Reinforcing cord for reinforcing rubber and rubber product using the same

A technology for reinforcing rubber and cords, applied in the field of reinforcing cords for reinforcing rubber and rubber products using the cords, which can solve problems such as low bending resistance, difficulty in obtaining strength and bending resistance, and reduced strength , to achieve excellent durability, high bending fatigue resistance, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

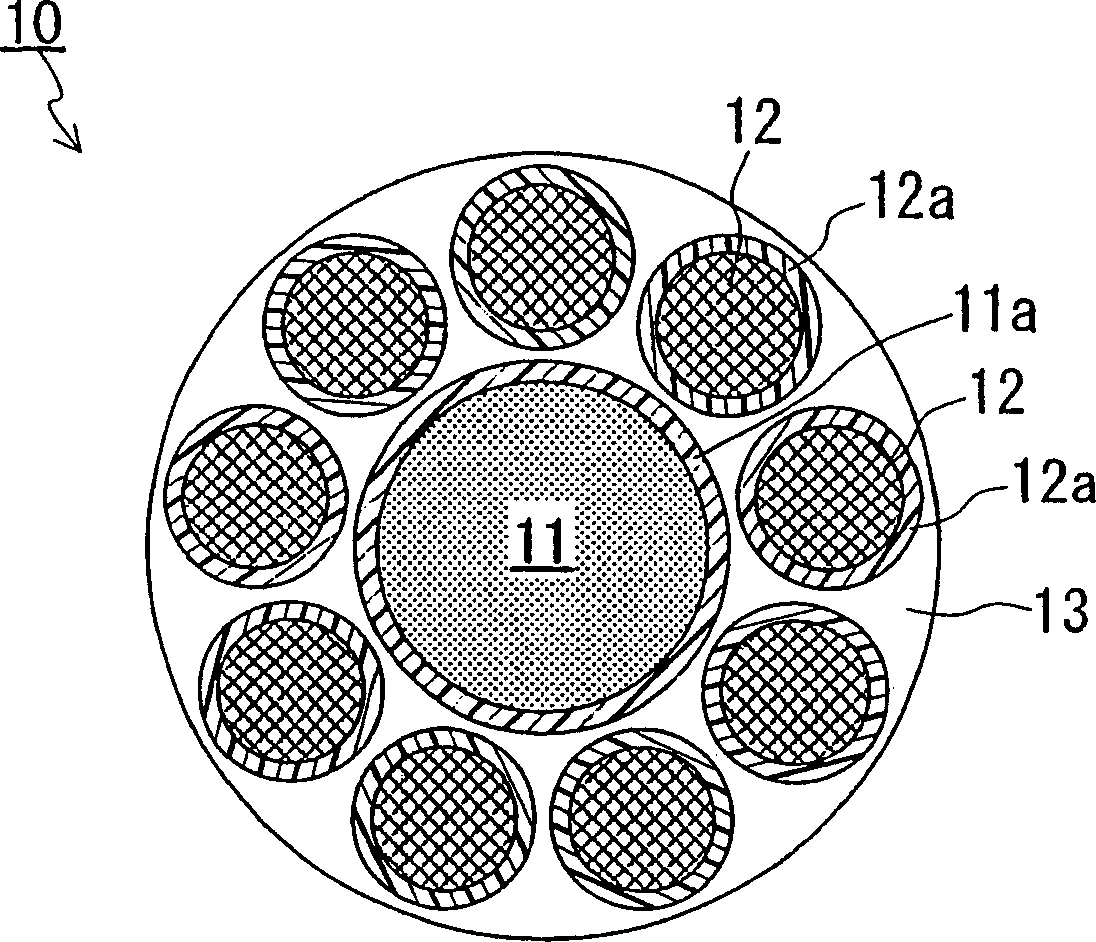

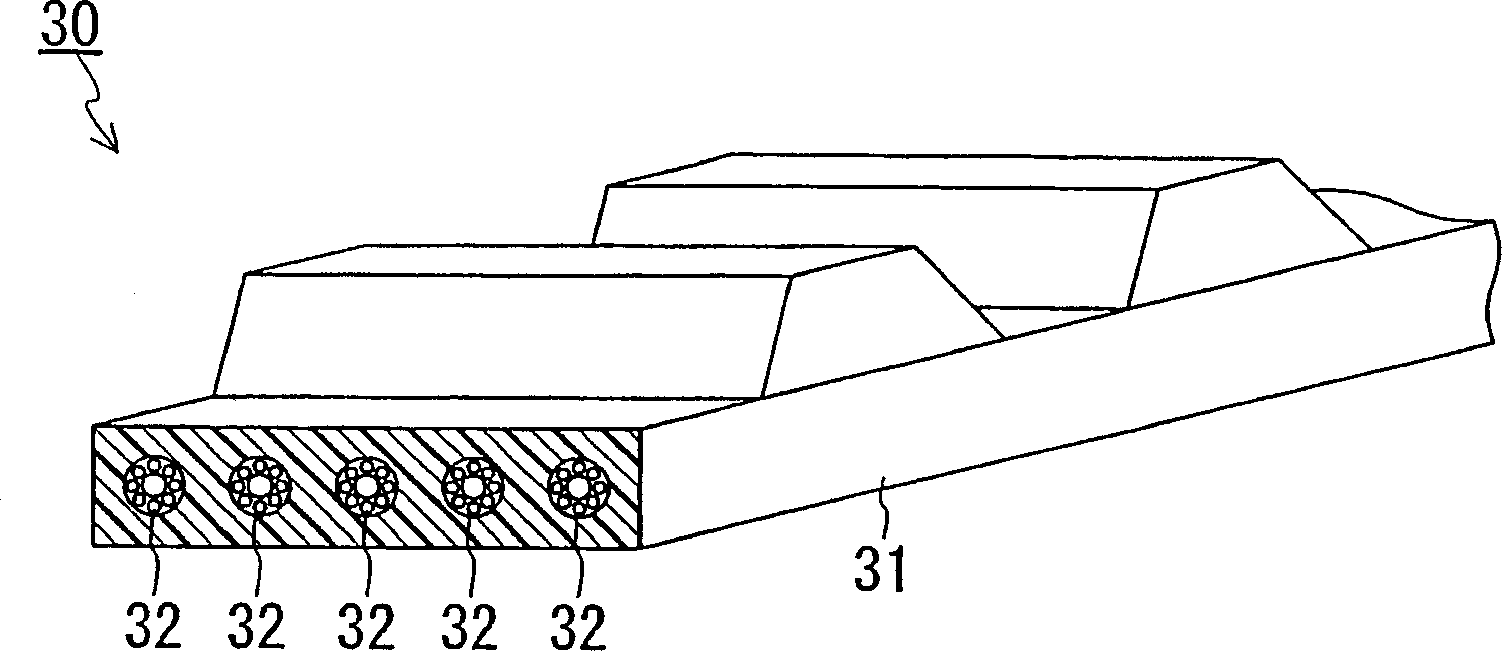

[0051] After the RFL treatment liquid was impregnated into the carbon fiber strands, heat treatment (180° C. for 120 seconds) was performed to dry them. Thus, a coated carbon fiber strand (20% by weight of the coating) was produced. Carbon fiber strands (400tex, outer diameter of about 0.76mm, modulus of elasticity of 235GPa, density of about 1.76g / cm2) were used as carbon fiber strands in bundles of 6,000 carbon fiber filaments (7.0μm in diameter). 3 , Untwisted product, manufactured by Toho Tenacus Co., Ltd.). In addition, a solution (8% by weight of solid content) of resorcinol-formalin condensate, vinylpyridine-styrene-butanediene was mixed at a solid content weight ratio of 2:13:6 for the RFL treatment liquid. A mixture of ethylene latex (solid content: 40% by weight) and chlorosulfonated polyethylene rubber dispersion (solid content: 40% by weight).

[0052] In addition, prepare a coated glass fiber strand (about 100 tex, an outer diameter of about 0.35 mm, a modulus o...

Embodiment 2

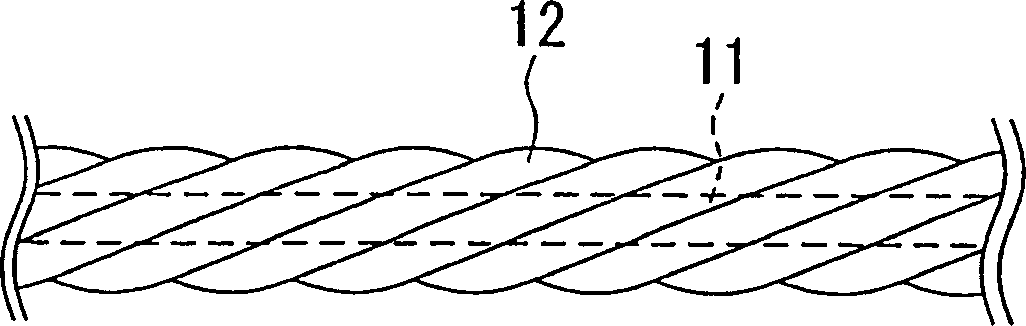

[0061] First, as in Example 1, a carbon fiber strand provided with a film was produced, and primary twist (2.0 times / 25 mm) was applied in the S direction. A first cord (diameter: 1.18 mm) was produced in the same manner as in Example 1 except that the carbon fiber strands thus obtained were used. The count of the first cord is 1770tex, that is, the weight per 1000m of length is 1770g.

[0062] Next, as in Example 1, a protective layer was formed on the surface of the first cord. In this way, the second cord provided with the protective layer is obtained. The weight of the protective layer was 5% by weight of the first cord. About this 2nd cord, it evaluated similarly to Example 1. In addition, a sample for a bending test was prepared in the same manner as in Example 1, and a bending test was performed.

[0063] As a result, the initial tensile strength per one cord was 1080 N / cord. The elongation at break was 2.1%. The tensile load per cord at 0.4% elongation is 200N / co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com