Quick-setting cement-based capillary crystalline self-repairing waterproofing material and preparation method therefor

A technology of permeable crystallization and quick-setting cement, applied in the field of waterproof building materials, can solve the problems of corrosion of concrete steel bars, troublesome preparation of permeable crystalline waterproof materials, and no consideration of setting time, etc., to promote hydration, improve compactness, improve The effect of flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

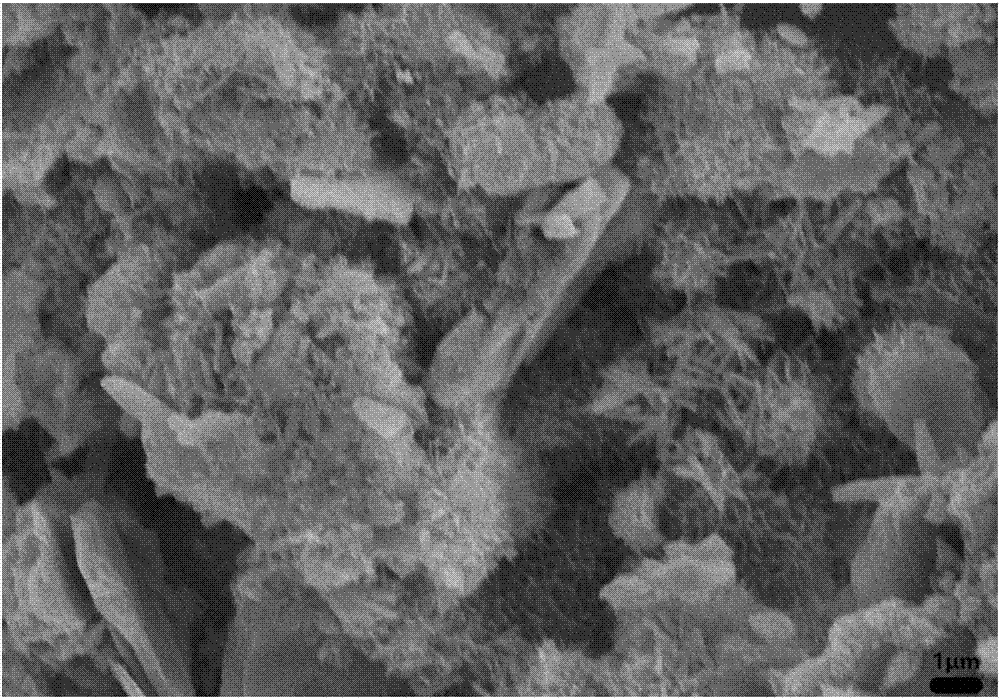

Image

Examples

Embodiment 1

[0054] A quick-setting cement-based permeable crystalline self-repairing waterproof material, which is composed of the following raw material components in parts by weight: 55 parts of 42.5R Portland cement, 25 parts of 70-140 mesh quartz sand, 10 parts of buffer agent, and active components 4 parts of A, 4 parts of active component B, 2 parts of expansion agent, 1 part of calcium ion supplement, 1 part of water reducer, 23 parts of water; wherein, the buffering agent is potassium bicarbonate and potassium carbonate with a mass ratio of 1:1 , active component A is ethylenediaminetetraacetic acid and sodium oxalate with a mass ratio of 2:1, active component B is sodium silicate, sodium phosphate and sodium metaaluminate with a mass ratio of 1:1:1, and expansion agent It is sodium sulfate and aluminum potassium sulfate with a mass ratio of 1:1, the calcium ion supplement is calcium sulfate, and the water reducing agent is sodium methylene dinaphthalene sulfonate.

[0055] Weigh ...

Embodiment 2

[0057] A quick-setting cement-based permeable crystalline self-repairing waterproof material, which is composed of the following raw material components in parts by weight: 65 parts of 42.5R Portland cement, 35 parts of 70-140 mesh quartz sand, 5 parts of buffer agent, and active components 8 parts of A, 5 parts of active component B, 2 parts of expansion agent, 3 parts of calcium ion supplement, 2 parts of water reducer, 26 parts of water; wherein, the buffering agent is sodium bicarbonate and carbonic acid with a mass ratio of 1:1 Sodium, active component A is ethylenediaminetetraacetic acid and sodium oxalate with a mass ratio of 3:1, active component B is sodium silicate and sodium metaaluminate with a mass ratio of 1:1, and the expansion agent is potassium aluminum sulfate , The calcium ion supplement is calcium hydroxide, and the water reducing agent is calcium lignosulfonate.

[0058] Weigh the raw materials of each component according to the above mass ratio, mix Portl...

Embodiment 3

[0061] A quick-setting cement-based permeable crystalline self-repairing waterproof material, which is composed of the following raw material components in parts by weight: 75 parts of 42.5R Portland cement, 45 parts of 70-140 mesh quartz sand, 3 parts of buffer agent, and active components 12 parts of A, 4 parts of active component B, 6 parts of expansion agent, 12 parts of calcium ion supplement, 4 parts of water reducer, 25 parts of water; wherein, the buffering agent is potassium bicarbonate and potassium carbonate with a mass ratio of 1:1 , the active component A is ethylenediaminetetraacetic acid and sodium oxalate with a mass ratio of 2:1, the active component B is sodium silicate and sodium metaaluminate with a mass ratio of 1:1, and the expansion agent is 1:1 Sodium sulfate and aluminum potassium sulfate, the calcium ion supplement is 1:1 calcium hydroxide and calcium sulfate, and the water reducer is sodium lignosulfonate.

[0062] Weigh the raw materials of each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com