Cement containing large volume of fly ash and preparation method thereof

A technology of fly ash cement and large dosage, applied in the field of high dosage cement, can solve the problems of reduced early strength of cement, low activity of fly ash, limited application range, etc., achieves good surface activity, enhanced force, reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention also discloses a preparation method of large-volume fly ash cement, comprising the following steps:

[0030] The nano-boehmite is evenly doped in the fly ash and Portland cement to obtain a large amount of fly ash cement.

[0031] The nano-boehmite must be uniformly doped in the fly ash and Portland cement, and the present invention has no special limitation on the specific doping method. The nano-boehmite can also be mixed with fly ash and Portland cement when in use. The preferred solution is: ultrasonically disperse the nano-boehmite in water, and the ultrasonic dispersion time is preferably 5 to 15 minutes ; Then, mix the fly ash and Portland cement with the aqueous solution uniformly dispersed with nano-boehmite, and then it can be used.

[0032] The high-volume fly ash cement of the present invention comprises: 30-70 wt% of fly ash; 0.01-10 wt% of nano-boehmite; the balance is Portland cement. Nano-boehmite particles are small, with excellent chemi...

Embodiment 1

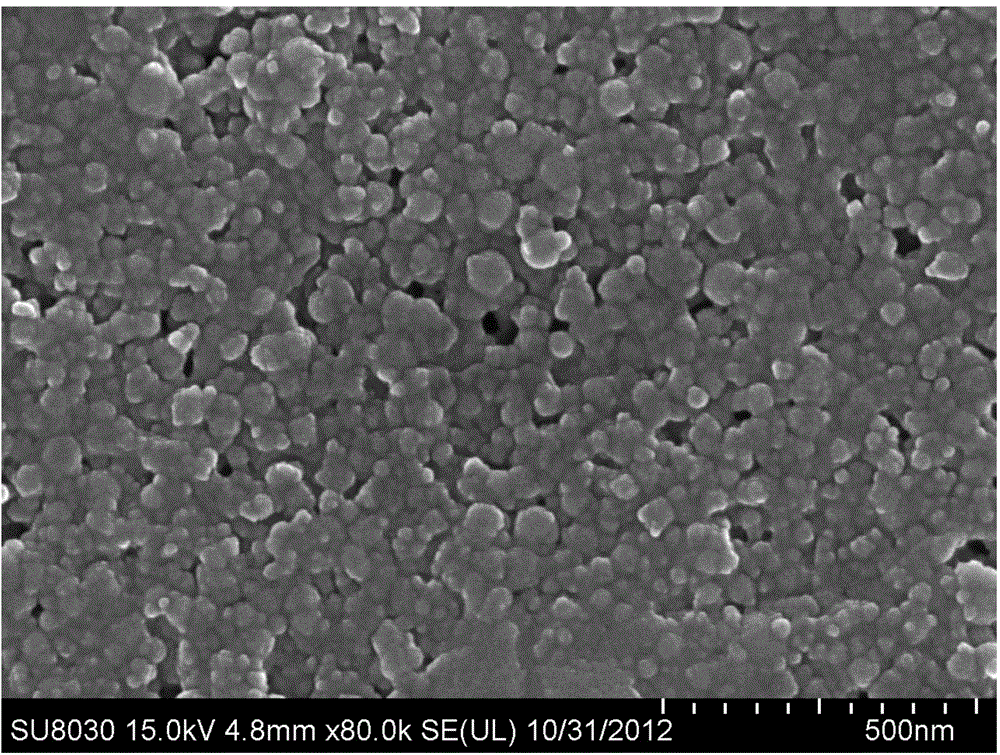

[0036] The high-volume fly ash cement in this embodiment includes 220.5 grams of PI type Portland cement cement clinker (gypsum accounts for 4% of the clinker mass), 220.5 grams of fly ash and 9 grams of nano boehmite. The particle size of the nano-boehmite is 10-50nm, and the specific structure is as follows: figure 1 as shown, figure 1 It is the SEM photo of the nano-boehmite used in Example 1.

[0037] The large-volume fly ash cement in Example 1 was made into cement mortar to test its early strength.

[0038] Disperse 9 grams of nano-boehmite in water evenly for 10 minutes, with an ultrasonic power of 300w (DS-5510DTH ultrasonic cleaning machine), and then prepare cement mortar specimens according to the preparation process of ordinary cement mortar specimens in my country's current standards. After the test piece is made, put it into a standard curing room (temperature 20±1°C, relative humidity ≥95%) for curing, remove the mold after 1 day and continue the standard curin...

Embodiment 2

[0052] The high-volume fly ash cement in this embodiment includes 218.25 grams of PI type Portland cement, 225 grams of fly ash and 6.75 grams of nano-boehmite. The particle size of the nano-boehmite is 10-50 nm.

[0053] The large-volume fly ash cement in Example 1 was made into cement mortar to test its early strength.

[0054]Disperse 11.25 grams of nano-boehmite in water evenly for 10 minutes, with an ultrasonic power of 300w (DS-5510DTH ultrasonic cleaning machine), and then prepare cement mortar specimens according to the preparation process of ordinary cement mortar specimens in my country's current standards. After the test piece is made, put it into a standard curing room (temperature 20±1°C, relative humidity ≥95%) for curing, remove the mold after 1 day and continue the standard curing to the set age, and then the cement mortar test piece can be obtained. The components of the cement mortar test piece are shown in Table 1.

[0055] After curing to the experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com