Control method for actively overcoming dead weight and line shape of vice cable saddle buttress concrete

A technology of linear control and scattered cable saddles, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as the deviation of scattered cable saddle piers from the design position, affecting construction quality and construction safety, and the difficulty of linearity to meet design requirements. , to achieve the effect of controlling construction quality, saving investment and pier structure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The method for actively overcoming the self-weight and line shape control of the sling saddle pier concrete provided by the embodiment of the present invention includes the following steps:

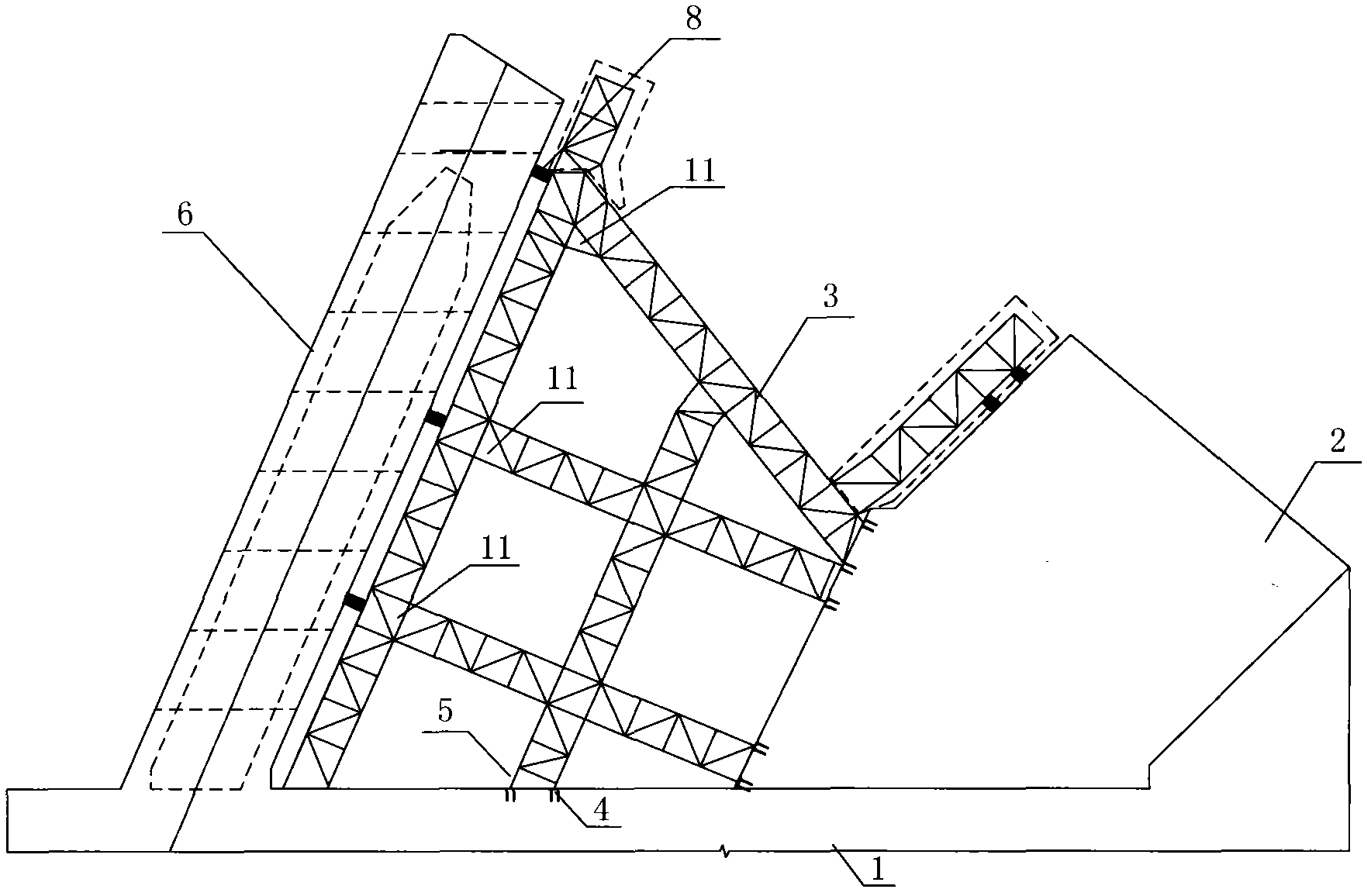

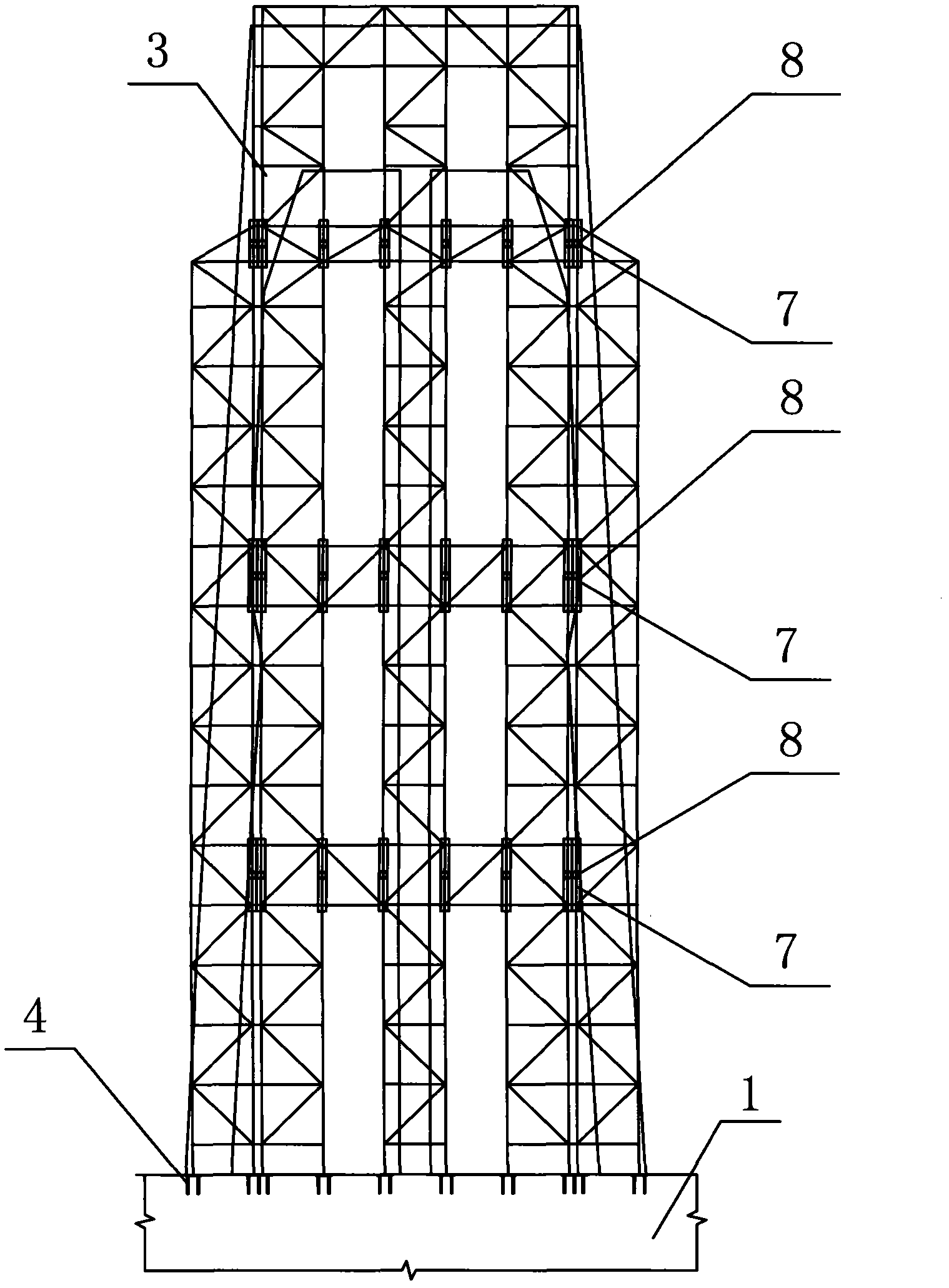

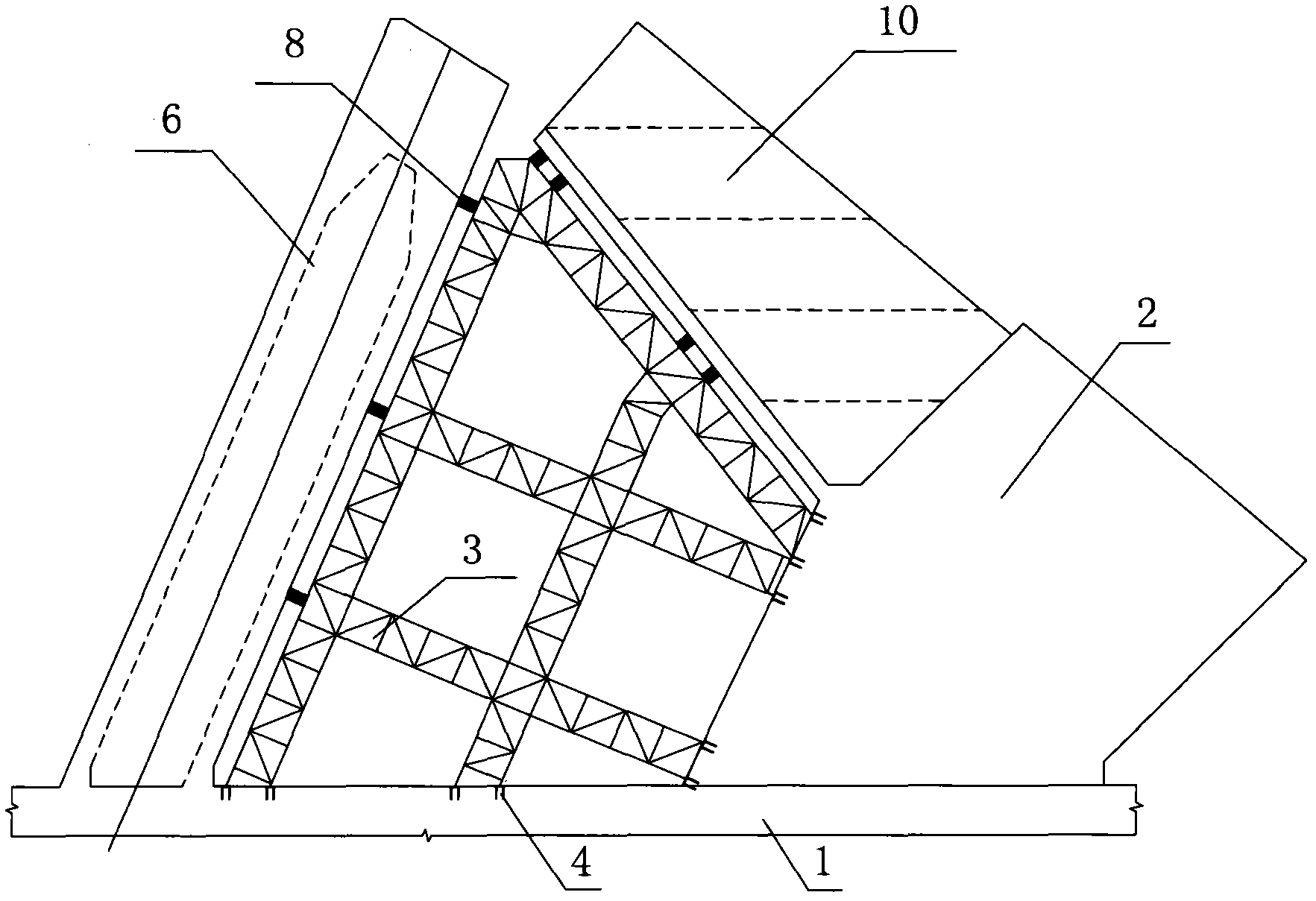

[0018] A. see figure 1 As shown in Fig. 1, after the construction of the large-volume concrete of the foundation 1 of the loose-cable saddle pier is completed, the concrete of the rear anchor block 2 is poured. The embedded part 4 of the frame 3. When initially assembling the bearing frame 3, the column foot 5 of the bearing frame 3 is spot welded with the embedded part 4 for positioning welding. After the positioning of the bearing frame 3 is completed, the column foot 5 and the embedded part 4 are welded according to the drawing requirements firm. The load-bearing frame 3 is then assembled in sections, and the load-bearing frame 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com