Electromagnetic wave shielding film and highly transparent strong electromagnetic wave shielding tape based on electromagnetic wave shielding film

A technology of electromagnetic wave and shielding film, which is applied in the direction of film/flaky adhesives, adhesives, conductive coatings, etc., which can solve the problem of insufficient transmittance and shielding effectiveness of electromagnetic wave shielding coatings, harsh construction environment of shielded components and conductive fabrics. Expensive and other problems, to achieve excellent fullness, easy to use, and strong shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

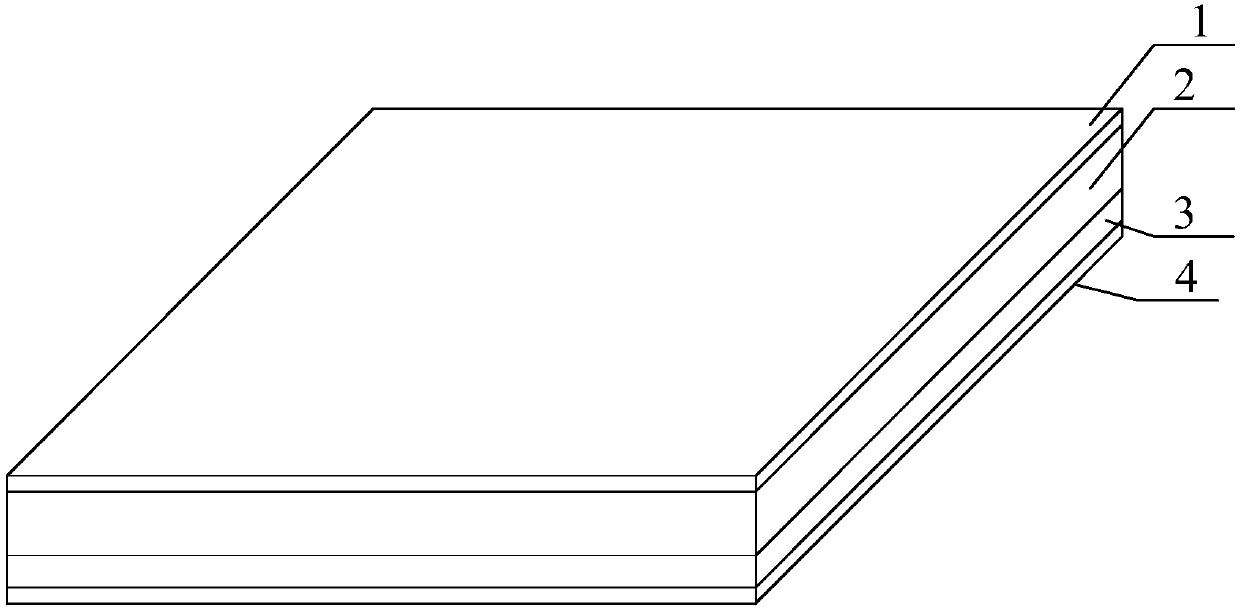

[0046] Such as figure 1 As shown, the strong electromagnetic wave shielding adhesive tape of this embodiment forms an electromagnetic wave shielding film 1 by coating electromagnetic wave shielding slurry on one side of the transparent substrate 2, and forms an adhesive layer 3 by coating an adhesive on the other side. A release paper 4 is pasted on the surface of the adhesive layer.

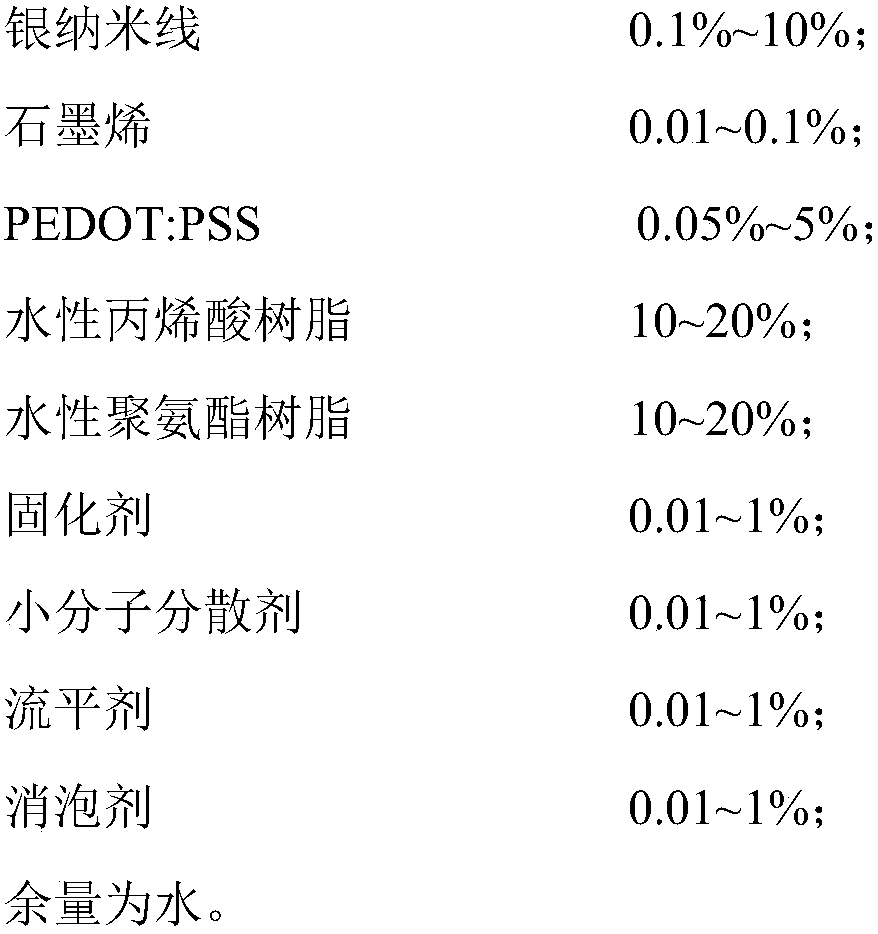

[0047] The mass ratio of each raw material used in the electromagnetic wave shielding slurry in this embodiment is shown in Table 1, and the balance is water. The preparation steps are as follows:

[0048] (1) Silver nanowires, PEDOT:PSS, graphene, water-based acrylic resin S-812, water-based polyurethane resin Bayhydrol B130, small molecule dispersant sodium dodecylbenzene sulfonate, leveling agent Zonyl FSO, defoamer Mix Foamex810, curing agent SD 230 and water evenly in proportion to obtain electromagnetic shielding slurry;

[0049] (2) Coat the electromagnetic wave shielding slurry on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com