Automatic deposition device and method applied to outer surface of environment-friendly container nozzle

An external surface and nozzle technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of unstable inert gas flow and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

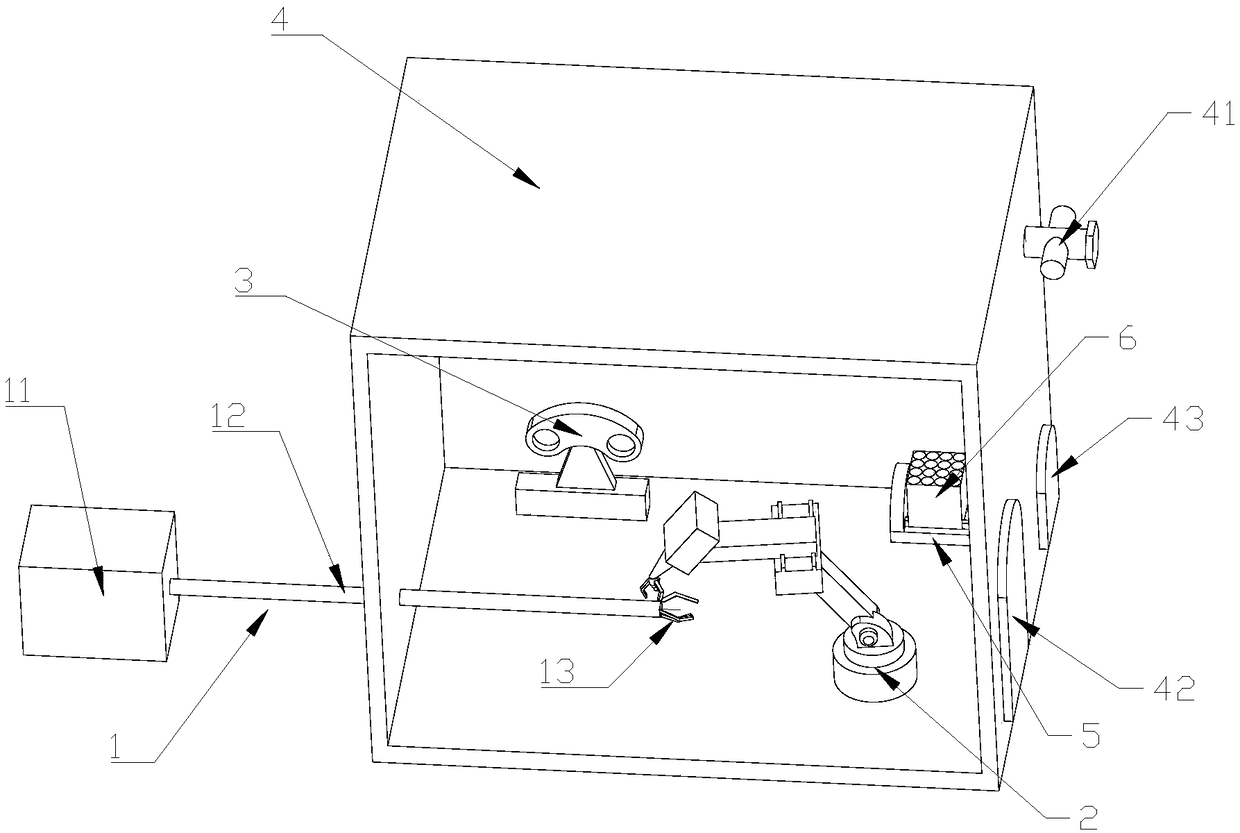

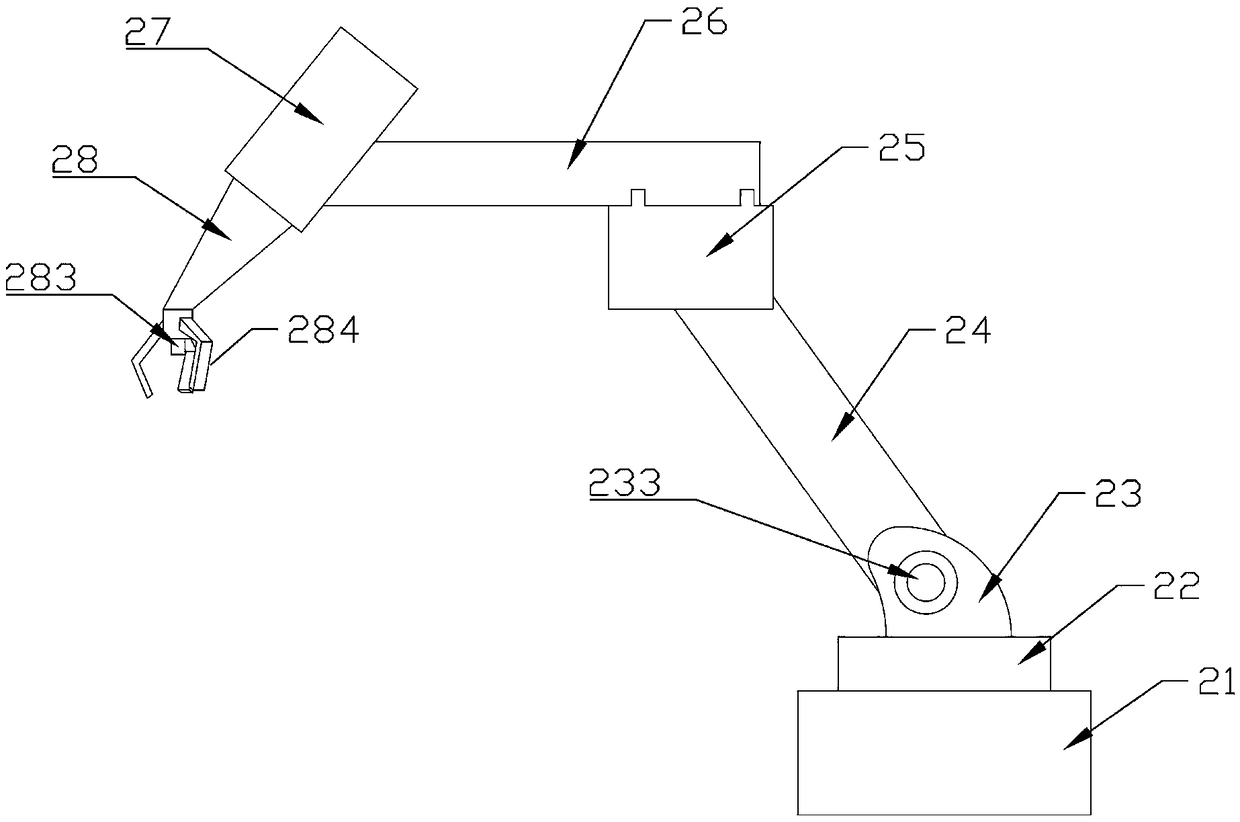

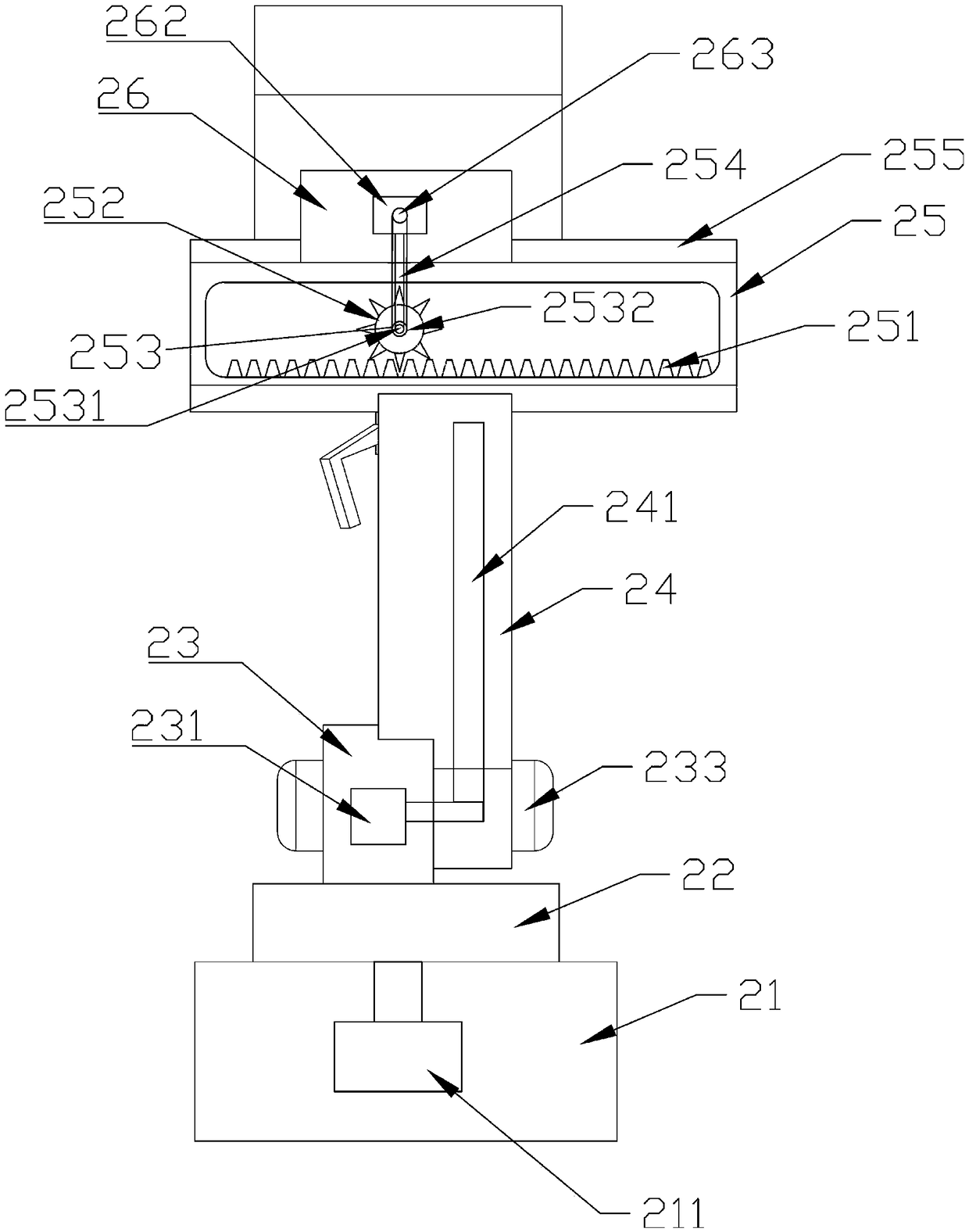

[0031] Such as figure 1As shown, an automatic cladding equipment applied to the outer surface of the nozzle of an environmental protection container includes a rotating device 1, a mechanical arm 2, a three-dimensional scanner 3, a welding box 4, a transport device 5 and a welding rod box 6, and the rotating device 1 includes a driving motor 11 , the rotating shaft 12 and the first gripper 13, the configuration of the welding box 4 is a cuboid, and the materials of the two opposite sides are high-temperature-resistant plexiglass, and the inside of the welding box 4 is provided with a mechanical arm 2, a three-dimensional scanner 3, and a transportation device 5 And the welding rod box 6, the rotating shaft 12 runs through the side wall of the welding box 4, the first gripper 13 is positioned at the inside of the welding box 4, the driving motor 11 is positioned at the outside of the welding box 4, the mechanical arm 2 and the three-dimensional scanner 3 are all arranged inside...

Embodiment 2

[0036] An automatic cladding method applied to the outer surface of the nozzle of an environmental protection container, the steps are as follows: pretreat the outer surface of the nozzle of the environmental protection container, the process includes mechanical cleaning, chemical cleaning and drying, and sandpaper is used in the mechanical cleaning process. The outer surface of the container nozzle is polished smooth, and the sandpaper will be carried out along the same direction when grinding on the alloy surface; the chemical cleaning is to use acetone and absolute ethanol to remove the polluting substances on the outer surface of the environmental protection container nozzle including grease, dirt and dust; In the drying process, the cleaned chemical container nozzle is placed on the workpiece rack to allow the surface of the chemical container nozzle to be fully dry; after the environmental protection container nozzle is pretreated, it is put into the grab in the welding bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com