Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "High bending fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength polyethylene fibers and their applications

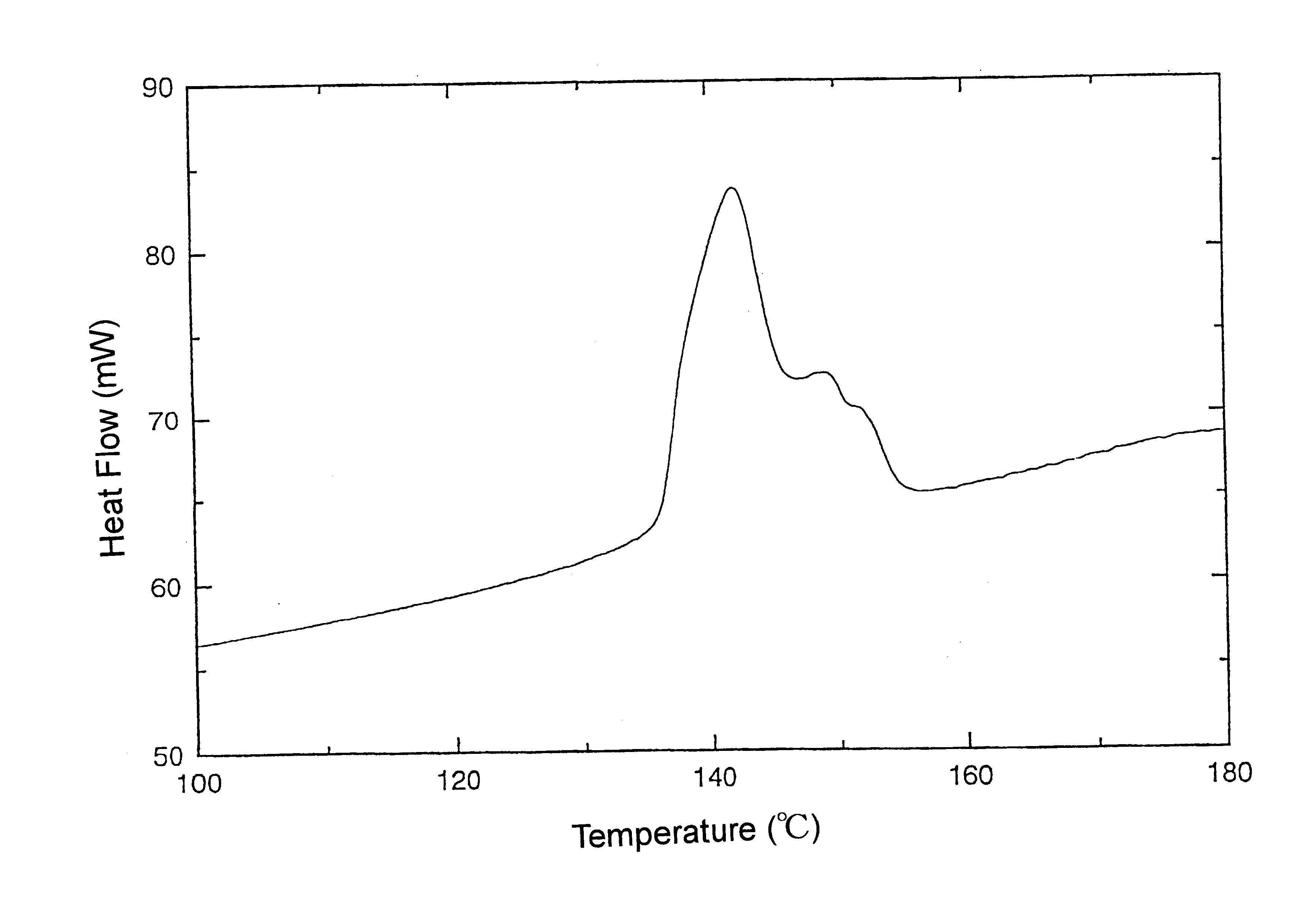

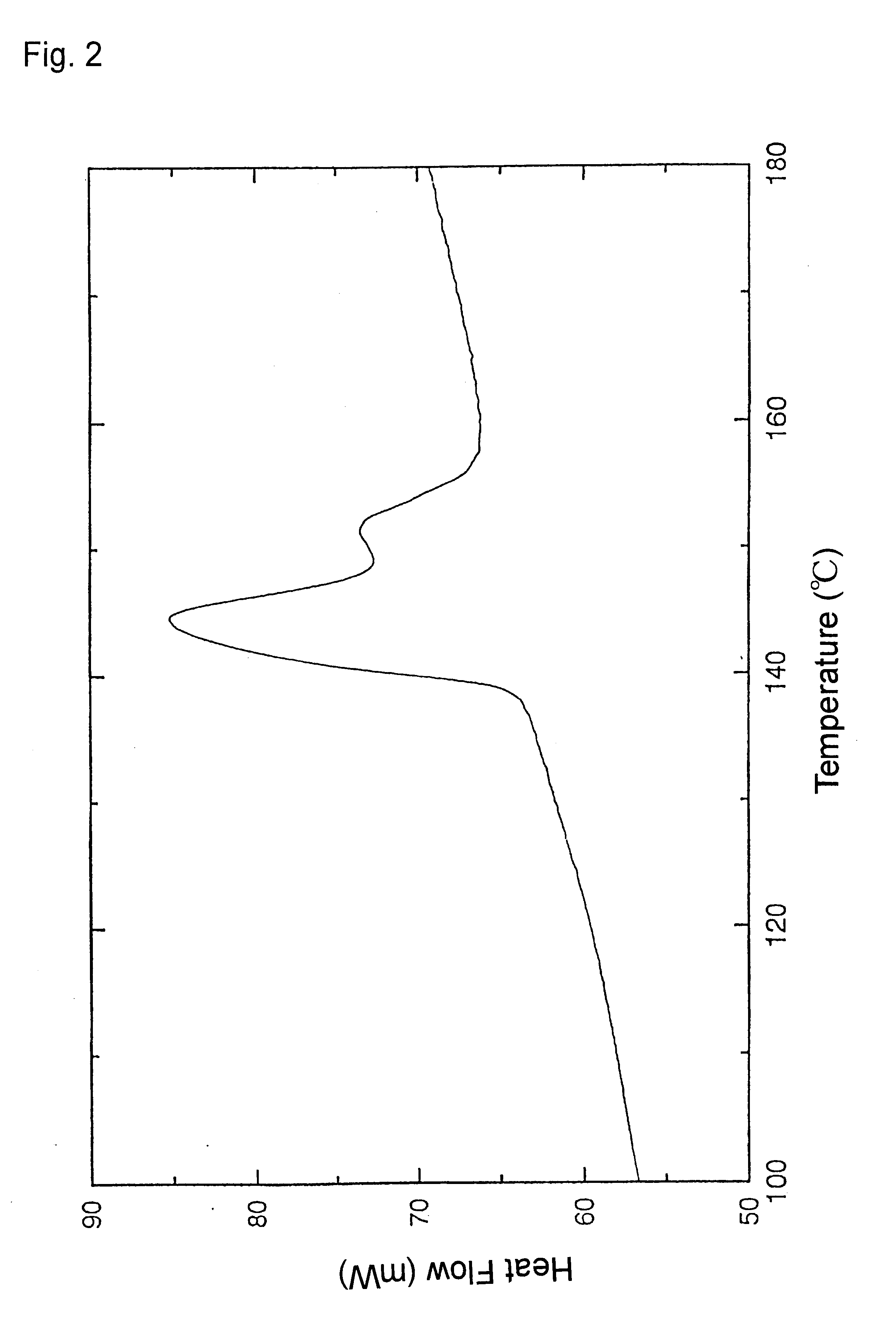

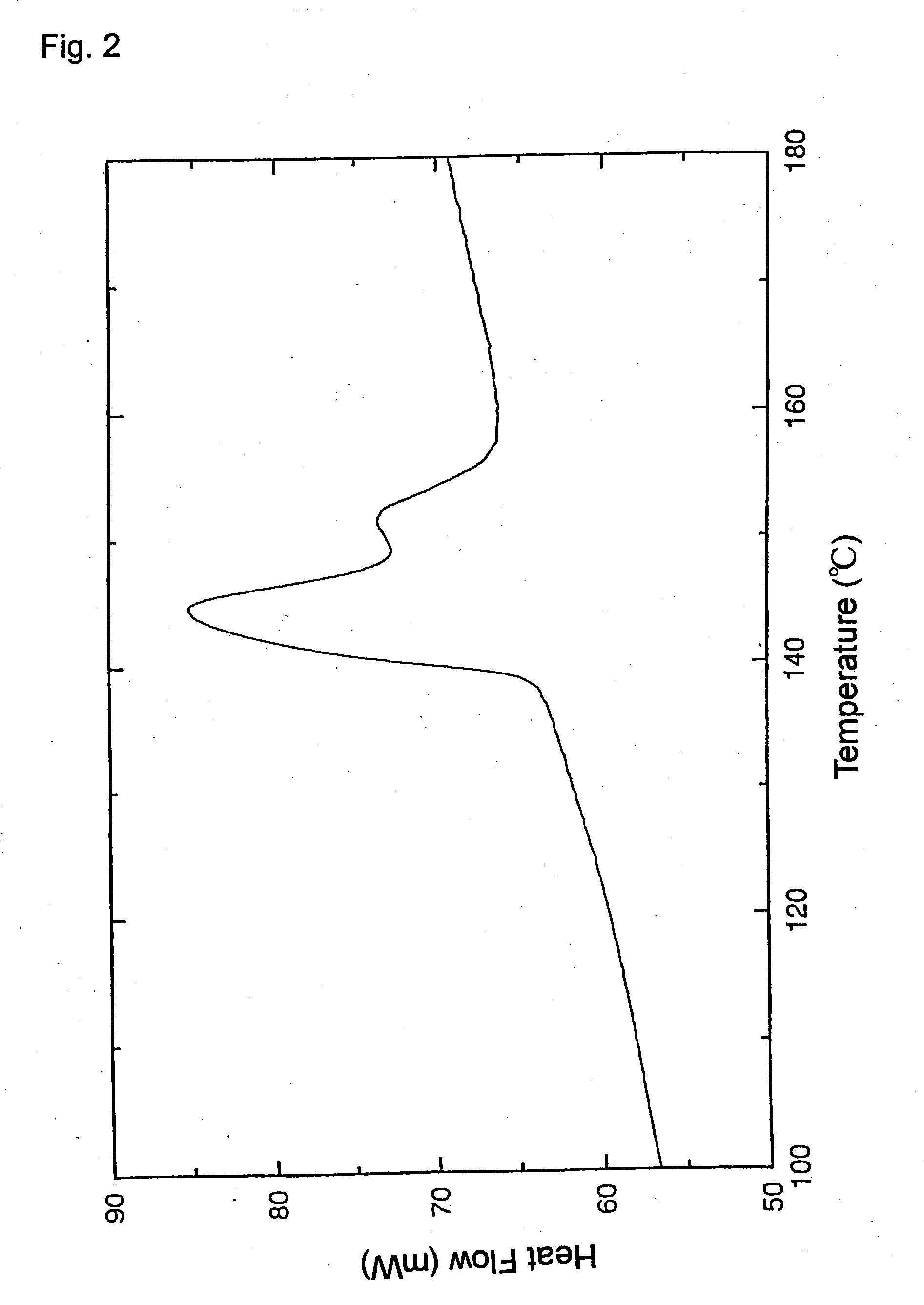

High strength polyethylene fibers and their applications, for example, chopped fibers, ropes, nets, ballistic materials or items, protective gloves, fiber reinforced concrete products, helmets, and other products obtained therefrom, in which the fiber is characterized in that: it contains a high molecular weight polyethylene consisting essentially of a repeating unit of ethylene; it has an intrinsic viscosity number of 5 or larger and an average strength of 22 cN / dtex or higher; and the measurement of the fiber by differential scanning calorimetry (DSC) exhibits a temperature-increasing DCS curve having at least one endothermic peak over a temperature region of 140° C. to 148° C. (on the low temperature side) and at least one endothermic peak over a temperature region of 148° C. or higher (on the high temperature side) or the number of frictions until the fiber is broken in an abrasion test according to method B for measuring abrasion resistance in the Testing Methods for Spun Yarn (JIS L 1095) is 100,000 or larger.

Owner:TOYOBO CO LTD

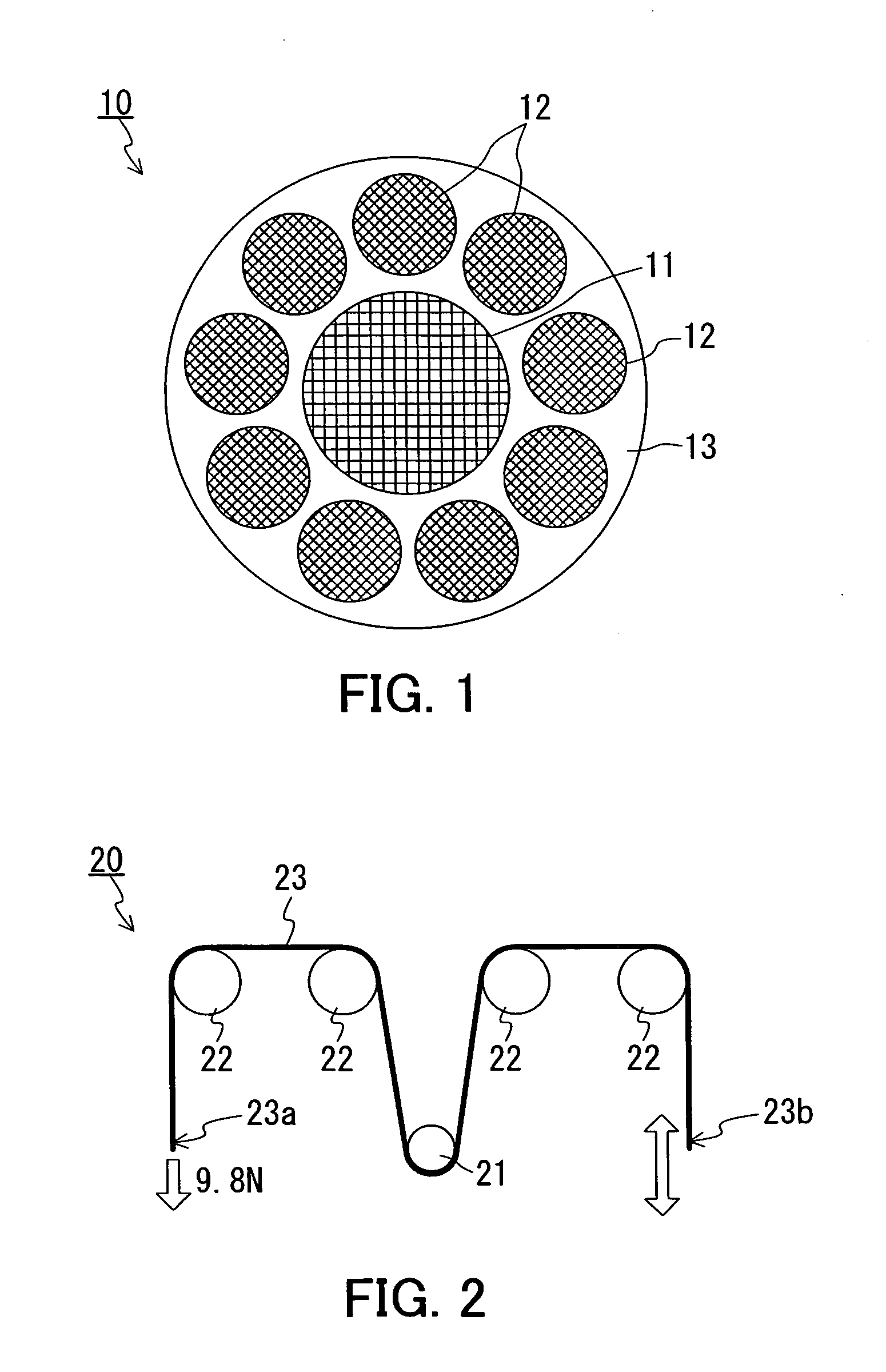

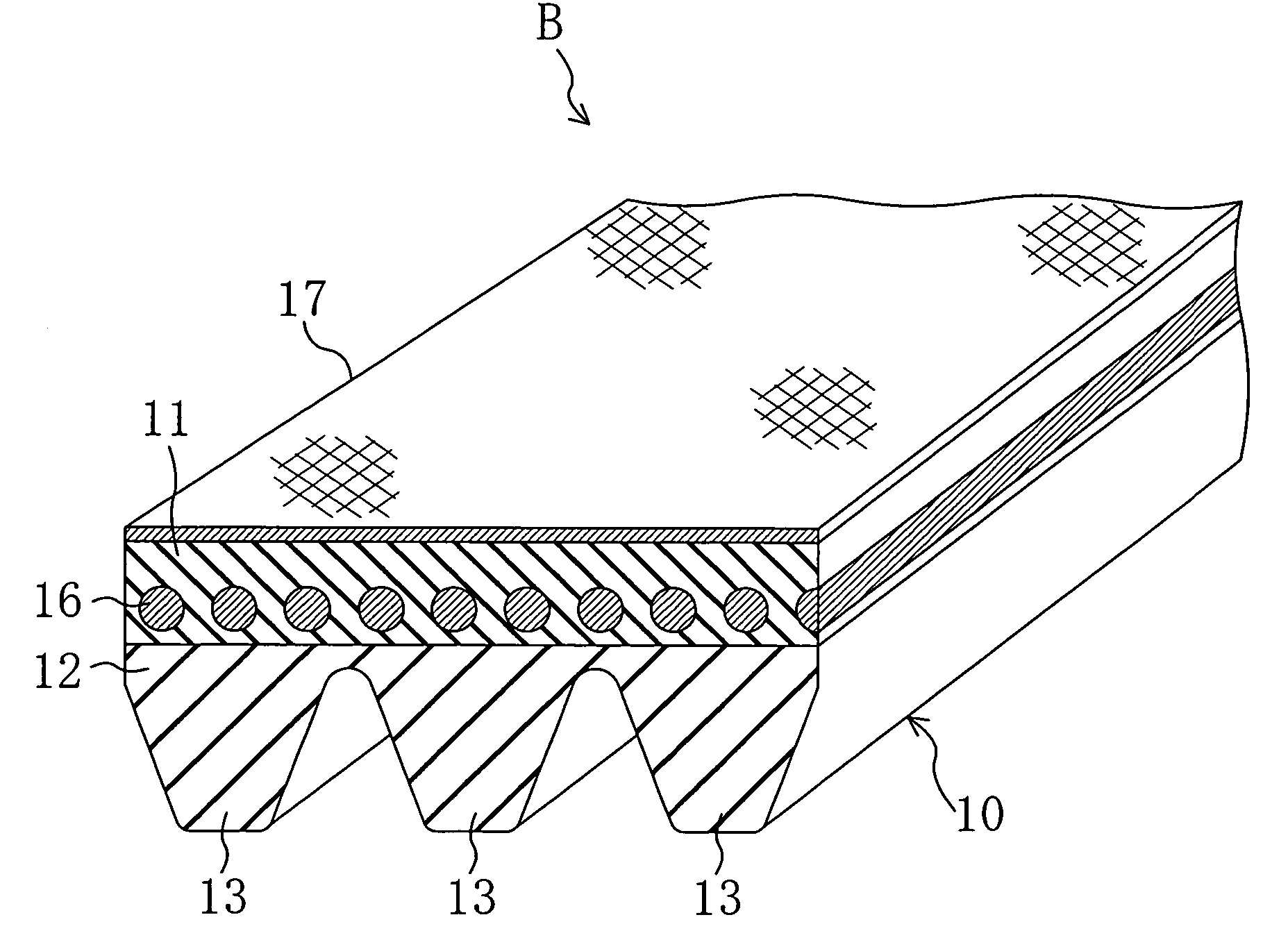

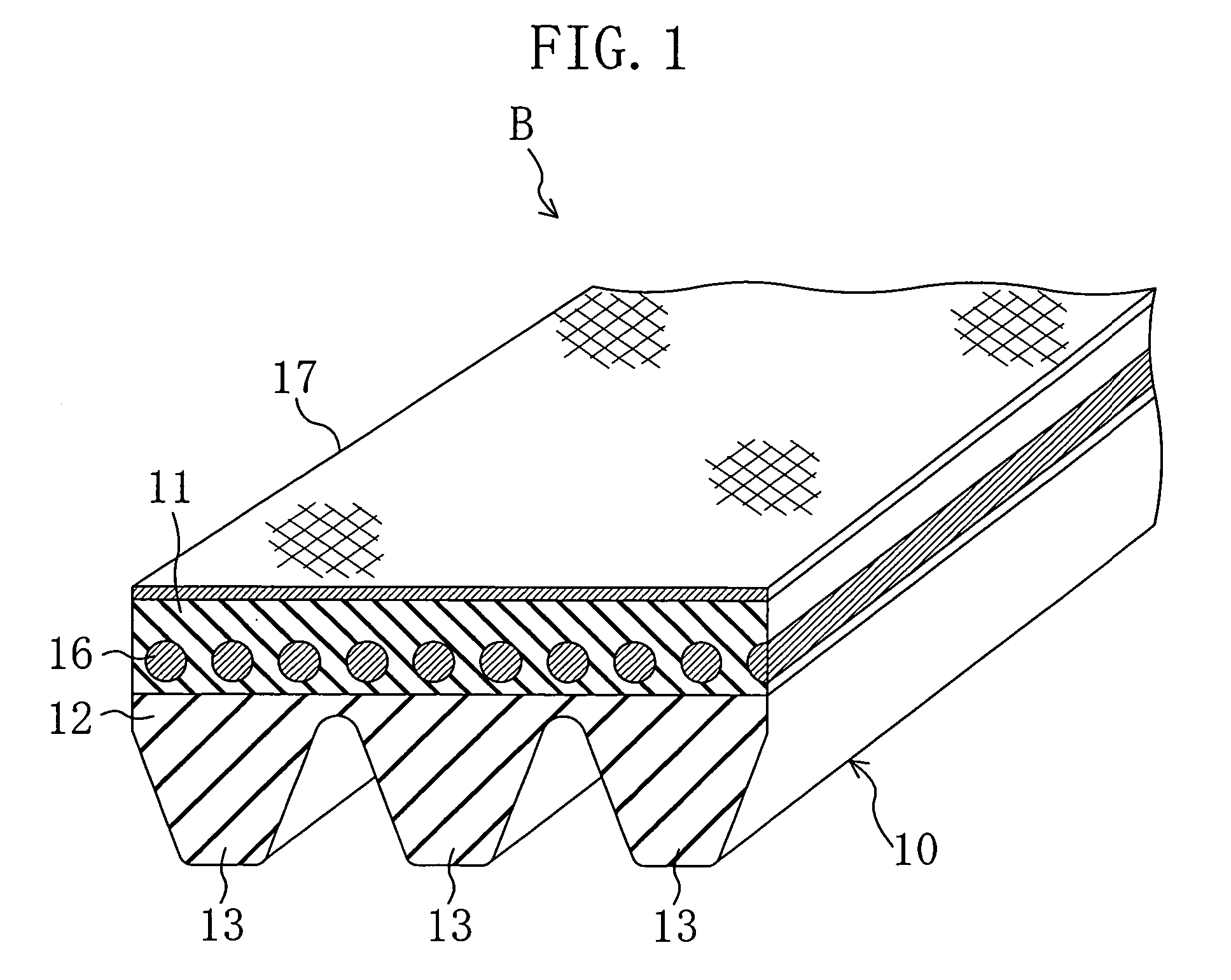

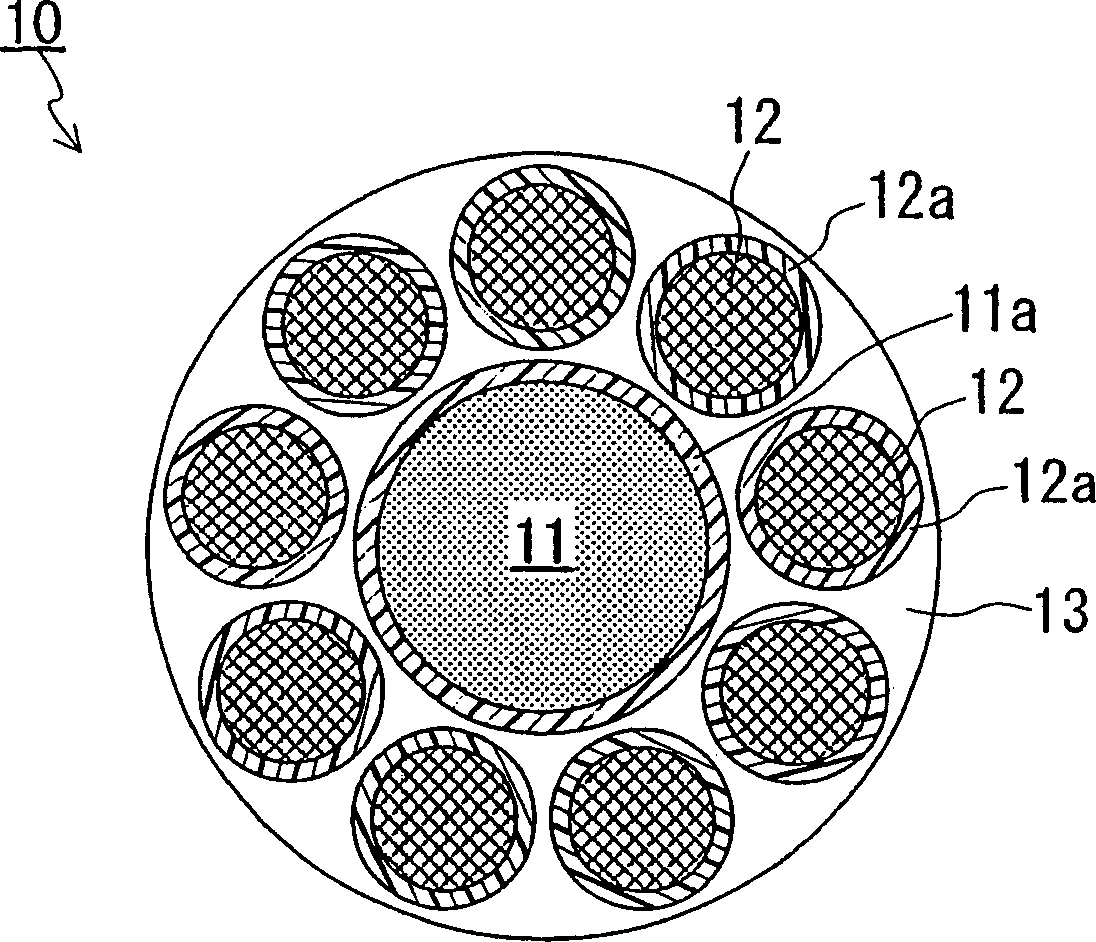

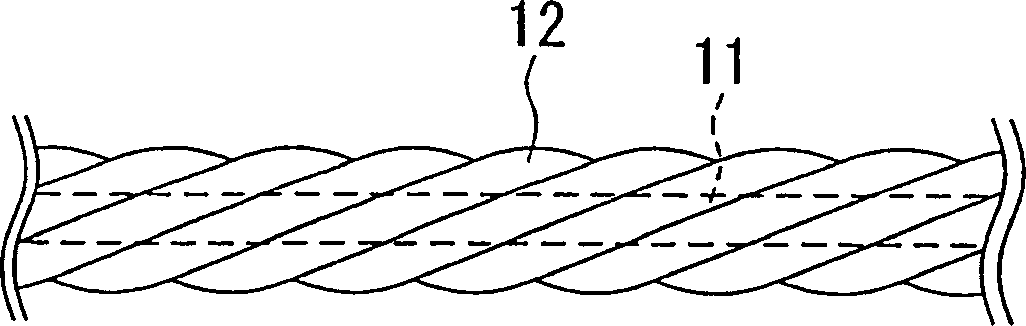

Reinforcing cord for rubber reinforcement and rubber product including the same

A reinforcing cord for rubber reinforcement of the present invention includes reinforcing fibers. The reinforcing fibers include polyarylate fibers 11 and a plurality of outer strands 12 that are arranged around the polyarylate fibers 11. The plurality of outer strands 12 include fibers other than polyarylate fibers. The use of this reinforcing cord for rubber reinforcement makes it possible to obtain a reinforcing cord for rubber reinforcement having high strength, elasticity, and bending fatigue resistance, and a rubber product including the same.

Owner:NIPPON SHEET GLASS CO LTD

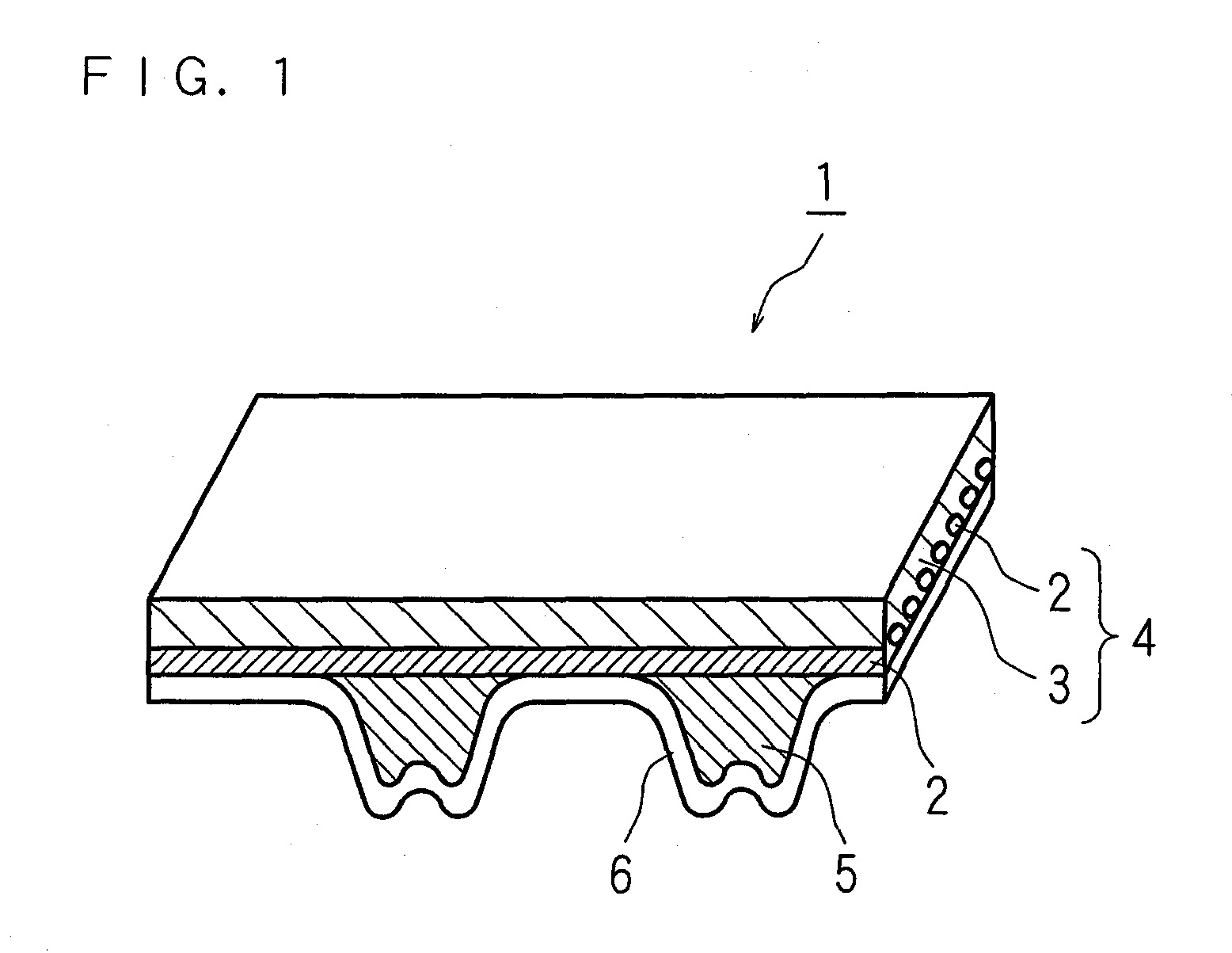

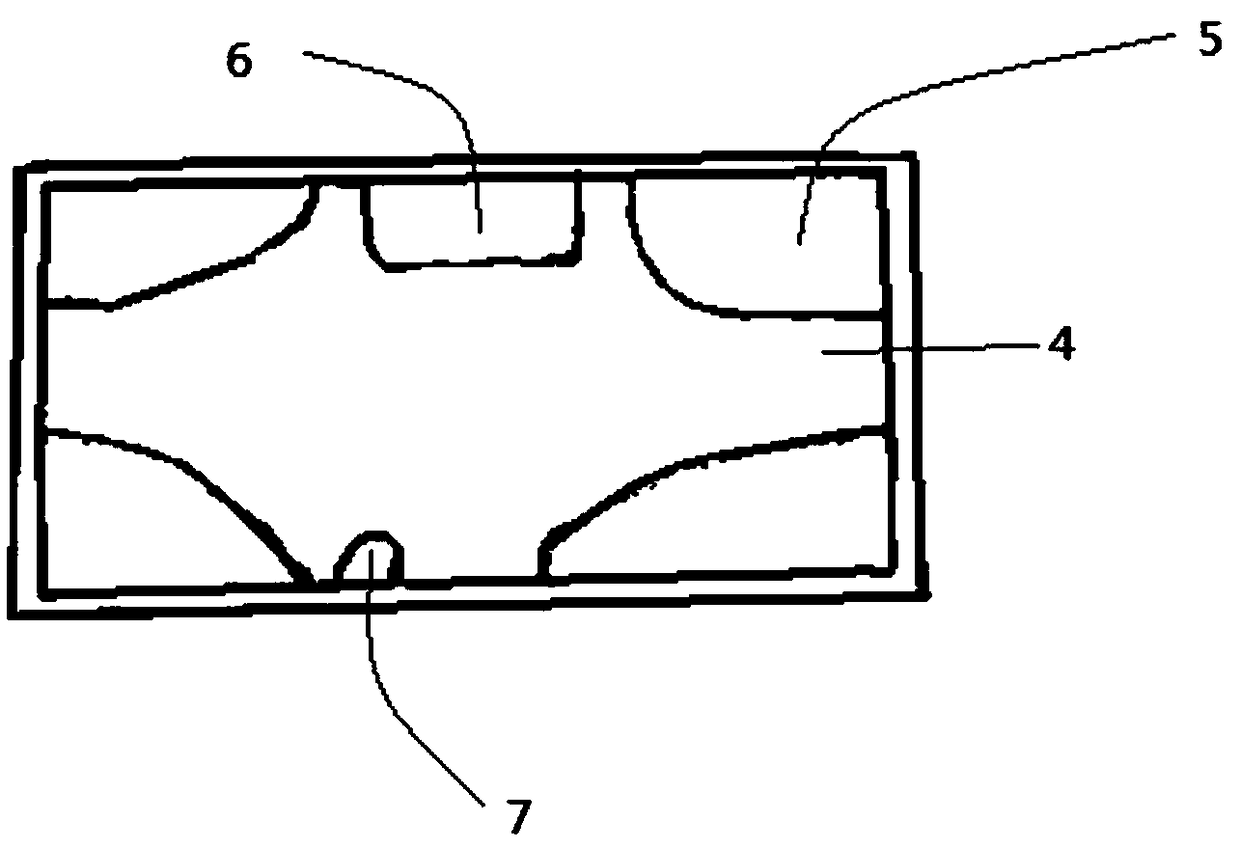

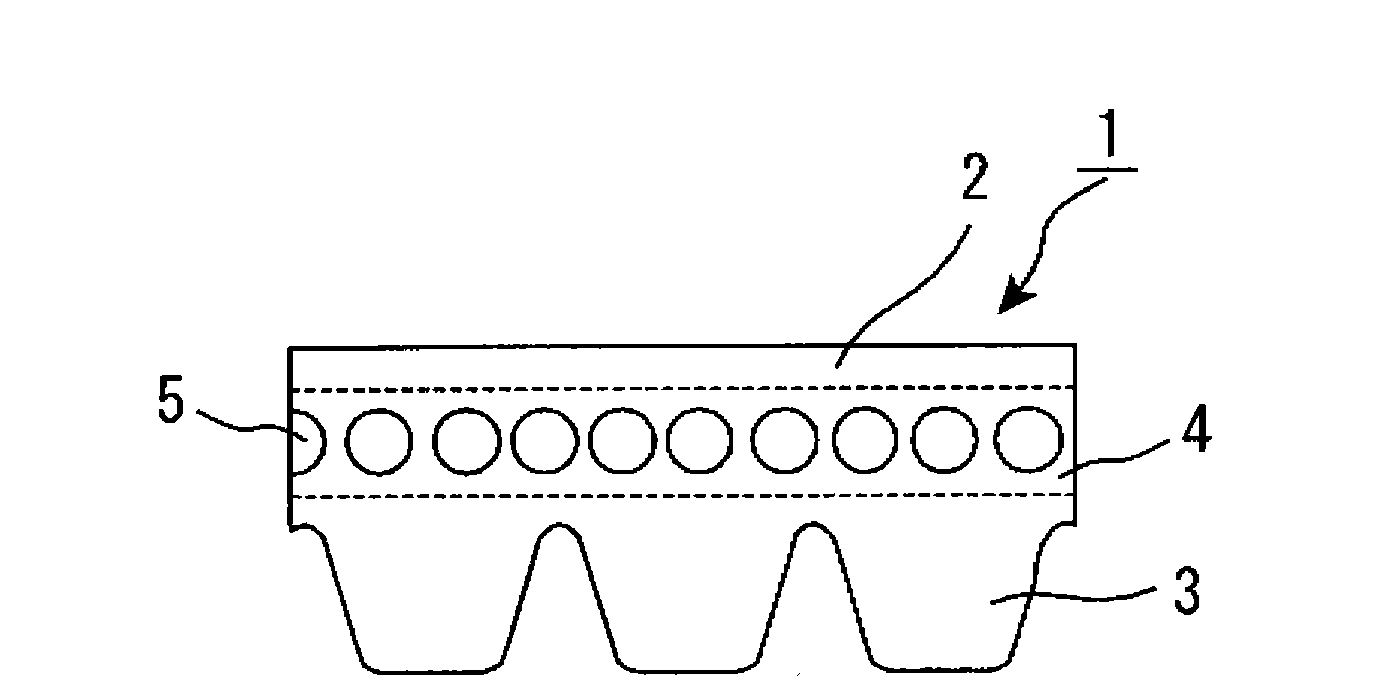

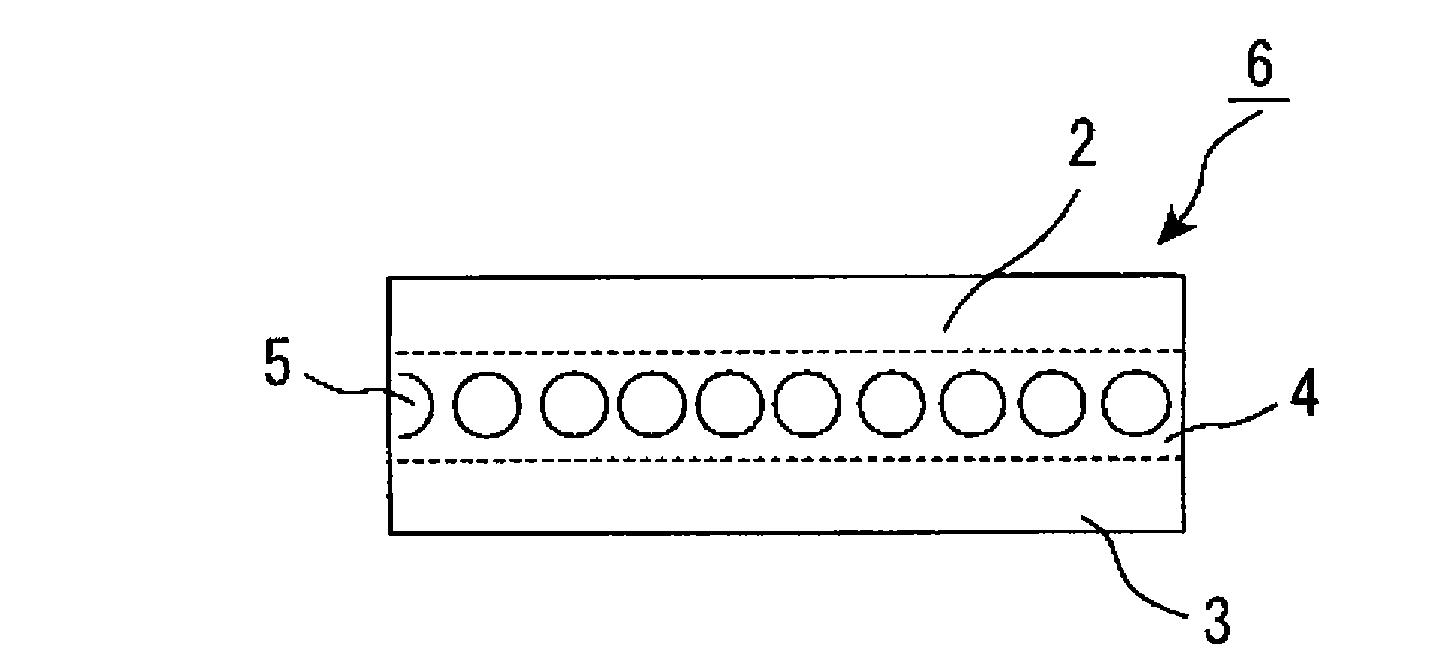

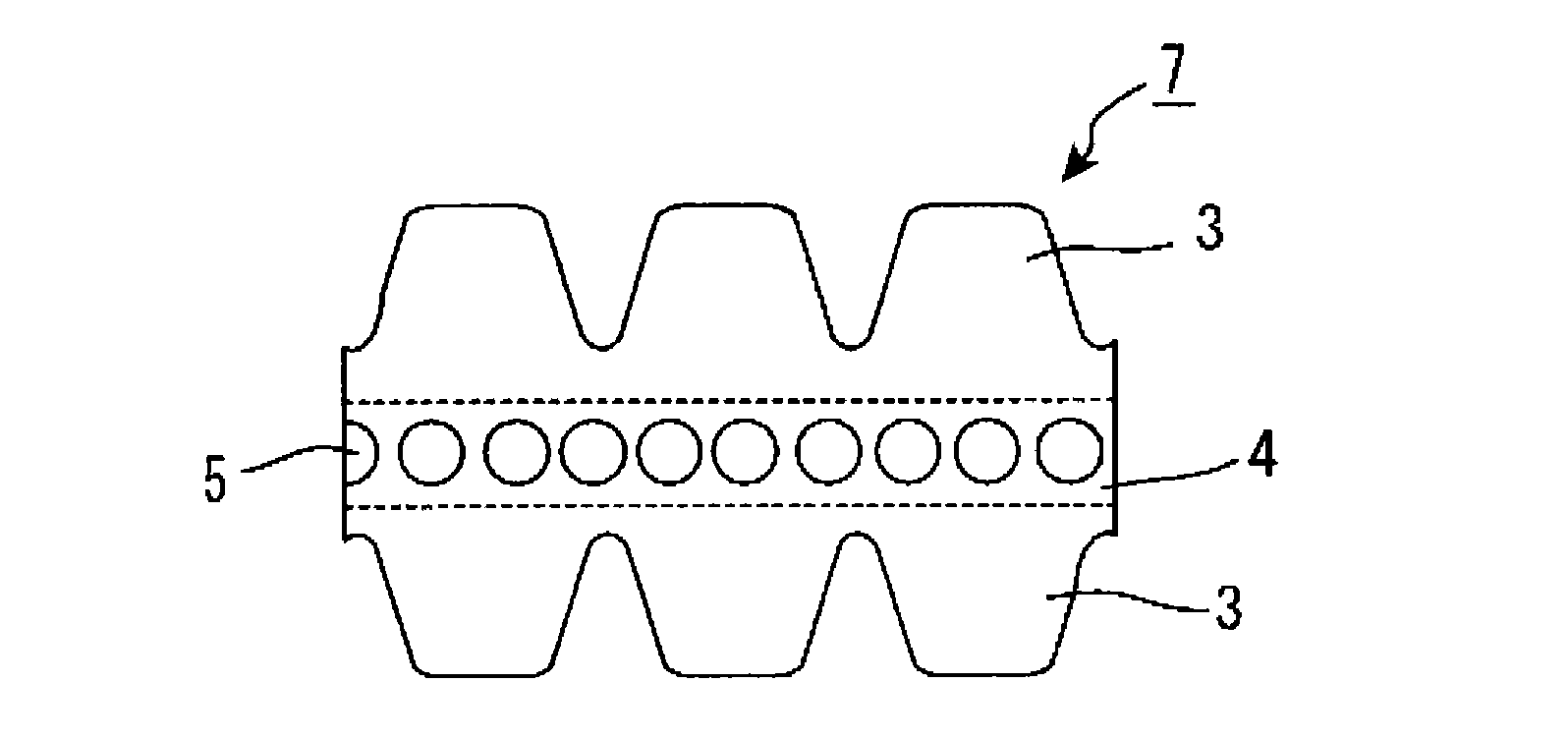

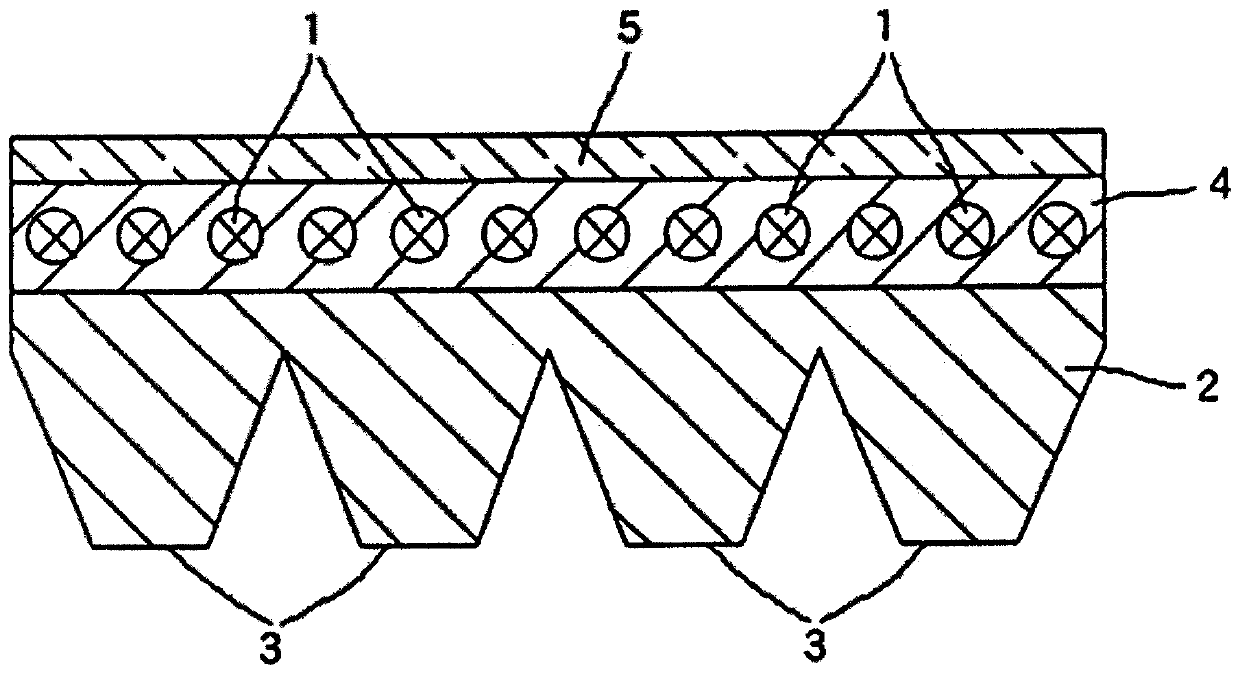

Toothed belt

InactiveUS20110237374A1Improve rigidityImprove adhesionV-beltsDriving beltsPolymer alloySurface layer

A toothed belt includes: a belt main body in which a plurality of cords are arranged side by side in a widthwise direction of a rubber layer; a plurality of teeth portions formed at one surface of the belt main body; and a tooth cloth covering surfaces of the teeth portions. A cloth base material is obtained by impregnating a surface layer rubber composition into an original canvas and by forming a surface layer, and an adhesion layer rubber composition is attached to one surface of the cloth base material to form an adhesion layer, thus forming the tooth cloth. The rubber layer contains: HNBR including HNBR in which a Mooney viscosity at 100° C. is in a range of from 100 to 160; and a polymer alloy obtained by finely dispersing zinc methacrylate in HNBR. The rubber layer and rubber compositions preferably contain hydrogenated carboxyl NBR.

Owner:TSUBAKIMOTO CHAIN CO

Frictional forced power transmission belt and belt drive system with the same

ActiveUS7258639B2Good noise reduction performanceImprove noise reductionV-beltsDrying solid materials with heatHardnessTransmitted power

A frictional forced power transmission belt transmits power to a pulley with its belt body wound around and in contact with the pulley. At least a contact part of the belt body with a pulley is formed of a rubber composition which contains ethylene-α-olefin elastomer as a rubber component but contains substantially no short fibers and which has a rubber hardness of not less than 80 but less than 95 when measured with a type A durometer in conformity with JIS K6253.

Owner:BANDO CHEM IND LTD

Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

ActiveCN106744820APrecise control of ingredientsPrecise control structureCarbon compoundsVacuum evaporation coatingComposite filmCarbon nanotube

The invention belongs to the field of composite materials and in particular relates to a laminated metal chalcogenide (LMC) / carbon nanotube (CTNs) flexible compound film material of a highly ordered structure and a preparation method thereof. The composite material comprises an ultrathin self-supporting (transparent) CNTs film substrate and an LMC film which uniformly wraps the surface thereof to form the flexible composite film material which has a nanoscale porous structure and a three-dimensional network structure of a high electric channel. The preparation method comprises the following steps: providing an alloy bracket for bearing a self-supporting CNTs film and cleaning the carried CNTs film under a heating condition with plasma; and preparing the LMC / CNTs composite functional film material from the pre-treated CNTs film at an air pressure of 0.2-2Pa and at a temperature of 30-800 DEG C by virtue of a magnetron sputtered deposition technology. According to the material provided by the invention, a crispy laminated metal chalcogenide functional two-dimensional (2D) material and one-dimensional (1D) CNTs are effectively connected to form a three-dimensional (3D) network structure of structural flexibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

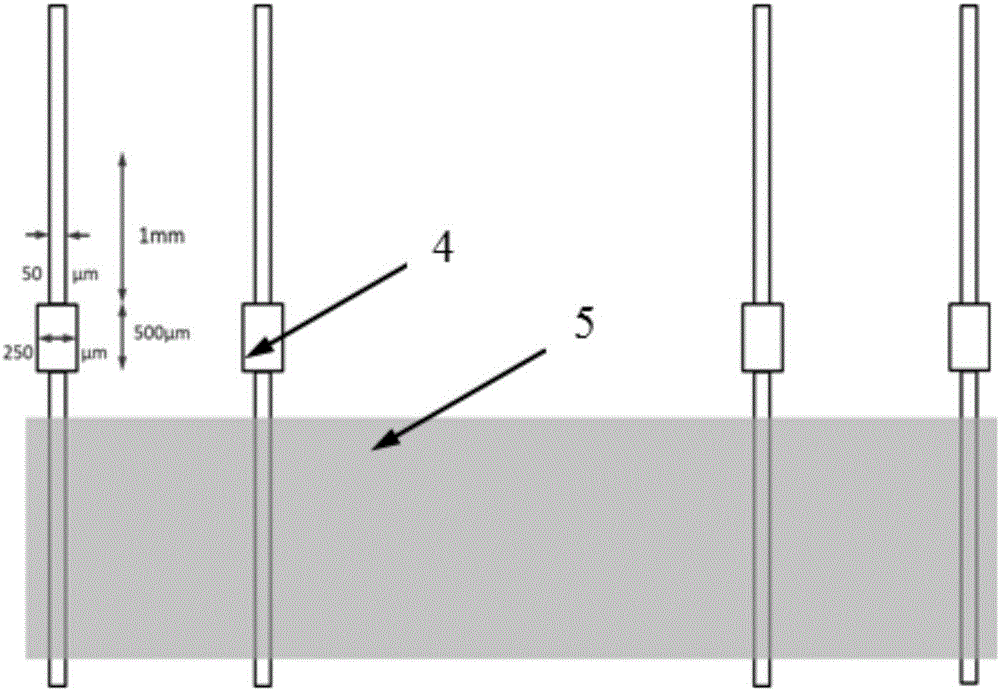

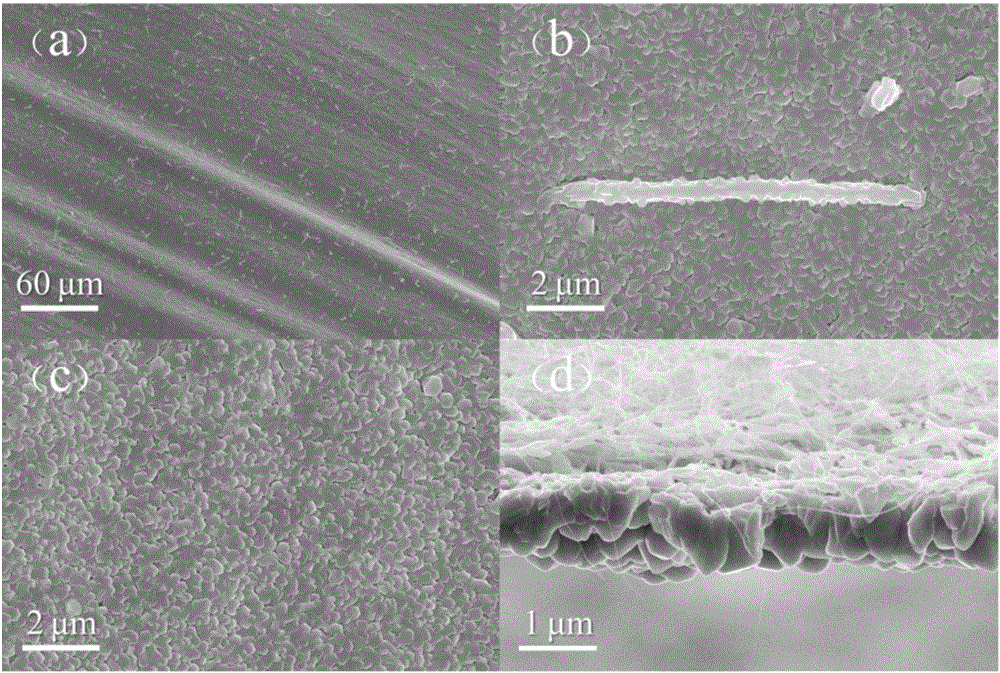

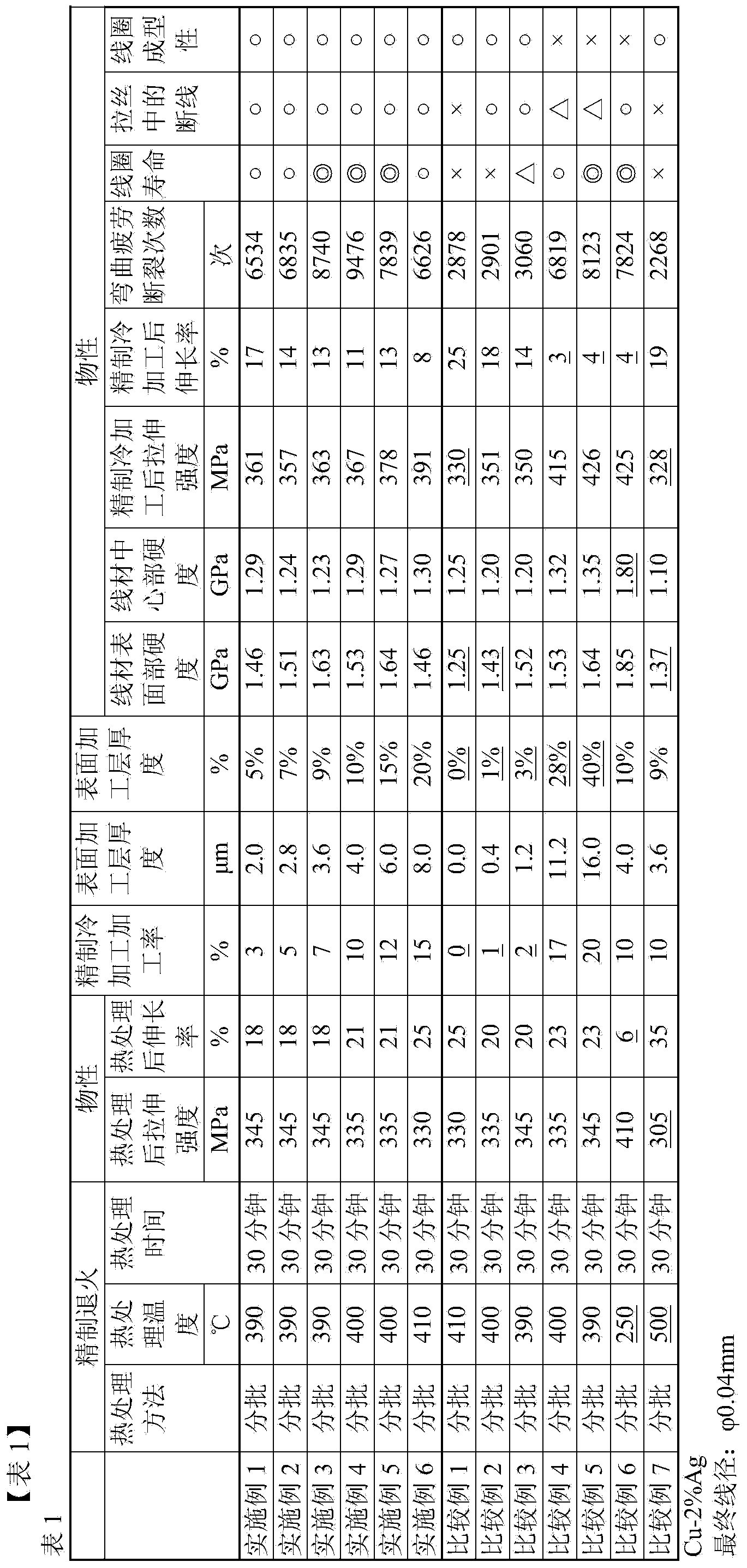

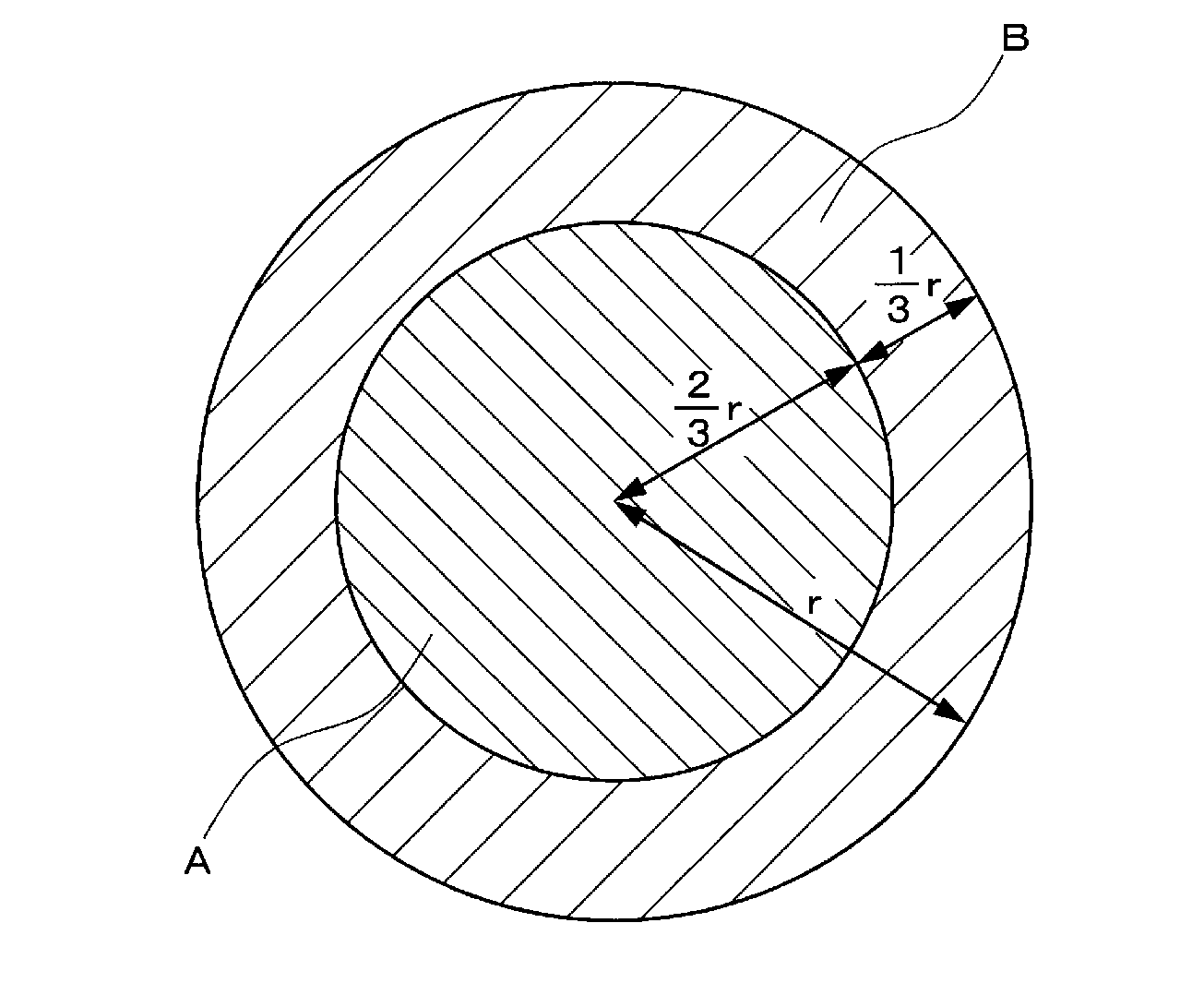

Copper-alloy wire rod and manufacturing method therefor

ActiveCN104169447AExcellent bending fatigue resistanceHigh bending fatigue resistanceSingle bars/rods/wires/strips conductorsConductive materialIndiumManganese

This copper-alloy wire rod and a manufacturing method therefor make it possible to inexpensively provide a copper-alloy wire rod that exhibits excellent elongation and flex-fatigue-resistance properties and can be used, for example, as a magnet wire. Said copper-alloy wire rod contains, by mass, 0.5% to 4% silver and 0.05% to 0.3% of each of at least one element selected from the group consisting of tin, manganese, zinc, indium, nickel, cobalt, zirconium, and chromium, with the remainder comprising copper and unavoidable impurities. This copper-alloy wire rod has a diameter or thickness of at most 0.1 mm and exhibits a nano-indentation hardness of at least 1.45 GPa in a region extending from the outer surface of the wire rod to a depth of at least 5% of the diameter or thickness of the wire rod, a nano-indentation hardness of less than 1.45 GPa in a central section, a tensile strength of at least 350 MPa, and an elongation of at least 7%.

Owner:FURUKAWA ELECTRIC CO LTD

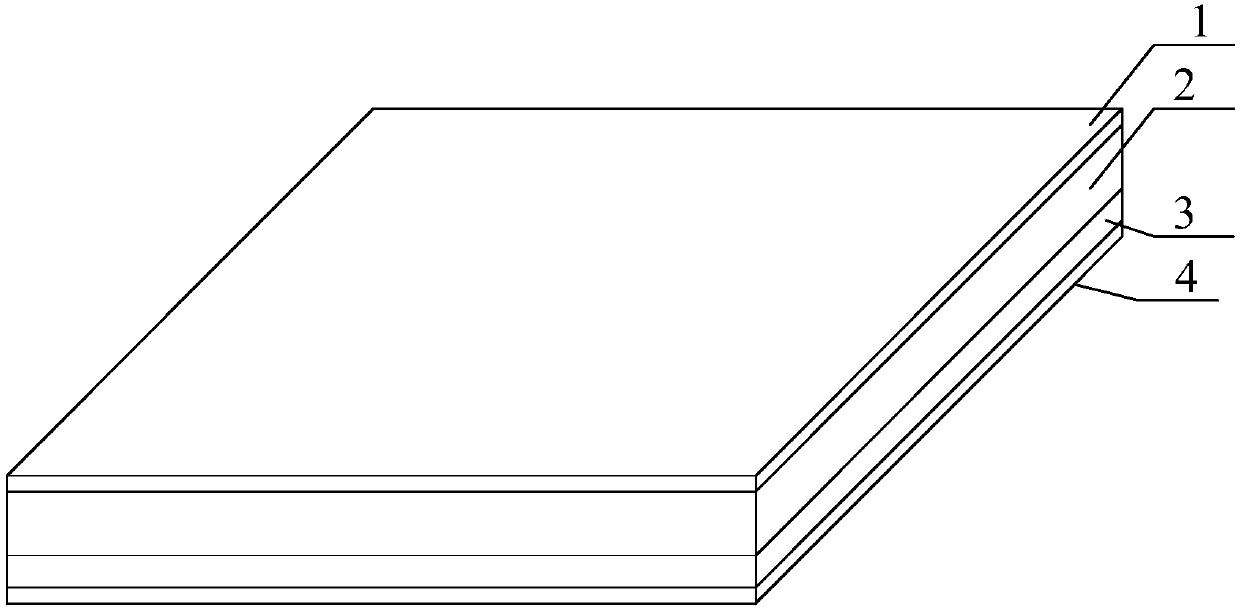

Polyamide laminated film

InactiveUS6294263B1Excellent gas barrier performanceIncrease resistanceSynthetic resin layered productsDomestic articlesElastomerXylylene

The present invention is to provide a polyamide laminated film comprising a resin layer A and a resin layer B formed on at least one surface of the resin layer A,the resin layer A being composed mainly of a m-xylylene group-containing polyamide polymer (a-1) which is one prepared from monomer components containing a xylylenediamine compound as a main diamine component and an alpha,omega-aliphatic dicarboxylic acid having from 6 to 12 carbon atoms as a main dicarboxylic acid component, the xylylenediamine compound being m-xylylenediamine alone or a mixture of m-xylylenediamine and p-xylylenediamine, andthe resin layer B being mainly composed of a mixed polymer (b-3) which is a mixture of from 99 to 80% by weight of an aliphatic polyamide (b-1) and from 1 to 20% by weight of an elastomer (b-2).The laminated film is good in a gas barrier property and also in a flexural fatigue resistance and a transparency.

Owner:TOYO TOYOBO CO LTD

Aluminum alloy conductor

InactiveUS20140020796A1Appropriate yield strengthEasy to operateSingle bars/rods/wires/strips conductorsConductive materialElectrical conductorArea ratio

An aluminum alloy conductor, which has a texture in which an area ratio of grains each having a (100) plane and being positioned in parallel to a cross-section vertical to a wire-drawing direction of a wire is 20% or more, and which has a grain size of 1 to 30 μm on the cross-section vertical to the wire-drawing direction of the wire.

Owner:FURUKAWA ELECTRIC CO LTD +1

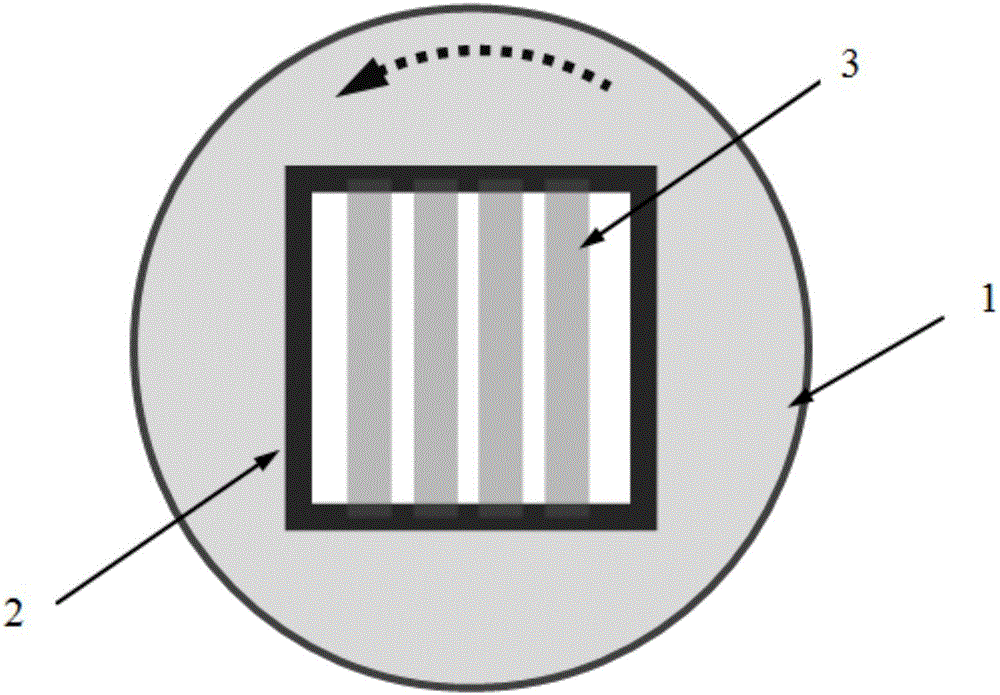

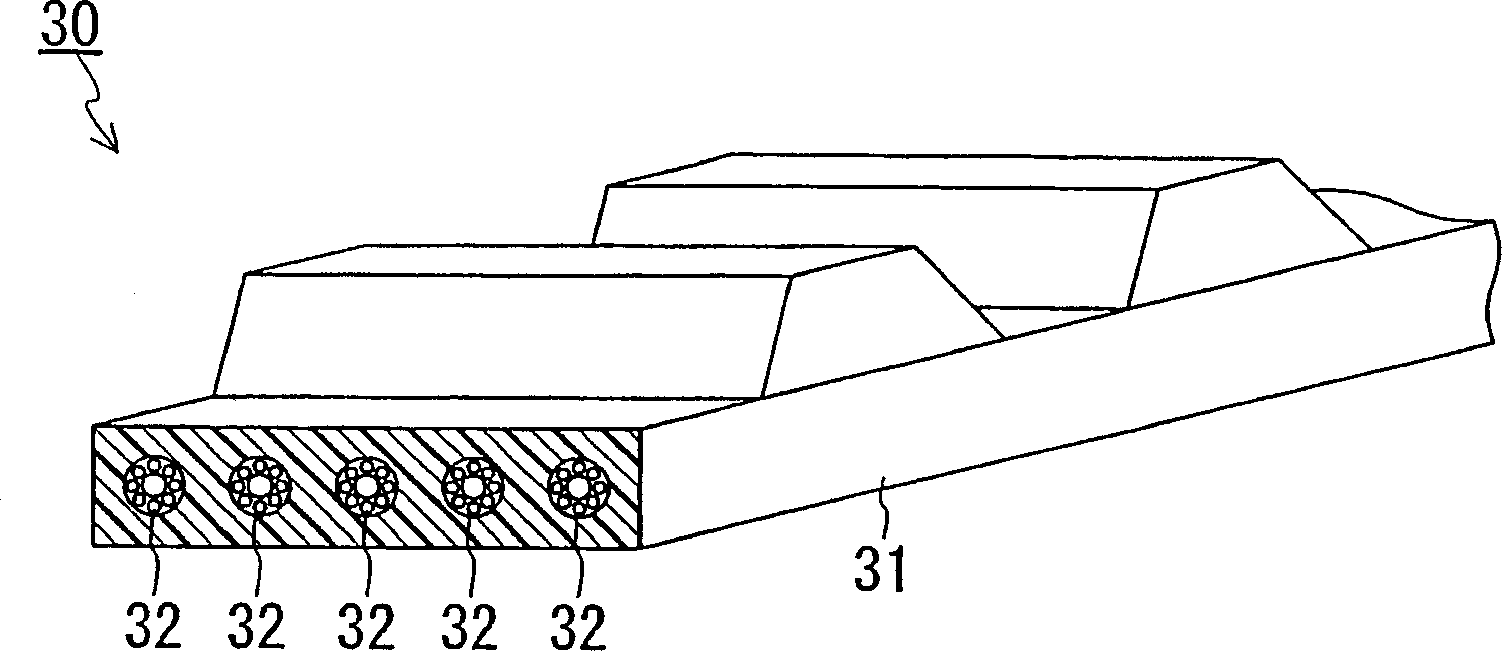

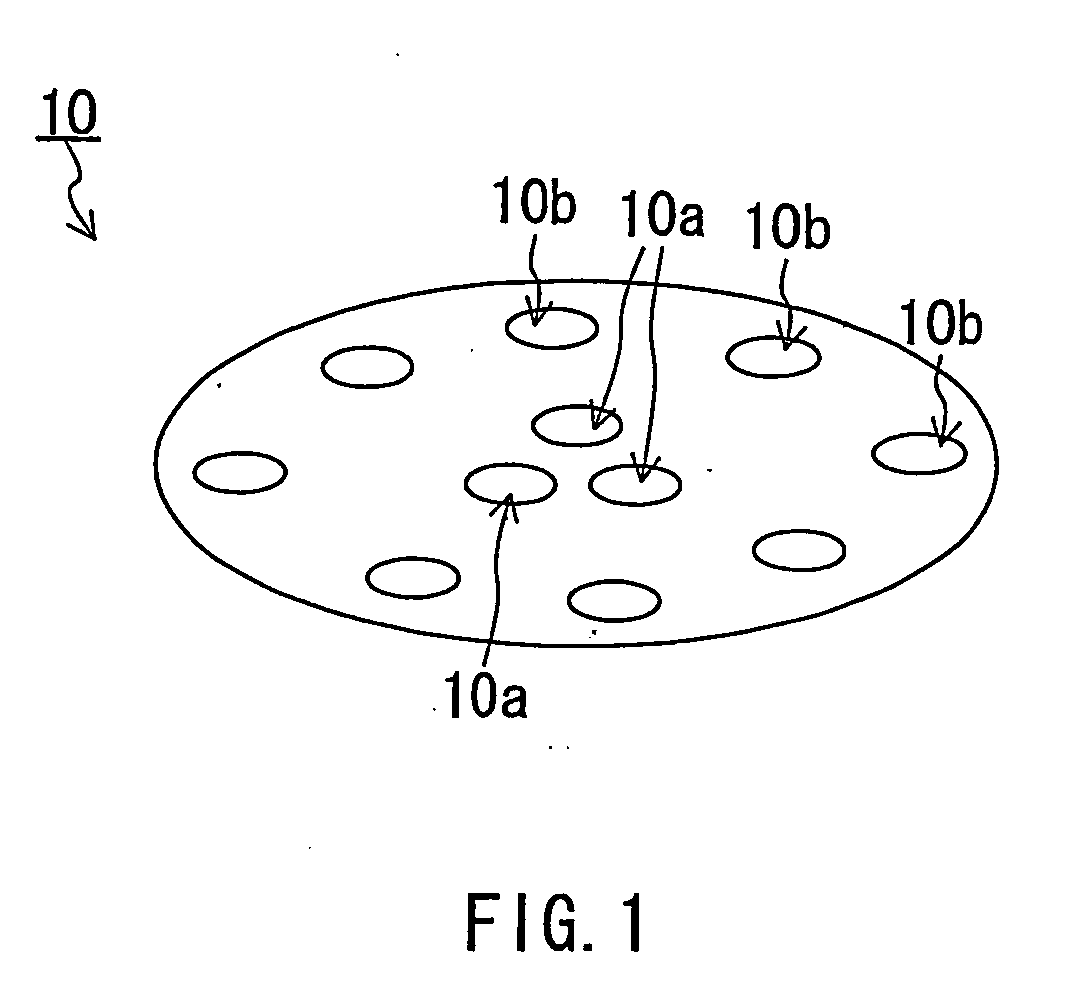

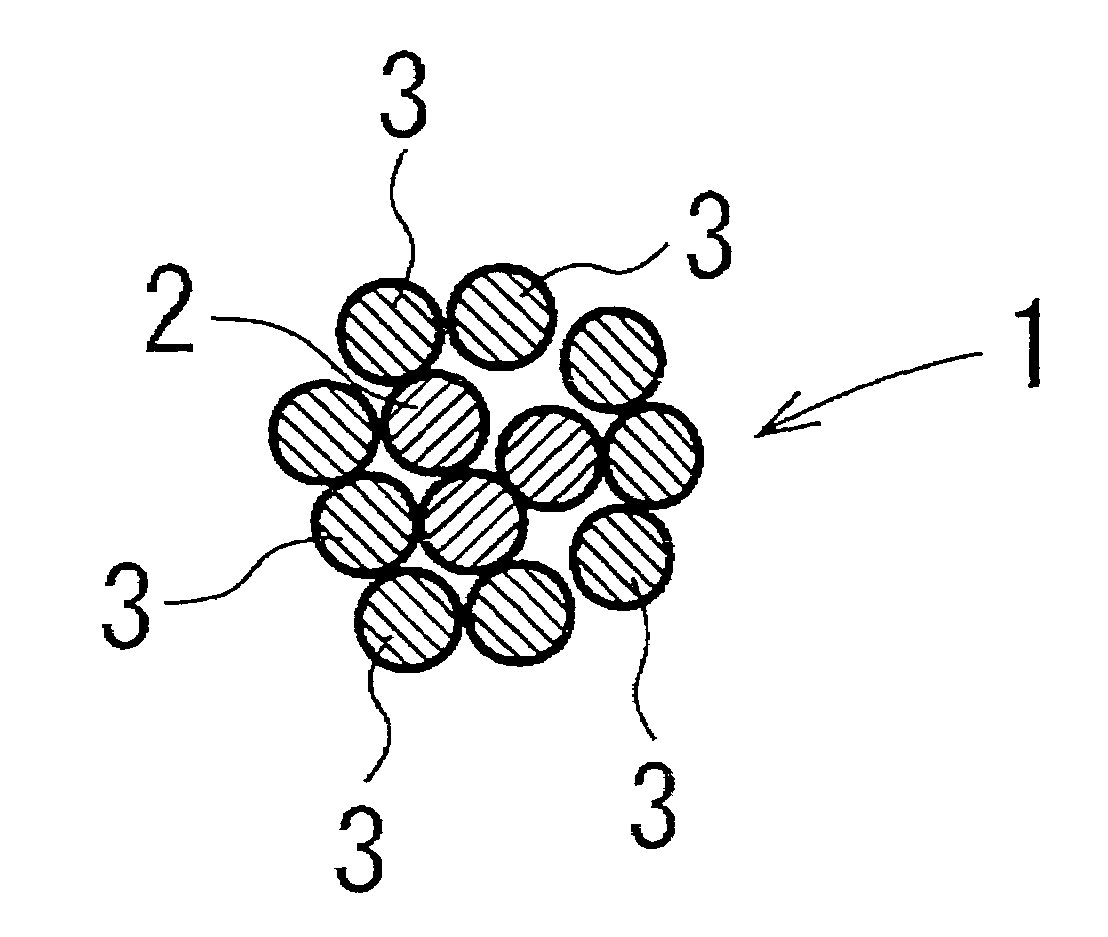

Hybrid cord and rubber product

InactiveUS20030175490A1Good dimensional stabilityReduce resistanceFibre typesSynthetic resin layered productsGlass fiberAramides

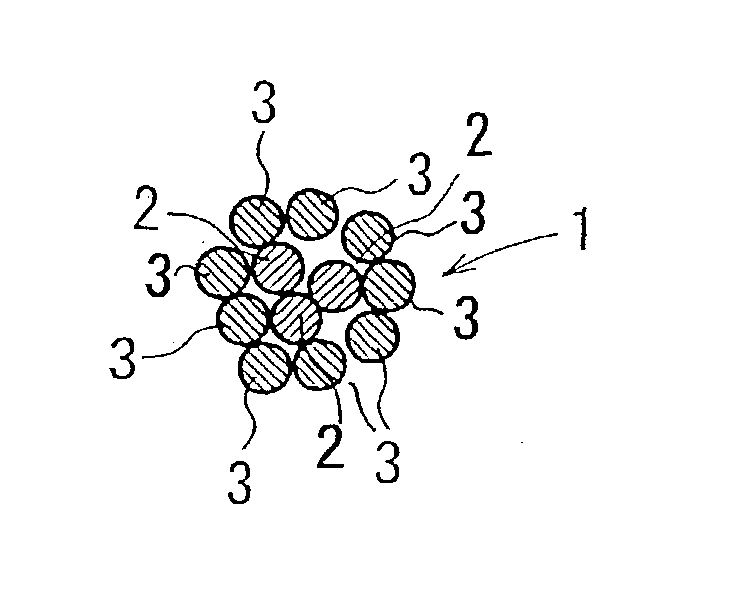

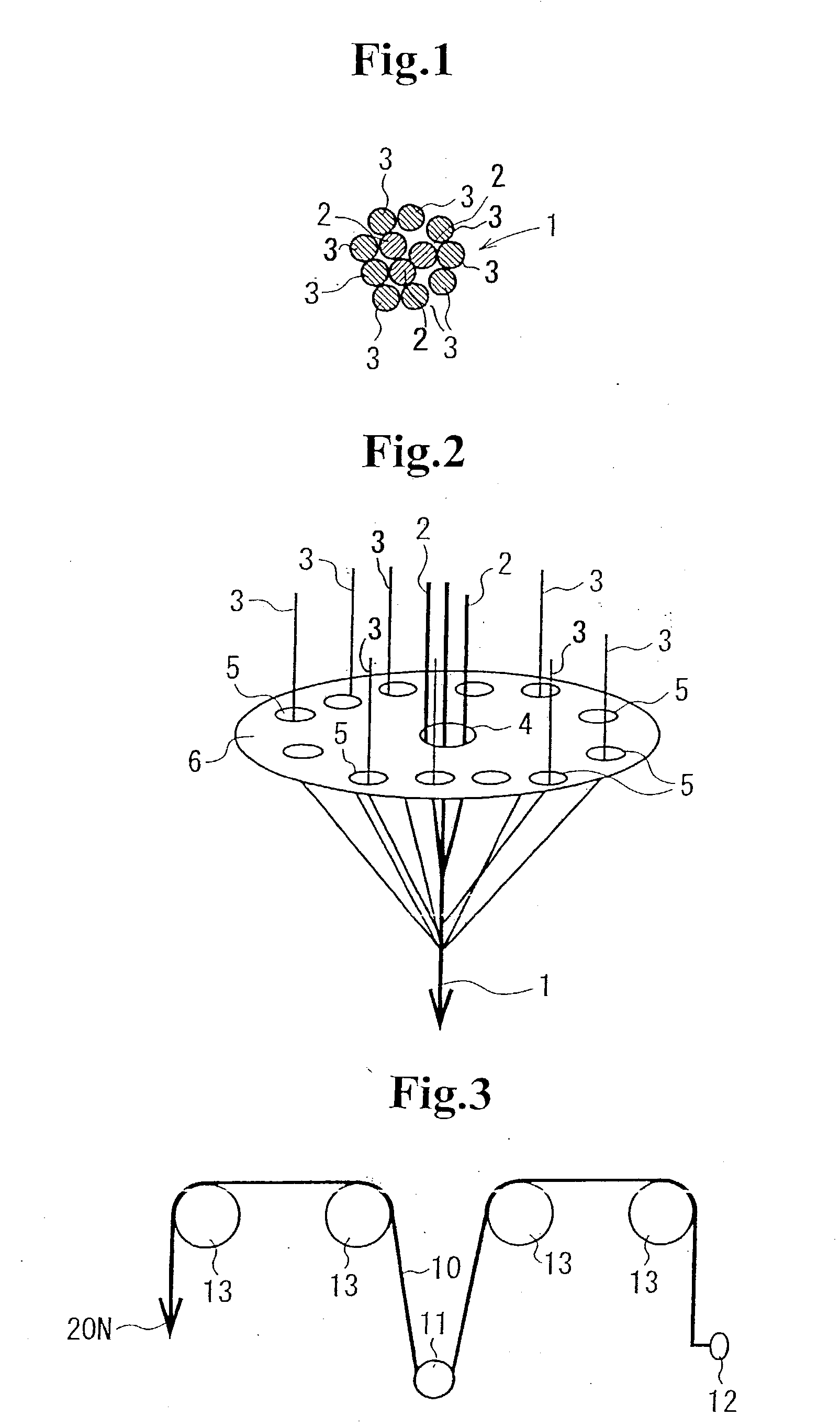

There is provided a hybrid cord having excellent dimensional stability and flexing resistance for use in a reinforcement of rubber, and a rubber product reinforced with the hybrid cord. The hybrid cord 1 has glass fiber strands 2 disposed at its center, and aramid fiber strands 3 disposed therearound. Glass fiber filaments applied with RFL treatment are bound to form the strands. A plurality of the strands are primarily twisted at a twisting rate of 1 to 10 turns / 25 mm. Aramid fiber filaments applied with RFL treatment are bound to form the strands. A plurality of the strands are primarily twisted at a twisting rate of 1 to 10 turns / 25 mm. The glass fiber strands 2 primarily twisted are disposed at a center, and the aramid fiber strands 3 are properly twisted in an opposite direction to the primary twist. The cord is overcoated to form a rubber coat.

Owner:NIPPON SHEET GLASS CO LTD

Reinforcing cord for reinforcing rubber and rubber product using the same

The reinforcing cord of the present invention is a reinforcing cord for reinforcing rubber, and includes a carbon fiber strand (11) and a plurality of glass fiber strands (12) arranged around the carbon fiber strand (11). According to the present invention, a reinforcing cord having sufficient tensile strength to reinforce rubber products and having high dimensional stability and bending fatigue resistance can be obtained.

Owner:NIPPON SHEET GLASS CO LTD

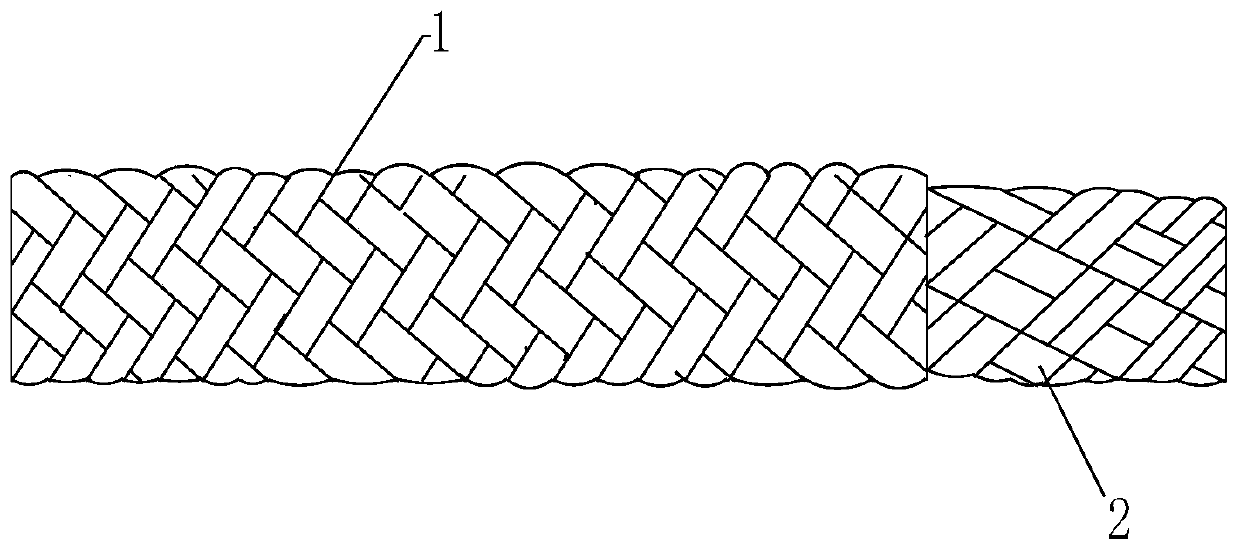

Anti-deformation co-combustion sintering fixture and material thereof

InactiveCN108687343AEfficient anti-deformationIncrease profitTransportation and packagingMetal-working apparatusPolyesterManufacturing cost reduction

The invention discloses an anti-deformation co-combustion sintering fixture. The anti-deformation co-combustion sintering fixture comprises a base body. The base body comprises a base and assembling structures making contract with the surface of a to-be-sintered workpiece. The material shrinkage rate of the anti-deformation co-combustion sintering fixture is identical with or close to that of thesurface of the to-be-sintered workpiece. The material sintering temperature of the anti-deformation co-combustion sintering fixture is higher than that of the surface of the to-be-sintered workpiece.The assembling structures are a plurality of protrusions or grooves. The invention further discloses a material of the anti-deformation co-combustion sintering fixture. The material is prepared from,by weight, 50%-60% of powder, 10%-20% of water-soluble polyester, 10%-20% of polypropylene, 8%-10% of fatty acid amide phosphate, 3%-5% of a coupling agent, 0.3%-0.5% of a stabilizer and 0.2%-0.5% ofan antioxidizer. According to the anti-deformation co-combustion sintering fixture and the material thereof, sintering deformation of an injection-formed surface shell of titanium alloy powder can beprevented, the product defective rate caused by sintering deformation is greatly decreased, the productivity is improved, and the manufacturing cost is reduced.

Owner:东莞市依诺电子科技有限公司

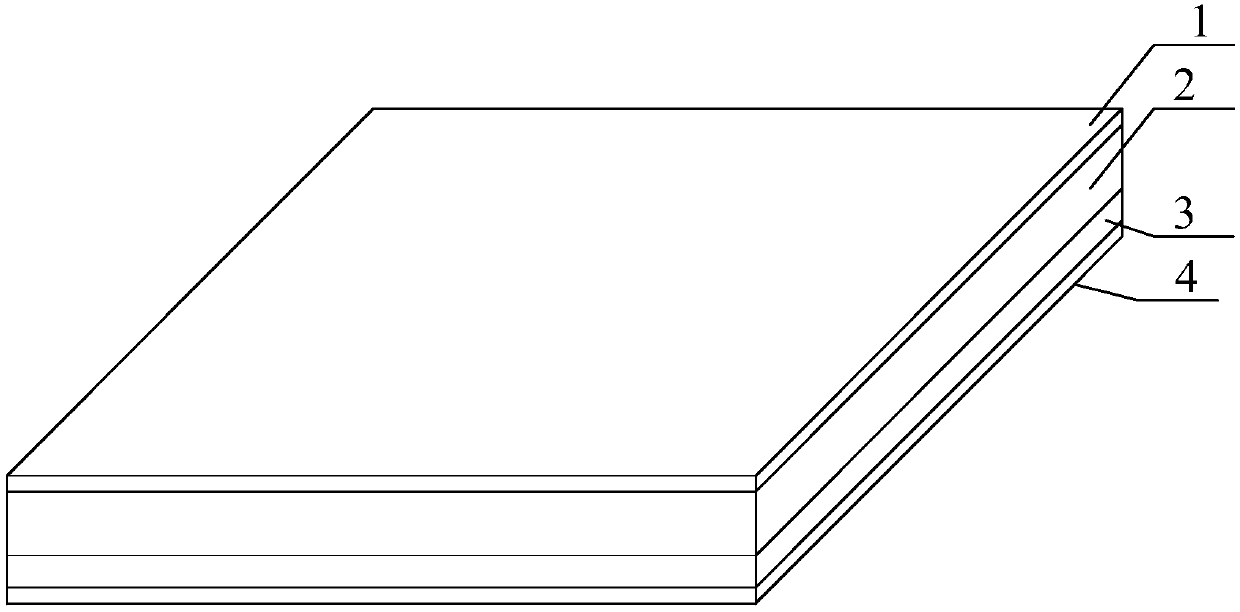

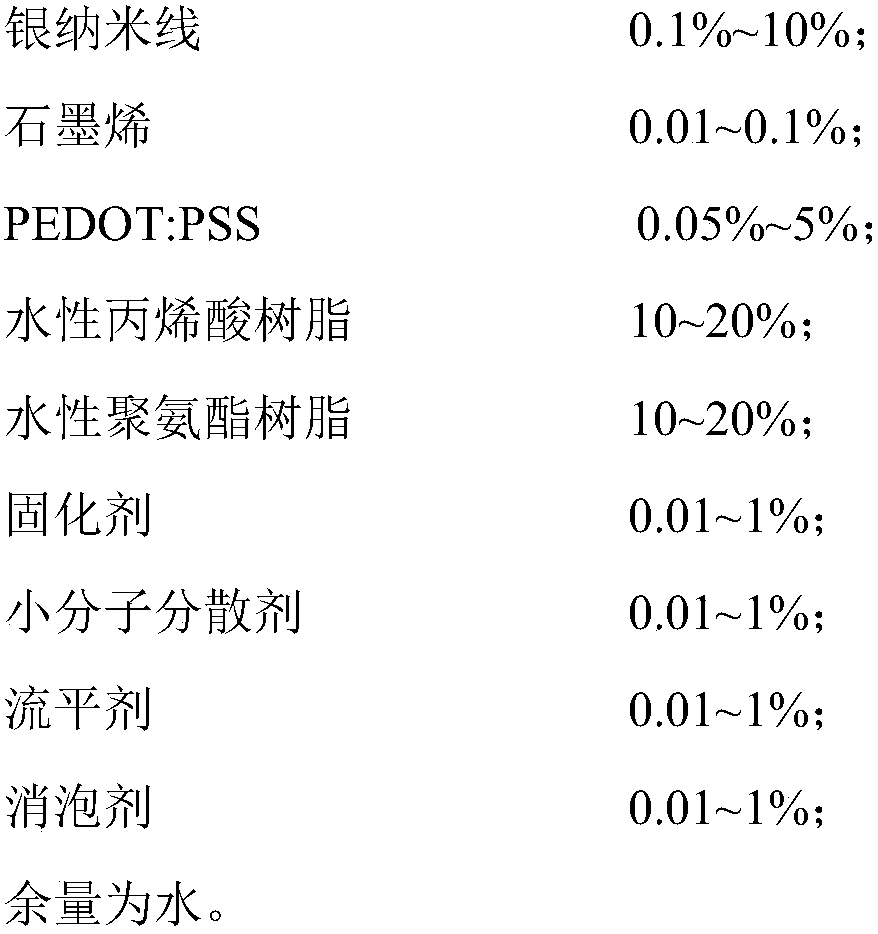

Electromagnetic wave shielding film and highly transparent strong electromagnetic wave shielding tape based on electromagnetic wave shielding film

ActiveCN106700961AReduce usageReduce use costFilm/foil adhesivesPolyurea/polyurethane coatingsTransmittanceSilver nanowires

The invention discloses an electromagnetic wave shielding film and a highly transparent strong electromagnetic wave shielding tape based on the electromagnetic wave shielding film. The invention is characterized in that the electromagnetic wave shielding film is prepared by coating electromagnetic wave shielding slurry on a transparent substrate, while the strong electromagnetic wave shielding tape is prepared based on the electromagnetic wave shielding film, wherein the electromagnetic wave shielding slurry is prepared by mixing silver nanowires, PEDOT:PSS, graphene, water-based acrylic resins, waterborne polyurethane resins, a curing agent, a small molecule dispersant, a flatting agent, an antifoaming agent and water. The electromagnetic wave shielding tape disclosed by the invention can reach the visible light transmittance of 90% or higher and is high in shielding effectiveness and wide in frequency range.

Owner:合肥微晶材料科技有限公司

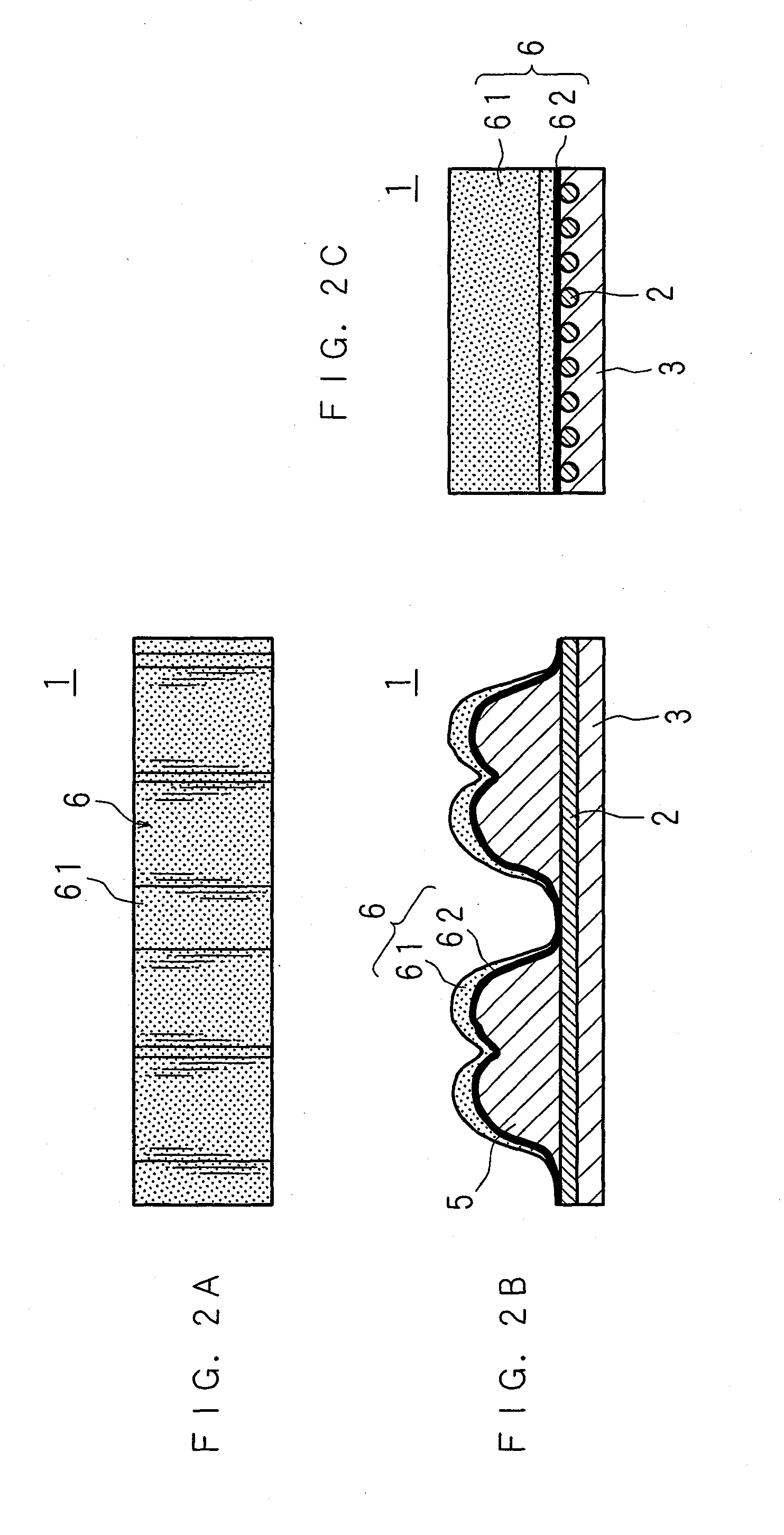

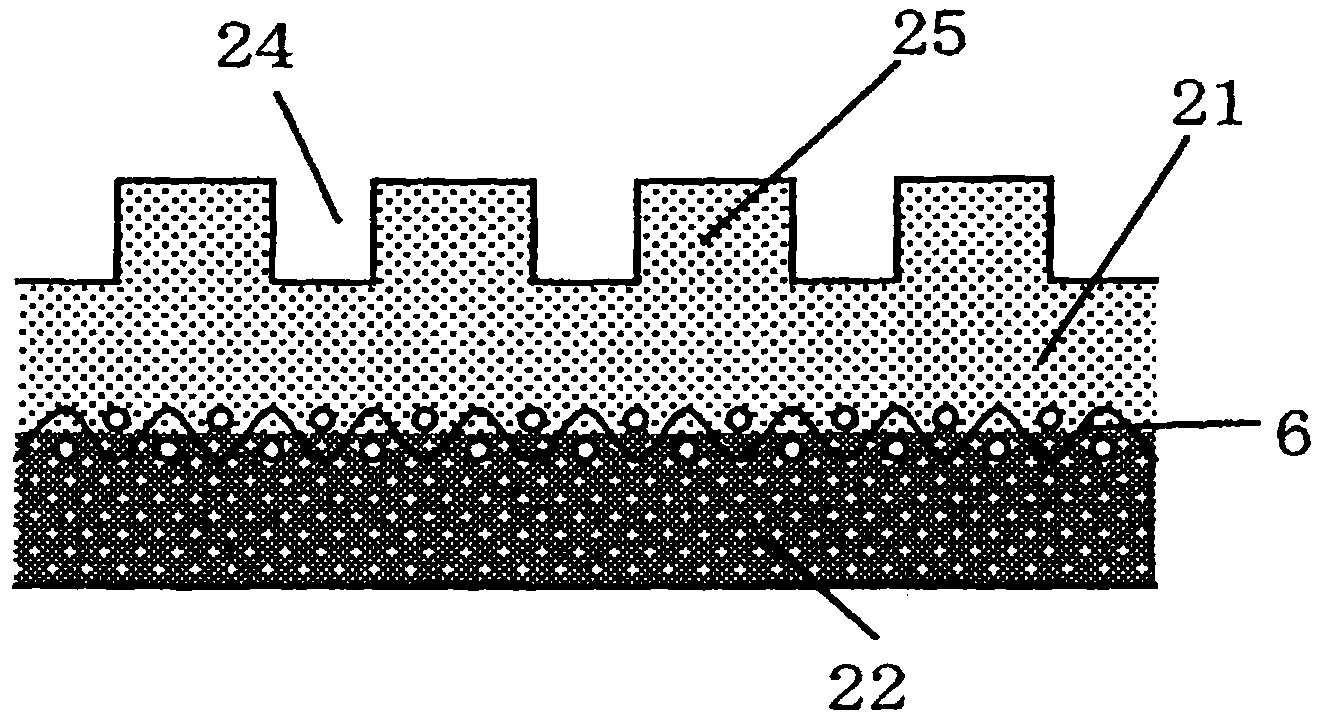

Shoe press belt for papermaking

ActiveCN101939483AExcellent mechanical propertiesIncreased durabilityPaper/cardboardPress sectionFiberCarbamate

A belt for papermaking shoe presses is provided which comprises a reinforcing fibrous base (6) and a polyurethane layer (2) united therewith, the reinforcing fibrous base (6) having been embedded in the polyurethane layer (2). The belt includes a polyurethane layer obtained by curing a mixture comprising: a urethane prepolymer obtained by reacting a polyisocyanate compound selected among p-phenylene diisocyanate, 4,4'-methylenebis(phenyl isocyanate), and tolylene diisocyanate with a polyol compound selected among polypropylene glycol, polytetramethylene glycol, and a polycarbonate diol; a hardener selected among an aliphatic diol compound, hydroquinone bis-ss-hydroxyethyl ether, and organic polyamine compound; and an aliphatic triol compound. Due to this layer, the shoe press belt for papermaking is excellent in wearing resistance and flexing fatigue resistance.

Owner:ICHIKAWA ELECTRIC CO LTD

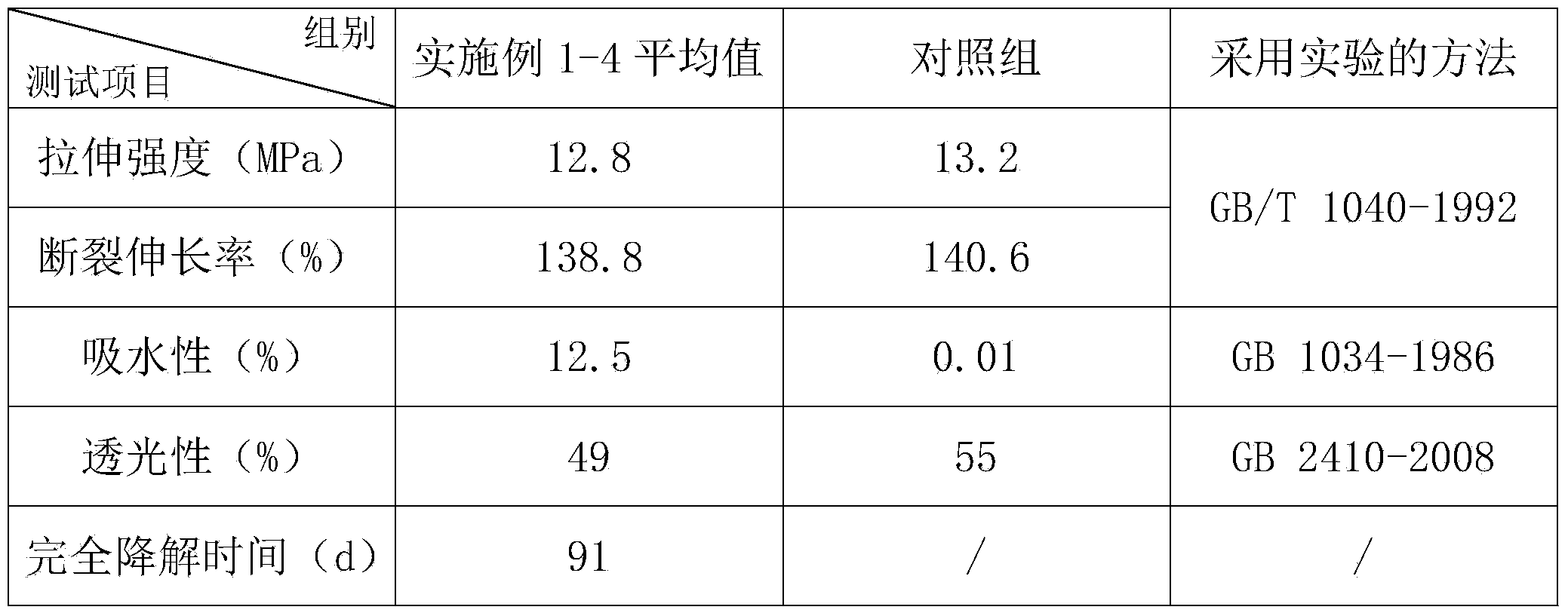

Degradable plastic material

The invention discloses a degradable plastic material. The degradable plastic material comprises the following raw materials in part by weight: 5-50 parts of hydroxybutyrate and valeric acid copolyester PHBV4, 50-55 parts of peanut protein prowder, 15-18 parts of nanometer cellulose whiskers, 12-15 parts of coconut fibers, 3-5 parts of amylase, 1.5-2.2 parts of silane coupling agents, 2-3 parts of potassium sorbate, 2-3 parts of dehydroacetic acids, 1.4-1.6 parts of dioctyl phthalate, 1.2-1.6 parts of zinc stearate, 10-12 parts of hard clay, 5-9 parts of kaolin, 7-11 parts of sepiolite and 1-1.4 parts of 2, 6- di-tert-butyl-4-methylphenol BHT. The degradable plastic material can be completely decomposed into micromolecule substances under effects of microorganisms; the tensile strength, the breakage elongation and the light transmission of the degradable plastic material are close to those of the existing polypropylene; and the degradable plastic material can replace the polypropylene in some fields.

Owner:浙江创新旭隆新材料科技有限公司

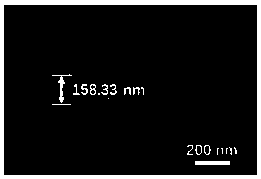

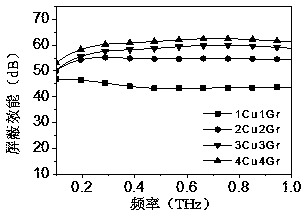

Preparation method of efficient and stable ultra-thin flexible terahertz shielding material

InactiveCN110545654AImprove performanceLow ultra-thin thicknessMagnetic/electric field screeningPolymer substrateThin membrane

The invention relates to a preparation method of an efficient and stable ultra-thin flexible terahertz shielding material. The preparation steps are as follows: firstly graphene is grown on the surface of a metal substrate by a chemical vapor deposition method; then a layer of transfer medium is coated on the metal substrate on which the graphene is grown; then the metal substrate is removed by anetching solution to leave the graphene supported by the transfer medium; then a layer of metal thin film is deposited on the polymer substrate; then the graphene supported by the transfer medium is transferred to the metal film deposited on the polymer substrate and the transfer medium supporting the graphene is removed; and then the steps of deposition of the metal thin film and transfer of thegraphene are alternately repeated so as to obtain a metal / graphene composite material assembled layer by layer. The metal / graphene layer-by-layer assembled terahertz shielding material has low thickness, high shielding efficiency, good flexibility and high stability and has broad prospects in the terahertz shielding field of microelectronic devices and flexible electronic equipment.

Owner:NANKAI UNIV

Toothed belt

A toothed belt (1) includes: a belt main body (4) in which a plurality of cords (2) are arranged side by side in a widthwise direction of a rubber layer (3); a plurality of teeth portions (5) formed at one surface of the belt main body (4); and a tooth cloth (6) covering surfaces of the teeth portions (5). A cloth base material is obtained by impregnating a surface layer rubber composition into an original canvas and by forming a surface layer, and an adhesion layer rubber composition is attached to one surface of the cloth base material to form an adhesion layer, thus forming the tooth cloth (6). The rubber layer (3) contains: HNBR including HNBR in which a Mooney viscosity at 100 DEG C. is in a range of from 100 to 160. The rubber layer (3), the rubber composition for a surface layer and the rubber composition for an adhesion layer preferably contain hydrogenated carboxyl NBR.

Owner:TSUBAKIMOTO CHAIN CO

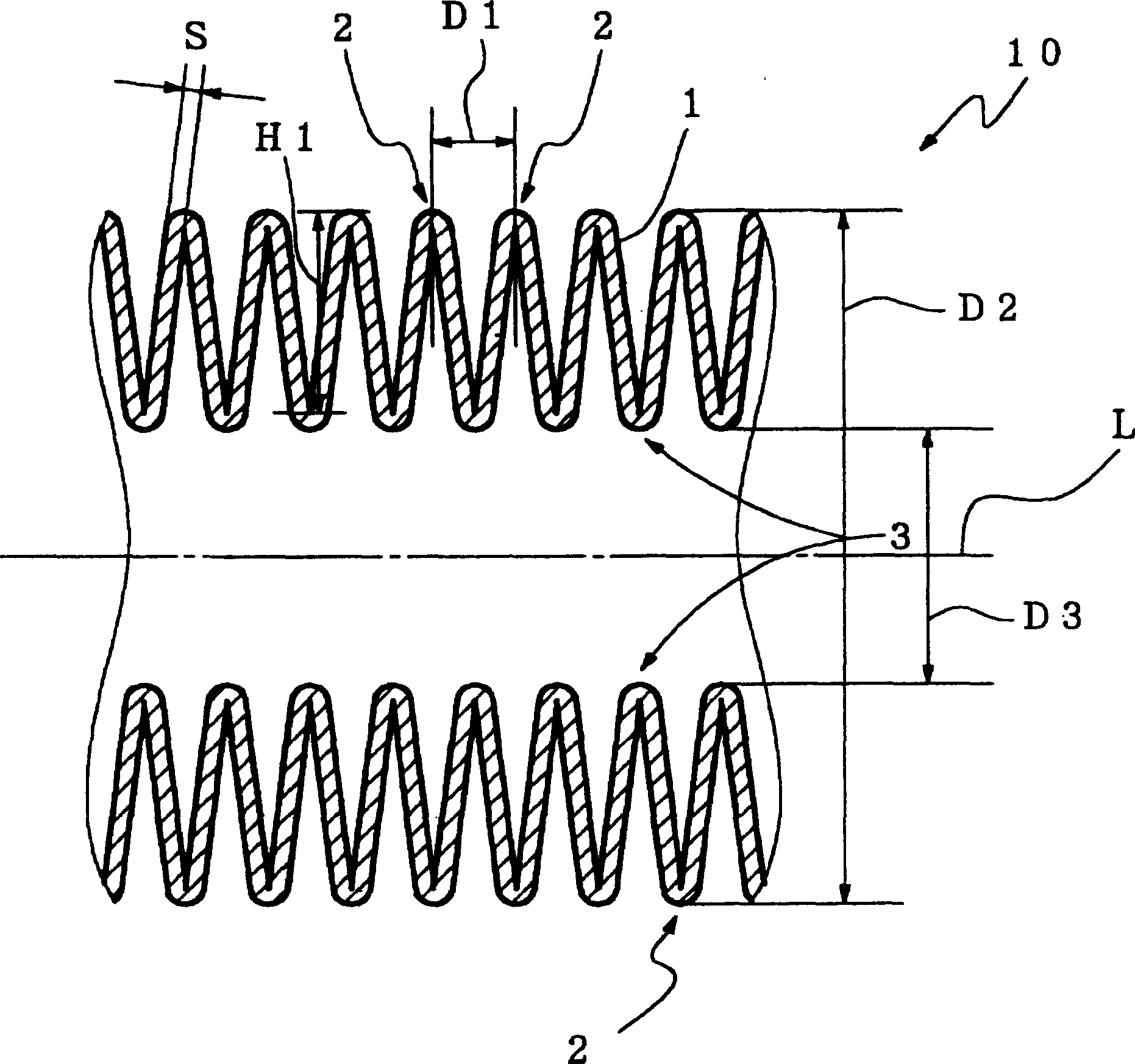

Metal bellows tube, method of producing the same, and flexible tube for high-pressure fluid

Cross sections of both a mountain (2) and a valley (3) of a bellows-like tube wall (1) of a metal bellows tube are made to a letter-V shape. This enables to provide a metal bellows tube with a much better bending fatigue resistance property than that available in conventional products. A flexible tube for a high-pressure fluid is structured from the metal bellows tube and a tube-like metal knitted body covering the outer side of the bellows tube. This makes it possible that a high-pressure fluid with a pressure exceeding 20 MPa can be, and particularly, even a very high-pressure fluid with a pressure of 70 MPa can be safely transported without allowing molecules of the fluid to permeate the tube.

Owner:ORK

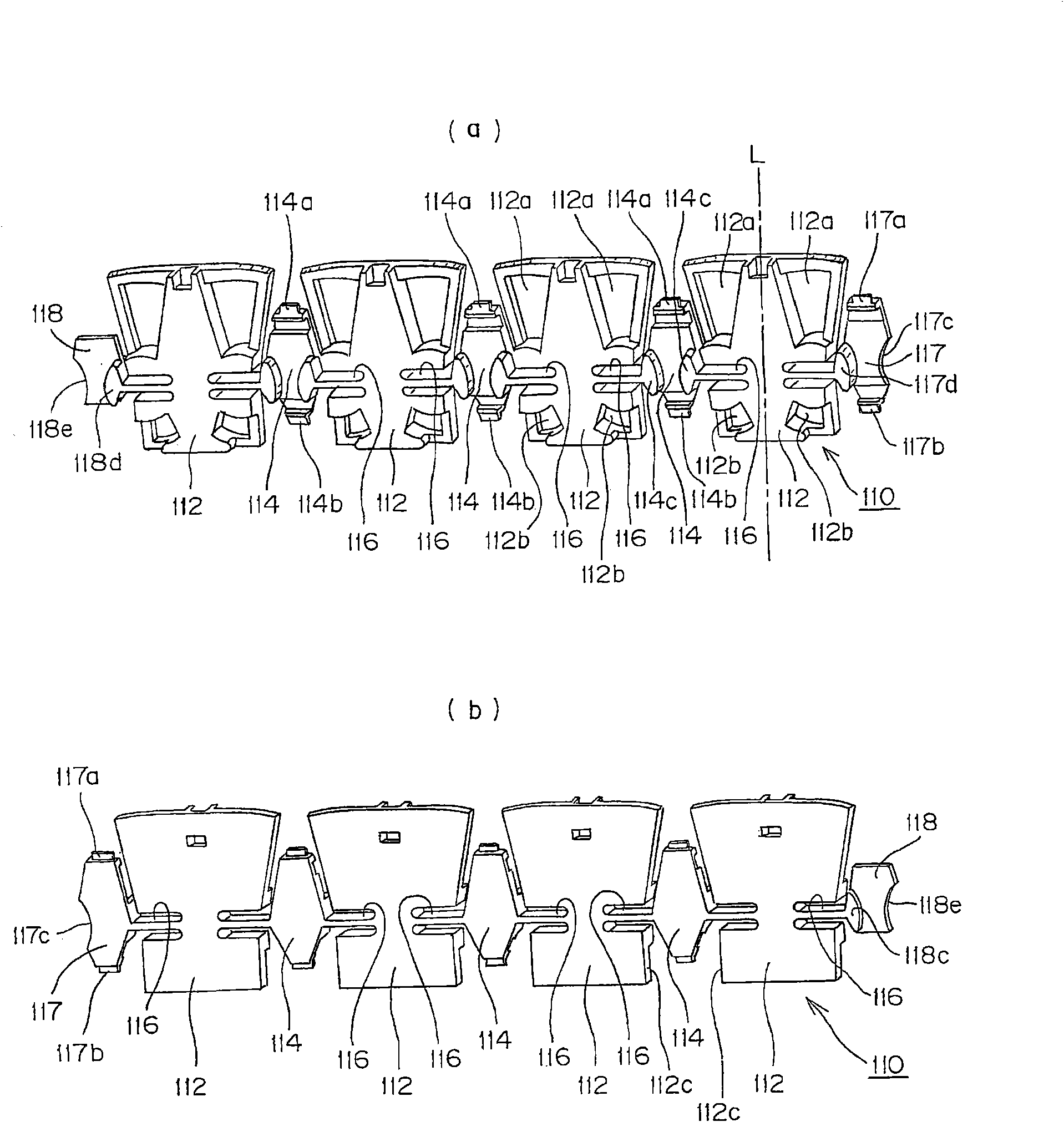

Cable protection and guide device

ActiveCN101567532AReduce in quantityLighten the burden of assemblyHauling chainsHoisting chainsCouplingPolyamide

A cable protection and guide device in which the number of parts used is reduced and assembly is simplified. Dust generation and bending fatigue is suppressed so that the cable protection and guide device exhibits excellent form stability of the cable accommodating space. Side plate portions and coupling portions are integrally molded from polyamide fatigue resistant resin into the form of a connecting link module. A polyacetal resin stopper link, which holds and limits the linear position and the bending position by engagement with the connecting link module, is inter-fitted with a coupling portion of the connecting link module by a snap-fit mechanism from the cable accommodating space side.

Owner:TSUBAKIMOTO CHAIN CO

High strength polyethylene fibers and their applications

High strength polyethylene fibers and their applications, for example, chopped fibers, ropes, nets, ballistic materials or items, protective gloves, fiber reinforced concrete products, helmets, and other products obtained therefrom, in which the fiber is characterized in that: it contains a high molecular weight polyethylene consisting essentially of a repeating unit of ethylene; it has an intrinsic viscosity number of 5 or larger and an average strength of 22 cN / dtex or higher; and the measurement of the fiber by differential scanning calorimetry (DSC) exhibits a temperature-increasing DCS curve having at least one endothermic peak over a temperature region of 140° C. to 148° C. (on the low temperature side) and at least one endothermic peak over a temperature region of 148° C. or higher (on the high temperature side) or the number of frictions until the fiber is broken in an abrasion test according to method B for measuring abrasion resistance in the Testing Methods for Spun Yarn (JIS L 1095) is 100,000 or larger.

Owner:TOYOBO CO LTD

Rubber composition for transmission belt and transmission belt

InactiveCN101636447AImprove conductivityHigh bending fatigue resistanceV-beltsDriving beltsPolymer scienceTransmission belt

This invention provides a rubber composition for a transmission belt, which can realize the manufacture of a transmission belt excellent in electroconductivity as well as in electroconductivity retaining property after running and having excellent resistance to fatigue from flexing and abrasion resistance. The rubber composition contains rubber, furnace carbon black, zinc oxide, and stearic acid. The furnace carbon black has a nitrogen adsorption specific surface area of not less than 75 m<2> / g and a DBP absorption of not less than 100 cm<3> / 100g and is contained in an amount of 50 to 100 parts by mass based on 100 parts by mass of the rubber. The content of the zinc oxide is not less than 6 parts by mass based on 100 parts by mass of the rubber. The content of the stearic acid is not less than 1 part by mass based on 100 parts by mass of the rubber.

Owner:BANDO CHEM IND LTD

Cold-resistant plastic bucket and preparation method thereof

ActiveCN108822385AImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

Stainless steel wire for spaceflight

The invention relates to a novel stainless steel wire for spaceflight. The structure of the novel stainless steel wire is CFRC8*19W or CFRC8*17S and is formed by twisting a central strand, eight inner-layer strands and eight outer-layer strands in one step, wherein the structure of the central strand is 1+7+7 and is formed by twisting fifteen steel wires in one step, the structure of eight inner-layer strands is 1+6 and is formed by twisting seven steel wires in one step, and the structure of the eight outer-layer strands is 1+6+6 / 6 or 1+8+8 and is formed by twisting nineteen or seventeen steel wires in one step. The novel stainless steel wire for spaceflight can greatly enhance the bearing capability by being tempered in a continuous tempering furnace with protection and has the advantages of high bending and fatigue resistant property, good flexible property and abrasion resisting property, long service life, good safety property, and the like.

Owner:GUIZHOU WIRE ROPE

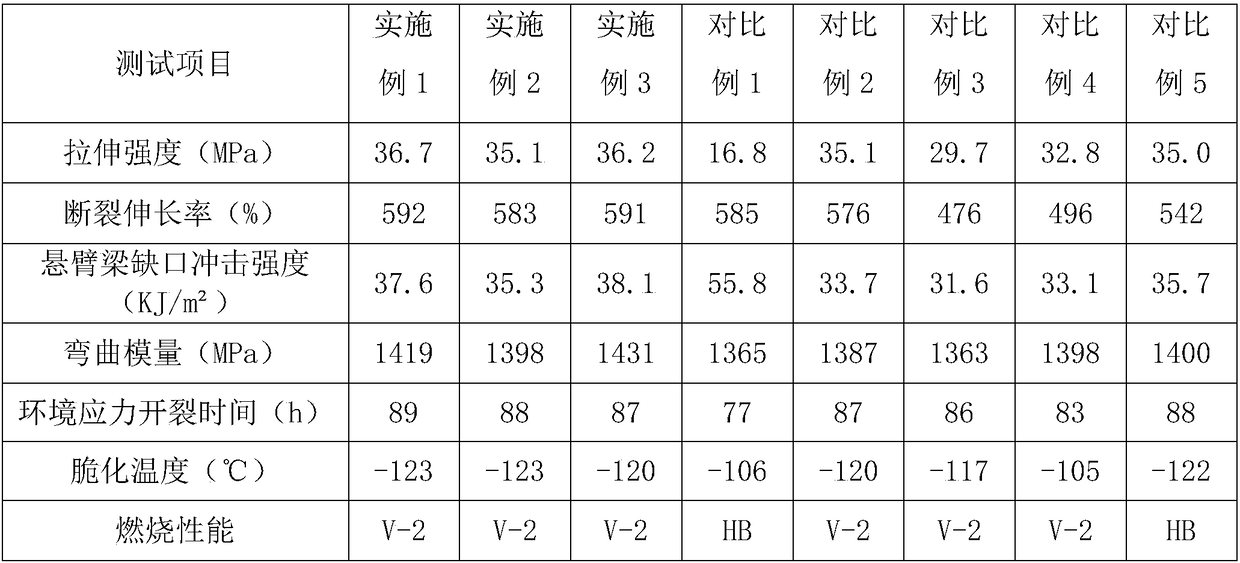

High-strength low-extension anti-bending-fatigue sailboat rope and manufacturing method thereof

PendingCN110016758AReduced load elongationReduced breaking strengthBraidLiquid/gas/vapor yarns/filaments treatmentFiberBreaking strength

The invention discloses a high-strength low-extension anti-bending-fatigue sailboat rope and a manufacturing method thereof. The sailboat rope comprises a woven rope core and a rope skin wrapping therope core, and the rope core is made from high-strength fibers; the rope skin is woven from multiple rope strands composed of multiple high-strength fibers through twisting; the rope core component orthe whole rope is subjected to tension thermal-setting treatment. On the premise of ensuring sufficient fullness and flexibility of a sailboat rope body, higher breaking strength and lower loading extension rate are achieved, and the anti-bending-fatigue performance of the sailboat rope is significantly improved.

Owner:TAIAN ROPE NET PLASTIC +1

Crosslinkabel rubber composition and crosslinked object

InactiveCN1860171AExcellent mechanical propertiesExcellent dynamic ozone resistancePolymer scienceCompression set

A crosslinkable rubber composition which comprises a mixture consisting of a nitrile copolymer rubber (A) having a carboxy content of 2x10<-3> to 1x10<-1> eq / 100 g and an acrylic polymer (B) having a carboxy content of 4x10<-4> to 1x10<-1> eq / 100 g in a proportion of from 40 / 60 to 90 / 10 by weight and, incorporated in the mixture, a crosslinking agent (C) capable of forming crosslinks with carboxy groups of each of the nitrile copolymer rubber (A) and the acrylic polymer (B), wherein the amount of the crosslinking agent (C) incorporated, in terms of the amount of that functional group of the crosslinking agent which is reactive with carboxy groups, is 0.3 to 3 equivalents to the sum of the carboxy groups of each of the nitrile copolymer rubber (A) and the acrylic polymer (B). The crosslinkable rubber composition gives a crosslinked object which is excellent not only in mechanical properties including tensile strength and reduced compression set and oil resistance but in a high degree of weatherability including dynamic ozone resistance and a high degree of mechanical properties including flexural fatigue resistance.

Owner:ZEON CORP

Cord for Rubber Reinforcement

InactiveUS20090229237A1Excels in bending fatigue resistanceWithout lowering dimensional stabilityYarnTextile cablesFiberEngineering

Owner:NIPPON SHEET GLASS CO LTD

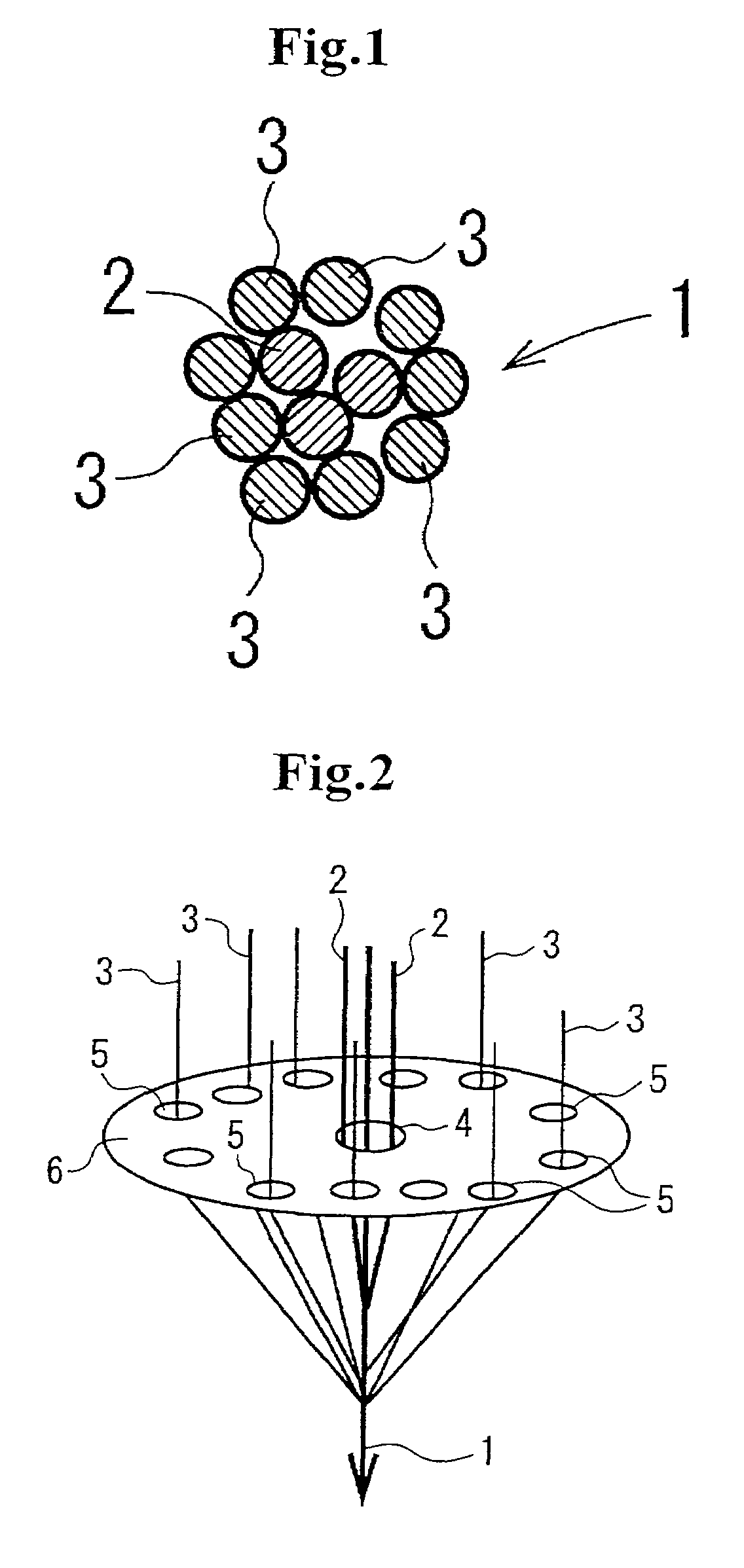

Hybrid cord for rubber reinforcement and rubber product employing the same

ActiveUS7404426B2High strengthHigh bending fatigue resistanceFibre typesPneumatic tyre reinforcementsFiberGlass fiber

A hybrid cord 1 for rubber reinforcement comprises a strand 2 having higher elastic modulus, made of PBO fiber or the like, which is disposed at the center of the cord, and strands 3 having lower elastic modulus, made of glass fiber or the like, which are disposed therearound. The hybrid cord has enough strength and is excellent in flexural fatigue resistance, adhesion property relative to rubber, and dimensional stability. A rubber product employs this hybrid cord 1 for rubber reinforcement.

Owner:NIPPON SHEET GLASS CO LTD

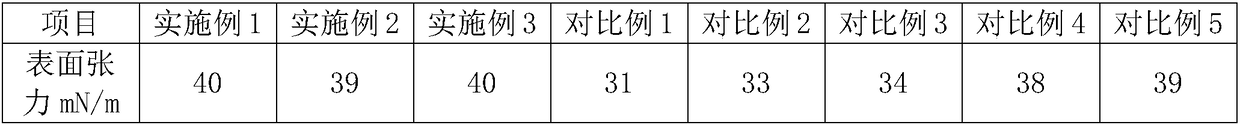

Slurry for sizing of polyester fiber

InactiveCN103696246AImprove impact resistanceHigh bending fatigue resistanceFibre typesFiberPolyester

The invention discloses a slurry for sizing of polyester fiber and belongs to the technical field of textile polyester fiber sizing slurries. The slurry comprises the following components: 30-50 percent of methyl benzoate, 30-40 percent of hydroxypropyl starch and 10-40 percent of water-soluble cellulose ether. The water-soluble cellulose ether is carboxymethylcellulose. The slurry has the beneficial effect of reducing the pollution of de-sizing wastewater to ecological environment.

Owner:JIANGSU BOBOBEAR TEXTILE

Cord for rubber reinforcement

InactiveUS7814740B2High bending fatigue resistanceWithout lowering dimensional stabilityYarnTextile cablesFiberEngineering

Owner:NIPPON SHEET GLASS CO LTD

Composition for cord coating, cord for rubber reinforcement made with the same, and rubber product made with the same

ActiveCN1938475AGood dimensional stabilityHigh bending fatigue resistanceRubber derivative coatingsCarbon fibresWater solubleSolid content

A composition for cord coating of the present invention comprises a latex of a first rubber, a phenol resin, and a water-soluble condensation product of resorcinol-formaldehyde so that a ratio of the first rubber to a solid content of the composition, a ratio of the phenol resin thereto, and a ratio of the water-soluble condensation product thereto are 30 to 95 wt.%, 0.01 to 30 wt.%, and 2 to 15 wt.%, respectively, wherein the first rubber is a nitrile group-containing highly saturated polymer rubber having an iodine value of 120 or less, and the above-described water-soluble condensation product is a novolac-type condensation product.

Owner:NIPPON SHEET GLASS CO LTD

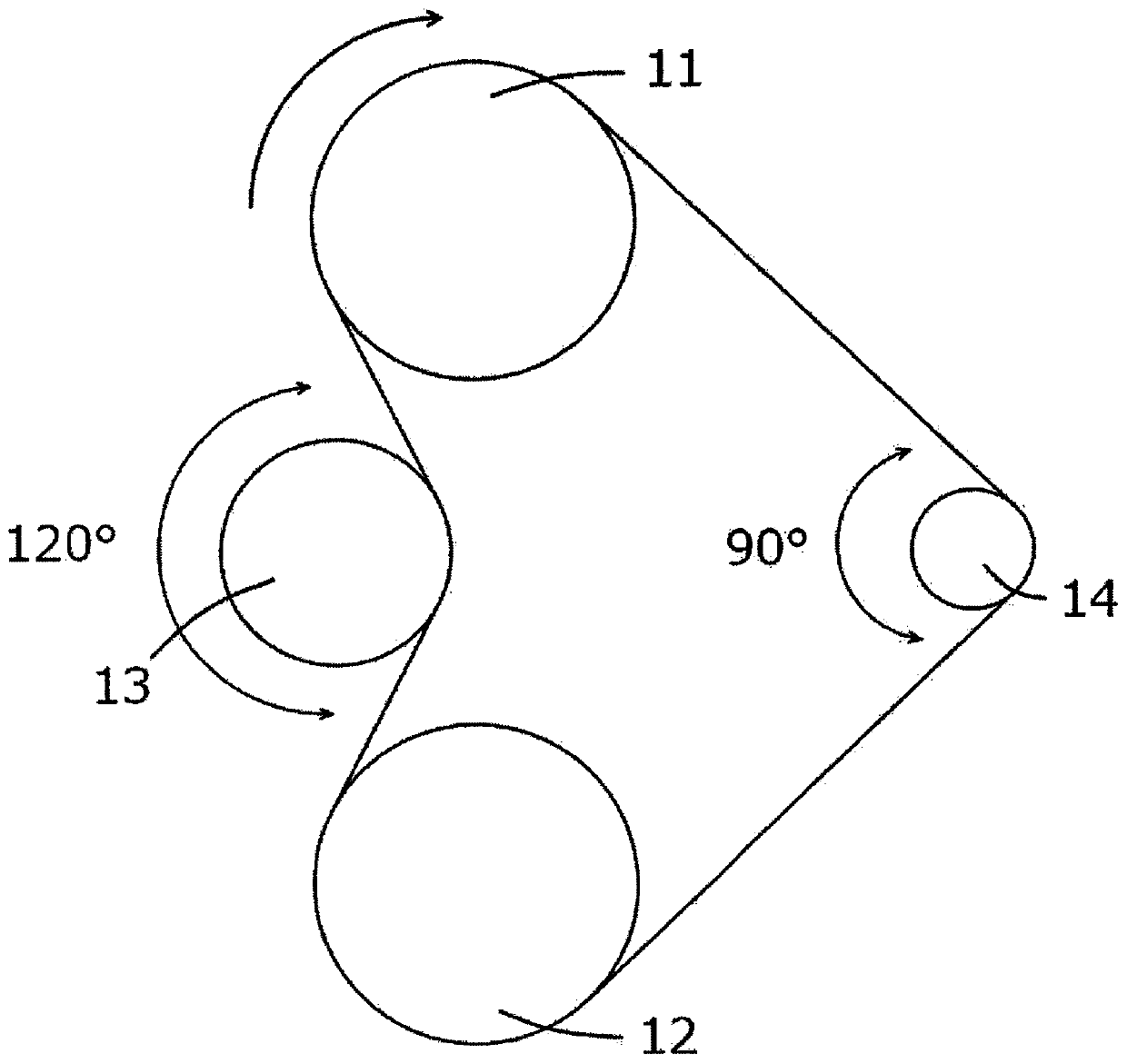

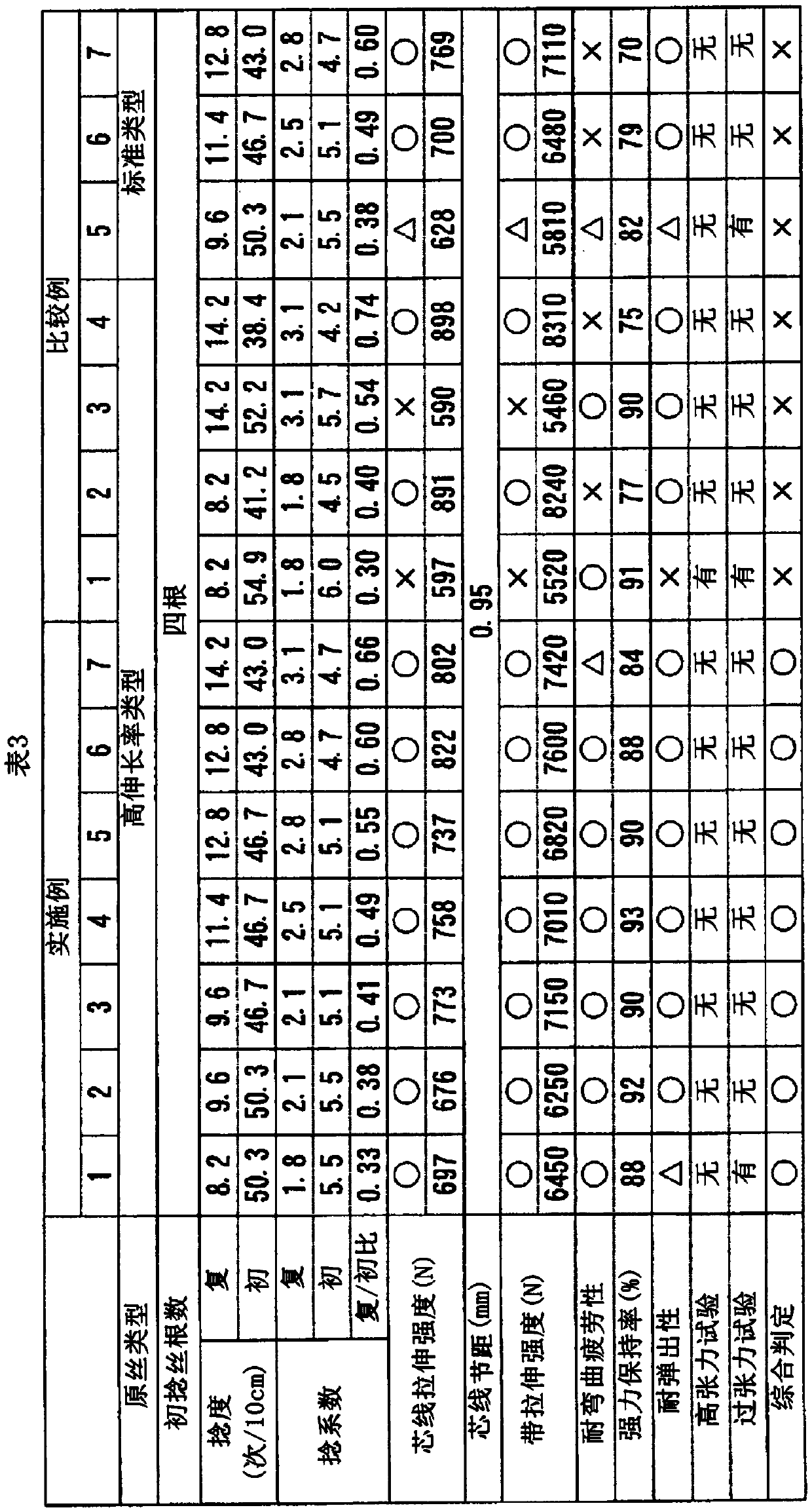

Plied cord, production method therefor, transmission belt, and method for using same

ActiveCN109844194AHigh tensile strengthHigh bending fatigue resistanceV-beltsDriving beltsYarnTransmission belt

The present invention relates to a plied cord comprising three or four first twist yarns containing para-aramid fibers, wherein: the para-aramid fibers have an average size of 1000-1250 dtex, a tensile elasticity of 55-70 GPa and a tensile strength of 2800-3500 MPa; and for the plied cord, the number of first twists when the number of the first twist yarns is three is 33-40 twists / 10 cm and the number of first twists when the number of the first twist yarns is four is 42-52 twists / 10 cm, the second twist direction is the opposite direction from the first twist, and the ratio of the second twist coefficient to the first twist coefficient is 0.25-1.

Owner:MITSUBOSHI BELTING LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com