Self-leveling floor material and preparation method thereof

A leveling and cement technology, which is applied in the field of self-leveling floor materials and its preparation, can solve problems such as increased project cost, short service life, and influence on construction progress, and achieves improved impermeability and impact resistance, improved stability and use life, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

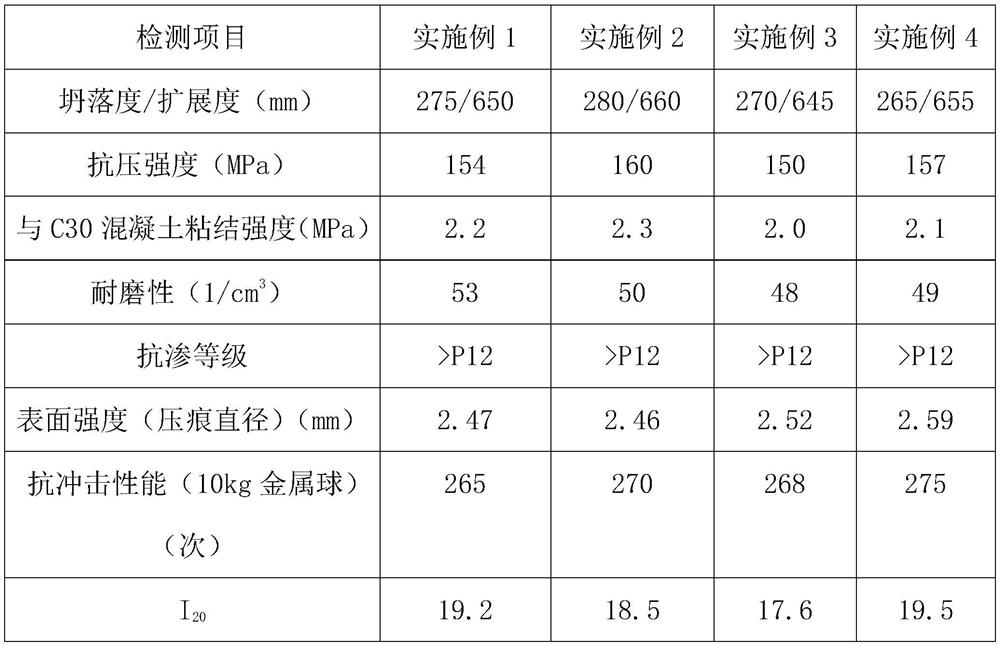

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned self-leveling floor material comprises the following steps:

[0039] Put the cement, silica fume, fly ash, stone powder, quartz sand and viscosity reducer in the mixing pot according to the formula, and stir for 2-3 minutes; add water, water reducer and shrinkage reducer, and stir for 5-8 minutes; add Toughening agent, stirred for 2-3 minutes, obtained from leveling floor materials.

Embodiment 1

[0041] A self-leveling floor material, comprising the following components by weight:

[0042] P.O 52.5 260 parts of ordinary Portland cement, 70 parts of silica fume, 40 parts of fly ash, 30 parts of stone powder, 430 parts of quartz sand, 7 parts of toughening agent, 10 parts of water reducing agent, 2 parts of shrinkage reducing agent, viscosity reducing agent 10 parts, 40 parts of water.

[0043] P.O 52.5 Ordinary Portland Cement has a specific surface area of 380m 2 / kg; the average particle size of silica fume is 0.2um, and the specific surface area is 17500m 2 / kg, the activity index is 106%, SiO 2 The mass content is 97%; the particle content of fineness less than 1um in silica fume is 88%; the fly ash is Class I fly ash, the sieve residue of 45μm square hole sieve is 8%, the loss on ignition is 3.5%, and the water demand The ratio is 90%; the stone powder is quartz powder, and the fineness of the stone powder is 400 mesh; the fineness modulus of quartz sand is 1....

Embodiment 2

[0048] A self-leveling floor material, comprising the following components by weight:

[0049] P.O 52.5 Ordinary Portland cement 300 parts, silica fume 100 parts, fly ash 60 parts, stone powder 50 parts, quartz sand 490 parts, toughening agent 12 parts, water reducing agent 15 parts, shrinkage reducing agent 6 parts, viscosity reducing agent 20 parts, 70 parts of water.

[0050] P.O 52.5 Ordinary Portland Cement has a specific surface area of 400m 2 / kg; the average particle size of silica fume is 0.3um, and the specific surface area is 18000m 2 / kg, the activity index is 108%, SiO 2 The mass content is 99%; the content of particles with fineness less than 1um in silica fume is 90%; the fly ash is Class I fly ash, the sieve residue of 45μm square hole sieve is 5%, the loss on ignition is 2%, and the water demand The ratio is 85%; the stone powder is quartz powder, and the fineness of the stone powder is 450 mesh; the fineness modulus of quartz sand is 2.0; the toughening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com