Cable protection and guide device

A technology for guiding devices and cables, applied in drag chains, hanging chains, chain components, etc., which can solve the problems of increased production burden, labor consumption of side panels, insufficient flexural rigidity or torsional rigidity, and reduce the burden of assembly work , Lighten the load on parts assembly and suppress bending fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

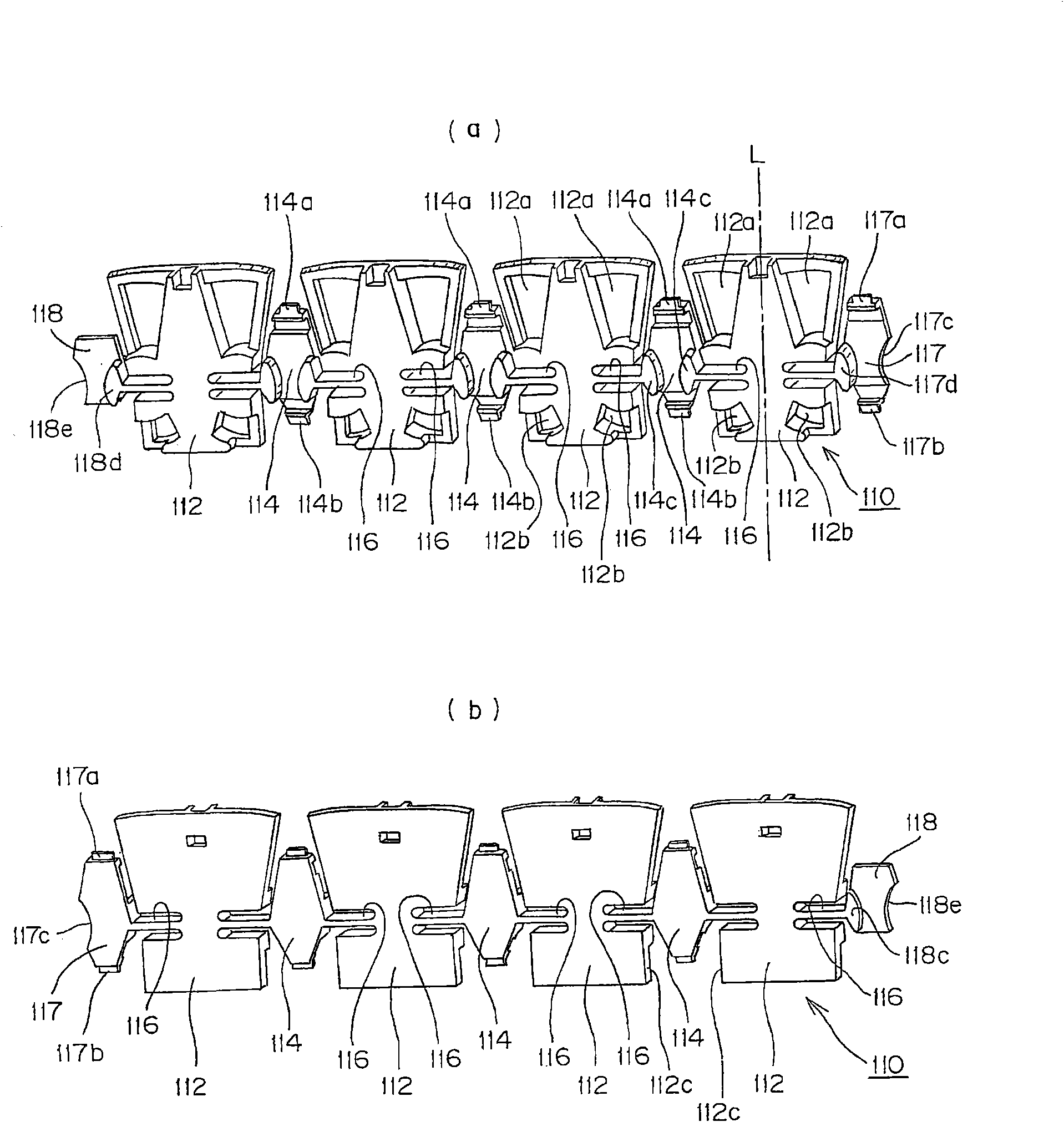

[0068] Below, combine Figure 1 to Figure 6 The cable protection guide device 100 which is Embodiment 1 of this invention is demonstrated.

[0069] here, figure 1 is a perspective view showing a part of the cable protection and guide device 100 of this embodiment, figure 2 yes figure 1 An exploded view of the cable protection guide 100 is shown. image 3 is as figure 1 The perspective view of the link assembly 110 which is a component part of the shown cable protection guide apparatus 100, (a) is a perspective view seen from the cable storage space side, (b) is a perspective view seen from the outside. Figure 4 is as figure 1 The perspective view of the limiter chain link, which is a component of the cable protection and guide device 100 shown, (a) is a perspective view showing the side assembled on the link assembly, and (b) is viewed from the side of the cable storage space stereogram.

[0070] The cable protection and guiding device 100 of Embodiment 1 of the p...

Embodiment 2

[0102] Below, combine Figure 7 and Figure 8 The cable protection guide device 200 of Example 2 which is another embodiment of the present invention will be described.

[0103] here, Figure 7 is a perspective view showing a part of the cable protection and guide device 200 of this embodiment, Figure 8 yes Figure 7 An exploded view of the cable protection guide 200 is shown.

[0104] For the cable protection guide device 200 of this embodiment, such as Figure 7 and Figure 8 As shown, a link assembly 210 formed of a polyamide-based fatigue-resistant resin containing a rubber component is formed by integrally molding a plurality of side plate portions 212 via a joint portion 214 .

[0105] Such as Figure 8 As shown, the plurality of side plate portions 212 form an elongated link assembly 210 by connecting horizontally extending joint arms 216 to substantially diamond-shaped joint portions 214 formed between adjacent side plate portions 212 , 212 .

[0106] Such as ...

Embodiment 3

[0113] Below, use Figure 9 and Figure 10 The cable protection guide device 300 of Example 3 which is another embodiment of the present invention will be described.

[0114] here, Figure 9 is a perspective view showing a part of the cable protection and guide device 300 of this embodiment, Figure 10 yes Figure 9 An exploded view of the cable protection guide 300 is shown.

[0115] The cable protection guide device 300 of this embodiment, such as Figure 9 and Figure 10 As shown, a plurality of side plate portions 312 are integrally formed by means of joint portions 314 to form a chain link assembly 310 .

[0116] Such as Figure 10 As shown, these plurality of side plate portions 312 form an elongated link assembly 310 by connecting horizontally extending joint arms 316 to substantially diamond-shaped joint portions 314 formed between adjacent side plate portions 312 .

[0117] Such as Figure 10 As shown, the limiting chain link 320 made of polyacetal resin is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com