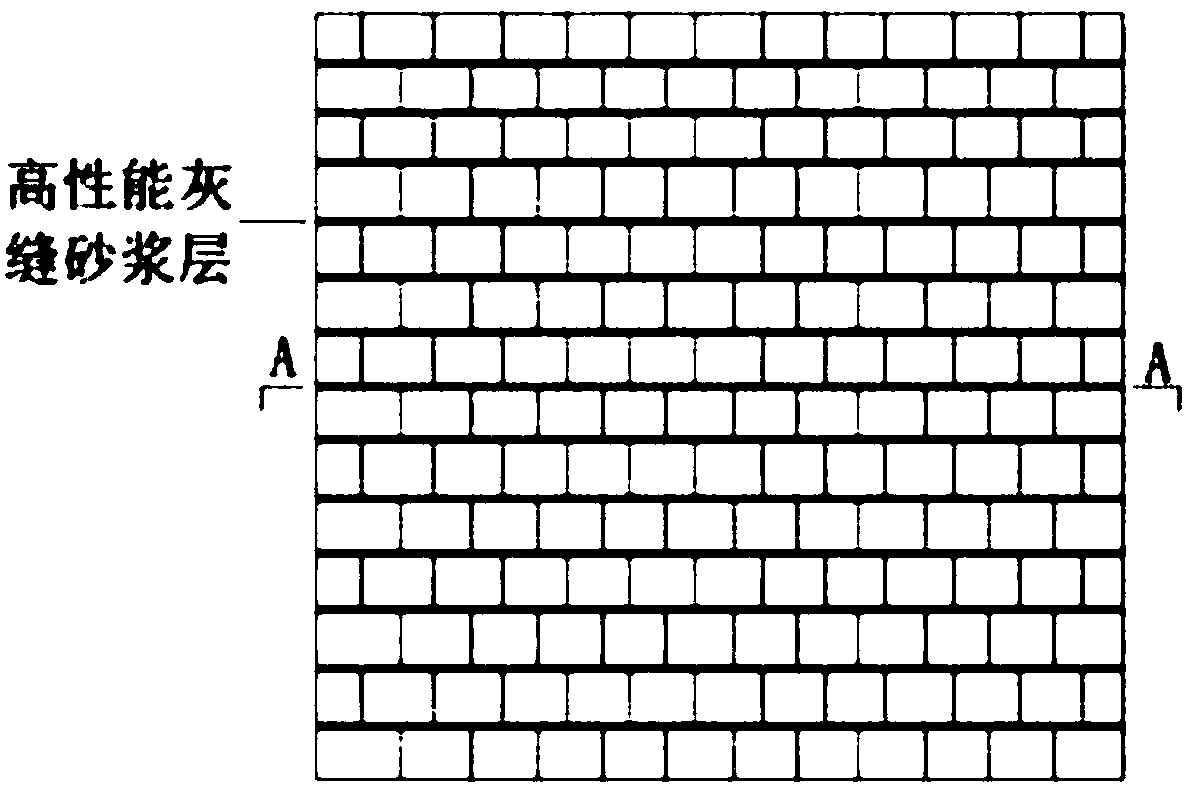

Construction method for high-ductility masonry wall with reinforced mortar-joint mortar layer

A construction method and mortar layer technology are applied in the construction field of high ductility masonry walls, which can solve the problems of high compressive strength, poor seismic performance, low tensile and shear strength, etc., and achieve increased shear performance and improved seismic resistance. performance, the effect of increasing shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: technical scheme of the present invention comprises the following steps:

[0021] 1) Moisten the blocks used for masonry walls in advance to avoid shrinkage cracks in the mortar layer of mortar joints caused by the blocks absorbing water;

[0022] In step 1), the blocks include: sintered ordinary bricks, sintered hollow bricks, sintered porous bricks, autoclaved lime-sand bricks, autoclaved fly ash bricks or concrete hollow bricks.

[0023] 2) In the process of building a masonry wall, according to the cross-sectional size of the wall, smear 3-5mm thick high-performance mortar on the first skin block along the cross-section of the wall;

[0024] In step 2), the production process of high-performance mortar joints: select 52.5 Portland cement, first mix 52.5 Portland cement, Class I fly ash, silica fume and silica sand with a mixer for 2 to 3 minutes according to the mass ratio, After stirring evenly, add water and stir, then add Sika third-generation wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com