Integrated permanent magnet rotor magnetic suspension high speed motor

A permanent magnet rotor and high-speed motor technology, applied to synchronous motors with stationary armatures and rotating magnets, etc., can solve the problems of low tensile strength of permanent magnets, solve life problems, simplify manufacturing processes, and reduce harmonics. Effects of wave loss and torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

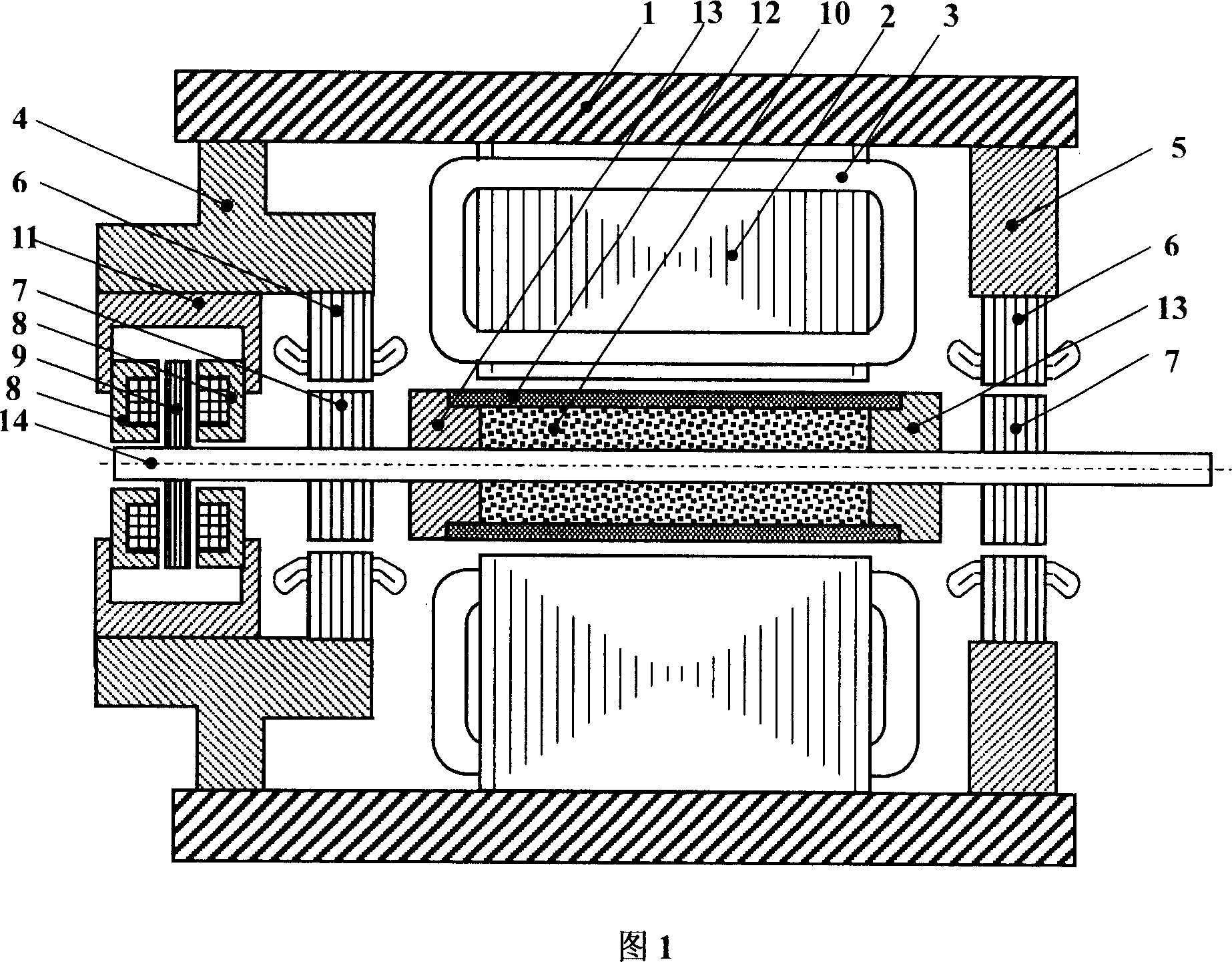

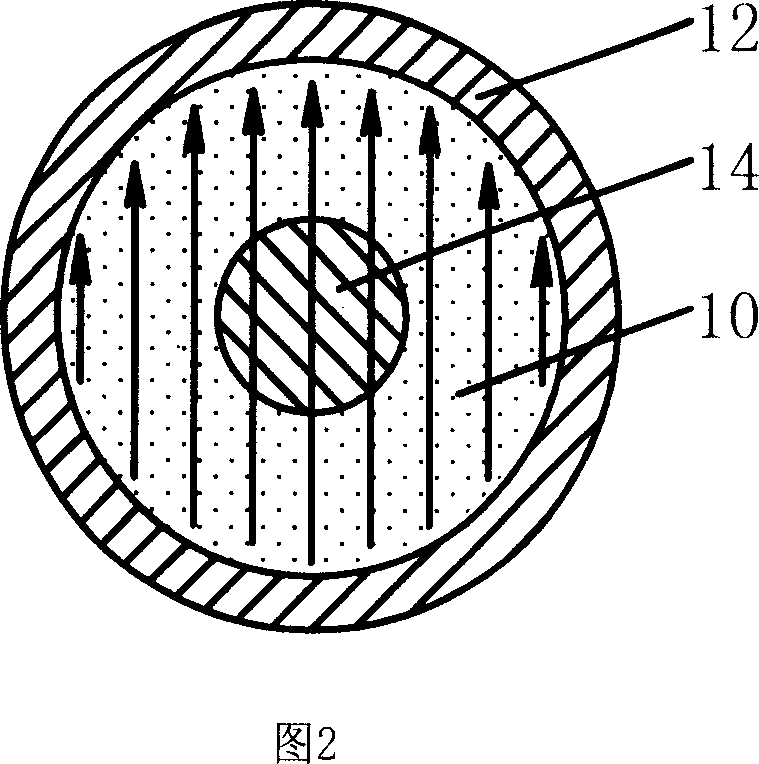

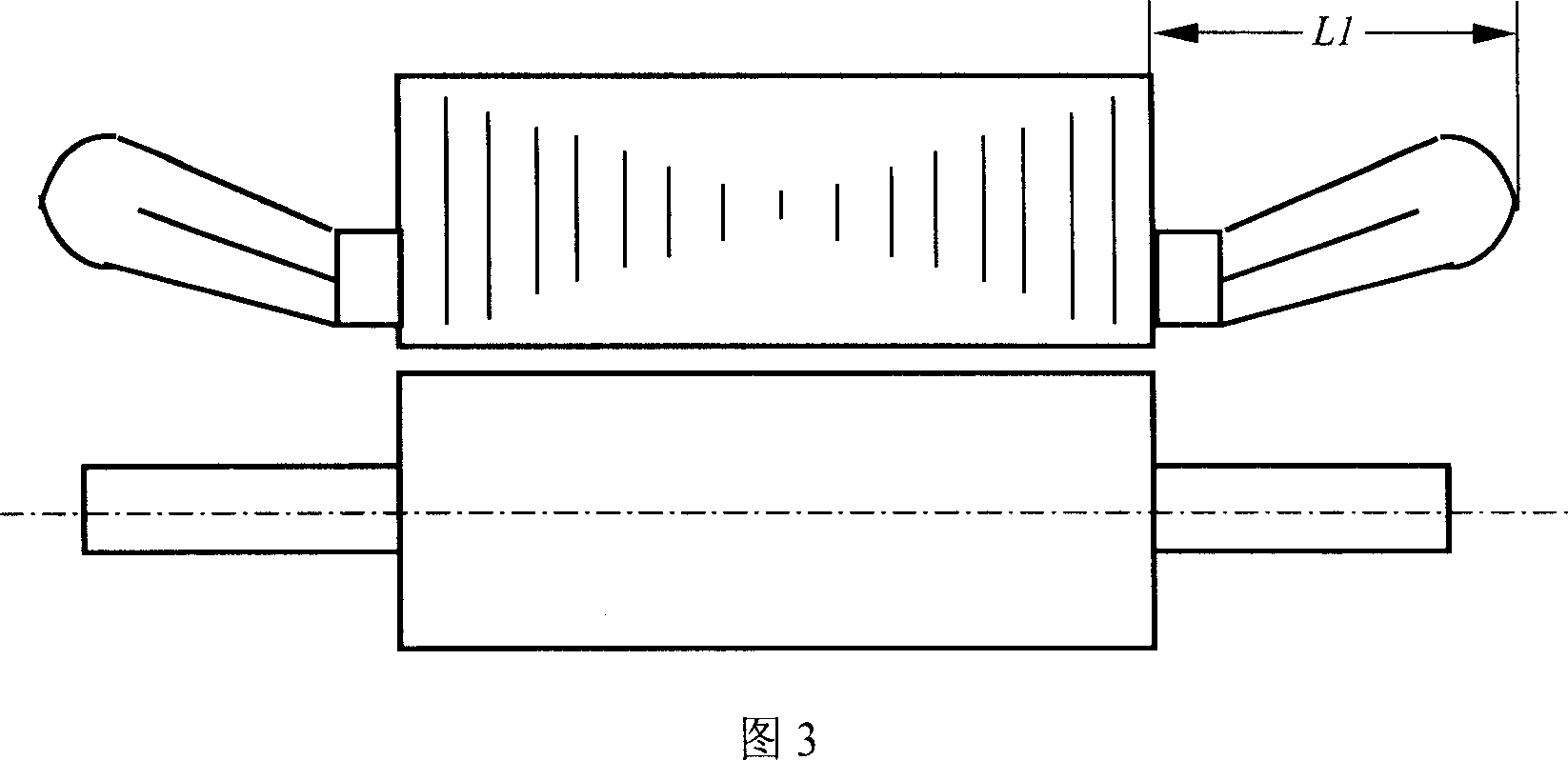

[0021] Embodiment: As shown in Figure 1, the structure of the present invention includes a casing 1, a left end cover 4, a right end cover 5, a stator core 2, a stator winding 3, a permanent magnet rotor, a rotating shaft 14, an axial magnetic suspension bearing and left and right radial Magnetic suspension bearing, a permanent magnet rotor is placed on the motor shaft 14, a stator core 2 is placed around the permanent magnet rotor on the inner wall of the casing 1, and the stator winding 3 is embedded in the slot of the stator core 2; the left end cover 4 and the right end cover 5 are respectively fixed At both ends of the casing 1 on both sides of the stator core 2; a right radial magnetic suspension bearing is placed between the rotating shaft 14 and the right end cover 5; The magnetic suspension bearing, the axial magnetic suspension bearing is placed at the end of the rotating shaft 14, and the other end of the rotating shaft 14 is connected with the driving machine throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com