Metal bellows tube, method of producing the same, and flexible tube for high-pressure fluid

一种金属波纹管、高压流体的技术,应用在挠性管领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

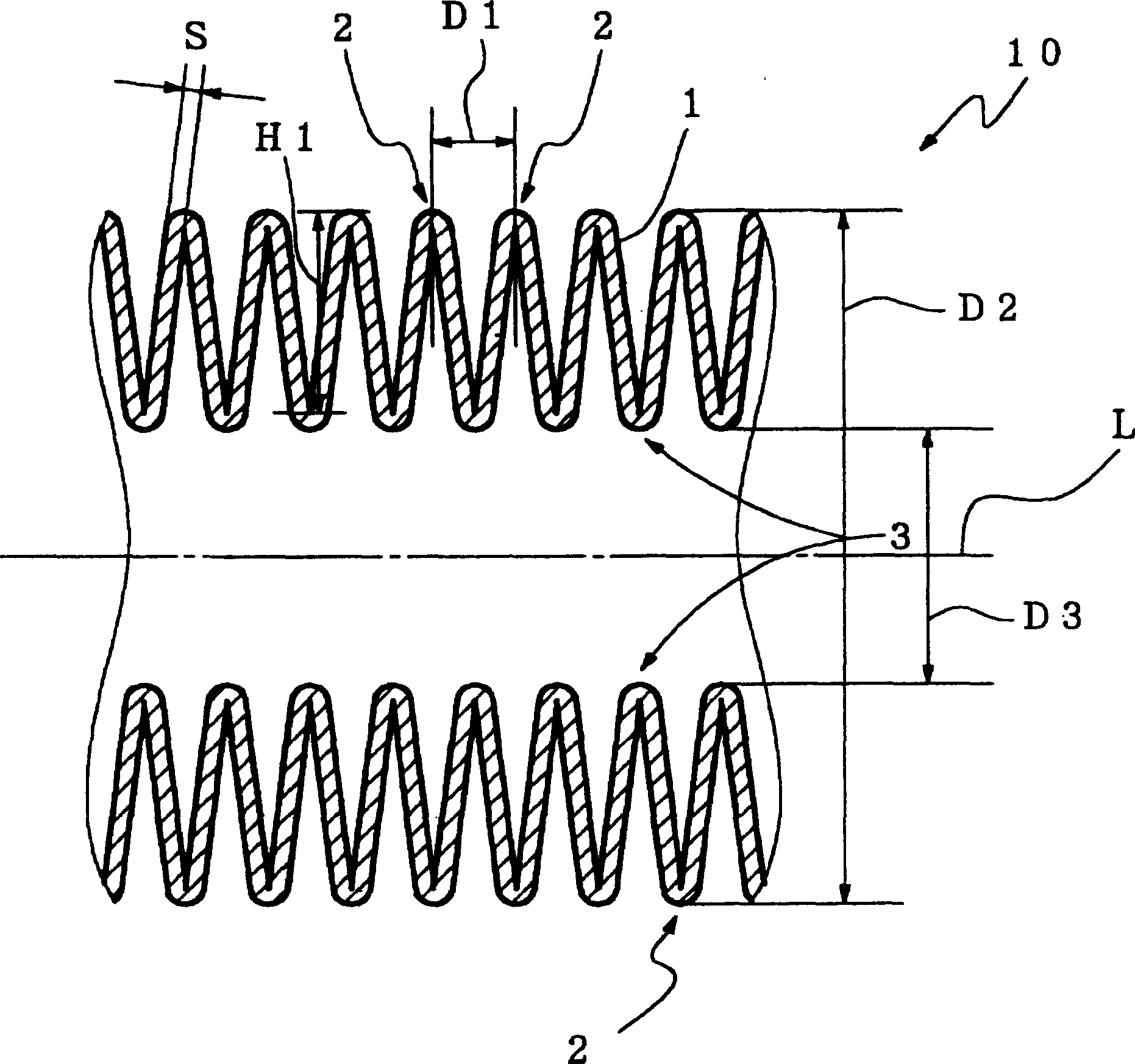

[0130] A stainless steel cylindrical pipe was formed into a corrugated base pipe (corrugation pitch: 2.5 mm) in which the cross-sectional shape of the ridges and recesses in the wall of the corrugated pipe was U-shaped by a continuous die forming method. Next, through the aforementioned second to fourth steps, a cross-section in which the cross-sectional shape of the ridges and recesses in the corrugated-shaped pipe wall is V-shaped is prepared.

[0131] The outer diameter is 9.3 mm, the inner diameter is 5.2 mm, the thickness of the corrugated pipe wall is 0.15 mm, the pitch of the corrugation is 0.5 mm (the number of ridges per 1 cm in the longitudinal direction of the pipe is: 20), the total The length is 30cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com