Pre-casting construction method for tunnel groove cover plate

A construction method and a technology of cover plates, which are applied in the direction of manufacturing tools and ceramic molding machines, etc., can solve the problems of insufficient tamping, easy damage, damage or deformation of corner parts, etc., so as to reduce the occupied area and ensure the construction quality , The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

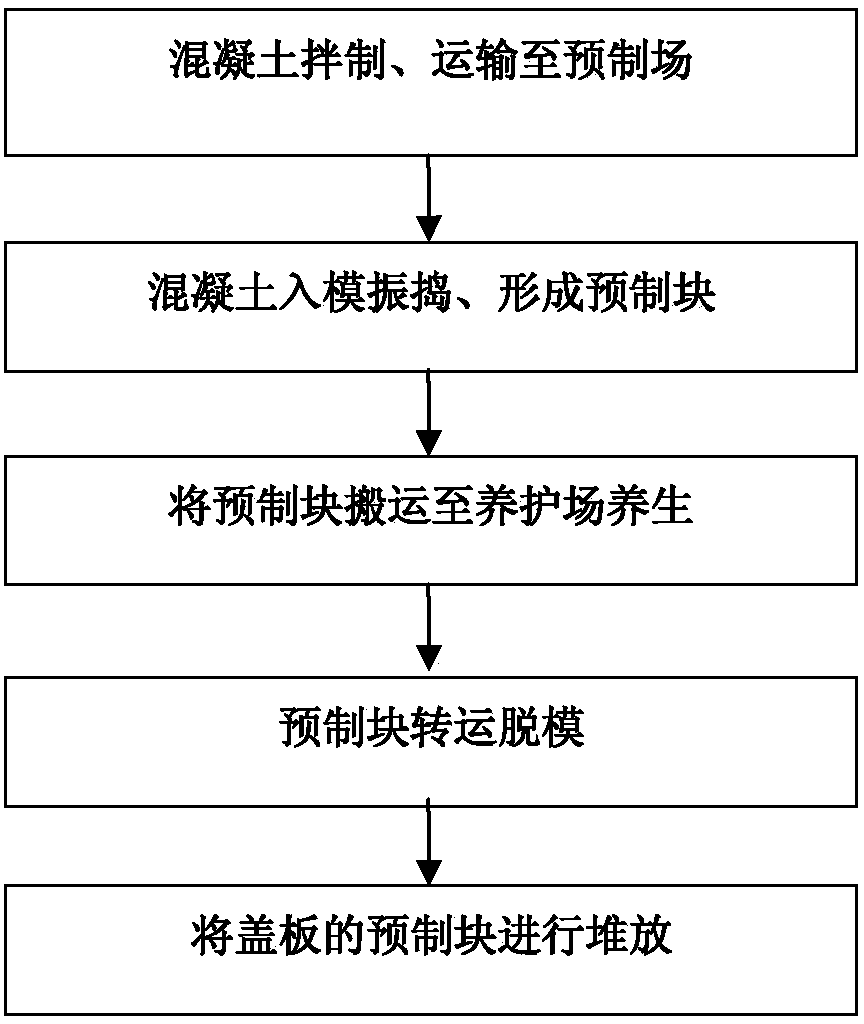

[0031] Such as figure 1 As shown, a prefabricated construction method of a tunnel trench cover plate in this embodiment includes the following steps:

[0032] a. Concrete mixing and transportation to the precast yard: Concrete is uniformly mixed at the mixing station located closest to the precast yard for the construction of the main line of the railway. After the mixing is completed, it is transported to the precast yard by concrete tanker;

[0033] In the above step a, a storage tank is provided in the prefabrication yard. After the concrete tank truck is transported to the preca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com