Welding process for prepressing stress bimetal centrifugal casting composite pipe end flange

A technology of centrifugal casting and pre-compression stress, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of separation and cracking of bimetallic layers, and achieve the effect of enhancing compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

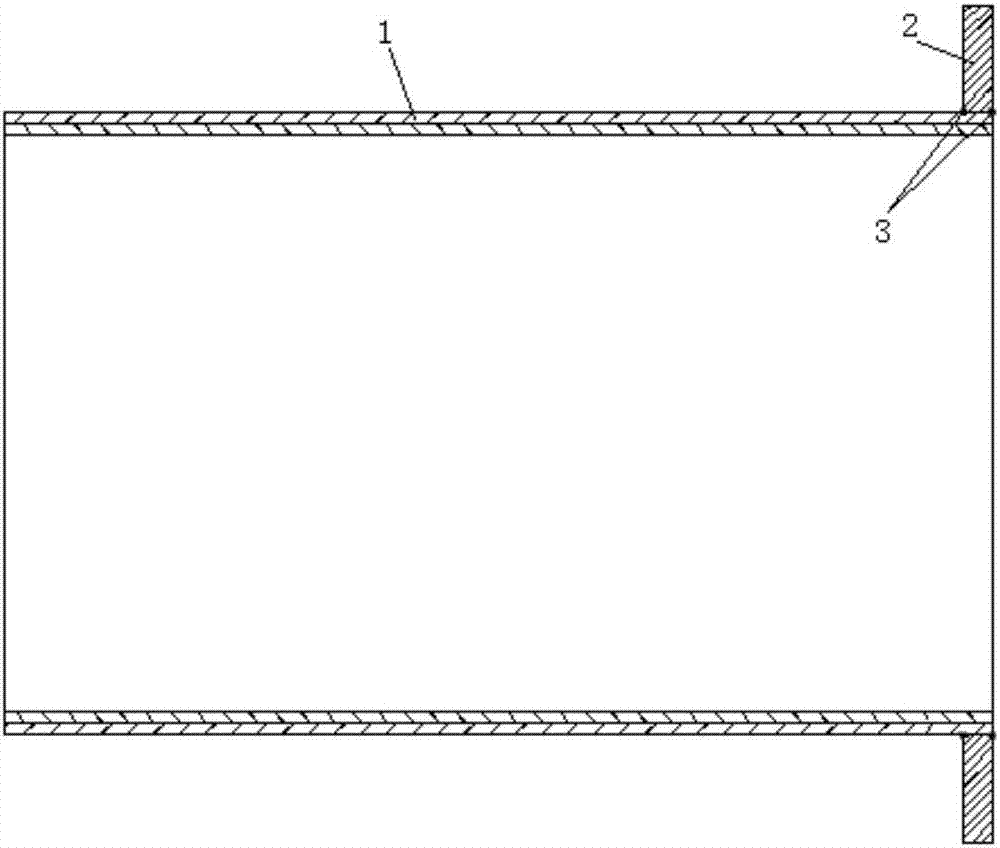

[0040] The prestressed bimetallic centrifugal casting composite pipe is composed of a high chromium cast iron inner layer and a stainless steel outer layer. The flange material is 20 steel. The welding position is shown in figure 1 . In the figure, prestressed bimetallic centrifugal casting composite pipe 1, flange 2, annular fillet weld 3, welding process of prestressed bimetallic centrifugal casting composite pipe end flange The specific welding process is as follows:

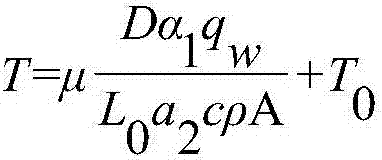

[0041] 1. Calculation of the theoretical preheating temperature of the flange: use the following formula to calculate the theoretical preheating problem T of the flange:

[0042]

[0043] In the formula, μ——stiffness coefficient;

[0044] D - the inner diameter of the flange;

[0045] alpha 1 - thermal expansion coefficient of stainless steel;

[0046] alpha 2 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com