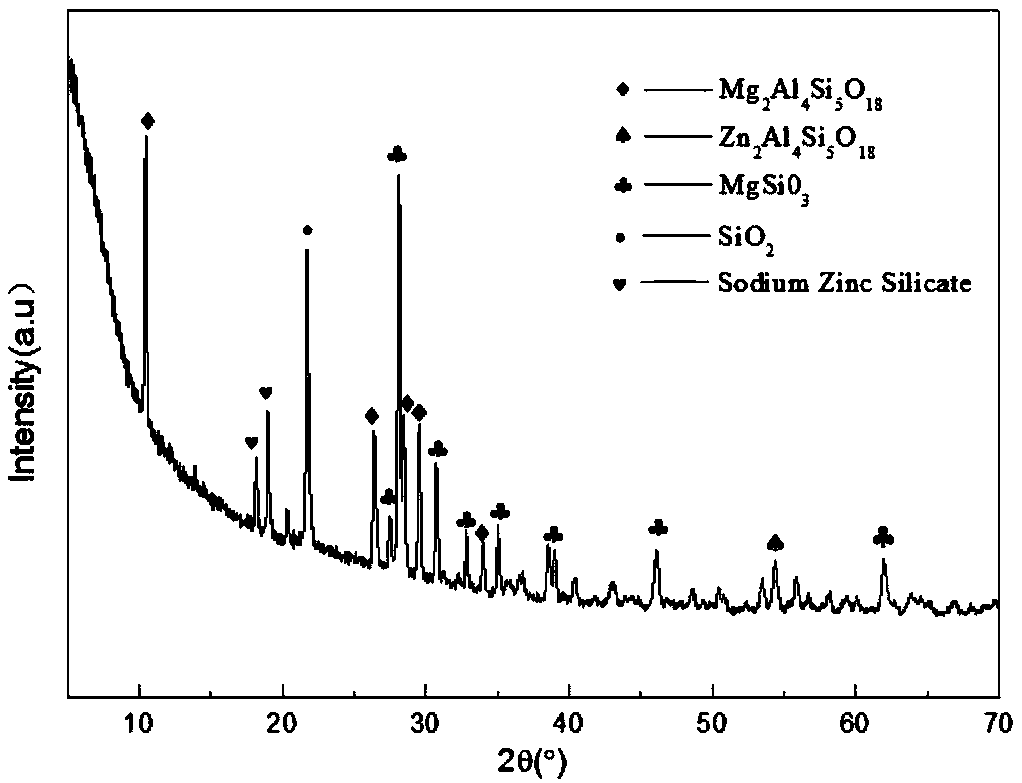

[0029] 1, a kind of high-strength daily-use ceramic prestressed coating material of the present embodiment is made up of base material and binder solution according to base material: binder solution=1g: 5mL; Wherein, the raw material of base material is composed of Al 2 o 3 16wt%, SiO 2 58wt%, MgO2 2wt%, ZnO 4wt%; the binder solution is an absolute ethanol solution of PVB, and its concentration is 5wt%.

[0030] 2, the preparation method of above-mentioned high-strength daily-use ceramic prestressed coating material, its step is as follows:

[0031] (1) Preparation of base material

[0032] According to the composition and ingredients of the above raw materials, after wet ball milling for 30 minutes, passing through a 200-mesh sieve and drying, calcining at a temperature of 1150°C, the heating rate is 4°C / min, and the holding time is 0.5h. After cooling, it is crushed and passed through a 250-mesh sieve, that is get base material;

[0033] (2) Preparation of binder solut...

Embodiment 2

[0042] The differences between this embodiment and Embodiment 1 are:

[0043] 1. The coating material of this embodiment is composed of base material and binder solution according to base material: binder solution=1g: 6mL; wherein, the raw material of base material is composed of Al 2 o 3 12.5wt%, SiO 2 62.5wt%, MgO 21wt%, ZnO 4wt%; the binder solution is a deionized aqueous solution of PVA.

[0044] 2. In the preparation method of the coating material in this embodiment, the calcination temperature in step (1) is 1180°C, the heating rate is 5°C / min, and the holding time is 1h; the softening treatment time in step (2) is 10h.

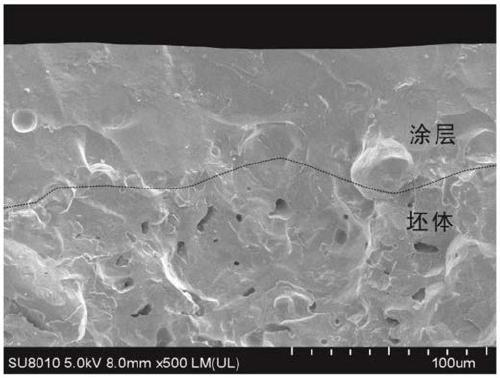

[0045] 3. In this embodiment, a high-strength daily-use ceramic product is prepared. The coating thickness is 200 μm; the sintering temperature is 1280° C., and the holding time is 2.5 hours.

Embodiment 3

[0047] The differences between this embodiment and Embodiment 1 are:

[0048] 1. The coating material of this embodiment is composed of base material and binder solution according to base material: binder solution=1g: 7mL; wherein, the raw material of base material is composed of Al 2 o 3 16wt%, SiO 2 60wt%, MgO 20wt%, ZnO 4wt%; the binder solution is a deionized water solution of PVA.

[0049]2. In the preparation method of the coating material in this embodiment, the calcination temperature in step (1) is 1190°C, the heating rate is 3°C / min, and the holding time is 1.5h; the softening treatment time in step (2) is 11h.

[0050] 3. In this embodiment, a high-strength daily-use ceramic product is prepared. The coating thickness is 280 μm; the sintering temperature is 1300° C., the heating rate is 4° C. / min, and the holding time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com