Engine ductile iron crankshaft

A nodular cast iron, engine technology, applied in the direction of the crankshaft, etc., can solve the problems of fatigue resistance and low bending resistance, and achieve the effect of enhancing the bending fatigue resistance and improving the fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The cast iron is smelted in an induction furnace, and the chemical composition of the cast iron is as follows after being spheroidized with rare earth magnesium with Re:Mg>1:

[0025] C: 3.91%, Si: 2.3%, Mn: 0.48%, P: 0.03%, S: 2%, Cu: 0.55%.

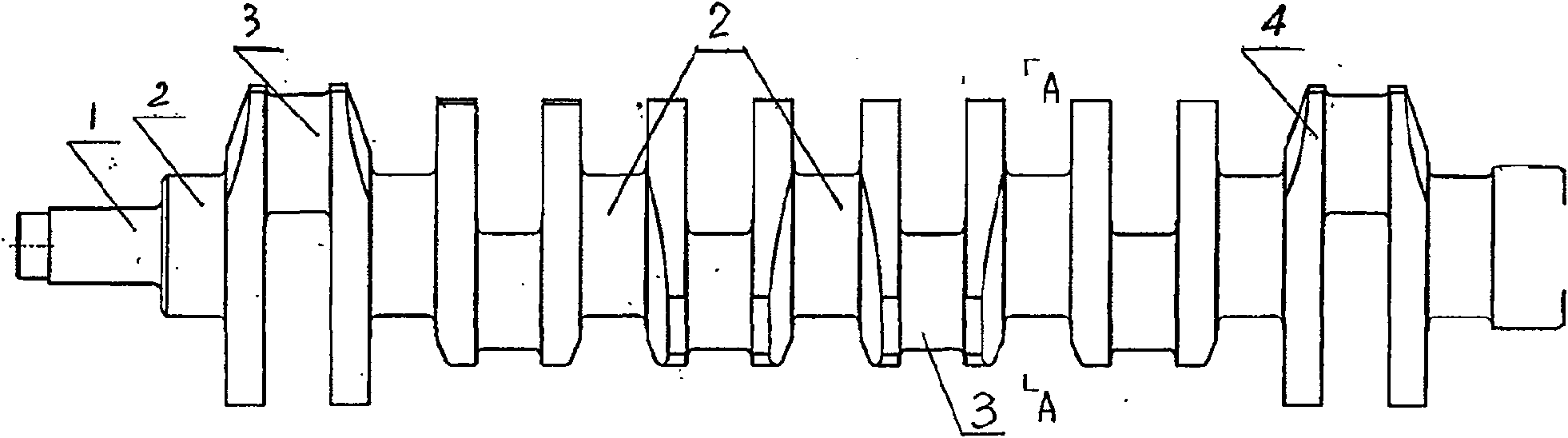

[0026] The nodular cast iron treated above was cast into a WD615 crankshaft blank, the spheroidization level was 2, the ball diameter was 6, and the pearlite content was 91%.

[0027] After the above blank is machined, it is normalized in stages: heat preservation at 910-920°C for 30 minutes; furnace cooling to 820°C, heat preservation for 1 hour; air cooling after coming out of the furnace.

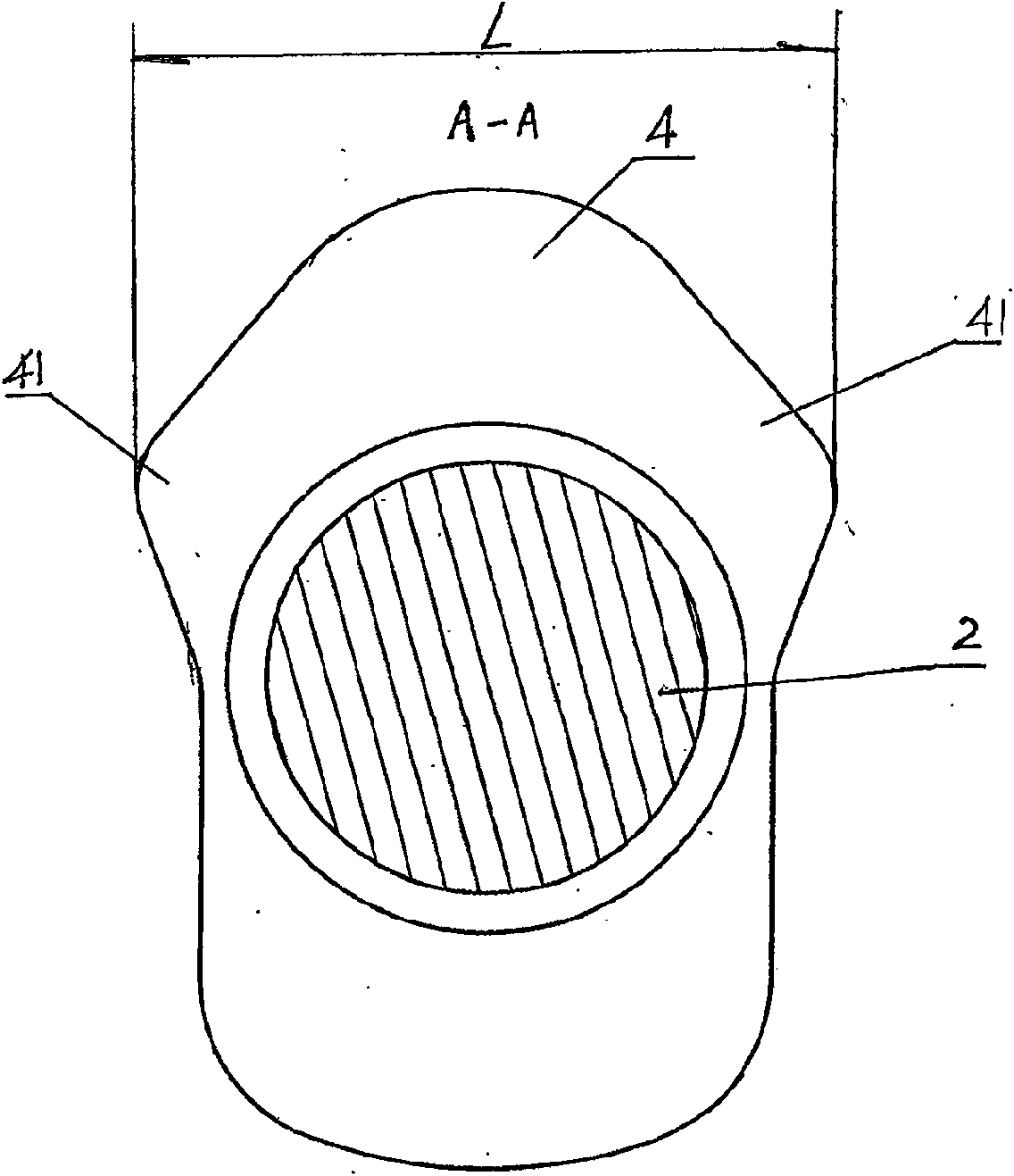

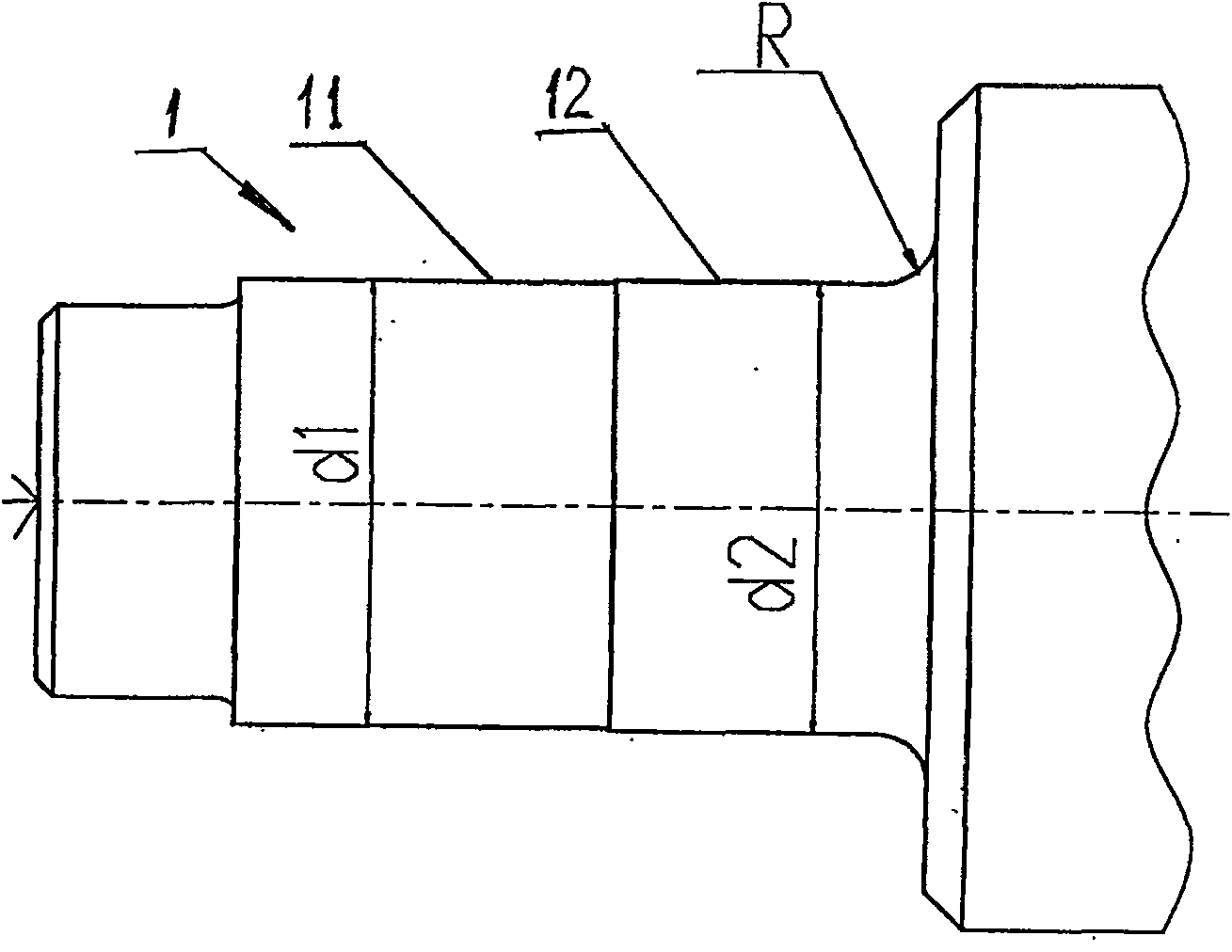

[0028] The size of the crankshaft after machining, the diameter d1 of the front journal 11 of the free end 1 and the diameter d2 of the inner journal 12 are 52.4mm and 53mm respectively. Compared with the same type of forged steel crankshaft, the diameter of the front journal 11 The diameter increases by 9.2%, and the diameter of the journ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com